MultilamTechnology The Multilam Principle - Multi-Contact

MultilamTechnology The Multilam Principle - Multi-Contact

MultilamTechnology The Multilam Principle - Multi-Contact

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Advanced <strong>Contact</strong> Technology<br />

Kontaktlamellen<br />

<strong><strong>Multi</strong>lam</strong> <strong>Contact</strong>s<br />

<strong>Contact</strong> à lamelles<br />

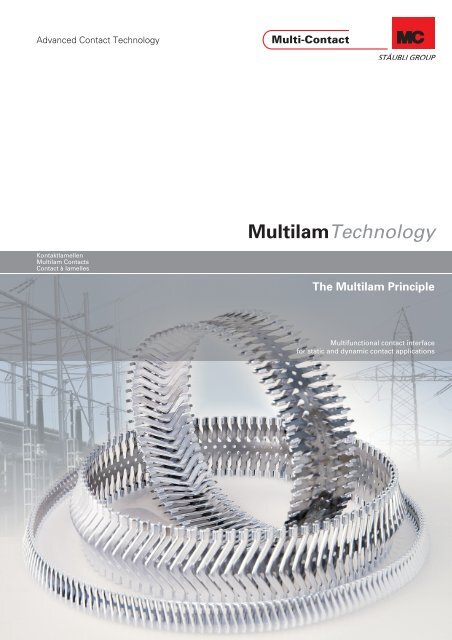

<strong><strong><strong>Multi</strong>lam</strong>Technology</strong><br />

<strong>The</strong> <strong><strong>Multi</strong>lam</strong> <strong>Principle</strong><br />

<strong>Multi</strong>functional contact interface<br />

for static and dynamic contact applications

Advanced <strong>Contact</strong> Technology<br />

Better contacts<br />

<strong>The</strong> MC <strong><strong>Multi</strong>lam</strong> brought substantial improvements in relation<br />

to conventional contact systems.<br />

Advantages<br />

<strong>The</strong> <strong><strong>Multi</strong>lam</strong> soon developed into a whole system of contact<br />

elements. Its users recognised its outstanding advantages and<br />

within a short time a wide range of new application possibilities<br />

had evolved.<br />

Basis for solutions<br />

This brochure is intended to show the principle and application<br />

of the <strong><strong>Multi</strong>lam</strong> and serves as an aid for designers and engineers<br />

in the development of high-quality and reliable contact<br />

systems.<br />

Further developments<br />

<strong>Multi</strong>-<strong>Contact</strong> uses the <strong><strong>Multi</strong>lam</strong> in all connectors in its product<br />

range, and is constantly developing new components – also in<br />

collaboration with customers.<br />

Experience<br />

<strong>Multi</strong> <strong>Contact</strong> offers total solutions because the installation and<br />

correct selection of the <strong><strong>Multi</strong>lam</strong>s require experience and<br />

know-how accumulated over many years.<br />

<strong>The</strong>re is always a solution<br />

With this extensive know-how <strong>Multi</strong>-<strong>Contact</strong> will be pleased to<br />

support you in your search for the best solution.<br />

RoHSready<br />

Directive 2002/95/EC on the restriction of the use of certain<br />

hazardous substances in electrical and electronic equipment<br />

2 www.multi-contact.com<br />

An ingenious idea<br />

<strong>The</strong> success story of <strong>Multi</strong> <strong>Contact</strong> is<br />

based on the development of specially<br />

formed hard copper strips for electrical<br />

contact, the so-called MC <strong><strong>Multi</strong>lam</strong>s.

Advanced <strong>Contact</strong> Technology<br />

<strong>Contact</strong> part A<br />

<strong><strong>Multi</strong>lam</strong> louver<br />

<strong>Contact</strong> part B <strong>The</strong> <strong><strong>Multi</strong>lam</strong> principle 4<br />

<strong>Contact</strong> part A<br />

Steel strip<br />

<strong>Contact</strong> part B<br />

Cu-louver<br />

List of terms<br />

with<br />

explanations<br />

Contents<br />

<strong>The</strong> various types of <strong><strong>Multi</strong>lam</strong>s 5<br />

Special forms of <strong><strong>Multi</strong>lam</strong> 6<br />

General contact technology 7 – 11<br />

Application range of the <strong><strong>Multi</strong>lam</strong>s, temperatures,<br />

plugging cycles, current-carrying capacity and<br />

calculation of current-carrying capacity 12 – 13<br />

Technical data and typical applications of <strong><strong>Multi</strong>lam</strong>s 14 – 19<br />

