Panels & Furniture Asia September/October 2020

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>September</strong> / <strong>October</strong> <strong>2020</strong>, Issue 5 | <strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> WOOD CLINIC | 63<br />

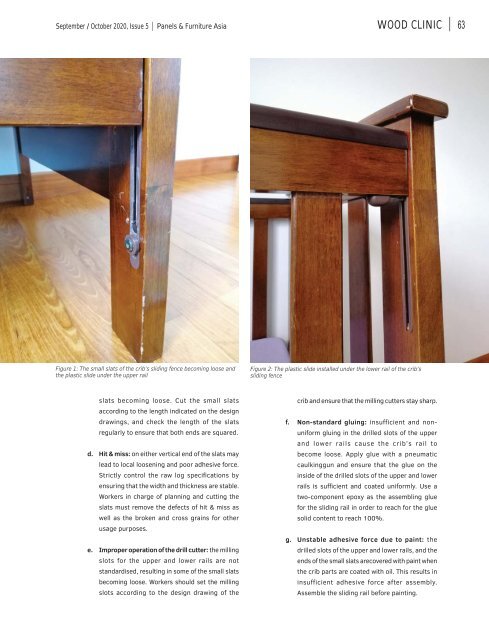

Figure 1: The small slats of the crib’s sliding fence becoming loose and<br />

the plastic slide under the upper rail<br />

Figure 2: The plastic slide installed under the lower rail of the crib’s<br />

sliding fence<br />

slats becoming loose. Cut the small slats<br />

according to the length indicated on the design<br />

drawings, and check the length of the slats<br />

regularly to ensure that both ends are squared.<br />

d. Hit & miss: on either vertical end of the slats may<br />

lead to local loosening and poor adhesive force.<br />

Strictly control the raw log specifications by<br />

ensuring that the width and thickness are stable.<br />

Workers in charge of planning and cutting the<br />

slats must remove the defects of hit & miss as<br />

well as the broken and cross grains for other<br />

usage purposes.<br />

e. Improper operation of the drill cutter: the milling<br />

slots for the upper and lower rails are not<br />

standardised, resulting in some of the small slats<br />

becoming loose. Workers should set the milling<br />

slots according to the design drawing of the<br />

crib and ensure that the milling cutters stay sharp.<br />

f. Non-standard gluing: insufficient and nonuniform<br />

gluing in the drilled slots of the upper<br />

and lower rails cause the crib’s rail to<br />

become loose. Apply glue with a pneumatic<br />

caulkinggun and ensure that the glue on the<br />

inside of the drilled slots of the upper and lower<br />

rails is sufficient and coated uniformly. Use a<br />

two-component epoxy as the assembling glue<br />

for the sliding rail in order to reach for the glue<br />

solid content to reach 100%.<br />

g. Unstable adhesive force due to paint: the<br />

drilled slots of the upper and lower rails, and the<br />

ends of the small slats arecovered with paint when<br />

the crib parts are coated with oil. This results in<br />

insufficient adhesive force after assembly.<br />

Assemble the sliding rail before painting.