Maintworld Magazine 4/2020

- maintenance & asset management

- maintenance & asset management

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INDUSTRIAL INTERNET<br />

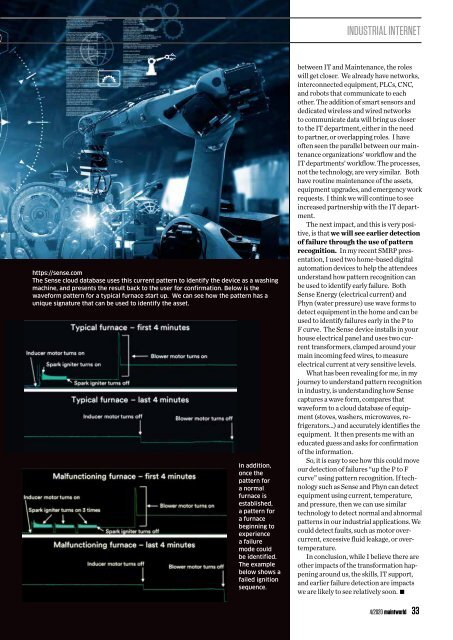

https://sense.com<br />

The Sense cloud database uses this current pattern to identify the device as a washing<br />

machine, and presents the result back to the user for confirmation. Below is the<br />

waveform pattern for a typical furnace start up. We can see how the pattern has a<br />

unique signature that can be used to identify the asset.<br />

In addition,<br />

once the<br />

pattern for<br />

a normal<br />

furnace is<br />

established,<br />

a pattern for<br />

a furnace<br />

beginning to<br />

experience<br />

a failure<br />

mode could<br />

be identified.<br />

The example<br />

below shows a<br />

failed ignition<br />

sequence.<br />

between IT and Maintenance, the roles<br />

will get closer. We already have networks,<br />

interconnected equipment, PLCs, CNC,<br />

and robots that communicate to each<br />

other. The addition of smart sensors and<br />

dedicated wireless and wired networks<br />

to communicate data will bring us closer<br />

to the IT department, either in the need<br />

to partner, or overlapping roles. I have<br />

often seen the parallel between our maintenance<br />

organizations’ workflow and the<br />

IT departments’ workflow. The processes,<br />

not the technology, are very similar. Both<br />

have routine maintenance of the assets,<br />

equipment upgrades, and emergency work<br />

requests. I think we will continue to see<br />

increased partnership with the IT department.<br />

The next impact, and this is very positive,<br />

is that we will see earlier detection<br />

of failure through the use of pattern<br />

recognition. In my recent SMRP presentation,<br />

I used two home-based digital<br />

automation devices to help the attendees<br />

understand how pattern recognition can<br />

be used to identify early failure. Both<br />

Sense Energy (electrical current) and<br />

Phyn (water pressure) use wave forms to<br />

detect equipment in the home and can be<br />

used to identify failures early in the P to<br />

F curve. The Sense device installs in your<br />

house electrical panel and uses two current<br />

transformers, clamped around your<br />

main incoming feed wires, to measure<br />

electrical current at very sensitive levels.<br />

What has been revealing for me, in my<br />

journey to understand pattern recognition<br />

in industry, is understanding how Sense<br />

captures a wave form, compares that<br />

waveform to a cloud database of equipment<br />

(stoves, washers, microwaves, refrigerators…)<br />

and accurately identifies the<br />

equipment. It then presents me with an<br />

educated guess and asks for confirmation<br />

of the information.<br />

So, it is easy to see how this could move<br />

our detection of failures “up the P to F<br />

curve” using pattern recognition. If technology<br />

such as Sense and Phyn can detect<br />

equipment using current, temperature,<br />

and pressure, then we can use similar<br />

technology to detect normal and abnormal<br />

patterns in our industrial applications. We<br />

could detect faults, such as motor overcurrent,<br />

excessive fluid leakage, or overtemperature.<br />

In conclusion, while I believe there are<br />

other impacts of the transformation happening<br />

around us, the skills, IT support,<br />

and earlier failure detection are impacts<br />

we are likely to see relatively soon.<br />

4/<strong>2020</strong> maintworld 33