Processing of Primary Fischer-Tropsch Products - University of Alberta

Processing of Primary Fischer-Tropsch Products - University of Alberta

Processing of Primary Fischer-Tropsch Products - University of Alberta

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

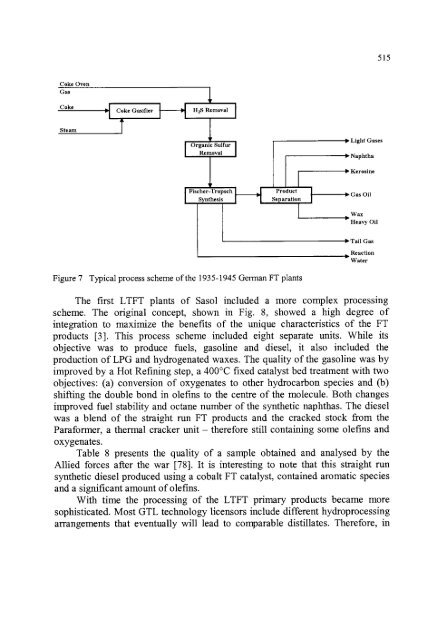

Coke Oven<br />

Gas<br />

Coke<br />

Steam<br />

Coke Gasifier HzS Removal<br />

Removal<br />

l <strong>Fischer</strong>-<strong>Tropsch</strong> I<br />

Synthesis I<br />

I<br />

Product<br />

Separation<br />

I<br />

Figure 7 Typical process scheme <strong>of</strong> the 1935-1945 German FT plants<br />

Light Gases<br />

~- Naphtha<br />

Kerosine<br />

Gas Oil<br />

Wax<br />

" Heavy Oil<br />

9 Tail Gas<br />

L Reaction<br />

Water<br />

The first LTFT plants <strong>of</strong> Sasol included a more complex processing<br />

scheme. The original concept, shown in Fig. 8, showed a high degree <strong>of</strong><br />

integration to maximize the benefits <strong>of</strong> the unique characteristics <strong>of</strong> the FT<br />

products [3]. This process scheme included eight separate units. While its<br />

objective was to produce fuels, gasoline and diesel, it also included the<br />

production <strong>of</strong> LPG and hydrogenated waxes. The quality <strong>of</strong> the gasoline was by<br />

improved by a Hot Refining step, a 400~ fixed catalyst bed treatment with two<br />

objectives: (a) conversion <strong>of</strong> oxygenates to other hydrocarbon species and (b)<br />

shifting the double bond in olefins to the centre <strong>of</strong> the molecule. Both changes<br />

improved fuel stability and octane number <strong>of</strong> the synthetic naphthas. The diesel<br />

was a blend <strong>of</strong> the straight run FT products and the cracked stock from the<br />

Paraformer, a thermal cracker unit- therefore still containing some olefins and<br />

oxygenates.<br />

Table 8 presents the quality <strong>of</strong> a sample obtained and analysed by the<br />

Allied forces after the war [78]. It is interesting to note that this straight run<br />

synthetic diesel produced using a cobalt FT catalyst, contained aromatic species<br />

and a significant amount <strong>of</strong> olefins.<br />

With time the processing <strong>of</strong> the LTFT primary products became more<br />

sophisticated. Most GTL technology licensors include different hydroprocessing<br />

arrangements that eventually will lead to comparable distillates. Therefore, in<br />

515