May/June 2010 - Global Aquaculture Alliance

May/June 2010 - Global Aquaculture Alliance

May/June 2010 - Global Aquaculture Alliance

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

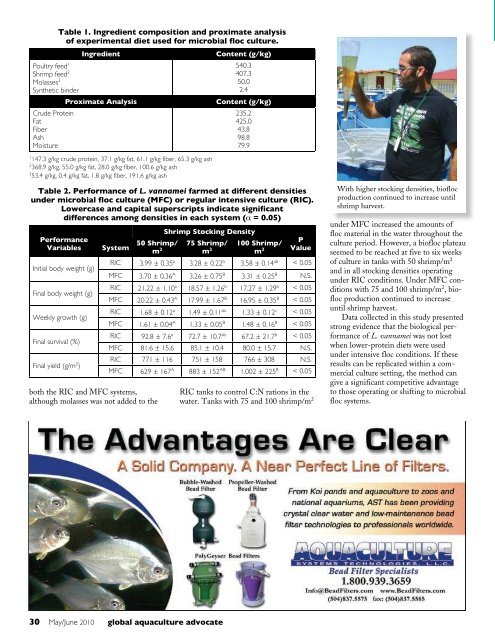

Poultry feed 1<br />

Shrimp feed 2<br />

Molasses 3<br />

Synthetic binder<br />

Crude Protein<br />

Fat<br />

Fiber<br />

Ash<br />

Moisture<br />

Table 1. Ingredient composition and proximate analysis<br />

of experimental diet used for microbial floc culture.<br />

Ingredient Content (g/kg)<br />

both the RIC and MFC systems,<br />

although molasses was not added to the<br />

540.3<br />

407.3<br />

50.0<br />

2.4<br />

Proximate Analysis Content (g/kg)<br />

1 147.3 g/kg crude protein, 37.1 g/kg fat, 61.1 g/kg fiber, 65.3 g/kg ash<br />

2 368.9 g/kg, 55.0 g/kg fat, 28.0 g/kg fiber, 100.6 g/kg ash<br />

3 53.4 g/kg, 0.4 g/kg fat, 1.8 g/kg fiber, 191.6 g/kg ash<br />

235.2<br />

425.0<br />

43.8<br />

98.8<br />

79.9<br />

Table 2. Performance of L. vannamei farmed at different densities<br />

under microbial floc culture (MFC) or regular intensive culture (RIC).<br />

Lowercase and capital superscripts indicate significant<br />

differences among densities in each system (α = 0.05)<br />

Performance<br />

Variables System<br />

Initial body weight (g)<br />

Final body weight (g)<br />

Weekly growth (g)<br />

Final survival (%)<br />

Final yield (g/m 2 )<br />

50 Shrimp/<br />

m 2<br />

Shrimp Stocking Density<br />

75 Shrimp/<br />

m 2<br />

100 Shrimp/<br />

m 2<br />

P<br />

Value<br />

RIC 3.99 ± 0.35 a 3.28 ± 0.22 b 3.58 ± 0.14 ab < 0.05<br />

MFC 3.70 ± 0.36 A 3.26 ± 0.75 B 3.31 ± 0.25 B N.S.<br />

RIC 21.22 ± 1.10 a 18.57 ± 1.26 b 17.27 ± 1.29 b < 0.05<br />

MFC 20.22 ± 0.43 A 17.99 ± 1.67 B 16.95 ± 0.35 B < 0.05<br />

RIC 1.68 ± 0.12 a 1.49 ± 0.11 ab 1.33 ± 0.12 c < 0.05<br />

MFC 1.61 ± 0.04 A 1.33 ± 0.05 B 1.48 ± 0.16 B < 0.05<br />

RIC 92.8 ± 7.6 a 72.7 ± 10.7 ab 67.2 ± 21.7 b < 0.05<br />

MFC 81.6 ± 15.6 85.1 ± 10.4 80.0 ± 15.7 N.S.<br />

RIC 771 ± 116 751 ± 158 766 ± 308 N.S.<br />

MFC 629 ± 167 A 883 ± 152 AB 1.002 ± 225 B < 0.05<br />

RIC tanks to control C:N rations in the<br />

water. Tanks with 75 and 100 shrimp/m 2<br />

With higher stocking densities, biofloc<br />

production continued to increase until<br />

shrimp harvest.<br />

under MFC increased the amounts of<br />

floc material in the water throughout the<br />

culture period. However, a biofloc plateau<br />

seemed to be reached at five to six weeks<br />

of culture in tanks with 50 shrimp/m2 and in all stocking densities operating<br />

