- Page 1:

ACCOUNTING PRINCIPLES TWELFTH EDITI

- Page 4 and 5:

Account Title Classification Financ

- Page 7 and 8:

ACCOUNTING PRINCIPLES TWELFTH EDITI

- Page 9 and 10:

Brief Contents 1 Accounting in Acti

- Page 11 and 12:

Author Commitment Jerry Weygandt Je

- Page 13 and 14:

Streamlined Learning Objectives New

- Page 15 and 16:

Table of Contents 1 Accounting in A

- Page 17 and 18:

LO *6: APPENDIX 6B: Describe the tw

- Page 19 and 20:

LO 3: Prepare and analyze a compreh

- Page 21 and 22:

LO *6: APPENDIX 21A: Apply activity

- Page 23 and 24:

LO 2: Compute present values. G-7 P

- Page 25 and 26:

Jeanette Milius Iowa Western Commun

- Page 27 and 28:

CHAPTER OUTLINE Learning Objectives

- Page 29 and 30:

Accounting Activities and Users 5 C

- Page 31 and 32:

Building Blocks of Accounting 7 DO

- Page 33 and 34:

Building Blocks of Accounting 9 The

- Page 35 and 36:

Building Blocks of Accounting 11 in

- Page 37 and 38:

The Accounting Equation 13 Owner’

- Page 39 and 40:

Analyzing Business Transactions 15

- Page 41 and 42:

Analyzing Business Transactions 17

- Page 43 and 44:

Analyzing Business Transactions 19

- Page 45 and 46:

The Four Financial Statements 21 LE

- Page 47 and 48:

The Four Financial Statements 23 Wh

- Page 49 and 50:

Appendix 1A: Career Opportunities i

- Page 51 and 52:

The Review and Practice section pro

- Page 53 and 54:

Practice Multiple-Choice Questions

- Page 55 and 56:

Practice Problem 31 5. Increase in

- Page 57 and 58:

Questions 33 QUESTIONS Brief Exerci

- Page 59 and 60:

DO IT! Exercises 35 ________ (a) Ad

- Page 61 and 62:

Exercises 37 says, “Showing the l

- Page 63 and 64:

Exercises 39 End of year: Total ass

- Page 65 and 66:

Problems: Set A 41 6. Withdrew $700

- Page 67 and 68:

Broadening Your Perspective 43 BROA

- Page 69 and 70:

Broadening Your Perspective 45 subm

- Page 71 and 72:

A Look at IFRS 47 Looking to the Fu

- Page 73 and 74:

Nick Laham/Getty Images, Inc. CHAPT

- Page 75 and 76:

Accounts, Debits, and Credits 51 Ev

- Page 77 and 78:

Accounts, Debits, and Credits 53 In

- Page 79 and 80:

The Journal 55 The steps in the rec

- Page 81 and 82:

The Ledger and Posting 57 DO IT! 2

- Page 83 and 84:

The Ledger and Posting 59 Posting T

- Page 85 and 86:

The Ledger and Posting 61 perform t

- Page 87 and 88:

The Ledger and Posting 63 Transacti

- Page 89 and 90:

The Ledger and Posting 65 Transacti

- Page 91 and 92:

The Ledger and Posting 67 Illustrat

- Page 93 and 94:

The Trial Balance 69 4. Incorrect a

- Page 95 and 96:

Practice Multiple-Choice Questions

- Page 97 and 98:

Practice Exercises 73 12. (c) The b

- Page 99 and 100:

Practice Problem 75 PRACTICE PROBLE

- Page 101 and 102:

Brief Exercises 77 4. Erica Mendez,

- Page 103 and 104:

Exercises 79 DO IT! Exercises DO IT

- Page 105 and 106:

Exercises 81 E2-8 Teresa Alvarez ha

- Page 107 and 108:

Problems: Set A 83 5. A cash purcha

- Page 109 and 110:

Problems: Set B and Set C 85 Each o

- Page 111 and 112:

Broadening Your Perspective 87 (b)

- Page 113 and 114:

Broadening Your Perspective 89 A r

- Page 115 and 116:

A Look at IFRS 91 (c) proves that a

- Page 117 and 118:

CHAPTER OUTLINE Learning Objectives

- Page 119 and 120:

Recognizing Revenues and Expenses I

- Page 121 and 122:

Adjusting Entries for Deferrals 97

- Page 123 and 124:

Adjusting Entries for Deferrals 99

- Page 125 and 126:

Adjusting Entries for Deferrals 101

- Page 127 and 128:

Adjusting Entries for Deferrals 103

- Page 129 and 130:

Adjusting Entries for Accruals 105

- Page 131 and 132:

Adjusting Entries for Accruals 107

- Page 133 and 134:

Adjusting Entries for Accruals 109

- Page 135 and 136:

Adjusted Trial Balance and Financia

- Page 137 and 138:

Adjusted Trial Balance and Financia

- Page 139 and 140:

Appendix 3A: Adjusting Entries for

- Page 141 and 142:

Appendix 3A: Adjusting Entries for

- Page 143 and 144:

Appendix 3B: Financial Reporting Co

- Page 145 and 146:

Review and Practice 121 REVENUE REC

- Page 147 and 148:

Practice Multiple-Choice Questions

- Page 149 and 150:

Practice Exercises 125 12. (b) Adju

- Page 151 and 152:

Questions 127 Solution GENERAL JOUR

- Page 153 and 154:

Brief Exercises 129 BE3-6 Using the

- Page 155 and 156:

Exercises 131 Debit Credit Prepaid

- Page 157 and 158:

Exercises 133 2. A count of supplie

- Page 159 and 160:

Exercises 135 (b) If the amount in

- Page 161 and 162:

Exercises 137 *E3-18 Presented belo

- Page 163 and 164:

Problems: Set A 139 In addition to

- Page 165 and 166:

Problems: Set A 141 3. Notes Payabl

- Page 167 and 168:

Broadening Your Perspective 143 5.

