2020_ADN_V5_No3_web

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fiber Logic<br />

Everything you need to know about<br />

fiber-based buffing pads<br />

By Clint Hintz<br />

chintz@buffandshine.com<br />

Clint Hintz, IDA CD-SV-RT - Certified<br />

Trainer, is the North American Sales<br />

Manager of Buff and Shine Mfg. of Rancho<br />

Dominguez, California.<br />

Buff and Shine acknowledges that<br />

our industry is everchanging with tools<br />

and polishing systems, which obviously<br />

keeps a need for constant evolution with<br />

buffing pads. In last year’s summer edition<br />

of Auto Detailing News, foam pad<br />

technology was showcased, so this article<br />

will be covering the makeup and differences<br />

in fiber-based buffing pads. One<br />

objective is to educate our audience on<br />

the actual makeup and differences in<br />

these pads. Another objective is for the<br />

audience to be better versed in which<br />

types of fibers will work best with their<br />

current or future processes. We believe<br />

that this information will be helpful for<br />

people in not only knowing the differences,<br />

but how these different options may<br />

help increase productivity and improve<br />

performance.<br />

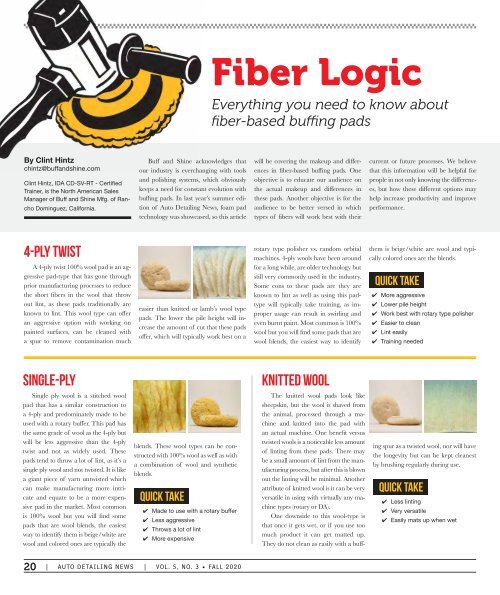

4-PLY TWIST<br />

A 4-ply twist 100% wool pad is an aggressive<br />

pad-type that has gone through<br />

prior manufacturing processes to reduce<br />

the short fibers in the wool that throw<br />

out lint, as these pads traditionally are<br />

known to lint. This wool type can offer<br />

an aggressive option with working on<br />

painted surfaces, can be cleaned with<br />

a spur to remove contamination much<br />

easier than knitted or lamb’s wool type<br />

pads. The lower the pile height will increase<br />

the amount of cut that these pads<br />

offer, which will typically work best on a<br />

rotary type polisher vs. random orbital<br />

machines. 4-ply wools have been around<br />

for a long while, are older technology but<br />

still very commonly used in the industry.<br />

Some cons to these pads are they are<br />

known to lint as well as using this padtype<br />

will typically take training, as improper<br />

usage can result in swirling and<br />

even burnt paint. Most common is 100%<br />

wool but you will find some pads that are<br />

wool blends, the easiest way to identify<br />

them is beige/white are wool and typically<br />

colored ones are the blends.<br />

Quick Take<br />

✔ More aggressive<br />

✔ Lower pile height<br />

✔ Work best with rotary type polisher<br />

✔ Easier to clean<br />

✔ Lint easily<br />

✔ Training needed<br />

SINGLE-PLY<br />

KNITTED WOOL<br />

Single ply wool is a stitched wool<br />

pad that has a similar construction to<br />

a 4-ply and predominately made to be<br />

used with a rotary buffer. This pad has<br />

the same grade of wool as the 4-ply but<br />

will be less aggressive than the 4-ply<br />

twist and not as widely used. These<br />

pads tend to throw a lot of lint, as it’s a<br />

single ply wool and not twisted. It is like<br />

a giant piece of yarn untwisted which<br />

can make manufacturing more intricate<br />

and equate to be a more expensive<br />

pad in the market. Most common<br />

is 100% wool but you will find some<br />

pads that are wool blends, the easiest<br />

way to identify them is beige/white are<br />

wool and colored ones are typically the<br />

blends. These wool types can be constructed<br />

with 100% wool as well as with<br />

a combination of wool and synthetic<br />

blends.<br />

Quick Take<br />

✔ Made to use with a rotary buffer<br />

✔ Less aggressive<br />

✔ Throws a lot of lint<br />

✔ More expensive<br />

The knitted wool pads look like<br />

sheepskin, but the wool is shaved from<br />

the animal, processed through a machine<br />

and knitted into the pad with<br />

an actual machine. One benefit versus<br />

twisted wools is a noticeable less amount<br />

of linting from these pads. There may<br />

be a small amount of lint from the manufacturing<br />

process, but after this is blown<br />

out the linting will be minimal. Another<br />

attribute of knitted wool is it can be very<br />

versatile in using with virtually any machine<br />

types (rotary or DA).<br />

One downside to this wool-type is<br />

that once it gets wet, or if you use too<br />

much product it can get matted up.<br />

They do not clean as easily with a buffing<br />

spur as a twisted wool, nor will have<br />

the longevity but can be kept cleanest<br />

by brushing regularly during use.<br />

Quick Take<br />

✔ Less linting<br />

✔ Very versatile<br />

✔ Easily mats up when wet<br />

20 | AUTO DETAILING NEWS | VOL. 5, NO. 3 • FALL <strong>2020</strong>