under RIC conditions. Under MFC conditions<br />

with 75 and 100 shrimp/m2 under MFC increased the amounts of<br />

, biofloc<br />

production continued to increase<br />

until shrimp harvest.<br />

Data collected in this study presented<br />

strong evidence that the biological performance<br />

of L. vannamei was not lost<br />

when lower-protein diets were used<br />

under intensive floc conditions. If these<br />

results can be replicated within a commercial<br />

culture setting, the method can<br />

give a significant competitive advantage<br />

to those operating or shifting to microbial<br />

floc systems.<br />

production<br />

Bioreactor Technology For Tilapia<br />

Advances In Latin America<br />

The construction of V-shaped commercial bioreactors inside plastic tunnel greenhouses<br />

began in 2000.<br />

Summary:<br />

Continued research and development<br />

on tilapia culture is leading<br />

to further advances in production<br />

technology. Early biofloc-based<br />

culture systems in tanks in Brazil<br />

have given way to commercialscale<br />

bioreactors housed in greenhouses<br />

that utilize water fertilization<br />

regimes, high-protein feeds<br />

and salinity controls. Survival<br />

and feed conversion have been<br />

excellent, although growth rates<br />

are less consistent than in more<br />

traditional systems.<br />

The first experiments with tilapia bioflocs<br />

in subtropical southern Brazil were<br />

conducted in September 1998 using procedures<br />

similar to those the Oceanic<br />

Institute concept of mesocosms, aquatic<br />

controlled (MAC), applied to Litopenaeus<br />

vannamei shrimp.<br />

The first experimental units were 20<br />

200-L plastic indoor tanks with aeration,<br />

into which Oreochromis niloticus larvae<br />

were stocked at densities of 1-10/L. An<br />

objective was to overwinter them in commercial<br />

units at low cost.<br />

The survival and feed-conversion<br />

ratios for fish at all densities were exceptionally<br />

good compared to the performance<br />

achieved using previously available<br />

techniques. However, growth was low,<br />

especially compared to shrimp produced<br />

in similar bacteria-based systems in<br />

Hawaii, USA, and Belize.<br />

Greenhouse Bioreactors<br />

The preliminary results motivated in<br />

early 2000 the construction of commercial<br />

1,000-m 3 V-shaped bioreactors inside two<br />

800-m 2 plastic tunnel greenhouses. The<br />

aim of the units was to overwinter 300,000<br />

1-g tilapia fry purchased inexpensively at<br />

the end of the growout season in late <strong>May</strong><br />

and sell large juveniles of up to 20 g at top<br />

prices in September, just before the breeding<br />

season.<br />

The results of this first commercial<br />

trial quickly changed when the fish grew<br />

to the targeted 20-g size in the first 40<br />

days, so it was impossible to sell them as<br />

juveniles 90 days later. The fish were kept<br />

growing with 25% of the forecasted feed<br />

in order to check the carrying capacity of<br />

the reactors and the growth curve up to<br />

market size.<br />

The fish attained commercial size in<br />

150 days with an average feed-conversion<br />

ratio of 0.77 and survival of 92%. However,<br />

the size variation was very large, and<br />

some fish grew 500 g in less than four<br />

months. While external temperatures<br />

averaged 5 to 10° C, water temperatures<br />

inside the greenhouses were never below<br />

28° C, and the floc was very stable and<br />

always dark green.<br />

The major changes to the MAC environment<br />

in these initial floc trials was the<br />

Sergio Zimmermann<br />

Akvaforsk Genetics Center A.S.<br />

N-6600 Sunndalsøra, Norway<br />

sergio.zimmermann@afgc.no<br />

higher water temperatures and the presence<br />

of plankton influenced by the sunlight<br />

in the greenhouse.<br />

Expansion, Invention<br />

By 2004, the project had 21 tilapia<br />

bioreactors and 16 commercial growout<br />

facilities in southern Brazil. One facility<br />

in Colombia was dedicated to mesocosm<br />

culture of first-feeding carnivorous larvae.<br />

Several in Ecuador and Angola handled<br />

nursery-phase tilapia juveniles.<br />

Over the years, several protocols were<br />

developed. A water fertilization regime<br />

aimed at proper balancing of carbon,<br />

nitrogen and phosphorus levels to favor<br />

chlorophytes and avoid cyanophyte<br />

blooms. High-protein feeds were used to<br />

achieve excellent feed conversion. Salinity<br />

controls that favor inland polyculture<br />

with white shrimp were established to<br />

improve the taste of both tilapia and<br />

shrimp.<br />

Recently, Storvik and Akvaforsk<br />

Genetics Center A.S. tested the effects<br />

of liquid oxygen at the FishSul facilities<br />

with promising results. The commercialization<br />

of tilapia culture in bioreactors is<br />

becoming a marketing success, with no<br />

diseases or water exchange reported over<br />

the last 10 years.<br />

Biofloc technology is an integral part of<br />

the ongoing development.<br />

30 <strong>May</strong>/<strong>June</strong> <strong>2010</strong> global aquaculture advocate global aquaculture advocate <strong>May</strong>/<strong>June</strong> <strong>2010</strong> 31