- Page 169 and 170:

Communication Activity BYP3-6 In re

- Page 171 and 172:

A Look at IFRS 147 Looking to the F

- Page 173 and 174:

Comstock/Getty ty Images, Inc. CHAP

- Page 175 and 176:

The Worksheet 151 STEP 1: PREPARE A

- Page 177 and 178:

The Worksheet 153 Illustration 4-3A

- Page 179 and 180:

STEP 4: EXTEND ADJUSTED TRIAL BALAN

- Page 181 and 182:

The Worksheet 157 Preparing Financi

- Page 183 and 184:

Closing the Books 159 In contrast,

- Page 185 and 186:

Closing the Books 161 GENERAL JOURN

- Page 187 and 188:

Closing the Books 163 Preparing a P

- Page 189 and 190:

Closing the Books 165 (Temporary Ac

- Page 191 and 192:

Accounting Cycle and Correcting Ent

- Page 193 and 194:

Classified Balance Sheet 169 LEARNI

- Page 195 and 196:

Classified Balance Sheet 171 As we

- Page 197 and 198:

Classified Balance Sheet 173 Illust

- Page 199 and 200:

Appendix 4A: Reversing Entries 175

- Page 201 and 202:

Review and Practice 177 2 3 Prepare

- Page 203 and 204:

Practice Multiple-Choice Questions

- Page 205 and 206:

Practice Exercises 181 (c) HERCULES

- Page 207 and 208:

Practice Problem 183 Instructions (

- Page 209 and 210:

Brief Exercises 185 QUESTIONS Brief

- Page 211 and 212:

Exercises 187 * BE4-12 At October 3

- Page 213 and 214:

Exercises 189 Instructions Prepare

- Page 215 and 216:

Exercises 191 E4-10 Renee Davis has

- Page 217 and 218:

Problems: Set A 193 * E4-18 Lovrek

- Page 219 and 220:

Problems: Set A 195 BRAY COMPANY Wo

- Page 221 and 222:

Comprehensive Problem: Chapters 2 t

- Page 223 and 224:

Broadening Your Perspective 199 Ins

- Page 225 and 226:

Communication Activity BYP4-6 The a

- Page 227 and 228:

A Look at IFRS 203 FRANKLIN COMPANY

- Page 229 and 230:

A Look at IFRS 205 International Co

- Page 231 and 232:

© omgimages/iStockphoto CHAPTER OU

- Page 233 and 234:

Merchandising Operations and Invent

- Page 235 and 236:

Recording Purchases under a Perpetu

- Page 237 and 238:

Recording Purchases under a Perpetu

- Page 239 and 240:

Recording Purchases under a Perpetu

- Page 241 and 242:

Recording Sales under a Perpetual S

- Page 243 and 244:

Recording Sales under a Perpetual S

- Page 245 and 246:

Merchandising Company Accounting Cy

- Page 247 and 248:

Multiple-Step vs. Single-Step Incom

- Page 249 and 250:

Multiple-Step vs. Single-Step Incom

- Page 251 and 252:

Multiple-Step vs. Single-Step Incom

- Page 253 and 254:

Appendix 5B: Periodic Inventory Sys

- Page 255 and 256:

Appendix 5B: Periodic Inventory Sys

- Page 257 and 258:

Appendix 5B: Periodic Inventory Sys

- Page 259 and 260:

Appendix 5B: Periodic Inventory Sys

- Page 261 and 262:

Review and Practice 237 REVIEW AND

- Page 263 and 264:

Practice Multiple-Choice Questions

- Page 265 and 266:

Practice Problem 241 Solution 2. (a

- Page 267 and 268:

Brief Exercises 243 12. Explain why

- Page 269 and 270:

DO IT! Exercises 245 Example Cash:

- Page 271 and 272:

Exercises 247 E5-5 Presented below

- Page 273 and 274:

Exercises 249 Adjusted Income Accou

- Page 275 and 276:

Problems: Set A 251 EXERCISES: SET

- Page 277 and 278:

Problems: Set A 253 The chart of ac

- Page 279 and 280:

Comprehensive Problem 255 Instructi

- Page 281 and 282:

Broadening Your Perspective 257 Ins

- Page 283 and 284:

A Look at IFRS 259 At what point sh

- Page 285 and 286:

A Look at IFRS 261 International Fi

- Page 287 and 288:

James Porter/Workbook/Getty Images,

- Page 289 and 290:

Classifying and Determining Invento

- Page 291 and 292:

Classifying and Determining Invento

- Page 293 and 294:

Specific Identification If Crivitz

- Page 295 and 296:

Inventory Methods and Financial Eff

- Page 297 and 298:

Inventory Methods and Financial Eff

- Page 299 and 300:

Inventory Methods and Financial Eff

- Page 301 and 302:

Effects of Inventory Errors 277 LEA

- Page 303 and 304:

Inventory Statement Presentation an

- Page 305 and 306:

Inventory Statement Presentation an

- Page 307 and 308:

Appendix 6A: Inventory Cost Flow Me

- Page 309 and 310:

Appendix 6B: Estimating Inventories

- Page 311 and 312:

Review and Practice 287 3 4 (LIFO)

- Page 313 and 314:

Practice Multiple-Choice Questions

- Page 315 and 316:

Practice Problems 291 2. Rhode Soft

- Page 317 and 318:

Questions 293 (b) LIFO Method Date

- Page 319 and 320:

DO IT! Exercises 295 BE6-7 Cruz Vid

- Page 321 and 322:

Exercises 297 3. Included in the in

- Page 323 and 324:

Exercises 299 Smart uses a periodic

- Page 325 and 326:

Problems: Set A 301 * E6-20 Kicks S

- Page 327 and 328:

Problems: Set A 303 Instructions (a

- Page 329 and 330:

Comprehensive Problem 305 Hardcover

- Page 331 and 332:

