DCN AUGUST Edition 2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

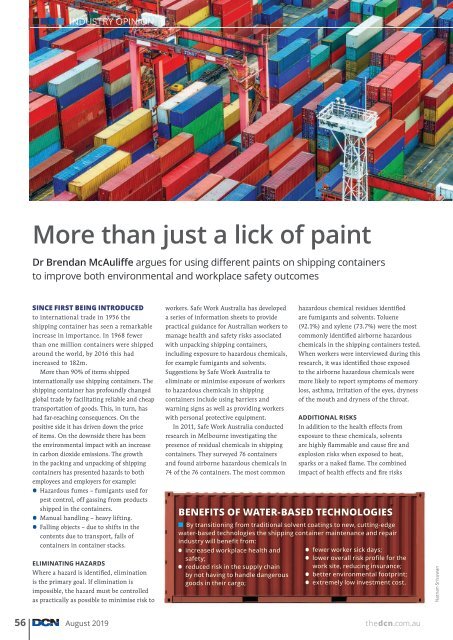

INDUSTRY OPINION<br />

More than just a lick of paint<br />

Dr Brendan McAuliffe argues for using different paints on shipping containers<br />

to improve both environmental and workplace safety outcomes<br />

SINCE FIRST BEING INTRODUCED<br />

to international trade in 1956 the<br />

shipping container has seen a remarkable<br />

increase in importance. In 1968 fewer<br />

than one million containers were shipped<br />

around the world, by 2016 this had<br />

increased to 182m.<br />

More than 90% of items shipped<br />

internationally use shipping containers. The<br />

shipping container has profoundly changed<br />

global trade by facilitating reliable and cheap<br />

transportation of goods. This, in turn, has<br />

had far-reaching consequences. On the<br />

positive side it has driven down the price<br />

of items. On the downside there has been<br />

the environmental impact with an increase<br />

in carbon dioxide emissions. The growth<br />

in the packing and unpacking of shipping<br />

containers has presented hazards to both<br />

employees and employers for example:<br />

• Hazardous fumes – fumigants used for<br />

pest control, off gassing from products<br />

shipped in the containers.<br />

Manual handling – heavy lifting.<br />

• Falling objects – due to shifts in the<br />

contents due to transport, falls of<br />

containers in container stacks.<br />

ELIMINATING HAZARDS<br />

Where a hazard is identified, elimination<br />

is the primary goal. If elimination is<br />

impossible, the hazard must be controlled<br />

as practically as possible to minimise risk to<br />

workers. Safe Work Australia has developed<br />

a series of information sheets to provide<br />

practical guidance for Australian workers to<br />

manage health and safety risks associated<br />

with unpacking shipping containers,<br />

including exposure to hazardous chemicals,<br />

for example fumigants and solvents.<br />

Suggestions by Safe Work Australia to<br />

eliminate or minimise exposure of workers<br />

to hazardous chemicals in shipping<br />

containers include using barriers and<br />

warning signs as well as providing workers<br />

with personal protective equipment.<br />

In 2011, Safe Work Australia conducted<br />

research in Melbourne investigating the<br />

presence of residual chemicals in shipping<br />

containers. They surveyed 76 containers<br />

and found airborne hazardous chemicals in<br />

74 of the 76 containers. The most common<br />

hazardous chemical residues identified<br />

are fumigants and solvents. Toluene<br />

(92.1%) and xylene (73.7%) were the most<br />

commonly identified airborne hazardous<br />

chemicals in the shipping containers tested.<br />

When workers were interviewed during this<br />

research, it was identified those exposed<br />

to the airborne hazardous chemicals were<br />

more likely to report symptoms of memory<br />

loss, asthma, irritation of the eyes, dryness<br />

of the mouth and dryness of the throat.<br />

ADDITIONAL RISKS<br />

In addition to the health effects from<br />

exposure to these chemicals, solvents<br />

are highly flammable and cause fire and<br />

explosion risks when exposed to heat,<br />

sparks or a naked flame. The combined<br />

impact of health effects and fire risks<br />

BENEFITS OF WATER-BASED TECHNOLOGIES<br />

By transitioning from traditional solvent coatings to new, cutting-edge<br />

water-based technologies the shipping container maintenance and repair<br />

industry will benefit from:<br />

• increased workplace health and<br />

fewer worker sick days;<br />

safety;<br />

• lower overall risk profile for the<br />

• reduced risk in the supply chain<br />

work site, reducing insurance;<br />

by not having to handle dangerous<br />

better environmental footprint;<br />

goods in their cargo; • extremely low investment cost.<br />

Natnan Srisuwan<br />

56 August <strong>2019</strong><br />

thedcn.com.au