consulting services for a technical assessment of the stills at the ...

consulting services for a technical assessment of the stills at the ...

consulting services for a technical assessment of the stills at the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Final Report<br />

CONSULTING SERVICES FOR A TECHNICAL ASSESSMENT OF<br />

THE STILLS AT THE OPUWO PROCESSING FACILITY<br />

25 th March 2011<br />

commissioned by <strong>the</strong> Millennium Challenge Account Namibia<br />

with funding from <strong>the</strong> Millennium Challenge Corpor<strong>at</strong>ion

Submitted by: Werner Bester<br />

Essential Distill<strong>at</strong>ion Equipment CC<br />

Riebeek Kasteel, South Africa<br />

werner.ede@vodamail.co.za<br />

+27 21 448 1387<br />

+ 27 82 334 3324<br />

Ref: MCAN/COM/IC/3D01001-D

Table <strong>of</strong> Contents<br />

Executive Summary ..................................................................................................................................1<br />

1. Background .......................................................................................................................................2<br />

1.1 Scope <strong>of</strong> work ........................................................................................................................................... 3<br />

2. Methodology ....................................................................................................................................3<br />

2.1 Pre-processing and steam distill<strong>at</strong>ion trials with <strong>the</strong> Mopane steam still ............................................... 3<br />

2.2 Pre-processing and steam distill<strong>at</strong>ion <strong>of</strong> Commiphora ............................................................................ 4<br />

3. Main Findings ....................................................................................................................................5<br />

3.1 General ..................................................................................................................................................... 5<br />

3.2 Mopane trials ........................................................................................................................................... 6<br />

3.3 Commiphora trials .................................................................................................................................... 6<br />

4. Recommend<strong>at</strong>ions .............................................................................................................................7<br />

4.1 General facility ......................................................................................................................................... 7<br />

4.2 Mopane distill<strong>at</strong>ion ................................................................................................................................... 7<br />

4.3 Commiphora distill<strong>at</strong>ion ........................................................................................................................... 8

Executive Summary<br />

This assignment had two main tasks:<br />

i) Inspect <strong>the</strong> install<strong>at</strong>ion <strong>of</strong> both <strong>the</strong> Commiphora and mopane still;<br />

ii) Conduct small processing trials and rectify any problems immedi<strong>at</strong>ely if possible;<br />

The tasks above were designed to lead to an <strong>assessment</strong> and identific<strong>at</strong>ion <strong>of</strong> <strong>the</strong> <strong>technical</strong> problems as<br />

well as any recommend<strong>at</strong>ions as to how <strong>the</strong>se might be practically solved in order to get <strong>the</strong> processing<br />

facility situ<strong>at</strong>ed in Opuwo fully functional.<br />

It was also imper<strong>at</strong>ive to get both <strong>the</strong> oil distill<strong>at</strong>ion plants working and producing oil without too many<br />

changes to <strong>the</strong> current equipment, to train <strong>the</strong> staff on <strong>the</strong> oper<strong>at</strong>ion and maintenance <strong>of</strong> <strong>the</strong> <strong>stills</strong> and<br />

to establish a basis <strong>for</strong> standard oper<strong>at</strong>ing procedures <strong>for</strong> <strong>the</strong> facility.<br />

The assignment was carried out from <strong>the</strong> 22 nd to <strong>the</strong> 26 th <strong>of</strong> March 2011.<br />

Key Findings<br />

General facility<br />

• changes to <strong>the</strong> electrical supply and fittings is needed,<br />

• upgrading w<strong>at</strong>er quality and supply,<br />

• install<strong>at</strong>ion <strong>of</strong> drainage and waste removal <strong>for</strong> a safer working environment.<br />

Mopane distill<strong>at</strong>ion<br />

• pods needs to be pre processed using a suitable machine,<br />

• stainless steel baskets need a re-usable m<strong>at</strong>erial cover to facilit<strong>at</strong>e stilling, loading and unloading.<br />