Broadening Your Perspective 307 ann

- Page 333 and 334:

A Look at IFRS 309 Similarities •

- Page 335 and 336:

Terra Images/Age Fotostock America,

- Page 337 and 338:

Basic Concepts of Accounting Inform

- Page 339 and 340:

Subsidiary Ledgers 315 LEARNING OBJ

- Page 341 and 342:

Using Special Journals 317 2. They

- Page 343 and 344:

Using Special Journals 319 General

- Page 345 and 346:

Using Special Journals 321 Postings

- Page 347 and 348:

Using Special Journals 323 Credit C

- Page 349 and 350:

Using Special Journals 325 General

- Page 351 and 352:

Using Special Journals 327 General

- Page 353 and 354:

Using Special Journals 329 Effects

- Page 355 and 356:

Review and Practice 331 Companies n

- Page 357 and 358:

Practice Exercises 333 (LO 3) (b) D

- Page 359 and 360:

Practice Problem 335 2. Below are s

- Page 361 and 362:

Brief Exercises 337 12. One column

- Page 363 and 364:

Exercises 339 DO IT! 7-3 Hinske Com

- Page 365 and 366:

Exercises 341 Instructions (a) Prep

- Page 367 and 368:

Problems: Set A 343 Instructions Fr

- Page 369 and 370:

Problems: Set A 345 5 Purchased mer

- Page 371 and 372:

Problems: Set A 347 Instructions (a

- Page 373 and 374:

Comprehensive Problems: Chapters 3

- Page 375 and 376:

Broadening Your Perspective 351 27

- Page 377 and 378:

A Look at IFRS 353 A Look at IFRS L

- Page 379 and 380:

© James Pauls/iStockphoto CHAPTER

- Page 381 and 382:

Fraud and Internal Control 357 the

- Page 383 and 384:

Fraud and Internal Control 359 Tota

- Page 385 and 386:

Fraud and Internal Control 361 Simi

- Page 387 and 388:

Fraud and Internal Control 363 Segr

- Page 389 and 390:

Fraud and Internal Control 365 Limi

- Page 391 and 392:

Cash Controls 367 tape is locked in

- Page 393 and 394:

Cash Controls 369 Cash Disbursement

- Page 395 and 396:

Cash Controls 371 expenditures that

- Page 397 and 398:

Control Features of a Bank Account

- Page 399 and 400:

Control Features of a Bank Account

- Page 401 and 402:

Control Features of a Bank Account

- Page 403 and 404:

Control Features of a Bank Account

- Page 405 and 406:

Reporting Cash 381 Solution Sally s

- Page 407 and 408:

Review and Practice 383 2 safeguard

- Page 409 and 410:

Practice Exercises 385 Solutions 1.

- Page 411 and 412:

Practice Problem 387 PRACTICE PROBL

- Page 413 and 414:

Brief Exercises 389 3. An employee

- Page 415 and 416:

Exercises 391 EXERCISES E8-1 Eve He

- Page 417 and 418:

Exercises 393 Receipt Date No. For

- Page 419 and 420:

Problems: Set A 395 EXERCISES: SET

- Page 421 and 422:

Problems: Set A 397 The cash record

- Page 423 and 424:

Broadening Your Perspective 399 Adj

- Page 425 and 426:

Broadening Your Perspective 401 At

- Page 427 and 428:

A Look at IFRS 403 Differences •

- Page 429 and 430:

© Cogal/iStockphoto CHAPTER OUTLIN

- Page 431 and 432:

Recognition of Accounts Receivable

- Page 433 and 434:

Valuation and Disposition of Accoun

- Page 435 and 436:

Valuation and Disposition of Accoun

- Page 437 and 438:

Valuation and Disposition of Accoun

- Page 439 and 440:

Valuation and Disposition of Accoun

- Page 441 and 442:

Recognition of Notes Receivable 417

- Page 443 and 444:

Recognition of Notes Receivable 419

- Page 445 and 446:

Valuation and Disposition of Notes

- Page 447 and 448:

Review and Practice 423 The result

- Page 449 and 450:

Practice Multiple-Choice Questions

- Page 451 and 452:

Practice Exercises 427 PRACTICE EXE

- Page 453 and 454:

Questions 429 May 10 Allowance for

- Page 455 and 456:

Exercises 431 BE9-10 Presented belo

- Page 457 and 458:

Exercises 433 E9-7 Presented below

- Page 459 and 460:

Problems: Set A 435 (c) Assume that

- Page 461 and 462:

Comprehensive Problem 437 Jan. 5 So

- Page 463 and 464:

Comparative Analysis Problem: Pepsi

- Page 465 and 466:

A Look at IFRS 441 Similarities •

- Page 467 and 468:

CHAPTER OUTLINE Learning Objectives

- Page 469 and 470:

Plant Asset Expenditures 445 Land a

- Page 471 and 472:

Plant Asset Expenditures 447 In con

- Page 473 and 474:

Depreciation Methods 449 Revenue-pr

- Page 475 and 476:

Depreciation Methods 451 Note that

- Page 477 and 478:

Depreciation Methods 453 A common d

- Page 479 and 480:

Plant Asset Disposals 455 Book valu

- Page 481 and 482:

Plant Asset Disposals 457 GAIN ON S

- Page 483 and 484:

Natural Resources and Intangible As

- Page 485 and 486:

Natural Resources and Intangible As

- Page 487 and 488:

Statement Presentation and Analysis

- Page 489 and 490:

Appendix 10A: Exchange of Plant Ass

- Page 491 and 492:

Review and Practice 467 In recordin

- Page 493 and 494:

Practice Multiple-Choice Questions

- Page 495 and 496:

Practice Problems 471 Solution 1. (

- Page 497 and 498:

Questions 473 (b) 7/1/20 Depreciati

- Page 499 and 500:

DO IT! Exercises 475 BE10-9 Prepare

- Page 501 and 502:

Exercises 477 Instructions Indicate

- Page 503 and 504:

