You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

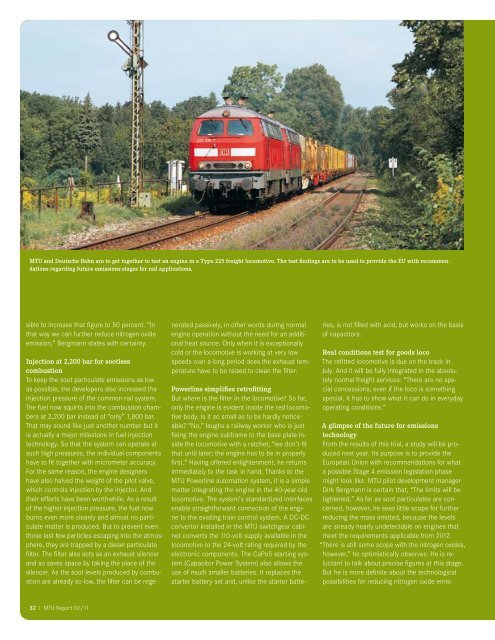

<strong>MTU</strong> and Deutsche Bahn are to get together to test an engine in a Type 225 freight locomotive. The test findings are to be used to provide the EU with recommen-<br />

dations regarding future emissions stages for rail applications.<br />

sible to increase that figure to 50 percent. “In<br />

that way we can further reduce nitrogen oxide<br />

emission,” Bergmann states with certainty.<br />

Injection at 2,200 bar for sootless<br />

combustion<br />

To keep the soot particulate emissions as low<br />

as possible, the developers also increased the<br />

injection pressure <strong>of</strong> the common-rail system.<br />

The fuel now squirts into the combustion chambers<br />

at 2,200 bar instead <strong>of</strong> “only” 1,800 bar.<br />

That may sound like just another number but it<br />

is actually a major milestone in fuel injection<br />

technology. So that the system can operate at<br />

such high pressures, the individual components<br />

have to fit together with micrometer accuracy.<br />

For the same reason, the engine designers<br />

have also halved the weight <strong>of</strong> the pilot valve,<br />

which controls injection by the injector. And<br />

their efforts have been worthwhile. As a result<br />

<strong>of</strong> the higher injection pressure, the fuel now<br />

burns even more cleanly and almost no particulate<br />

matter is produced. But to prevent even<br />

those last few particles escaping into the atmos-<br />

phere, they are trapped by a diesel particulate<br />

filter. The filter also acts as an exhaust silencer<br />

and so saves space by taking the place <strong>of</strong> the<br />

silencer. As the soot levels produced by combustion<br />

are already so low, the filter can be rege-<br />

32 I <strong>MTU</strong> Report 02/11<br />

nerated passively, in other words during normal<br />

engine operation without the need for an additional<br />

heat source. Only when it is exceptionally<br />

cold or the locomotive is working at very low<br />

speeds over a long period does the exhaust temperature<br />

have to be raised to clean the filter.<br />

Powerline simplifies retr<strong>of</strong>itting<br />

But where is the filter in the locomotive? So far,<br />

only the engine is evident inside the red locomotive<br />

body. Is it so small as to be hardly noticeable?<br />

“No,” laughs a railway worker who is just<br />

fixing the engine subframe to the base plate inside<br />

the locomotive with a ratchet, “we don’t fit<br />

that until later; the engine has to be in properly<br />

first.” Having <strong>of</strong>fered enlightenment, he returns<br />

immediately to the task in hand. Thanks to the<br />

<strong>MTU</strong> Powerline automation system, it is a simple<br />

matter integrating the engine in the 40-year-old<br />

locomotive. The system’s standardized interfaces<br />

enable straightforward connection <strong>of</strong> the engine<br />

to the existing train control system. A DC-DC<br />

convertor installed in the <strong>MTU</strong> switchgear cabinet<br />

converts the 110-volt supply available in the<br />

locomotive to the 24-volt rating required by the<br />

electronic components. The CaPoS starting system<br />

(Capacitor Power System) also allows the<br />

use <strong>of</strong> much smaller batteries. It replaces the<br />

starter battery set and, unlike the starter batte-<br />

ries, is not filled with acid, but works on the basis<br />

<strong>of</strong> capacitors.<br />

Real conditions test for goods loco<br />

The refitted locomotive is due on the track in<br />

July. And it will be fully integrated in the absolutely<br />

normal freight services: “There are no special<br />

concessions, even if the loco is something<br />

special. It has to show what it can do in everyday<br />

operating conditions.“<br />

A glimpse <strong>of</strong> the future for emissions<br />

technology<br />

From the results <strong>of</strong> this trial, a study will be produced<br />

next year. Its purpose is to provide the<br />

European Union with recommendations for what<br />

a possible Stage 4 emission legislation phase<br />

might look like. <strong>MTU</strong> pilot development manager<br />

Dirk Bergmann is certain that, “The limits will be<br />

tightened.” As far as soot particulates are concerned,<br />

however, he sees little scope for further<br />

reducing the mass emitted, because the levels<br />

are already nearly undetectable on engines that<br />

meet the requirements applicable from 2012.<br />

“There is still some scope with the nitrogen oxides,<br />

however,” he optimistically observes. He is reluctant<br />

to talk about precise figures at this stage.<br />

But he is more definite about the technological<br />

possibilities for reducing nitrogen oxide emis-