Commiphora distill<strong>at</strong>ion<br />

• steam distill<strong>at</strong>ion is superior to hydro distill<strong>at</strong>ion <strong>for</strong> Commiphora extraction in oil yield, separ<strong>at</strong>ion<br />

and cleaning <strong>of</strong> equipment after distill<strong>at</strong>ion,<br />

• hand pre processing is <strong>the</strong> easiest and most convenient method,<br />

• establish best seal and basket arrangement in <strong>the</strong> pot <strong>for</strong> <strong>the</strong> current use <strong>of</strong> <strong>the</strong> hydro still as steam<br />

still.<br />

Key Recommend<strong>at</strong>ions<br />

General facility<br />

• employing a contractor to make <strong>the</strong> necessary changes to <strong>the</strong> electrical system,<br />

• employing a contractor to make <strong>the</strong> necessary changes to <strong>the</strong> w<strong>at</strong>er supply system,<br />

Report on <strong>the</strong> Technical Assessment <strong>of</strong> <strong>the</strong> Stills <strong>at</strong> <strong>the</strong> Opuwo Processing Facility (April 2011) Page 1

• testing <strong>the</strong> w<strong>at</strong>er quality and making <strong>the</strong> necessary changes to supply <strong>the</strong> boiler with suitable quality<br />

w<strong>at</strong>er,<br />

• employing a contractor to make <strong>the</strong> necessary changes to <strong>the</strong> drainage <strong>for</strong> cleaner and safer<br />

working area,<br />

• establish standard oper<strong>at</strong>ing protocols once <strong>the</strong> facility is fully oper<strong>at</strong>ional.<br />

Mopane distill<strong>at</strong>ion<br />

• to send some mopane pods to a hammer mill supplier to test different size equipment to establish<br />

<strong>the</strong> best pre processing means be<strong>for</strong>e purchasing <strong>of</strong> equipment,<br />

• have a supplier make up some removable hessian covers <strong>for</strong> <strong>the</strong> chain baskets.<br />

Commiphora distill<strong>at</strong>ion<br />

• building custom sorting tables to facilit<strong>at</strong>e <strong>the</strong> pre processing <strong>of</strong> <strong>the</strong> Commiphora,<br />

• acquiring more baskets and seals to use <strong>the</strong> full capacity <strong>of</strong> <strong>the</strong> current pot and to have an extra set<br />

to facilit<strong>at</strong>e and speed up <strong>the</strong> loading, unloading and cleaning process <strong>of</strong> <strong>the</strong> pots and baskets,<br />

• look <strong>at</strong> acquiring a pot custom designed <strong>for</strong> <strong>the</strong> steam distill<strong>at</strong>ion <strong>of</strong> <strong>the</strong> Commiphora in <strong>the</strong> long<br />

term.<br />

1. Background<br />

In 2004, IRDNC started investig<strong>at</strong>ing <strong>the</strong> possibility <strong>of</strong> commercial harvesting <strong>of</strong> Commiphora resin.<br />

Commiphora wildii is endemic to north western Namibia and spontaneously produces large quantities <strong>of</strong><br />

resin in response to environmental stresses. The resin is similar to myrrh but can be sustainably<br />

harvested. Attempts <strong>at</strong> marketing <strong>the</strong> resin have met with limited success. Current indic<strong>at</strong>ions are th<strong>at</strong><br />

<strong>the</strong> market would prefer to purchase <strong>the</strong> essential oil ra<strong>the</strong>r than having to deal with extracting it from<br />