Exercises: Set B and Challenge Exer

- Page 505 and 506:

Problems: Set A 481 Instructions (a

- Page 507 and 508:

Comprehensive Problem: Chapters 3 t

- Page 509 and 510:

Broadening Your Perspective 485 Ins

- Page 511 and 512:

A Look at IFRS 487 (2) Dairy Queen

- Page 513 and 514:

A Look at IFRS 489 IFRS10-3 Some pr

- Page 515 and 516:

CHAPTER OUTLINE Learning Objectives

- Page 517 and 518:

Accounting for Current Liabilities

- Page 519 and 520:

Reporting and Analyzing Current Lia

- Page 521 and 522:

Reporting and Analyzing Current Lia

- Page 523 and 524:

Accounting for Payroll 499 Solution

- Page 525 and 526:

Accounting for Payroll 501 FICA TAX

- Page 527 and 528:

Accounting for Payroll 503 Recordin

- Page 529 and 530:

Accounting for Payroll 505 AC Pay t

- Page 531 and 532:

Accounting for Payroll 507 Illustra

- Page 533 and 534:

Accounting for Payroll 509 22222 Vo

- Page 535 and 536:

Appendix 11A: Additional Fringe Ben

- Page 537 and 538:

Review and Practice 513 To the exte

- Page 539 and 540:

Practice Multiple-Choice Questions

- Page 541 and 542:

Practice Problem 517 Solution 2. (a

- Page 543 and 544:

Brief Exercises 519 What informatio

- Page 545 and 546:

Exercises 521 EXERCISES E11-1 C.S.

- Page 547 and 548:

Exercises 523 E11-10 Employee earni

- Page 549 and 550:

Problems: Set A 525 Instructions (a

- Page 551 and 552:

Broadening Your Perspective 527 6.

- Page 553 and 554:

Broadening Your Perspective 529 The

- Page 555 and 556:

A Look at IFRS 531 • For those it

- Page 557 and 558:

Ollyy/Shutterstoc y/ CHAPTER OUTLIN

- Page 559 and 560:

Forming a Partnership 535 contribut

- Page 561 and 562:

Forming a Partnership 537 Advantage

- Page 563 and 564:

Accounting for Net Income or Net Lo

- Page 565 and 566:

Accounting for Net Income or Net Lo

- Page 567 and 568:

Accounting for Liquidation 543 KING

- Page 569 and 570:

Accounting for Liquidation 545 3. P

- Page 571 and 572:

Accounting for Liquidation 547 1. T

- Page 573 and 574:

Appendix 12A: Admission and Withdra

- Page 575 and 576:

Appendix 12A: Admission and Withdra

- Page 577 and 578:

Appendix 12A: Admission and Withdra

- Page 579 and 580:

Review and Practice 555 Note that i

- Page 581 and 582:

Practice Multiple-Choice Questions

- Page 583 and 584:

Practice Problem 559 2. The Braun C

- Page 585 and 586:

Brief Exercises 561 gain and alloca

- Page 587 and 588:

Exercises 563 EXERCISES E12-1 Mark

- Page 589 and 590:

Exercises: Set B and Challenge Exer

- Page 591 and 592:

Problems: Set A 567 P12-3A The part

- Page 593 and 594:

Broadening Your Perspective 569 mig

- Page 595 and 596:

Franck Fife/AFP/Getty Images, Inc.

- Page 597 and 598:

Corporate Form of Organization 573

- Page 599 and 600:

Corporate Form of Organization 575

- Page 601 and 602:

Corporate Form of Organization 577

- Page 603 and 604:

Corporate Form of Organization 579

- Page 605 and 606:

Accounting for Common and Preferred

- Page 607 and 608:

Accounting for Common and Preferred

- Page 609 and 610:

Accounting for Treasury Stock 585 O

- Page 611 and 612:

Statement Presentation of Stockhold

- Page 613 and 614:

Review and Practice 589 DO IT! 4 St

- Page 615 and 616:

Practice Multiple-Choice Questions

- Page 617 and 618:

Practice Problem 593 PRACTICE PROBL

- Page 619 and 620:

Exercises 595 BE13-6 Garb Inc. issu

- Page 621 and 622:

Exercises 597 Instructions Journali

- Page 623 and 624:

Problems: Set A 599 Instructions Pr

- Page 625 and 626:

Continuing Problem 601 Common Stock

- Page 627 and 628:

Broadening Your Perspective 603 Ins

- Page 629 and 630:

A Look at IFRS 605 A Look at IFRS L

- Page 631 and 632:

A Look at IFRS 607 International Fi

- Page 633 and 634:

Daisy Daisy/Photographer’s Choice

- Page 635 and 636:

Accounting for Cash Dividends 611 E

- Page 637 and 638:

Accounting for Cash Dividends 613 D

- Page 639 and 640:

Accounting for Stock Dividends and

- Page 641 and 642:

Accounting for Stock Dividends and

- Page 643 and 644:

Retained Earnings Statement and Sto

- Page 645 and 646:

Retained Earnings Statement and Sto

- Page 647 and 648:

Corporation Income Statements 623 N

- Page 649 and 650:

Corporation Income Statements 625 I

- Page 651 and 652:

Practice Multiple-Choice Questions

- Page 653 and 654:

Practice Exercises 629 11. (c) Retu

- Page 655 and 656:

Practice Problem 631 During the yea

- Page 657 and 658:

Do It! Exercises 633 is declared wh

- Page 659 and 660:

Exercises 635 Instructions Prepare

- Page 661 and 662:

Problems: Set A 637 Instructions Co

- Page 663 and 664:

Problems: Set B and Set C 639 4. Th

- Page 665 and 666:

Broadening Your Perspective 641 Ste

- Page 667 and 668:

A Look at IFRS 643 • Equity is gi

- Page 669 and 670:

CHAPTER OUTLINE Learning Objectives

- Page 671 and 672:

