Innovation directory 4th edition

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

manufacturing process<br />

Efficient Method for Producing High<br />

Quality Timber from Oil Palm Wood<br />

TECHNOLOGY DESCRIPTION<br />

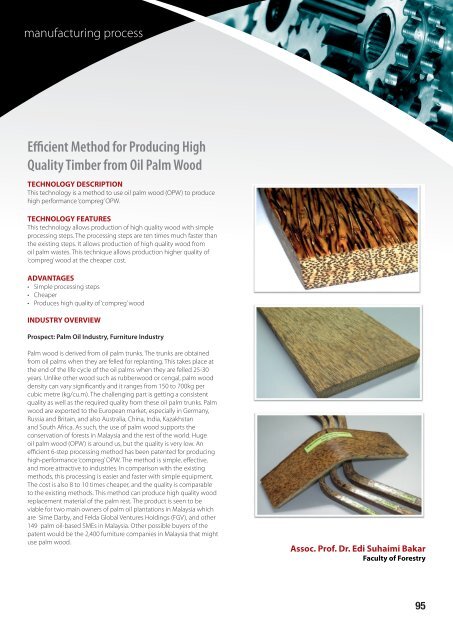

This technology is a method to use oil palm wood (OPW) to produce<br />

high performance ‘compreg’ OPW.<br />

TECHNOLOGY FEATURES<br />

This technology allows production of high quality wood with simple<br />

processing steps. The processing steps are ten times much faster than<br />

the existing steps. It allows production of high quality wood from<br />

oil palm wastes. This technique allows production higher quality of<br />

‘compreg’ wood at the cheaper cost.<br />

ADVANTAGES<br />

• Simple processing steps<br />

• Cheaper<br />

• Produces high quality of ‘compreg’ wood<br />

INDUSTRY OVERVIEW<br />

Prospect: Palm Oil Industry, Furniture Industry<br />

Palm wood is derived from oil palm trunks. The trunks are obtained<br />

from oil palms when they are felled for replanting. This takes place at<br />

the end of the life cycle of the oil palms when they are felled 25-30<br />

years. Unlike other wood such as rubberwood or cengal, palm wood<br />

density can vary significantly and it ranges from 150 to 700kg per<br />

cubic metre (kg/cu.m). The challenging part is getting a consistent<br />

quality as well as the required quality from these oil palm trunks. Palm<br />

wood are exported to the European market, especially in Germany,<br />

Russia and Britain, and also Australia, China, India, Kazakhstan<br />

and South Africa. As such, the use of palm wood supports the<br />

conservation of forests in Malaysia and the rest of the world. Huge<br />

oil palm wood (OPW) is around us, but the quality is very low. An<br />

efficient 6-step processing method has been patented for producing<br />

high-performance ‘compreg’ OPW. The method is simple, effective,<br />

and more attractive to industries. In comparison with the existing<br />

methods, this processing is easier and faster with simple equipment.<br />

The cost is also 8 to 10 times cheaper, and the quality is comparable<br />

to the existing methods. This method can produce high quality wood<br />

replacement material of the palm rest. The product is seen to be<br />

viable for two main owners of palm oil plantations in Malaysia which<br />

are Sime Darby, and Felda Global Ventures Holdings (FGV), and other<br />

149 palm oil-based SMEs in Malaysia. Other possible buyers of the<br />

patent would be the 2,400 furniture companies in Malaysia that might<br />

use palm wood.<br />

Assoc. Prof. Dr. Edi Suhaimi Bakar<br />

Faculty of Forestry<br />

95