<strong>the</strong> raw resin. Also, processing it locally adds value to <strong>the</strong> product and reduces <strong>the</strong> high costs <strong>of</strong><br />

transporting <strong>the</strong> heavy drums <strong>of</strong> resin. This was <strong>the</strong> motiv<strong>at</strong>ion <strong>for</strong> applying <strong>for</strong> funding to ICEMA to<br />

build a processing facility in Opuwo. Similarly, <strong>the</strong> bulk <strong>of</strong> <strong>the</strong> bags <strong>of</strong> mopane seeds and <strong>the</strong> associ<strong>at</strong>ed<br />

challenges with transport<strong>at</strong>ion and storage motiv<strong>at</strong>ed <strong>the</strong> purchase <strong>of</strong> <strong>the</strong> mopane still. The building<br />

was erected <strong>at</strong> <strong>the</strong> IRDNC Training Centre on <strong>the</strong> outskirts <strong>of</strong> Opuwo, <strong>the</strong> town closest to <strong>the</strong> PPOs th<strong>at</strong><br />

produce <strong>the</strong> raw m<strong>at</strong>erial. The building was jointly funded by IRDNC and ICEMA.<br />

In 2009 two steam distill<strong>at</strong>ion units, a hydro/w<strong>at</strong>er still and a direct injected steam still, were<br />

commissioned by <strong>the</strong> ICEMA project to process <strong>the</strong> Commiphora resin and <strong>the</strong> Colophospermum<br />

mopane seeds harvested by Kunene Producer and Processor Organiz<strong>at</strong>ions. These were collected from<br />

South Africa and delivered to Opuwo in May 2010. Due to delays in <strong>the</strong> install<strong>at</strong>ion <strong>of</strong> <strong>the</strong> three phase<br />

electricity <strong>at</strong> <strong>the</strong> site, <strong>the</strong> equipment could not be connected and tested. The ICEMA High Value Plants<br />

Project ended in June 2010.<br />

Report on <strong>the</strong> Technical Assessment <strong>of</strong> <strong>the</strong> Stills <strong>at</strong> <strong>the</strong> Opuwo Processing Facility (April 2011) Page 2

Technical difficulties have been experienced with <strong>the</strong> oper<strong>at</strong>ionalis<strong>at</strong>ion <strong>of</strong> <strong>the</strong> still. These <strong>technical</strong><br />

difficulties need to be resolved and standard oper<strong>at</strong>ing procedures need to be established to ensure<br />

th<strong>at</strong> essential oils <strong>of</strong> a standardized quality are produced. The Opuwo Processing Facility is targeted <strong>for</strong><br />

training support by <strong>the</strong> MCA-N INP Sub-activity (PPO number 1.1.12) in 2011 but be<strong>for</strong>e this can take<br />

place <strong>the</strong> facility needs to be fully commissioned.<br />

1.1 Scope <strong>of</strong> work<br />

2. Inspect <strong>the</strong> install<strong>at</strong>ion <strong>of</strong> both <strong>the</strong> Commiphora and mopane still<br />

3. Conduct small processing trials and rectify any problems immedi<strong>at</strong>ely if possible<br />

4. Advise as to possible solutions <strong>for</strong> problems th<strong>at</strong> cannot be rectified immedi<strong>at</strong>ely<br />

5. Establish an outline and recommend<strong>at</strong>ions <strong>for</strong> standard oper<strong>at</strong>ing procedures<br />

Although not required in terms <strong>of</strong> <strong>the</strong> scope <strong>of</strong> work <strong>for</strong> <strong>the</strong>se consultancy <strong>services</strong> <strong>the</strong> consultant was<br />

requested by <strong>the</strong> IRDNC to manufacture trial components (baskets and seals) to make it possible <strong>for</strong> <strong>the</strong><br />

small processing trials outlined above in point 2 to be carried out.<br />

In addition to <strong>the</strong> above work training <strong>of</strong> <strong>the</strong> staff on <strong>the</strong> oper<strong>at</strong>ion and use <strong>of</strong> <strong>the</strong> equipment and <strong>the</strong><br />

distill<strong>at</strong>ion procedure was also conducted during <strong>the</strong> trials. A short training video was also made.<br />