Major Characteristics of Bonds 647

- Page 673 and 674:

Accounting for Bond Transactions 64

- Page 675 and 676:

Accounting for Bond Transactions 65

- Page 677 and 678:

Accounting for Bond Transactions 65

- Page 679 and 680:

Accounting for Bond Transactions 65

- Page 681 and 682:

Statement Presentation and Analysis

- Page 683 and 684:

Statement Presentation and Analysis

- Page 685 and 686:

Statement Presentation and Analysis

- Page 687 and 688:

Appendix 15A: Straight-Line Amortiz

- Page 689 and 690:

Appendix 15B: Effective-Interest Am

- Page 691 and 692:

Review and Practice 667 For the fir

- Page 693 and 694:

Practice Multiple-Choice Questions

- Page 695 and 696:

Practice Exercises 671 2. Hollenbec

- Page 697 and 698:

Questions 673 (b) 2017 Dec. 31 Inte

- Page 699 and 700:

Brief Exercises 675 BE15-8 Presente

- Page 701 and 702:

Exercises 677 (a) The issuance of t

- Page 703 and 704:

Exercises 679 E15-14 Presented belo

- Page 705 and 706:

Problems: Set A 681 (c) Show how th

- Page 707 and 708:

Comprehensive Problem: Chapters 13

- Page 709 and 710:

Broadening Your Perspective 685 Ins

- Page 711 and 712:

A Look at IFRS 687 Similarities •

- Page 713 and 714:

A Look at IFRS 689 International Fi

- Page 715 and 716:

Robert Voets/CBS via Getty Images C

- Page 717 and 718:

Accounting for Debt Investments 693

- Page 719 and 720:

Accounting for Stock Investments 69

- Page 721 and 722:

Accounting for Stock Investments 69

- Page 723 and 724:

Accounting for Stock Investments 69

- Page 725 and 726:

Reporting Investments in Financial

- Page 727 and 728:

Reporting Investments in Financial

- Page 729 and 730:

Reporting Investments in Financial

- Page 731 and 732:

Review and Practice 707 REVIEW AND

- Page 733 and 734:

Practice Exercises 709 (c) loss in

- Page 735 and 736:

Practice Problem 711 Solution 3. De

- Page 737 and 738:

DO IT! Exercises 713 BE16-3 Noler C

- Page 739 and 740:

Exercises 715 E16-5 Nosker Inc. had

- Page 741 and 742:

Problems: Set A 717 P16-2A In Janua

- Page 743 and 744:

Comprehensive Problem: Chapters 12

- Page 745 and 746:

Broadening Your Perspective 721 Ken

- Page 747 and 748:

Ethics Case BYP16-7 Harding Financi

- Page 749 and 750:

A Look at IFRS 725 2. Under IFRS, t

- Page 751 and 752:

Justin Sullivan/Getty Images, Inc.

- Page 753 and 754:

Usefulness and Format of the Statem

- Page 755 and 756:

Preparing the Statement of Cash Flo

- Page 757 and 758:

Preparing the Statement of Cash Flo

- Page 759 and 760:

Preparing the Statement of Cash Flo

- Page 761 and 762:

Preparing the Statement of Cash Flo

- Page 763 and 764:

Preparing the Statement of Cash Flo

- Page 765 and 766:

Preparing the Statement of Cash Flo

- Page 767 and 768:

Appendix 17A: Statement of Cash Flo

- Page 769 and 770:

Appendix 17A: Statement of Cash Flo

- Page 771 and 772:

Appendix 17A: Statement of Cash Flo

- Page 773 and 774:

Appendix 17A: Statement of Cash Flo

- Page 775 and 776:

Step 3: Net Change in Cash Appendix

- Page 777 and 778:

Appendix 17B: Worksheet for Prepari

- Page 779 and 780:

Appendix 17C: Statement of Cash Flo

- Page 781 and 782:

Appendix 17C: Statement of Cash Flo

- Page 783 and 784:

Practice Multiple-Choice Questions

- Page 785 and 786:

Practice Exercises 761 7. (b) Issua

- Page 787 and 788:

Practice Problems 763 Depreciation

- Page 789 and 790:

Questions 765 Instructions Prepare

- Page 791 and 792:

Brief Exercises 767 BE17-4 Telfer,

- Page 793 and 794:

Exercises 769 EXERCISES E17-1 Tabar

- Page 795 and 796:

Exercises 771 Accounts payable $ 12

- Page 797 and 798:

Problems: Set A 773 Sales Sales rev

- Page 799 and 800:

Problems: Set A 775 Instructions Pr

- Page 801 and 802:

Problems: Set A 777 CHENG INC. Inco

- Page 803 and 804:

Broadening Your Perspective 779 CON

- Page 805 and 806:

Broadening Your Perspective 781 (a)

- Page 807 and 808:

A Look at IFRS 783 from that projec

- Page 809 and 810:

CHAPTER OUTLINE Learning Objectives

- Page 811 and 812:

Horizontal and Vertical Analysis 78

- Page 813 and 814:

Horizontal and Vertical Analysis 78

- Page 815 and 816:

Horizontal and Vertical Analysis 79

- Page 817 and 818:

Ratio Analysis 793 Liquidity Ratios

- Page 819 and 820:

Ratio Analysis 795 Cash, short-term

- Page 821 and 822:

Ratio Analysis 797 5. PROFIT MARGIN

- Page 823 and 824:

Ratio Analysis 799 Note that Qualit

- Page 825 and 826:

Ratio Analysis 801 losses without i

- Page 827 and 828:

Ratio Analysis 803 DO IT! 2 Ratio A

- Page 829 and 830:

Sustainable Income 805 CRUZ COMPANY

- Page 831 and 832:

Sustainable Income 807 Companies al

- Page 833 and 834:

Review and Practice 809 REVIEW AND

- Page 835 and 836:

Practice Exercises 811 Solutions 1.

