PB mixed issue sampler - updated Jul18

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

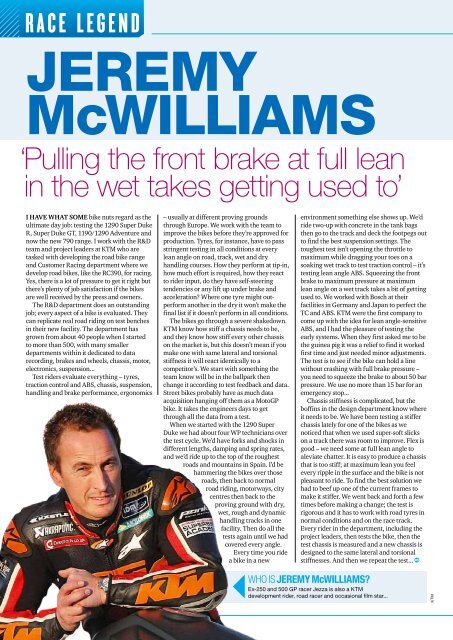

JEREMY<br />

McWILLIAMS<br />

‘ Pulling the front brake at full lean<br />

in the wet takes getting used to’<br />

These panniers may or<br />

may not be full of concrete<br />

Jezza with RC390 R&D<br />

colleagues Thomas Kuttruf<br />

and Wolfgang Welber<br />

I HAVE WHAT SOME bike nuts regard as the<br />

ultimate day job: testing the 1290 Super Duke<br />

R, Super Duke GT, 1190/1290 Adventure and<br />

now the new 790 range. I work with the R&D<br />

team and project leaders at KTM who are<br />

tasked with developing the road bike range<br />

and Customer Racing department where we<br />

develop road bikes, like the RC390, for racing.<br />

Yes, there is a lot of pressure to get it right but<br />

there’s plenty of job satisfaction if the bikes<br />

are well received by the press and owners.<br />

The R&D department does an outstanding<br />

job; every aspect of a bike is evaluated. They<br />

can replicate real road riding on test benches<br />

in their new facility. The department has<br />

grown from about 40 people when I started<br />

to more than 500, with many smaller<br />

departments within it dedicated to data<br />

recording, brakes and wheels, chassis, motor,<br />

electronics, suspension...<br />

Test riders evaluate everything – tyres,<br />

traction control and ABS, chassis, suspension,<br />

handling and brake performance, ergonomics<br />

– usually at different proving grounds<br />

through Europe. We work with the team to<br />

improve the bikes before they’re approved for<br />

production. Tyres, for instance, have to pass<br />

stringent testing in all conditions at every<br />

lean angle on road, track, wet and dry<br />

handling courses. How they perform at tip-in,<br />

how much effort is required, how they react<br />

to rider input, do they have self-steering<br />

tendencies or any lift up under brake and<br />

acceleration? Where one tyre might outperform<br />

another in the dry it won’t make the<br />

final list if it doesn’t perform in all conditions.<br />

The bikes go through a severe shakedown.<br />

KTM know how stiff a chassis needs to be,<br />

and they know how stiff every other chassis<br />

on the market is, but this doesn’t mean if you<br />

make one with same lateral and torsional<br />

stiffness it will react identically to a<br />

competitor’s. We start with something the<br />

team know will be in the ballpark then<br />

change it according to test feedback and data.<br />

Street bikes probably have as much data<br />

acquisition hanging off them as a MotoGP<br />

bike. It takes the engineers days to get<br />

through all the data from a test.<br />

When we started with the 1290 Super<br />

Duke we had about four WP technicians over<br />

the test cycle. We’d have forks and shocks in<br />

different lengths, damping and spring rates,<br />

and we’d ride up to the top of the roughest<br />

roads and mountains in Spain. I’d be<br />

hammering the bikes over those<br />

roads, then back to normal<br />

road riding, motorways, city<br />

centres then back to the<br />

proving ground with dry,<br />

wet, rough and dynamic<br />

handling tracks in one<br />

facility. Then do all the<br />

tests again until we had<br />

covered every angle.<br />

Every time you ride<br />

a bike in a new<br />

environment something else shows up. We’d<br />

ride two-up with concrete in the tank bags<br />

then go to the track and deck the footpegs out<br />

to find the best suspension settings. The<br />

toughest test isn’t opening the throttle to<br />

maximum while dragging your toes on a<br />

soaking wet track to test traction control – it’s<br />

testing lean angle ABS. Squeezing the front<br />

brake to maximum pressure at maximum<br />

lean angle on a wet track takes a bit of getting<br />

used to. We worked with Bosch at their<br />

facilities in Germany and Japan to perfect the<br />

TC and ABS. KTM were the first company to<br />

come up with the idea for lean angle-sensitive<br />

ABS, and I had the pleasure of testing the<br />

early systems. When they first asked me to be<br />

the guinea pig it was a relief to find it worked<br />

first time and just needed minor adjustments.<br />

The test is to see if the bike can hold a line<br />

without crashing with full brake pressure –<br />

you need to squeeze the brake to about 50 bar<br />

pressure. We use no more than 15 bar for an<br />

emergency stop...<br />

Chassis stiffness is complicated, but the<br />

boffins in the design department know where<br />

it needs to be. We have been testing a stiffer<br />

chassis lately for one of the bikes as we<br />

noticed that when we used super-soft slicks<br />

on a track there was room to improve. Flex is<br />

good – we need some at full lean angle to<br />

aleviate chatter. It is easy to produce a chassis<br />

that is too stiff; at maximum lean you feel<br />

every ripple in the surface and the bike is not<br />

pleasant to ride. To find the best solution we<br />

had to beef up one of the current frames to<br />

make it stiffer. We went back and forth a few<br />

times before making a change; the test is<br />

rigorous and it has to work with road tyres in<br />

normal conditions and on the race track.<br />

Every rider in the department, including the<br />

project leaders, then tests the bike, then the<br />

test chassis is measured and a new chassis is<br />

designed to the same lateral and torsional<br />

stiffnesses. And then we repeat the test...<br />

It’s not all high-action;<br />

there’s a fair amount of<br />

sitting around involved...<br />

When<br />

your 9-to-5<br />

involves pushing new<br />

bikes to – and beyond –<br />

the limits of traction, this is<br />

sometimes how your day<br />

ends. Followed by a lengthy sit<br />

down with your boss to<br />

explain the demise of their<br />

priceless pre-production<br />

performance<br />

motorcycle.<br />

WHO IS JEREMY McWILLIAMS?<br />

Ex-250 and 500 GP racer Jezza is also a KTM<br />

development rider, road racer and occasional film star...<br />

KTM<br />

We’ll twat anyone who<br />

questions McWilliams’<br />

commitment<br />

MARCH 2018 | PERFORMANCEBIKES.CO.UK 21