Through <strong>the</strong> above tasks it was expected th<strong>at</strong> an <strong>assessment</strong> and identific<strong>at</strong>ion <strong>of</strong> <strong>the</strong> <strong>technical</strong><br />

problems would be made and th<strong>at</strong> recommend<strong>at</strong>ions as to how <strong>the</strong>se might be practically solved in<br />

order to get <strong>the</strong> processing facility fully functional would be addressed.<br />

2. Methodology<br />

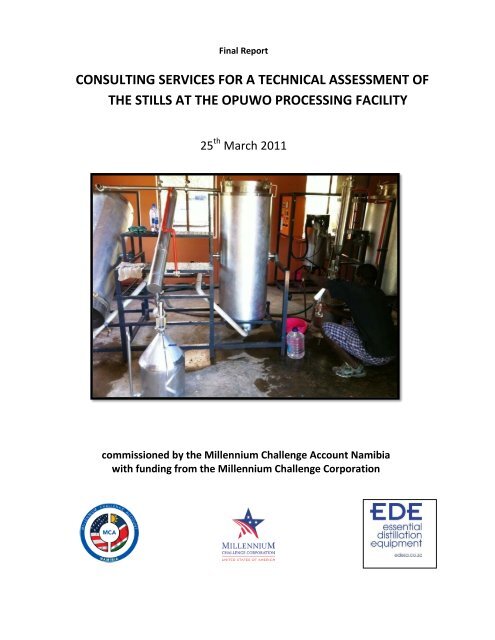

On initial inspection <strong>of</strong> <strong>the</strong> processing facility it was decided to first clean <strong>the</strong> facility and equipment in<br />

order to start with a fresh approach. This was done by physical means and by use <strong>of</strong> <strong>the</strong> boiler to steamclean<br />

<strong>the</strong> plant, including <strong>the</strong> m<strong>at</strong>erial pots, cooling condenser and oil/w<strong>at</strong>er separ<strong>at</strong>or <strong>of</strong> both <strong>the</strong><br />

mopane and Commiphora distill<strong>at</strong>ion units. After cleaning <strong>the</strong> layout <strong>of</strong> <strong>the</strong> equipment was rearranged<br />

in a more permanent position to utilise <strong>the</strong> space more efficiently.<br />

Two main processing trials were conducted, one on <strong>the</strong> Mopane steam still and <strong>the</strong> o<strong>the</strong>r on <strong>the</strong><br />

Commiphora hydro still. In <strong>the</strong> case <strong>of</strong> both trials <strong>the</strong> raw m<strong>at</strong>erial to be distilled was weighed to<br />

correl<strong>at</strong>e <strong>the</strong> weight to oil percentage <strong>for</strong> <strong>the</strong> different trials, as this will also have an effect on <strong>the</strong> final<br />

decision. All trials were conducted <strong>for</strong> a period <strong>of</strong> two hours.<br />

The components <strong>of</strong> <strong>the</strong>se trials are described below.<br />

2.1 Pre-processing and steam distill<strong>at</strong>ion trials with <strong>the</strong> Mopane steam still<br />

Three trials were done using different pre-processed m<strong>at</strong>erial with a piece <strong>of</strong> hessian on <strong>the</strong> basket<br />

using <strong>the</strong> same distill<strong>at</strong>ion process:<br />

Report on <strong>the</strong> Technical Assessment <strong>of</strong> <strong>the</strong> Stills <strong>at</strong> <strong>the</strong> Opuwo Processing Facility (April 2011) Page 3

1. Whole unprocessed pods<br />

2. Crushed pods with current hammer mill (on loan from CRIAA SA-DC)<br />

3. Hand shelled kernels<br />

The two pots th<strong>at</strong> make up <strong>the</strong> mopane steam still<br />

2.2 Pre-processing and steam distill<strong>at</strong>ion <strong>of</strong> Commiphora<br />

Two trials were conducted on <strong>the</strong> Commiphora resin using <strong>the</strong> adapted hydro still.<br />