- Page 837 and 838:

Practice Problem 813 (e) Profit mar

- Page 839 and 840:

Brief Exercises 815 BRIEF EXERCISES

- Page 841 and 842:

DO IT! Exercises 817 BE18-14 An ine

- Page 843 and 844:

Exercises 819 GURLEY CORPORATION Co

- Page 845 and 846:

Exercises 821 Instructions Compute

- Page 847 and 848:

Problems 823 EXERCISES: SET B AND C

- Page 849 and 850:

Problems 825 LANDWEHR CORPORATION I

- Page 851 and 852:

Problems 827 Target Wal-Mart Corpor

- Page 853 and 854:

Problems: Set B 829 Liabilities and

- Page 855 and 856:

Broadening Your Perspective 831 ann

- Page 857 and 858:

A Look at IFRS 833 The latter part

- Page 859 and 860:

© iNoppadal/Shutterstock CHAPTER O

- Page 861 and 862:

Managerial Accounting Overview 837

- Page 863 and 864:

Managerial Accounting Overview 839

- Page 865 and 866:

Managerial Cost Concepts 841 DIRECT

- Page 867 and 868:

Managerial Cost Concepts 843 5. Adv

- Page 869 and 870:

Manufacturer Financial Statements 8

- Page 871 and 872:

Manufacturer Financial Statements 8

- Page 873 and 874:

Managerial Accounting Trends 849 th

- Page 875 and 876:

Managerial Accounting Trends 851 fa

- Page 877 and 878:

Managerial Accounting Trends 853 gu

- Page 879 and 880:

Practice Multiple-Choice Questions

- Page 881 and 882:

Practice Exercises 857 9. (c) Both

- Page 883 and 884:

Practice Problem 859 Solution (a) S

- Page 885 and 886:

Brief Exercises 861 BE19-2 Listed b

- Page 887 and 888:

Exercises 863 DO IT! 19-4 Match the

- Page 889 and 890:

Exercises 865 The administrators wa

- Page 891 and 892:

Exercises 867 Instructions (a) Prep

- Page 893 and 894:

Problems: Set A 869 Instructions (a

- Page 895 and 896:

Continuing Problems 871 Instruction

- Page 897 and 898:

Broadening Your Perspective 873 The

- Page 899 and 900:

Broadening Your Perspective 875 1.

- Page 901 and 902:

© Pictorial Press Ltd/Alamy CHAPTE

- Page 903 and 904:

Cost Accounting Systems 879 associa

- Page 905 and 906:

Cost Accounting Systems 881 At this

- Page 907 and 908:

Assigning Manufacturing Costs 883 I

- Page 909 and 910:

Assigning Manufacturing Costs 885 s

- Page 911 and 912:

Predetermined Overhead Rate 887 and

- Page 913 and 914:

Predetermined Overhead Rate 889 Thi

- Page 915 and 916:

Jobs Completed and Sold 891 When a

- Page 917 and 918:

Jobs Completed and Sold 893 Job Ord

- Page 919 and 920:

Applied Manufacturing Overhead 895

- Page 921 and 922:

