TST brochure / english language

All TST cable line systems / mountain harvester / cable yarder for tractor plus carriages and information of the harvester head TST 60H Timbernator.

All TST cable line systems / mountain harvester / cable yarder for tractor plus carriages and information of the harvester head TST 60H Timbernator.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TST

JUNIOR

INNOVATIONS

PREIS 2016

INNOVATIVE AND RELIABLE FORESTRY TECHNOLOGY

MADE IN AUSTRIA

TST 400

THE VERSATILE TST 400 CAN

COPE WITH ALL DEMANDS

The automated two or three cable all-rounder TST 400 is ideal for

forest thinning. The customizable configuration caters for every

situation – available as 2 ton, 2.5 ton or 3 ton version. Attached on

trailer for tractor, on trailer with stationary engine, on truck and

of course in combination with crane and processor head on truck

(Mountain Harvester). Skyline length up to 600 m.

WIRE ROBES 2 T 2,5 T 3T

Skyline 550 m Ø 16 mm 550 m Ø 17 mm 600 m Ø 77 mm

Mainline 1100 m Ø 8 mm 1100 m Ø 10 mm 1200 m Ø 10 mm

Haul back line 1100 m Ø 7 mm 1100 m Ø 7 mm 1200 m Ø 7 mm

Guy line 55 m Ø 16 mm 55 m Ø 16 mm 65 m Ø 16 mm

Line speed max. 10 m/sek. max. 10 m/sek. max. 10 m/sek.

Tower hight 9.5 m 9.5 m 12 m

ADVANTAGES OF TST TOWER YARDERS

ADVANTAGES OF TST TOWER YARDERS

• Minimum maintenance and high performance

• Wireless remote control and automatic target

control increase productivity with less personnel

• Rigid construction and ease of operation

• Large diameter cable drums ensure constant

speed and tension

• Drums are hydrostatically driven

• Overload protected brakes

• Work area: 300° because of the rotatable

tower head.

• Minimum wear of cables because of big drums

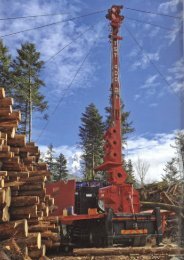

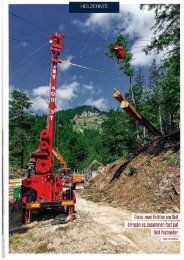

Photos clockwise, starting

from top left

TST 400 3t on truck

TST 400 3t Mountain

Harvester

TST tower yarder on

tracked vehicle

In combination with

harvester (company Haas)

TST 400 on trailer with

stationary engine.

TST 400

TST JUNIOR

ON TRUCK FOR JAPAN

2 ODER 3 TONNEN ZUGKRAFT

INNOVATIONS

PREIS 2016

COMPACT - AGILE - SMALL

FOOTPRINT

Skyline length: 500m oder 450m

Forest contractors and forest owners are

impressed: easy operation and unbeatable

value for money.

• This machine is compact and offers a spacesaving

installation.

• For uphill and downhill or uphill only

applications.

• With or without automatic target control.

• Special version: with drawbar and axis.

• For tractors from 100 hp up

• Total weight incl. cables: from 4100 kg

• Up and downhill or uphill only

WIRE ROBES 2T 3T

Skyline 500 m Ø 15 mm 450 m Ø 16 mm

Mainline 1000 m Ø 8 mm 800 m Ø 10 mm

Haul back line 900 m Ø 6 mm 800 m Ø 6 mm

Guy line 50 m Ø 16 mm 50 m Ø 16 mm

Line speed max. 4,5 m/sek. max. 3,5 m/sek.

Tower hight 9.5 m 9.5 m

THIS SUPER-LIGHTWEIGHT TOWER YARDER

IS ALWAYS IN SEASON!