1. In <strong>the</strong> first trial 5 baskets, manufactured <strong>for</strong> <strong>the</strong>se trials, were prepared with a covering <strong>of</strong> 5<br />

different types <strong>of</strong> m<strong>at</strong>erial placed in <strong>the</strong>m and <strong>the</strong>n filled with different sized pieces <strong>of</strong> Commiphora<br />

resin and placed in <strong>the</strong> pot with seals <strong>of</strong> different sizes and m<strong>at</strong>erials.<br />

2. In <strong>the</strong> second trial and based on <strong>the</strong> findings <strong>of</strong> <strong>the</strong> first trial it was decided to establish whe<strong>the</strong>r it<br />

would be possible to use less seals and pieces <strong>of</strong> m<strong>at</strong>erial. In this trial <strong>the</strong> bottom basket was<br />

covered with mutton cloth, filled with fine Commiphora powder and placed in <strong>the</strong> pot with a seal.<br />

The next three baskets where filled with bigger Commiphora pieces (according to <strong>the</strong> mesh size <strong>of</strong><br />

<strong>the</strong> baskets) and placed in <strong>the</strong> pot without covering m<strong>at</strong>erial and seals. The final basket with <strong>the</strong><br />

finest mesh size was placed on top with a silicon seal.<br />

Report on <strong>the</strong> Technical Assessment <strong>of</strong> <strong>the</strong> Stills <strong>at</strong> <strong>the</strong> Opuwo Processing Facility (April 2011) Page 4

The Commiphora hydro still<br />

The Commiphora still was originally designed to work as a hydro still where <strong>the</strong> product is submersed in<br />

w<strong>at</strong>er in a single basket. After trials it was decide th<strong>at</strong> this method was not sufficient <strong>for</strong> oil extraction<br />

and cre<strong>at</strong>ed gre<strong>at</strong> difficulty during <strong>the</strong> cleaning process. The modific<strong>at</strong>ions will allow <strong>the</strong> still to oper<strong>at</strong>e<br />

as a steam still; although not ideal it is a workable solution <strong>for</strong> <strong>the</strong> immedi<strong>at</strong>e future.<br />

3. Main Findings<br />

3.1 General<br />

During <strong>the</strong> inspection, cleaning and steam cleaning (running <strong>the</strong> distill<strong>at</strong>ion units with empty pots and<br />

no cooling) it was established th<strong>at</strong>:<br />

1. The electric breaker in <strong>the</strong> actual distill<strong>at</strong>ion room and on <strong>the</strong> main box was insufficient and will<br />

need to be upgraded,<br />

2. The quality <strong>of</strong> <strong>the</strong> w<strong>at</strong>er feeding <strong>the</strong> boiler is not good enough and some <strong>for</strong>m <strong>of</strong> purific<strong>at</strong>ion will be<br />

needed. A w<strong>at</strong>er sample was taken and analysed by a lab where it was noted th<strong>at</strong> it has a high lime<br />

content and Total Dissolved Solids (TDS) level, pending subsequent discussions with experts a<br />

solution needs to be implemented,<br />

3. Changes to <strong>the</strong> plumbing <strong>of</strong> <strong>the</strong> feed w<strong>at</strong>er to <strong>the</strong> boiler and to <strong>the</strong> cooling w<strong>at</strong>er <strong>for</strong> <strong>the</strong> condenser<br />

will be required,<br />

4. Drainage measures need to be taken to cre<strong>at</strong>e a safe and clean working environment.<br />

Report on <strong>the</strong> Technical Assessment <strong>of</strong> <strong>the</strong> Stills <strong>at</strong> <strong>the</strong> Opuwo Processing Facility (April 2011) Page 5

3.2 Mopane trials<br />

The following are <strong>the</strong> main findings with respect to <strong>the</strong> trials conducted on <strong>the</strong> mopane steam <strong>stills</strong>.<br />

