Maintworld 2/2018

The criticality spectrum // Align wind turbines safely // Pre-operational checklists reinvented // IoT brings maintenance rewards

The criticality spectrum // Align wind turbines safely // Pre-operational checklists reinvented // IoT brings maintenance rewards

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

OPIL will be available as a ready integration<br />

platform for mobile robots and<br />

other logistics automation equipment,<br />

allowing the full utilization of system<br />

integrators in the sales and implementation<br />

of logistics systems. There are<br />

thousands of system integrators globally<br />

ranging from large multinationals<br />

to SMEs and start-ups. With thousands<br />

of system integrators and the mobile<br />

robots with less than 1% of the 1 million<br />

global forklift market, robot manufactures<br />

can be flooded with orders and<br />

system integrators can take the role of<br />

developing small logistics systems for<br />

SMEs which fits perfectly in their business<br />

model.<br />

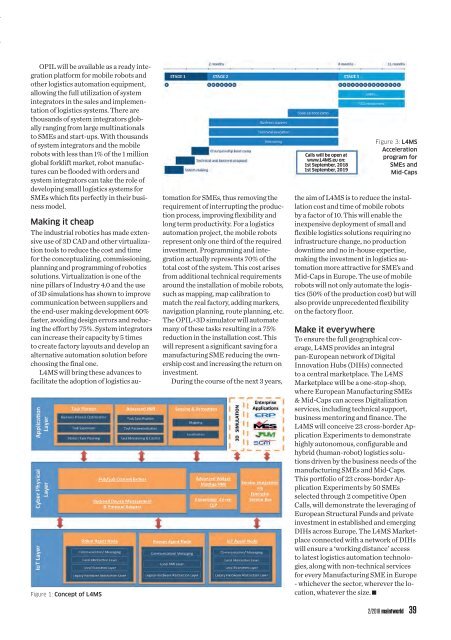

Figure 1: Concept of L4MS<br />

Making it cheap<br />

The industrial robotics has made extensive<br />

use of 3D CAD and other virtualization<br />

tools to reduce the cost and time<br />

for the conceptualizing, commissioning,<br />

planning and programming of robotics<br />

solutions. Virtualization is one of the<br />

nine pillars of Industry 4.0 and the use<br />

of 3D simulations has shown to improve<br />

communication between suppliers and<br />

the end-user making development 60%<br />

faster, avoiding design errors and reducing<br />

the effort by 75%. System integrators<br />

can increase their capacity by 5 times<br />

to create factory layouts and develop an<br />

alternative automation solution before<br />

choosing the final one.<br />

L4MS will bring these advances to<br />

facilitate the adoption of logistics automation<br />

for SMEs, thus removing the<br />

requirement of interrupting the production<br />

process, improving flexibility and<br />

long term productivity. For a logistics<br />

automation project, the mobile robots<br />

represent only one third of the required<br />

investment. Programming and integration<br />

actually represents 70% of the<br />

total cost of the system. This cost arises<br />

from additional technical requirements<br />

around the installation of mobile robots,<br />

such as mapping, map calibration to<br />

match the real factory, adding markers,<br />

navigation planning, route planning, etc.<br />

The OPIL+3D simulator will automate<br />

many of these tasks resulting in a 75%<br />

reduction in the installation cost. This<br />

will represent a significant saving for a<br />

manufacturing SME reducing the ownership<br />

cost and increasing the return on<br />

investment.<br />

During the course of the next 3 years,<br />

Calls will be open at<br />

www.L4MS.eu on:<br />

1st September, <strong>2018</strong><br />

1st September, 2019<br />

Figure 3: L4MS<br />

Acceleration<br />

program for<br />

SMEs and<br />

Mid-Caps<br />

the aim of L4MS is to reduce the installation<br />

cost and time of mobile robots<br />

by a factor of 10. This will enable the<br />

inexpensive deployment of small and<br />

flexible logistics solutions requiring no<br />

infrastructure change, no production<br />

downtime and no in-house expertise,<br />

making the investment in logistics automation<br />

more attractive for SME’s and<br />

Mid-Caps in Europe. The use of mobile<br />

robots will not only automate the logistics<br />

(50% of the production cost) but will<br />

also provide unprecedented flexibility<br />

on the factory floor.<br />

Make it everywhere<br />

To ensure the full geographical coverage,<br />

L4MS provides an integral<br />

pan-European network of Digital<br />

Innovation Hubs (DIHs) connected<br />

to a central marketplace. The L4MS<br />

Marketplace will be a one-stop-shop,<br />

where European Manufacturing SMEs<br />

& Mid-Caps can access Digitalization<br />

services, including technical support,<br />

business mentoring and finance. The<br />

L4MS will conceive 23 cross-border Application<br />

Experiments to demonstrate<br />

highly autonomous, configurable and<br />

hybrid (human-robot) logistics solutions<br />

driven by the business needs of the<br />

manufacturing SMEs and Mid-Caps.<br />

This portfolio of 23 cross-border Application<br />

Experiments by 50 SMEs<br />

selected through 2 competitive Open<br />

Calls, will demonstrate the leveraging of<br />

European Structural Funds and private<br />

investment in established and emerging<br />

DIHs across Europe. The L4MS Marketplace<br />

connected with a network of DIHs<br />

will ensure a ‘working distance’ access<br />

to latest logistics automation technologies,<br />

along with non-technical services<br />

for every Manufacturing SME in Europe<br />

- whichever the sector, wherever the location,<br />

whatever the size.<br />

2/<strong>2018</strong> maintworld 39