BusinessDay 16 Apr 2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

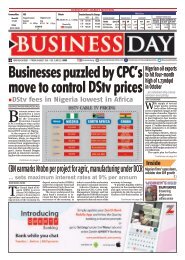

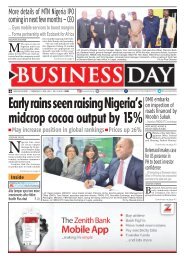

Monday <strong>16</strong> <strong>Apr</strong>il <strong>2018</strong><br />

C002D5556 BUSINESS DAY 43<br />

REAL SECTOR WATCH<br />

Steel firms expand capacity, tap<br />

export opportunity to earn FX<br />

Stories by ODINAKA ANUDU<br />

Nigerian steel<br />

firms are expanding<br />

capacity<br />

and tapping<br />

into export opportunity<br />

in the neighbouring<br />

markets to earn foreign<br />

exchange.<br />

Aarti Steel Nigeria Limited,<br />

which recently completed<br />

a 120,000- tonnes capacity<br />

cold-rolled mill in Ota, Ogun<br />

State, exports steel to Togo<br />

and Mali and plans to expand<br />

to Central Africa, Ivory Coast<br />

and Benin to boost capacity,<br />

earn more foreign exchange<br />

and tap the growth potential<br />

in the continent’s market.<br />

Aniket Singal, Aarti’s vice<br />

chairman, told <strong>BusinessDay</strong><br />

that the company was looking<br />

at expanding its export<br />

footprints, but said there<br />

was a need for a policy that<br />

would keep substandard roofing<br />

sheets at bay. African<br />

Industries, in October 20<strong>16</strong>,<br />

exported finished steel products<br />

to Morocco, Ghana and<br />

other parts of Africa for the<br />

first time.<br />

The company said its export<br />

of finished steel products<br />

would save the country over<br />

$650 million yearly. Alok<br />

Gupta, group managing director,<br />

African Industries<br />

Group, said that the quality<br />

of steel products of African Industries<br />

was at par with steel<br />

from Ukraine, if not better,<br />

adding that the company had<br />

become internationally competitive<br />

in exporting products<br />

Nigerian Breweries expanding local input sourcing operations, says MD<br />

The Nigerian<br />

Breweries (NB)<br />

says it is committed<br />

to raising<br />

its current<br />

50 percent local raw materials<br />

sourcing to 60 percent<br />

before 2020.<br />

Speaking at the annual<br />

general meeting held last<br />

Wednesday in Lagos, Jordi<br />

Borrut Bel, managing<br />

director of NB, said the<br />

brewer would continue<br />

to improve on its value<br />

extraction from local raw<br />

materials, including cassava<br />

and sorghum.<br />

Bel stated that the company<br />

was determined to<br />

improve the sorghum value<br />

chain in the country.<br />

The brewer’s profit after<br />

tax (PAT) on the financial<br />

year ended December 31,<br />

2017, surged to N33 billion,<br />

from N28.4 billion reported<br />

in the correspond-<br />

A cross section of participants trained by Nigerian-American Chamber of Commerce (NACC) on “Customer Relationship<br />