1. Distilling <strong>the</strong> whole unprocessed pods was not successful and no oil was recovered as <strong>the</strong> shells did<br />

not open during distill<strong>at</strong>ion,<br />

2. Distilling <strong>the</strong> pods th<strong>at</strong> have been processed with <strong>the</strong> hammer mill produced a good amount and<br />

quality oil <strong>of</strong> about 2% when compared to <strong>the</strong> full weight <strong>of</strong> <strong>the</strong> crushed shell and kernel,<br />

3. It was calcul<strong>at</strong>ed after weighing <strong>the</strong> empty shells and kernels th<strong>at</strong> weight distribution is about equal.<br />

The kernels were <strong>the</strong>n distilled and nearly no oil was recovered.<br />

3.3 Commiphora trials<br />

The following are <strong>the</strong> main findings with respect to <strong>the</strong> trials conducted on distilling <strong>the</strong> Commiphora<br />

resin.<br />

Using <strong>the</strong> hammer mill to pre-process <strong>the</strong> Commiphora resin was rejected due to <strong>the</strong> previous trials with<br />

<strong>the</strong> resinous mopane seeds and build up within <strong>the</strong> hammer mill. Hand pre-processing seems to be <strong>the</strong><br />

easiest and best as <strong>the</strong> oper<strong>at</strong>ors have enough idle time during distill<strong>at</strong>ion <strong>for</strong> this procedure; some<br />

extra tools may be needed and designed.<br />

During <strong>the</strong> first steam distill<strong>at</strong>ion trail <strong>of</strong> <strong>the</strong> Commiphora resin was successful and approxim<strong>at</strong>ely ±6%<br />

oil was recovered/volume (i.e. 100kg myrrh = 6kg oil), which was good, comparable to results from trail<br />

distill<strong>at</strong>ion done in labor<strong>at</strong>ory conditions. As <strong>the</strong>re is no norm quantity <strong>of</strong> oil recovered only fur<strong>the</strong>r trials<br />

will establish this. Of <strong>the</strong> m<strong>at</strong>erial th<strong>at</strong> was used to cover <strong>the</strong> baskets in this trail, <strong>the</strong> mutton cloth and<br />

hessian was <strong>the</strong> considered to be <strong>the</strong> most appropri<strong>at</strong>e. The only seal th<strong>at</strong> was re-usable was <strong>the</strong> silicon<br />

seal. Upon opening <strong>the</strong> pot after distill<strong>at</strong>ion it was established th<strong>at</strong> <strong>the</strong> Commiphora resin boils and<br />

make bubbles th<strong>at</strong> rise to certain height making it possible to determine <strong>the</strong> optimal amount <strong>of</strong> baskets<br />

th<strong>at</strong> can be used in <strong>the</strong> hydro still. It was also established th<strong>at</strong> <strong>the</strong> boiling myrrh bubbles could also<br />

possibly seal around <strong>the</strong> baskets neg<strong>at</strong>ing <strong>the</strong> use <strong>of</strong> too many seals. This would be tested in <strong>the</strong> second<br />

trial. A few different cleaning methods <strong>for</strong> <strong>the</strong> baskets and still were also carried out.<br />

In <strong>the</strong> second trial approxim<strong>at</strong>ely 5% oil was recovered. On opening and inspection it was found th<strong>at</strong> <strong>the</strong><br />

boiling myrrh did seal as quickly as expected and it would better to use more silicon seals to get a better<br />

yield in a shorter time. Based on this a final basket and seal layout determined (see below in <strong>the</strong><br />

recommend<strong>at</strong>ions). Cleaning protocols were finalised.<br />

Report on <strong>the</strong> Technical Assessment <strong>of</strong> <strong>the</strong> Stills <strong>at</strong> <strong>the</strong> Opuwo Processing Facility (April 2011) Page 6

