Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

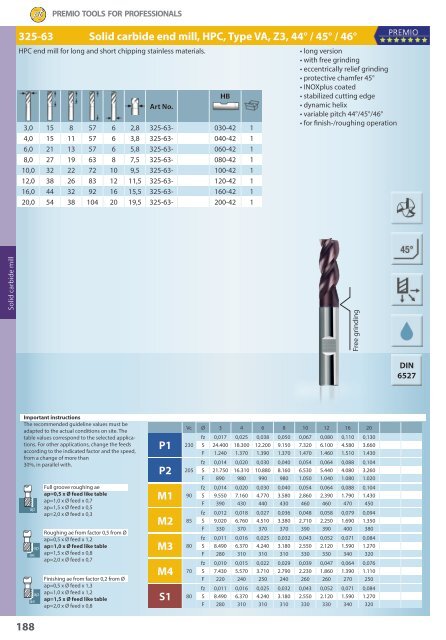

325-63<br />

PREMIO TOOLS FOR PROFESSIONALS<br />

Solid carbide end mill, HPC, Type VA, Z3, 44° / 45° / 46°<br />

HPC end mill for long and short chipping stainless materials.<br />

Art No.<br />

3,0 15 8 57 6 2,8 325-63- 030-42 1<br />

4,0 15 11 57 6 3,8 325-63- 040-42 1<br />

6,0 21 13 57 6 5,8 325-63- 060-42 1<br />

8,0 27 19 63 8 7,5 325-63- 080-42 1<br />

10,0 32 22 72 10 9,5 325-63- 100-42 1<br />

12,0 38 26 83 12 11,5 325-63- 120-42 1<br />

16,0 44 32 92 16 15,5 325-63- 160-42 1<br />

20,0 54 38 104 20 19,5 325-63- 200-42 1<br />

HB<br />

• long version<br />

• with free grinding<br />

• eccentrically relief grinding<br />

• protective chamfer 45°<br />

• INOXplus coated<br />

• stabilized cutting edge<br />

• dynamic helix<br />

• variable pitch 44°/45°/46°<br />

• for finish-/roughing operation<br />

Solid carbide mill<br />

Free grinding<br />

DIN<br />

6527<br />

Important instructions<br />

The recommended guideline values must be<br />

adapted to the actual conditions on site. The<br />

table values correspond to the selected applications.<br />

For other applications, change the feeds<br />

according to the indicated factor and the speed,<br />

from a change of more than<br />

30%, in parallel with.<br />

ap<br />

ap<br />

ae<br />

ap<br />

ae<br />

Full groove roughing ae<br />

ap=0,5 x Ø feed like table<br />

ap=1,0 x Ø feed x 0,7<br />

ap=1,5 x Ø feed x 0,5<br />

ap=2,0 x Ø feed x 0,3<br />

Roughing ae from factor 0,5 from Ø<br />

ap=0,5 x Ø feed x 1,2<br />

ap=1,0 x Ø feed like table<br />

ap=1,5 x Ø feed x 0,8<br />

ap=2,0 x Ø feed x 0,7<br />

Finishing ae from factor 0,2 from Ø<br />

ap=0,5 x Ø feed x 1,3<br />

ap=1,0 x Ø feed x 1,2<br />

ap=1,5 x Ø feed like table<br />

ap=2,0 x Ø feed x 0,8<br />

Vc<br />

P1 230<br />

P2 205<br />

M1 90<br />

M2 85<br />

M3 80<br />

M4 70<br />

S1 80<br />

Ø 3 4 6 8 10 12 16 20<br />

fz 0,017 0,025 0,038 0,050 0,067 0,080 0,110 0,130<br />

S 24.400 18.300 12.200 9.150 7.320 6.100 4.580 3.660<br />

F 1.240 1.370 1.390 1.370 1.470 1.460 1.510 1.430<br />

fz 0,014 0,020 0,030 0,040 0,054 0,064 0,088 0,104<br />

S 21.750 16.310 10.880 8.160 6.530 5.440 4.080 3.260<br />

F 890 980 990 980 1.050 1.040 1.080 1.020<br />

fz 0,014 0,020 0,030 0,040 0,054 0,064 0,088 0,104<br />

S 9.550 7.160 4.770 3.580 2.860 2.390 1.790 1.430<br />

F 390 430 440 430 460 460 470 450<br />

fz 0,012 0,018 0,027 0,036 0,048 0,058 0,079 0,094<br />

S 9.020 6.760 4.510 3.380 2.710 2.250 1.690 1.350<br />

F 330 370 370 370 390 390 400 380<br />

fz 0,011 0,016 0,025 0,032 0,043 0,052 0,071 0,084<br />

S 8.490 6.370 4.240 3.180 2.550 2.120 1.590 1.270<br />

F 280 310 310 310 330 330 340 320<br />

fz 0,010 0,015 0,022 0,029 0,039 0,047 0,064 0,076<br />

S 7.430 5.570 3.710 2.790 2.230 1.860 1.390 1.110<br />

F 220 240 250 240 260 260 270 250<br />

fz 0,011 0,016 0,025 0,032 0,043 0,052 0,071 0,084<br />

S 8.490 6.370 4.240 3.180 2.550 2.120 1.590 1.270<br />

F 280 310 310 310 330 330 340 320<br />

188