a.aa MMC M11 52pp Web

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

External Building Envelope<br />

EFFICIENCY BOOST FOR LOCAL BUILDERS<br />

Spantherm is an innovative ground floor system from Creagh Concrete which is being adopted by a growing number of local<br />

house builders.<br />

The regulations have been designed to make<br />

house builders consider more than just the<br />

physical performance of the structural envelope,<br />

they are now obliged to consider each individual<br />

component’s impact on the buildings overall<br />

energy efficiency and particularly the removal of<br />

thermal bridging.<br />

All of these factors are combined within<br />

Standard Assessment Procedure (SAP)<br />

calculations and this adds a further dimension<br />

for builders to consider as they seek the most<br />

cost effective specification for each house type.<br />

Creagh Spantherm in situ<br />

As housebuilders increasingly explore the<br />

opportunities for new ideas to reduce<br />

labour onsite and boost efficiency in the<br />

build it makes sense that they start with the<br />

ground floor. The initial appeal of Spantherm is<br />

clear, because a typical floor on a detached<br />

house or a pair of semis is fitted onsite in less<br />

than two hours.<br />

Most builders opt for the work to be completed<br />

by Creagh’s expert fitting team, requiring no<br />

labour from the house builder; however the floor<br />

can also be ordered on a supply only basis for<br />

installation by the builder’s own team. Once in<br />

place and grouted, the floor achieves its full<br />

structural capability with 72 hours but building<br />

activity can commence on perimeter walls within<br />

24 hours.<br />

Practicality<br />

The speed of construction saves around a week<br />

off the total schedule when compared to the<br />

typical poured concrete floor alternative. A<br />

further advantage is that the factory made<br />

Spantherm floor come to site as single units<br />

combining the precast concrete and insulation<br />

material, so there is no requirement to stock or<br />

handle loose insulation. This feature also means<br />

that the installation of Spantherm is not weather<br />

dependant and creates zero waste onsite.<br />

Each Spantherm floor is manufactured to the<br />

house plans provided, taking account of the<br />

required loadings and the positioning of services<br />

which penetrate the slab. Creagh’s technical<br />

team however, are on hand to measure the<br />

builder’s sub-floor works prior to manufacture, so<br />

any site issues are eliminated.<br />

The Creagh flooring team work closely with each<br />

site manager to ensure the floors are available to<br />

call off when required and this level of<br />

cooperation greatly simplifies the process for<br />

the builder.<br />

Performance<br />

Everyone can understand the advantages of<br />

faster completion however Spantherm brings a<br />

second major benefit in the form of its excellent<br />

thermal performance and the impact that brings<br />

within the most recent building regulations.<br />

Getting off to a good start with an energy<br />

efficient floor system is essential to a strong<br />

fabric first solution.<br />

Designing and building energy efficient homes<br />

to meet current regulations can be a complex<br />

process but installing a high performance<br />

insulated ground floor is always a good start.<br />

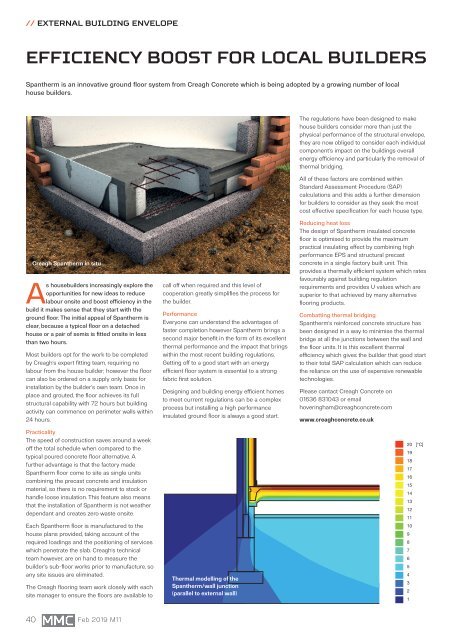

Thermal modelling of the<br />

Spantherm/wall junction<br />

(parallel to external wall)<br />

Reducing heat loss<br />

The design of Spantherm insulated concrete<br />

floor is optimised to provide the maximum<br />

practical insulating effect by combining high<br />

performance EPS and structural precast<br />

concrete in a single factory built unit. This<br />

provides a thermally efficient system which rates<br />

favourably against building regulation<br />

requirements and provides U values which are<br />

superior to that achieved by many alternative<br />

flooring products.<br />

Combatting thermal bridging<br />

Spantherm’s reinforced concrete structure has<br />

been designed in a way to minimise the thermal<br />

bridge at all the junctions between the wall and<br />

the floor units. It is this excellent thermal<br />

efficiency which gives the builder that good start<br />

to their total SAP calculation which can reduce<br />

the reliance on the use of expensive renewable<br />

technologies.<br />

Please cantact Creagh Concrete on<br />

01636 831043 or email<br />

hoveringham@creaghconcrete.com<br />

www.creaghconcrete.co.uk<br />

20 [°C]<br />

19<br />

18<br />

17<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

40 Feb 2019 <strong>M11</strong>