Review and Practice 897 After Walla

- Page 923 and 924: Practice Multiple-Choice Questions

- Page 925 and 926: Practice Problem 901 (b) Jan. 31 Wo

- Page 927 and 928: Brief Exercises 903 Brief Exercises

- Page 929 and 930: Exercises 905 EXERCISES E20-1 The g

- Page 931 and 932: Exercises 907 3. Factory labor cost

- Page 933 and 934: Problems: Set A 909 EXERCISES: SET

- Page 935 and 936: Problems: Set A 911 (b) Post the en

- Page 937 and 938: Broadening Your Perspective 913 BRO

- Page 939 and 940: Broadening Your Perspective 915 Ali

- Page 941 and 942: Elaine Thompson/AP Photo CHAPTER OU

- Page 943 and 944: Overview of Process Cost System 919

- Page 945 and 946: Process Cost Flow 921 LEARNING OBJE

- Page 947 and 948: Process Cost Flow 923 TRANSFER TO N

- Page 949 and 950: Equivalent Units 925 This method of

- Page 951 and 952: Production Cost Report 927 LEARNING

- Page 953 and 954: Production Cost Report 929 Equivale

- Page 955 and 956: Production Cost Report 931 1 2 3 4

- Page 957 and 958: Just-in-Time Processing and Activit

- Page 959 and 960: Just-in-Time Processing and Activit

- Page 961 and 962: Appendix 21A: Applying Activity-Bas

- Page 963 and 964: Appendix 21A: Applying Activity-Bas

- Page 965 and 966: Practice Multiple-Choice Questions

- Page 967 and 968: Practice Exercises 943 4. (b) The d

- Page 969 and 970: Practice Problem 945 PRACTICE PROBL

- Page 971 and 972: Brief Exercises 947 and (b) the Fin

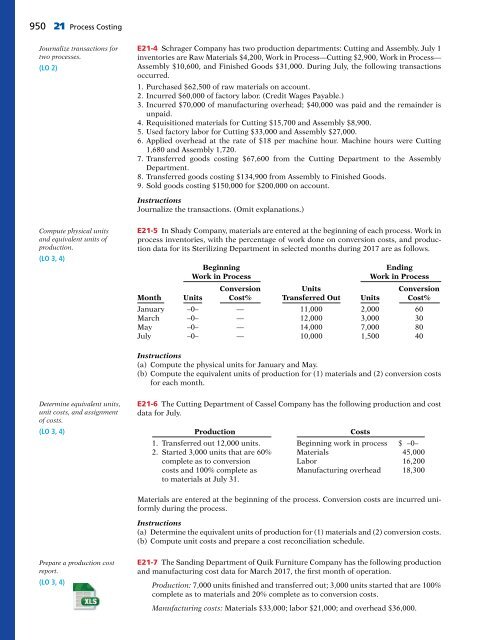

- Page 973: Exercises 949 EXERCISES E21-1 Rober

- Page 977 and 978: Exercises 953 1. Applications in pr

- Page 979 and 980: Problems: Set A 955 Cutting Departm

- Page 981 and 982: Continuing Problems 957 *P21-7A Sch

- Page 983 and 984: Broadening Your Perspective 959 Ins

- Page 985 and 986: CHAPTER OUTLINE Eric Gerrard/iStock

- Page 987 and 988: Cost Behavior Analysis 963 shows, t

- Page 989 and 990: Cost Behavior Analysis 965 (a) Tota

- Page 991 and 992: Mixed Costs Analysis 967 collect da

- Page 993 and 994: Mixed Costs Analysis 969 Importance

- Page 995 and 996: CVP Analysis 971 VARGO VIDEO COMPAN

- Page 997 and 998: CVP Analysis 973 We can also see th

- Page 999 and 1000: Break-Even Analysis 975 Contributio

- Page 1001 and 1002: Target Net Income and Margin of Saf

- Page 1003 and 1004: Target Net Income and Margin of Saf

- Page 1005 and 1006: CVP Analysis and the Business Envir

- Page 1007 and 1008: Appendix 22A: Absorption Costing vs

- Page 1009 and 1010: Appendix 22A: Absorption Costing vs

- Page 1011 and 1012: Review and Practice 987 REVIEW AND

- Page 1013 and 1014: Practice Exercises 989 2. (c) The r

- Page 1015 and 1016: Questions 991 (c) Margin of safety

- Page 1017 and 1018: DO IT! Exercises 993 BE22-6 Rice Co

- Page 1019 and 1020: Exercises 995 Instructions (a) Defi

- Page 1021 and 1022: Exercises 997 E22-11 Naylor Company

- Page 1023 and 1024: Problems: Set A 999 Total Variable

- Page 1025 and 1026:

BROADENING YOUR MANAGEMENT DECISION

- Page 1027 and 1028:

Broadening Your Perspective 1003 In

- Page 1029 and 1030:

CHAPTER OUTLINE Deidre Schoo/The Ne

- Page 1031 and 1032:

Effective Budgeting and the Master

- Page 1033 and 1034:

Effective Budgeting and the Master

- Page 1035 and 1036:

Sales, Production, and Direct Mater

- Page 1037 and 1038:

Sales, Production, and Direct Mater

- Page 1039 and 1040:

Sales, Production, and Direct Mater

- Page 1041 and 1042:

Direct Labor, Manufacturing Overhea

- Page 1043 and 1044:

Direct Labor, Manufacturing Overhea

- Page 1045 and 1046:

Cash Budget and Budgeted Balance Sh

- Page 1047 and 1048:

Cash Budget and Budgeted Balance Sh

- Page 1049 and 1050:

Budgeting in Nonmanufacturing Compa

- Page 1051 and 1052:

Budgeting in Nonmanufacturing Compa

- Page 1053 and 1054:

Practice Multiple-Choice Questions

- Page 1055 and 1056:

Practice Exercises 1031 10. (a) The

- Page 1057 and 1058:

Practice Problems 1033 PRACTICE PRO

- Page 1059 and 1060:

Questions 1035 (c) BARRETT COMPANY

- Page 1061 and 1062:

DO IT! Exercises 1037 BE23-5 For Gu

- Page 1063 and 1064:

Exercises 1039 Department Quarter 1

- Page 1065 and 1066:

Exercises 1041 Variable overhead co

- Page 1067 and 1068:

Problems: Set A 1043 Beginning cash

- Page 1069 and 1070:

Problems: Set A 1045 P23-4A Colter

- Page 1071 and 1072:

Comprehensive Case 1047 PROBLEMS: S

- Page 1073 and 1074:

Broadening Your Perspective 1049 Th

- Page 1075 and 1076:

All About You BYP23-6 In order to g

- Page 1077 and 1078:

Eviled/Shutterstock CHAPTER OUTLINE

- Page 1079 and 1080:

Budgetary Control and Static Budget

- Page 1081 and 1082:

Flexible Budget Reports 1057 Soluti

- Page 1083 and 1084:

Flexible Budget Reports 1059 When y

- Page 1085 and 1086:

Flexible Budget Reports 1061 The fo

- Page 1087 and 1088:

Flexible Budget Reports 1063 1 2 3

- Page 1089 and 1090:

Responsibility Accounting and Respo

- Page 1091 and 1092:

Responsibility Accounting and Respo

- Page 1093 and 1094:

Responsibility Accounting and Respo

- Page 1095 and 1096:

Responsibility Accounting and Respo

- Page 1097 and 1098:

Evaluating Investment Centers 1073

- Page 1099 and 1100:

Evaluating Investment Centers 1075

- Page 1101 and 1102:

Review and Practice 1077 Solution (

- Page 1103 and 1104:

Practice Multiple-Choice Questions

- Page 1105 and 1106:

Practice Problem 1081 (b) (1) Contr

- Page 1107 and 1108:

DO IT! Exercises 1083 BE24-4 Gundy

- Page 1109 and 1110:

Exercises 1085 Instructions (a) Pre

- Page 1111 and 1112:

Exercises 1087 As a result of this

- Page 1113 and 1114:

Exercises 1089 Instructions (a) Com

- Page 1115 and 1116:

Problems: Set A 1091 PROBLEMS: SET

- Page 1117 and 1118:

Problems: Set A 1093 P24-5A Optimus

- Page 1119 and 1120:

WATERWAYS (Note: This is a continua

- Page 1121 and 1122:

Real-World Focus BYP24-3 Computer A

- Page 1123 and 1124:

Broadening Your Perspective 1099 Be

- Page 1125 and 1126:

CHAPTER OUTLINE Learning Objectives

- Page 1127 and 1128:

Standard Costs 1103 a way to place

- Page 1129 and 1130:

Standard Costs 1105 Quantity Item (

- Page 1131 and 1132:

