November 2018 Punch PDF

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

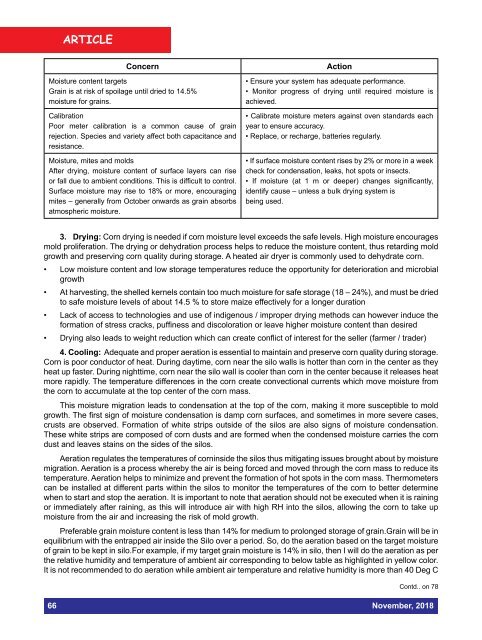

ARTICLE<br />

Concern<br />

Moisture content targets<br />

Grain is at risk of spoilage until dried to 14.5%<br />

moisture for grains.<br />

Calibration<br />

Poor meter calibration is a common cause of grain<br />

rejection. Species and variety affect both capacitance and<br />

resistance.<br />

Moisture, mites and molds<br />

After drying, moisture content of surface layers can rise<br />

or fall due to ambient conditions. This is difficult to control.<br />

Surface moisture may rise to 18% or more, encouraging<br />

mites – generally from October onwards as grain absorbs<br />

atmospheric moisture.<br />

Action<br />

• Ensure your system has adequate performance.<br />

• Monitor progress of drying until required moisture is<br />

achieved.<br />

• Calibrate moisture meters against oven standards each<br />

year to ensure accuracy.<br />

• Replace, or recharge, batteries regularly.<br />

• If surface moisture content rises by 2% or more in a week<br />

check for condensation, leaks, hot spots or insects.<br />

• If moisture (at 1 m or deeper) changes significantly,<br />

identify cause – unless a bulk drying system is<br />

being used.<br />

3. Drying: Corn drying is needed if corn moisture level exceeds the safe levels. High moisture encourages<br />

mold proliferation. The drying or dehydration process helps to reduce the moisture content, thus retarding mold<br />

growth and preserving corn quality during storage. A heated air dryer is commonly used to dehydrate corn.<br />

• Low moisture content and low storage temperatures reduce the opportunity for deterioration and microbial<br />

growth<br />

• At harvesting, the shelled kernels contain too much moisture for safe storage (18 – 24%), and must be dried<br />

to safe moisture levels of about 14.5 % to store maize effectively for a longer duration<br />

• Lack of access to technologies and use of indigenous / improper drying methods can however induce the<br />

formation of stress cracks, puffiness and discoloration or leave higher moisture content than desired<br />

• Drying also leads to weight reduction which can create conflict of interest for the seller (farmer / trader)<br />

4. Cooling: Adequate and proper aeration is essential to maintain and preserve corn quality during storage.<br />

Corn is poor conductor of heat. During daytime, corn near the silo walls is hotter than corn in the center as they<br />

heat up faster. During nighttime, corn near the silo wall is cooler than corn in the center because it releases heat<br />

more rapidly. The temperature differences in the corn create convectional currents which move moisture from<br />

the corn to accumulate at the top center of the corn mass.<br />

This moisture migration leads to condensation at the top of the corn, making it more susceptible to mold<br />

growth. The first sign of moisture condensation is damp corn surfaces, and sometimes in more severe cases,<br />

crusts are observed. Formation of white strips outside of the silos are also signs of moisture condensation.<br />

These white strips are composed of corn dusts and are formed when the condensed moisture carries the corn<br />

dust and leaves stains on the sides of the silos.<br />

Aeration regulates the temperatures of corninside the silos thus mitigating issues brought about by moisture<br />

migration. Aeration is a process whereby the air is being forced and moved through the corn mass to reduce its<br />

temperature. Aeration helps to minimize and prevent the formation of hot spots in the corn mass. Thermometers<br />

can be installed at different parts within the silos to monitor the temperatures of the corn to better determine<br />

when to start and stop the aeration. It is important to note that aeration should not be executed when it is raining<br />

or immediately after raining, as this will introduce air with high RH into the silos, allowing the corn to take up<br />

moisture from the air and increasing the risk of mold growth.<br />

Preferable grain moisture content is less than 14% for medium to prolonged storage of grain.Grain will be in<br />

equilibrium with the entrapped air inside the Silo over a period. So, do the aeration based on the target moisture<br />

of grain to be kept in silo.For example, if my target grain moisture is 14% in silo, then I will do the aeration as per<br />

the relative humidity and temperature of ambient air corresponding to below table as highlighted in yellow color.<br />

It is not recommended to do aeration while ambient air temperature and relative humidity is more than 40 Deg C<br />

Contd.. on 78<br />

66 <strong>November</strong>, <strong>2018</strong>