Special design features 20 – 21<br />

Glossary 22<br />

www.multi-contact.com 3

Advanced <strong>Contact</strong> Technology<br />

<strong>The</strong> louver contacts are produced from strips, and allow electrical<br />

contact to be made via a large number of defined, current<br />

carrying contact points.<br />

<strong>Contact</strong> part A<br />

<strong><strong>Multi</strong>lam</strong> louver<br />

<strong>Contact</strong> part B<br />

<strong>Contact</strong> arrangement with torsion spring-type <strong><strong>Multi</strong>lam</strong><br />

<strong>The</strong> <strong><strong>Multi</strong>lam</strong> <strong>Principle</strong><br />

R �R �2(R �R<br />

)<br />

k � e f<br />

Rk1 Rk2 Rk3 Rkn<br />

4 www.multi-contact.com<br />

Each louver forms an independent, spring loaded current<br />

bridge, so that the many parallel louvers substantially reduce<br />

the overall contact resistance.<br />

I<br />

<strong>Contact</strong> part B<br />

Re1 Rf1<br />

Rl Rf2 Re2<br />

<strong>The</strong> contact resistance Rk of a <strong><strong>Multi</strong>lam</strong> louver can be found by the following<br />

formula:<br />

Re 1 /Re 2 = constriction resistance<br />

R � = internal resistance of louver<br />

Rf 1 /Rf 2 = film resistance<br />

I = nominal current<br />

<strong>The</strong> contact resistance Rg of the <strong><strong>Multi</strong>lam</strong> is determined<br />

as follows: (Parallel connection of louvers)<br />

Rg<br />

1 1 1 1 1<br />

� � � �<br />

R R R R R<br />

R<br />

Rf1<br />

g k 1 k 2 k 3 kn<br />

g<br />

Rk<br />

�<br />

n<br />

Rl<br />

Re1<br />

n = number of louvers<br />

Re2<br />

Rf2<br />

<strong>Contact</strong> part A<br />

I

Advanced <strong>Contact</strong> Technology<br />

LA0 LA0-G LAIA<br />

LAIB<br />

LA-CU<br />

LAII<br />

LA-CUT/0,25/0<br />

LAI-GSR<br />

LA-CUT/0,25<br />

LAIII LAIV LAV LAVII Twisted<br />

Characteristic features of the <strong><strong>Multi</strong>lam</strong>s<br />

high resistance to heat<br />

high electrical and thermal conductivity<br />

sufficiently high contact forces<br />

high number of contact cycles<br />

large operating range (LA-CUT)<br />

<strong>The</strong> various types of <strong><strong>Multi</strong>lam</strong>s<br />

MC <strong><strong>Multi</strong>lam</strong>s based on the torsion spring principle<br />

MC <strong><strong>Multi</strong>lam</strong>s based on the leaf spring principle<br />

excellent resistance to corrosion<br />

easy to process (form- and electroplate) small space requirement<br />

low cost contact elements<br />

resistance to vibration<br />

long product life<br />

www.multi-contact.com 5

Advanced <strong>Contact</strong> Technology<br />

Special forms of <strong><strong>Multi</strong>lam</strong>s for special requirements<br />

LA-CUT<br />

LA-CU<br />

Functional division between spring element (steel strip) and<br />

electrical conducting element (Cu louver)<br />

Features<br />

very good electrical and thermal conductivity<br />

excellent spring characteristics<br />

low but adequate contact force keeps wear rates to an absolute<br />

minimum<br />

Functional division between spring element (steel strip) and<br />

electrical conducting element (Cu louver)<br />

Features<br />

excellent electrical conductivity<br />

high continuous current-carrying capacity<br />

high short-circuit current-carrying capacity<br />

large radial tolerance absorption<br />

6 www.multi-contact.com<br />

<strong>Contact</strong> part A<br />

Steel strip<br />

<strong>Contact</strong> part B<br />

security against excessive elongation<br />

compact width, saves space<br />

Cu-louver<br />

resistant to high tempartures (up to 180°C)<br />

Angular misalignment absorption<br />

Angular absorption +/-2° dependent on the installation mode,<br />

diameter and plug-in depth<br />

large operating range<br />

angular misalignment absorption<br />

easy to machine recess<br />

easy to install

Advanced <strong>Contact</strong> Technology<br />

<strong>The</strong> contact force<br />

General <strong>Contact</strong> Technology<br />

Connector Definitions<br />

Plug connectors are electrical connectors that must not be connected or disconnected<br />

when in use for their intended purpose (under load).<br />

Connectors: – are designed to be disconnected without load only<br />

Plug and socket devices: – are designed to be connected and disconnected under load<br />

