EN | Round Baler & Baler-Wrapper Combination | G-1 F125 Kombi | Goeweil

The round baler G-1F125 and the baler-wrapper combination G-1F125 Kombi are presenting themselves in a new design: Engineered exclusively for professionals, the machines of the first generation already delivered maximum impact force, but life teaches us that there is always room for improvement, and GÖWEIL has managed to optimize the new generation and add a host of exciting highlights.

The round baler G-1F125 and the baler-wrapper combination G-1F125 Kombi are presenting themselves in a new design: Engineered exclusively for professionals, the machines of the first generation already delivered maximum impact force, but life teaches us that there is always room for improvement, and GÖWEIL has managed to optimize the new generation and add a host of exciting highlights.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

G-1<strong>F125</strong> & G-1<strong>F125</strong> <strong>Kombi</strong><br />

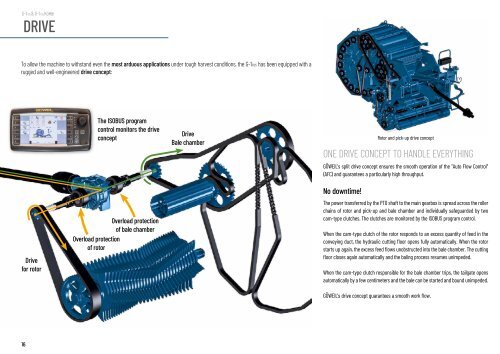

DRIVE<br />

To allow the machine to withstand even the most arduous applications under tough harvest conditions, the G-1<strong>F125</strong> has been equipped with a<br />

rugged and well-engineered drive concept:<br />

The ISOBUS program<br />

control monitors the drive<br />

concept<br />

Drive<br />

Bale chamber<br />

Rotor and pick-up drive concept<br />

ONE DRIVE CONCEPT TO HANDLE EVERYTHING<br />

GÖWEIL's split drive concept ensures the smooth operation of the "Auto Flow Control"<br />

(AFC) and guarantees a particularly high throughput.<br />

Drive<br />

for rotor<br />

Overload protection<br />

of bale chamber<br />

Overload protection<br />

of rotor<br />

No downtime!<br />

The power transferred by the PTO shaft to the main gearbox is spread across the roller<br />

chains of rotor and pick-up and bale chamber and individually safeguarded by two<br />

cam-type clutches. The clutches are monitored by the ISOBUS program control.<br />

When the cam-type clutch of the rotor responds to an excess quantity of feed in the<br />

conveying duct, the hydraulic cutting floor opens fully automatically. When the rotor<br />

starts up again, the excess feed flows unobstructed into the bale chamber. The cutting<br />

floor closes again automatically and the baling process resumes unimpeded.<br />

When the cam-type clutch responsible for the bale chamber trips, the tailgate opens<br />

automatically by a few centimeters and the bale can be started and bound unimpeded.<br />

GÖWEIL's drive concept guarantees a smooth work flow.<br />

16