4. Recommend<strong>at</strong>ions<br />

4.1 General facility<br />

The facility, being built be<strong>for</strong>e <strong>the</strong> actual arrival and install<strong>at</strong>ion <strong>of</strong> <strong>the</strong> <strong>stills</strong>, will need some minor<br />

changes to cre<strong>at</strong>e a user-friendly and safe working environment, based on <strong>the</strong> findings <strong>of</strong> this<br />

<strong>assessment</strong> it is <strong>the</strong>re<strong>for</strong>e recommended th<strong>at</strong>:<br />

1. The 5KA r<strong>at</strong>ing electrical breaker in distill<strong>at</strong>ion room and in <strong>the</strong> main box needs to be upgraded to a<br />

breaker with a 15KA r<strong>at</strong>ing due to <strong>the</strong> type <strong>of</strong> boiler used as it causes fluctu<strong>at</strong>ions in Amperage, this<br />

change was discussed with <strong>the</strong> contractor in Opuwo,<br />

2. The w<strong>at</strong>er supply system be modified to facilit<strong>at</strong>e <strong>the</strong> movement <strong>of</strong> <strong>the</strong> boiler which has already<br />

been discussed with a contractor in Opuwo,<br />

3. Depending on <strong>the</strong> results <strong>of</strong> <strong>the</strong> w<strong>at</strong>er analysis a w<strong>at</strong>er purific<strong>at</strong>ion unit (such as w<strong>at</strong>er s<strong>of</strong>tener to<br />

remove lime and Reverse Osmosis to bring down <strong>the</strong> TDS) to supply <strong>the</strong> boiler with suitable quality<br />

w<strong>at</strong>er needs to be installed,<br />

4. Upgrading <strong>of</strong> w<strong>at</strong>er tanks from 5000 ℓ -10000ℓ <strong>for</strong> sufficient w<strong>at</strong>er supply <strong>for</strong> cooling as <strong>the</strong>re is not<br />

sufficient supply <strong>for</strong> a full day’s worth <strong>of</strong> oper<strong>at</strong>ing <strong>the</strong> <strong>stills</strong>,<br />

5. After discussions with contractor in Opuwo a suitable solution was reached to modify <strong>the</strong> floor by<br />

cutting channels into so th<strong>at</strong> <strong>the</strong> excess w<strong>at</strong>er (from <strong>the</strong> boiler and cleaning) can drain out <strong>of</strong> <strong>the</strong><br />

processing room thus cre<strong>at</strong>ing a safer working environment,<br />

6. Cre<strong>at</strong>e a simple method <strong>for</strong> removing spent plant m<strong>at</strong>erial from <strong>the</strong> facility and floor to a waste or<br />

composting site after each distill<strong>at</strong>ion procedure by cre<strong>at</strong>ing some ramps <strong>for</strong> a fl<strong>at</strong> bed wheel<br />

barrow type vehicle which can <strong>the</strong>n be tipped into a waiting trailer <strong>for</strong> removal from <strong>the</strong> site, if<br />

necessary, not withstanding th<strong>at</strong> this “waste m<strong>at</strong>erial” could also be valuable on its own. Ei<strong>the</strong>r way<br />

a suitable storage area or dump area will need to be identified;<br />

7. Standard oper<strong>at</strong>ing procedures will have to be established to produce a product <strong>of</strong> uni<strong>for</strong>m quality<br />

and to determine <strong>the</strong> cost <strong>of</strong> production in order to be able to calcul<strong>at</strong>e a sales price;<br />

