November 2018 Punch PDF

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ARTICLE<br />

Grain storage in sub-tropical climate<br />

Sarwar Ali & Manab Samanta<br />

Grain storage is an art and science which help in maintaining good quality of grain and minimize the losses<br />

at storage.Storage of corn in sub- tropical climate has often posed a problem of quality deterioration, which is<br />

more often a result of mold growth. Good hygiene, effective grain drying and cooling, mold inhibition and welltargeted<br />

pest control all combine to maintain grain quality in store. Followings are important factors for grain<br />

storage in silo-<br />

1.Pre-storage condition 2 Moisture 3. Drying 4 Cooling 5. Pest management 6.Mold inhibition<br />

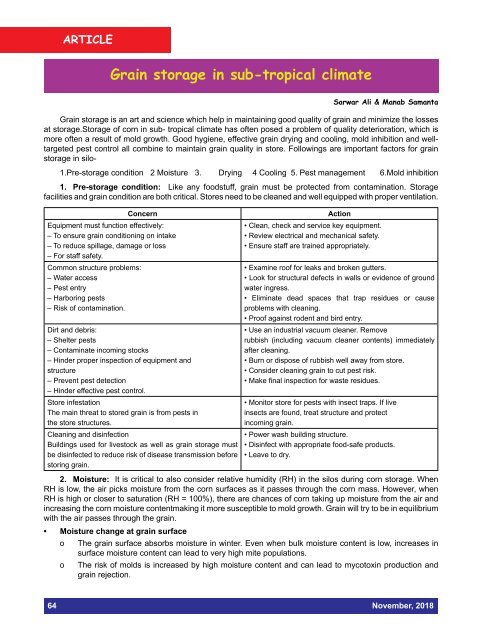

1. Pre-storage condition: Like any foodstuff, grain must be protected from contamination. Storage<br />

facilities and grain condition are both critical. Stores need to be cleaned and well equipped with proper ventilation.<br />

Concern<br />

Equipment must function effectively:<br />

– To ensure grain conditioning on intake<br />

– To reduce spillage, damage or loss<br />

– For staff safety.<br />

Common structure problems:<br />

– Water access<br />

– Pest entry<br />

– Harboring pests<br />

– Risk of contamination.<br />

Dirt and debris:<br />

– Shelter pests<br />

– Contaminate incoming stocks<br />

– Hinder proper inspection of equipment and<br />

structure<br />

– Prevent pest detection<br />

– Hinder effective pest control.<br />

Store infestation<br />

The main threat to stored grain is from pests in<br />

the store structures.<br />

Cleaning and disinfection<br />

Buildings used for livestock as well as grain storage must<br />

be disinfected to reduce risk of disease transmission before<br />

storing grain.<br />

Action<br />

• Clean, check and service key equipment.<br />

• Review electrical and mechanical safety.<br />

• Ensure staff are trained appropriately.<br />

• Examine roof for leaks and broken gutters.<br />

• Look for structural defects in walls or evidence of ground<br />

water ingress.<br />

• Eliminate dead spaces that trap residues or cause<br />

problems with cleaning.<br />

• Proof against rodent and bird entry.<br />

• Use an industrial vacuum cleaner. Remove<br />

rubbish (including vacuum cleaner contents) immediately<br />

after cleaning.<br />

• Burn or dispose of rubbish well away from store.<br />

• Consider cleaning grain to cut pest risk.<br />

• Make final inspection for waste residues.<br />

• Monitor store for pests with insect traps. If live<br />

insects are found, treat structure and protect<br />

incoming grain.<br />

• Power wash building structure.<br />

• Disinfect with appropriate food-safe products.<br />

• Leave to dry.<br />

2. Moisture: It is critical to also consider relative humidity (RH) in the silos during corn storage. When<br />

RH is low, the air picks moisture from the corn surfaces as it passes through the corn mass. However, when<br />

RH is high or closer to saturation (RH = 100%), there are chances of corn taking up moisture from the air and<br />

increasing the corn moisture contentmaking it more susceptible to mold growth. Grain will try to be in equilibrium<br />

with the air passes through the grain.<br />

• Moisture change at grain surface<br />

o The grain surface absorbs moisture in winter. Even when bulk moisture content is low, increases in<br />

surface moisture content can lead to very high mite populations.<br />

o The risk of molds is increased by high moisture content and can lead to mycotoxin production and<br />

grain rejection.<br />

64 <strong>November</strong>, <strong>2018</strong>