TST 600 | 3,5T TST 800

THE UNIVERSAL TOWER YARDER

FOR LIGHT TO HEAVY TREES

FOR LARGE DIAMETER TIMBER,

4 OR 5 TONS

THE LIGHT VERSION OF A LARGE DIAMETER

TIMBER TOWER YARDER

Installed on a truck, trailer with stationary motor, or in combination with a

harvester head on a crane (

) – the TST 600 is a versatile

all-terrain cable yarder for any diameter timber. Skyline length: 650 m

TECHNICAL DATA TST 600 | 3,5 T

Skyline: 2.100 ft Ø 3/4´

650 m Ø 18,5 mm

Mainline: 4.600 ft Ø 7/16´

1.400 m Ø 11 mm

Haul back line: 4.600 ft Ø 3/8´

1.400 m Ø 9 mm

Guyline: 4 x 213 ft Ø 3/4´

4 x 65 m Ø 18 mm

THE FLEXIBLE TOWER YARDER FOR THINNING OR CLEARANCE

In combination with a harvester head on a crane, the TST 800 is the top of the range model from TST. Its rigid

construction makes it suitable for any task. Downhill yarding up to 1000m! On truck, trailer or in combination with

crane and harvester head on truck – Mountain Harvester.

TECHNICAL DATA TST 800 | 5 T

Skyline: 2.300 ft Ø 7/8´

700 m Ø 22 mm

Mainline: 4.600 ft Ø 1/2´

1.400 m Ø 13 mm

Haul back line: 4.600 ft Ø 3/8´

1.400 m Ø 9 mm

Guyline: 4 x 262 ft Ø 3/4´

4 x 80 m Ø 20 mm

Drum drive:

Hydrostatically

Drum drive:

Hydrostatically

Carriage:

TST 3500 / I

Carriage:

TST 4500 / I

Prozessing unit:

Prozessing unit:

Tower height:

40 ft/12 m

Hydraulic adjusting

Tower height:

40 ft/12 m

Hydraulic adjusting

TST 80W CABLE WINCH

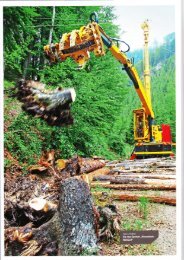

THE HARVESTER HEAD FROM TST

WITH THE UNIQUE FEEDING SYSTEM

TECHNICAL DATA TST 80W CABLE WINCH

Pulling force max.

Drum inner side/outer side

Line speed gear #1

Drum inner side/outer side

Line speed gear #1

Drum inner side/outer side

80 kN/40,4 kN

ca. 0,9 m/sek. |

1,8 m/sek.

ca. 1,8 m/sek. |

3,6 m/sek.

Operating pressure 280 bar (max. 320)

Necessary oil quantity

150 l/min

Wire ropes max. 300 m ø 12

Rope max. 250 m ø 13

Weight without wire rope

1124 lbs

ROBUST, LIGHTWEIGHT AND SIMPLE TO USE

Extension arm and quick-hitch on mobile

excavator with TST 60H Timbernator

TECHNICAL DATA TST 60 H TIMBERNATOR

Maximum diameter for felling:

27.5 inch

Timbernator convinces through its rigid construction,

large tilt angle and immense feeding force.

The grapple opens to a maximum of 50 inches and

can cope with any challenge. The long chain belt

ensures a high feed rate with low contact pressure

and friction – resulting in great delimbing performance

of small – to large diameter timber.

Maximum feeding force:

Feed Speed

Max. grapple opening:

Delimbing knives

Recommended drive power

P max.:

Oil volume:

Weight:

60 kN

0 – 4 m / sec.

51 inch

2 - 25 inch

110 kW |150 PS

5100 psi

from 220 l/min

approx.

2870 lbs

The arrangement of the grapples simplifies the

work on hard and twisted timber, the large tilt angle

facilitates work on steep slopes.

Thanks to a sophisticated hydraulic system, Timbernator

can be controlled by most well-known

harvester control systems. But Timbernator is also

an independent harvester head which can process

timber with a diameter of 2 - 25 inch.