8. A business plan should be put toge<strong>the</strong>r <strong>for</strong> future changes to improve productivity and <strong>for</strong> <strong>the</strong><br />

marketing <strong>of</strong> <strong>the</strong> oil.<br />

4.2 Mopane distill<strong>at</strong>ion<br />

The mopane distill<strong>at</strong>ion system seems to functioning well and only a couple <strong>of</strong> minor changes needs to<br />

be implemented on <strong>the</strong> pre-processing and on <strong>the</strong> baskets <strong>for</strong> loading and unloading, based on <strong>the</strong><br />

findings <strong>of</strong> this <strong>assessment</strong> it is <strong>the</strong>re<strong>for</strong>e recommended th<strong>at</strong>:<br />

1. The crushed Mopane seeds are <strong>the</strong> best <strong>for</strong> distill<strong>at</strong>ion in yield/weight and ease and speed <strong>of</strong><br />

processing, although more trials should be done with size <strong>of</strong> pre-processing,<br />

2. Oil samples should be tested <strong>for</strong> quality and also be sent to prospective buyers,<br />

Report on <strong>the</strong> Technical Assessment <strong>of</strong> <strong>the</strong> Stills <strong>at</strong> <strong>the</strong> Opuwo Processing Facility (April 2011) Page 7

3. Acquire a strong enough hammer mill with a suitable grid <strong>for</strong> processing <strong>the</strong> seeds, preferably only<br />

breaking <strong>the</strong> shell, not too fine,<br />

4. Making some clip or tie-on pre-fitted, re-usable hessian covers <strong>for</strong> <strong>the</strong> baskets.<br />

4.3 Commiphora distill<strong>at</strong>ion<br />

The Commiphora distill<strong>at</strong>ion plant, which was originally designed <strong>for</strong> hydro distill<strong>at</strong>ion, can be used to<br />

steam distil <strong>the</strong> Commiphora and based on <strong>the</strong> findings <strong>of</strong> this <strong>assessment</strong> it is <strong>the</strong>re<strong>for</strong>e recommended<br />

th<strong>at</strong>:<br />

1. Individual mesh (<strong>of</strong> <strong>the</strong> correct size) tables with c<strong>at</strong>chment area below should be constructed to<br />

facilit<strong>at</strong>e with pre-processing,<br />

2. Steam distill<strong>at</strong>ion will be used as it is superior to hydro distill<strong>at</strong>ion in <strong>the</strong> case <strong>of</strong> <strong>the</strong> extraction <strong>of</strong> oil<br />

from <strong>the</strong> Commiphora (time and quantity) and ease <strong>of</strong> cleaning after distill<strong>at</strong>ion,<br />

3. In longer term it would be better to acquire a pot and baskets designed to steam distil <strong>the</strong><br />

Commiphora as current use <strong>of</strong> <strong>the</strong> hydro still does not use <strong>the</strong> steam supplied as effectively as<br />

possible and to facilit<strong>at</strong>e with loading, unloading and cleaning,<br />

4. Oil samples should be tested <strong>for</strong> quality and also be sent to prospective buyers,<br />

5. Basket layout in pot will be nine baskets, <strong>the</strong> bottom basket and 5 th basket to be covered with<br />

m<strong>at</strong>erial (mutton cloth or hessian) and 5 silicon seals <strong>for</strong> every 2 nd basket starting on <strong>the</strong> bottom,<br />

6. Two sets <strong>of</strong> 9 baskets with two sets <strong>of</strong> 5 seals to be acquired <strong>for</strong> ease <strong>of</strong> cleaning and re-filling,<br />

7. Lifting out <strong>of</strong> baskets and seals out <strong>of</strong> pot after distilling to be done while pot is warm,<br />

8. The pot to be physically cleaned <strong>at</strong> <strong>the</strong> end <strong>of</strong> day or when <strong>the</strong> build up <strong>of</strong> spent resin in <strong>the</strong> pot<br />

interferes with inserting <strong>of</strong> baskets <strong>for</strong> new distill<strong>at</strong>ion.<br />

Report on <strong>the</strong> Technical Assessment <strong>of</strong> <strong>the</strong> Stills <strong>at</strong> <strong>the</strong> Opuwo Processing Facility (April 2011) Page 8