Direct Materials Variances 1107 DO

- Page 1133 and 1134:

Direct Materials Variances 1109 to

- Page 1135 and 1136:

Direct Labor and Manufacturing Over

- Page 1137 and 1138:

Direct Labor and Manufacturing Over

- Page 1139 and 1140:

Variance Reports and Balanced Score

- Page 1141 and 1142:

Variance Reports and Balanced Score

- Page 1143 and 1144:

Variance Reports and Balanced Score

- Page 1145 and 1146:

Appendix 25A: Standard Cost Account

- Page 1147 and 1148:

Appendix 25B: Overhead Controllable

- Page 1149 and 1150:

Review and Practice 1125 REVIEW AND

- Page 1151 and 1152:

Practice Multiple-Choice Questions

- Page 1153 and 1154:

Practice Problem 1129 Labor price v

- Page 1155 and 1156:

Brief Exercises 1131 15. What are t

- Page 1157 and 1158:

Exercises 1133 Hank estimates that

- Page 1159 and 1160:

Exercises 1135 Analysis reveals tha

- Page 1161 and 1162:

Exercises 1137 3. Contribution marg

- Page 1163 and 1164:

Problems: Set A 1139 The predetermi

- Page 1165 and 1166:

Continuing Problems 1141 5. Incurre

- Page 1167 and 1168:

Broadening Your Perspective 1143 ea

- Page 1169 and 1170:

Ethics Case BYP25-7 At Symond Compa

- Page 1171 and 1172:

Gabriela Hasbun/Redux CHAPTER OUTLI

- Page 1173 and 1174:

Decision-Making and Incremental Ana

- Page 1175 and 1176:

Decisions Involving Incremental Ana

- Page 1177 and 1178:

Decisions Involving Incremental Ana

- Page 1179 and 1180:

Decisions Involving Incremental Ana

- Page 1181 and 1182:

Decisions Involving Incremental Ana

- Page 1183 and 1184:

Annual Rate of Return and Cash Payb

- Page 1185 and 1186:

Annual Rate of Return and Cash Payb

- Page 1187 and 1188:

Annual Rate of Return and Cash Payb

- Page 1189 and 1190:

Net Present Value and Internal Rate

- Page 1191 and 1192:

Net Present Value and Internal Rate

- Page 1193 and 1194:

Review and Practice 1169 REVIEW AND

- Page 1195 and 1196:

Practice Exercises 1171 Solutions 1

- Page 1197 and 1198:

Practice Problems 1173 3. MCA Corpo

- Page 1199 and 1200:

Brief Exercises 1175 Brief Exercise

- Page 1201 and 1202:

DO IT! Exercises 1177 Revenues Main

- Page 1203 and 1204:

Exercises 1179 A supplier offers to

- Page 1205 and 1206:

Problems: Set A 1181 Annual income

- Page 1207 and 1208:

Problems: Set A 1183 Division I II

- Page 1209 and 1210:

Continuing Problems 1185 (f) What t

- Page 1211 and 1212:

BROADENING YOUR MANAGEMENT DECISION

- Page 1213:

Broadening Your Perspective 1189 CR

- Page 1216 and 1217:

A-2 Appendix A Specimen Financial S

- Page 1218 and 1219:

A-4 Appendix A Specimen Financial S

- Page 1221 and 1222:

Appendix B Specimen Financial State

- Page 1223 and 1224:

Appendix B Specimen Financial State

- Page 1225:

Appendix B Specimen Financial State

- Page 1228 and 1229:

C-2 Appendix C Specimen Financial S

- Page 1230 and 1231:

C-4 Appendix C Specimen Financial S

- Page 1232 and 1233:

D-2 Appendix D Specimen Financial S

- Page 1234 and 1235:

D-4 Appendix D Specimen Financial S

- Page 1237 and 1238:

Appendix E Specimen Financial State

- Page 1239 and 1240:

Consolidated Statements of Sharehol

- Page 1241 and 1242:

Appendix F Specimen Financial State

- Page 1243 and 1244:

Appendix F Specimen Financial State

- Page 1245 and 1246:

Appendix F Specimen Financial State

- Page 1247 and 1248:

Appendix G Time Value of Money APPE

- Page 1249 and 1250:

Interest and Future Values G-3 unpa

- Page 1251 and 1252:

Interest and Future Values G-5 seri

- Page 1253 and 1254:

Present Values G-7 LEARNING OBJECTI

- Page 1255 and 1256:

Present Values G-9 The following tw

- Page 1257 and 1258:

Present Values G-11 Table 4 shows t

- Page 1259 and 1260:

Present Values G-13 Illustration G-

- Page 1261 and 1262:

Using Financial Calculators G-15 Pr

- Page 1263 and 1264:

Using Financial Calculators G-17 CO

- Page 1265 and 1266:

Brief Exercises G-19 4 inflows and

- Page 1267 and 1268:

Brief Exercises G-21 BEG-14 Assume

- Page 1269 and 1270:

Appendix H Standards of Ethical Con

- Page 1271 and 1272:

Company Index A Ace Hardware, 285 A

- Page 1273:

Company Index I-3 Sharp, 1166 Shell

- Page 1276 and 1277:

I-6 Subject Index Available-for-sal

- Page 1278 and 1279:

I-8 Subject Index Cost flow assumpt

- Page 1280 and 1281:

I-10 Subject Index Financial statem

- Page 1282 and 1283:

I-12 Subject Index Inventory(-ies)

- Page 1284 and 1285:

I-14 Subject Index Net income, 21 c

- Page 1286 and 1287:

I-16 Subject Index Recordkeeping, s

- Page 1288 and 1289:

I-18 Subject Index Unearned revenue

- Page 1290 and 1291:

RAPID REVIEW Chapter Content RECEIV

- Page 1292 and 1293:

RAPID REVIEW Chapter Content BUDGET

- Page 1294 and 1295:

RAPID REVIEW Using the Information