The maximum diameter for felling is 27.5 inch.

CARRIAGES

FIVE MODELLS, PATENTED

Carriage

LW 4500/I

• Overload protected brakes

• radio activated brakes for main lines and

skylines

• Large rollers

• With any other cable line system compatible

The skidding line is wound solely by the main

-and haul back line, no additional motor is

required.

All TST carriages feature radio activated brakes

for main lines and skylines which are activated

in an alternating fashion. This ensures

that the carriage can be moved whilst pulling

the logs and it enables them to be mounted in

arbitrary height, too. Ideal for economical work

with harvesters on entire trees, especially for

depositing those, with minimal damage to the

stock.

The sophisticated hydraulic system ensures

reliable operation with low maintenance and

allows for many switching operations to be

carried out without transferring the carriage.

INNOVATIONSPREIS

The company received the innovation award In 2018 TST Junior plus carriage TST 2500/I

for their modular set up yarder TST Junior at received the official seal called “KWF-Profi”

the international wood fair in Klagenfurt 2016. by the German Board of Trustees for Forestry

As a result of a longstanding and consistent Work and Technology (KWF).

implementation of innovation and research

strategy the Federal Ministry of agriculture and

forestry presented this award.

3-LINE / UPHILL + DOWNHILL

2-LINE / UPHILL

LW TST 2500/I LW TST 3500/I LW TST 5000/I LW TST 2500

(3500) uphill

Mainline: max. Ø 11 mm max. Ø 12 mm max. Ø 11 - 14 mm max. Ø 12 mm

(14 mm)

Skidding line: max. Ø 11 mm max. Ø 12 mm max. Ø 11 - 14 mm

Haul back line: max. Ø 11 mm max. Ø 8,5 mm 160 m @ Ø 9 mm

Skidding line

storage:

max. 85 m

@ Ø 11 mm

max. 85 m

@ Ø 11 mm

120 m

@ Ø 11 mm

Skyline diameter: Ø 14 - 22 mm Ø 16 - 22 mm Ø 18 - 24 mm Ø 12 - 18 mm

(18 - 24 mm)

Load capacity: 2,5 t 3,5 t 5 t 2,5 t (3,5 t)

Weight:

approx. 330 kg

w/o wire ropes

approx. 380 kg

w/o wire ropes

approx. 700 kg

w/o wire ropes

ca. 210 kg

Typical application: ALL TERRAIN ALL TERRAIN ALL TERRAIN UPHILL IN 2-LINE

OPERATION

„During the test run

the tower yarder is set

up to function at optimum

performance and our

customer and/or their staff

receive extensive training.

They will be able to carry

out maintenance work

independently during

future operations.“

Johann Tröstl, MD

POSSIBLE OPERATING TECHNIQUES

TS = Skyline

ZS = Main line

RS = Haul back line

LS = Traction line

HORIZONTAL & UPHILL

DOWNHILL

DOWNHILL

THROUGH SELF-WEIGHT

1986 First ever radio-controlled 3-line carriage for downhill yarding

has been developed by Johann Tröstl sen.

1995 Johann Tröstl sen. receives innovation award for tower yarder

Syncrofalke.

2015 TST equipment in UK, France, Switzerland successfully in

operation.

2016 TST Seilgeräte Tröstl GmbH got voted forest supplier of the year.

2016 Innovation award for cable line System TST Junior given by the

Federal Ministry of agriculture and forestry.

2017 First TST tower yarder in Japan.

2018 TST Junior receives official seal „KWF Profi“

2019 TST Junior is nominated for Austrofoma’s Innovation Award

TST Seilgeräte Tröstl GmbH

Hammerstraße 9

3184 Türnitz

Austria

Phone: (+43) 664 | 47 67 604

Fax: (+43) 02769 | 8664 - 26

info@tst-forestry.com

www.tst-forestry.com