Management” in Lagos recently<br />

ers.<br />

He said the firm had<br />

cut water consumption for<br />

production by 28 percent<br />

in the last 10 years, sourcing<br />

100 percent of its packfrom<br />

Nigeria.<br />

He called for Export Expansion<br />

Grant to enable the<br />

company to sustain its exports.<br />

He added that freight<br />

cost from Ukraine to Ghana<br />

was $40 per metric tonne<br />

(MT) while that of Nigeria to<br />

Ghana is $65/MT, which was<br />

expensive.<br />

Uche Iwuamadi, executive<br />

director of the group, said the<br />

company’s operational capacity<br />

was below 70 percent,<br />

stating that there would likely<br />

be excess steel in the country<br />

when African Industries<br />

reached 100 percent capacity.<br />

African Industries has 12<br />

subsidiaries, including six big<br />

ing period of 2017, representing<br />

a <strong>16</strong> percent rise.<br />

Revenue for the period was<br />

N344 billion, as against<br />

N313 billion recorded in<br />

the previous year, representing<br />

approximately 10<br />

percent increase.<br />

Bel said the board of<br />

directors of NB recommended<br />

dividend of N33<br />

billion to shareholders,<br />

which was highest in the<br />

company’s history.<br />

The recommendation<br />

amounts to a total dividend<br />

of N4.13 per share<br />

for the 2017 operating year.<br />

Bell explained that the<br />

brewer gave out 100 per<br />

cent dividend as part of its<br />

dividend policy, consistent<br />

in its robust balance sheet.<br />

He explained that the<br />

company’s stable growth<br />

amid economic headwinds<br />

was a result of the company’s<br />

ability to cut cost.<br />

steel plants such as African<br />

Steel Mills, Ikorodu Steel Mills,<br />

African Foundries, and Abuja<br />

Steel Mills.<br />

“We produce one million<br />

tonnes of steel per year and<br />

our target is to export between<br />

200,000MT and 400,000 MT<br />

this year. You can see we are<br />

earning foreign exchange<br />

when others are demanding<br />

it from the government,” Uche<br />

Iwuamadi, group executive<br />

director, African Industries,<br />

told <strong>BusinessDay</strong>.<br />

Standard Metallurgical<br />

Company Limited (SMC) is<br />

planning to launch a billet mill<br />

to produce standard wire rods<br />

in Nigeria for the local and<br />

ECOWAS market.<br />

Mohammed Saade, managing<br />

director, SMC, said was<br />

producing 300,000 tonnes of<br />

wire rods per year.<br />

“With phase two, we would<br />

produce 260,000 tons of billets<br />

in Nigeria. Nigeria today<br />

is a big market and we are<br />

committed to meeting local<br />

demands and the surplus can<br />

go to the ECOWAS market,”<br />

Saade said.<br />

Nigeria, Africa’s biggest<br />

economy, spends about $3.3<br />

billion on steel imports every<br />

year. Eighteen of the 30 steel<br />

manufacturers in Nigeria produce<br />

about 2.2 million tons a<br />

year with scraps and billets<br />

Bel explained that the<br />

foreign exchange situation<br />

improved last year, but<br />

pointed out that double<br />

digit inflation impacted<br />

businesses and consum-<br />

imported mainly from China.<br />

An average of steel products<br />

such as standard plates,<br />

hot-rolled coil, cold-rolled<br />

coil and rebar is $464.7 using<br />

Chinese prices, which means<br />

Nigeria imports roughly 7.1<br />

million metric tonnes of steel<br />

annually. Many of the exports<br />

are still scraps, billets, and<br />

nails .<br />

The publicly-owned Ajaokuta<br />

Steel Complex is in<br />

disrepair after government<br />

sinking over $5 billion into the<br />

plant. The government has<br />

been slow in handing over<br />

the behemoth to a private investor<br />

despite interests from<br />

foreigners.<br />

aging materials locally.<br />

Bell noted that development<br />

of employees was<br />

important for sustainable<br />

company performance,<br />

adding that early signs<br />

of improvement in the<br />

macro-economic condition<br />

were yet to reflect on<br />

consumer confidence.<br />

He said the firm remained<br />

committed to the<br />

market in the long term as<br />

the fundamentals of the<br />

beer market were strong<br />

and attractive in the both<br />

medium and long term.<br />

He pointed out that<br />

firm was well positioned<br />

to trade through difficult<br />

times by leveraging its<br />

innovative brands across<br />

different market segments.<br />

NB sources its sorghum<br />

through a company known<br />

as Psaltry International<br />

Limited, located at Alayide<br />

village, Ado Awaiye near<br />

Iseyin, Oyo State,<br />

Initiate policies to<br />

revive moribund<br />

textile mills,<br />

NTGTEA tells FG<br />

The Nigeria Textile,<br />

Garment and Tailoring<br />

Employers<br />

Association (NT-<br />

GTEA) has urged the Federal<br />

Government to initiate<br />

steps to revive moribund<br />

textile mills in Nigeria.<br />

By 1985, Nigeria had over<br />

180 textile mills employing<br />

more than one million<br />

Nigerians. Some of the<br />

mills were United Nigerian<br />

Textile Limited (UNTL),<br />

Aswani Textile, Afprint,<br />

Asaba Textile Mills, and Edo<br />

Textile Mills, among others,<br />

but there are fewer than<br />

three full-fledged healthy<br />

textile mills in Africa’s biggest<br />

economy and most<br />

populous country today.<br />

Speaking in a telephone<br />

interview, Hamma Kwajaffa,<br />

director-general of NTG-<br />

TEA, said unbridled importation<br />

of cheaper but substandard<br />

textile products<br />

killed local firms, stating<br />

that 95 percent of the textile<br />

market in the country today<br />

is dominated by China.<br />

Kwajaffa said the very<br />

few surviving textile firms<br />

are struggling and cannot<br />

compete with China and India,<br />

whose production costs<br />

in their home countries are<br />

much lower than Nigeria’s.<br />

“Energy costs four cents<br />

per kilowatt in other African<br />

countries but 20 cents per<br />

kilowatt in Nigeria. So how<br />

can a struggling textile firm<br />

compete? We need government<br />

intervention to be<br />

able to compete,” he asked.<br />

The textile industry in<br />

Nigeria is currently made<br />

up of fabrics makers, cotton<br />

producers, rug and carpet<br />

manufacturers as well as<br />

fashion and designers.<br />

“We can produce military<br />

uniforms. We have bed<br />

sheets, blankets, towels<br />

and handkerchiefs. We can<br />

make good products, but<br />

there is a need for incentives<br />

for the industry,” he<br />

said.<br />

In the first quarter of<br />

20<strong>16</strong>, Aisha Abubakar,<br />

minister of state for industry,<br />

trade and investment,<br />

toured three textile firms,<br />

which include Lucky Fibres<br />

Nigeria Plc, Spintex Mills<br />

and Nichemtex Plc in Lagos<br />

and Ogun states, promising<br />

to draw government attention<br />

to the challenges in the<br />

industry.<br />

However, smuggling,<br />

high production cost, poor<br />

patronage and lack of quality<br />

control on imports, which<br />

are age-old problems in<br />

the industry, continue with<br />

little or minimal government<br />

response.