Panels & Furniture Asia September/October 2020

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

28 | PRODUCT HIGHLIGHT<br />

<strong>September</strong> / <strong>October</strong> <strong>2020</strong>, Issue 5 | <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong><br />

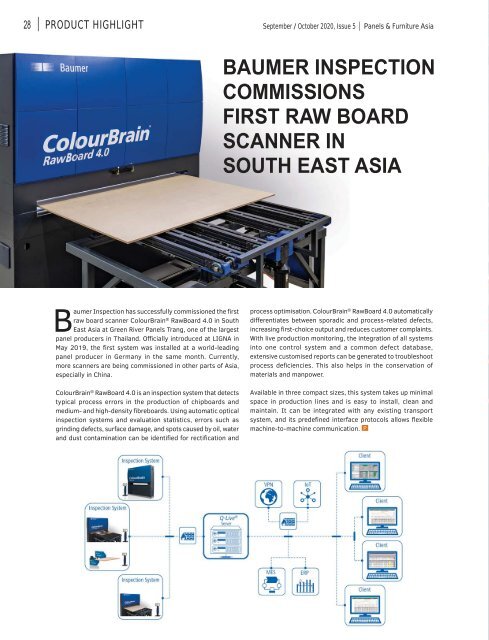

BAUMER INSPECTION<br />

COMMISSIONS<br />

FIRST RAW BOARD<br />

SCANNER IN<br />

SOUTH EAST ASIA<br />

Baumer Inspection has successfully commissioned the first<br />

raw board scanner ColourBrain ® RawBoard 4.0 in South<br />

East <strong>Asia</strong> at Green River <strong>Panels</strong> Trang, one of the largest<br />

panel producers in Thailand. Officially introduced at LIGNA in<br />

May 2019, the first system was installed at a world-leading<br />

panel producer in Germany in the same month. Currently,<br />

more scanners are being commissioned in other parts of <strong>Asia</strong>,<br />

especially in China.<br />

ColourBrain ® RawBoard 4.0 is an inspection system that detects<br />

typical process errors in the production of chipboards and<br />

medium- and high-density fibreboards. Using automatic optical<br />

inspection systems and evaluation statistics, errors such as<br />

grinding defects, surface damage, and spots caused by oil, water<br />

and dust contamination can be identified for rectification and<br />

process optimisation. ColourBrain ® RawBoard 4.0 automatically<br />

differentiates between sporadic and process-related defects,<br />

increasing first-choice output and reduces customer complaints.<br />

With live production monitoring, the integration of all systems<br />

into one control system and a common defect database,<br />

extensive customised reports can be generated to troubleshoot<br />

process deficiencies. This also helps in the conservation of<br />

materials and manpower.<br />

Available in three compact sizes, this system takes up minimal<br />

space in production lines and is easy to install, clean and<br />

maintain. It can be integrated with any existing transport<br />

system, and its predefined interface protocols allows flexible<br />

machine-to-machine communication. P