Constant contact force<br />

over its working life<br />

Constant contact resistance<br />

over its working life<br />

Good heat dissipation<br />

during continuous operation<br />

<strong>The</strong> hardness of the contact material<br />

<strong>The</strong> service temperature<br />

Adequate contact force<br />

to break through the oxide film<br />

<strong>Contact</strong> requirements<br />

Parameters influencing the constriction resistance:<br />

the higher the contact force, the lower the constriction resistance<br />

the harder the material, the higher the constriction resistance<br />

With increasing temperature, the constriction resistance increases and then gradually<br />

breaks down when softening and melting temperatures are reached.<br />

<strong>The</strong> higher the constriction resistance increases,<br />

the higher the risk of contact welding!<br />

Low contact resistance<br />

Good thermal-shock resistance<br />

in event of short-circuit<br />

Low constriction resistance Re<br />

i.e. many and large a-spots<br />

www.multi-contact.com 7

Advanced <strong>Contact</strong> Technology<br />

Flat contact surfaces<br />

With flat contact surfaces there is no real danger of a welding effect, because the constriction resistance is spread out over many<br />

contact points. Flat contact surfaces are very susceptible to the formation of pollution films.<br />

When contact parts close, contact areas with different electrical characteristics are formed<br />

<strong>Contact</strong> parts with pollution film <strong>Contact</strong> parts closed<br />

Cu-rail under the microscope<br />

apparent contact area<br />

8 www.multi-contact.com<br />

film barrier within the supporting contact area<br />

quasi-metallic contacts<br />

effective contact area (a-spots)

Advanced <strong>Contact</strong> Technology<br />

Flat contact<br />

Current paths evenly distributed, but oxide film may not be<br />

completely broken through<br />

�<br />

R e �<br />

2�a�n<br />

Formation of contact transitions<br />

2a<br />

� = specific resistance of the contact material<br />

Re = constriction resistance<br />

n = sum of the a-spots<br />

a = radius of the effective contact areas (a-spots)<br />

Point contact<br />

Current paths restricted, oxide film is broken through but there<br />

is a high risk of welding<br />

�<br />

R e �<br />

2�a�<br />

n<br />

Assessment of contact quality<br />

<strong>The</strong> quality of a connector can be assessed by measuring the voltage drop at the rated current (DC) over the point of contact. <strong>The</strong><br />

values in the following table are based on practical experience:<br />

Class Voltage drop at rated current (DC) Assessment<br />

1 < 5mV very good<br />

2 5mV – 12mV good<br />

3 13mV – 25mV sufficient, usable<br />

4 26mV – 50mV critical unsure<br />

5 51mV – 100mV unusable<br />

6 > 100mV failed<br />

www.multi-contact.com 9<br />

2a

Advanced <strong>Contact</strong> Technology<br />

Material Electrical<br />

conductivity<br />

m<br />

2<br />

� xmm<br />

CuZn<br />

Brass<br />

CuSn6<br />

Spring bronze<br />

CuBe2<br />

Beryllium-copper<br />

CuNi18Zn20<br />

Nickel silver<br />

CuNi9Sn2<br />

Wieland L49 Ca72<br />

NiBe<br />

Nickel-Beryllium<br />

Comparison between electrical, mechanical and thermal characteristics<br />

of copper alloys and spring contact materials<br />

<strong>The</strong>rmal<br />

conductivity<br />

W<br />

m �K<br />

Vickers<br />

hardness<br />

10 www.multi-contact.com<br />

HV<br />

bending stress<br />

limit<br />

N<br />

mm 2<br />

Max. working<br />

temperature<br />

15,5 121 150 – 180 > 290 85<br />

9,5 75 160 – 220 370 125<br />

12 113<br />

max. 450<br />

hardened<br />

max. 1050<br />

hardened<br />

3,3 33 170 – 200 > 390 125<br />

6,4 48 160 – 190 > 440 125<br />

4 38<br />

440 – 510<br />

hardened<br />

max. 1600<br />

hardened<br />

°C<br />

180<br />

350<br />

Application<br />

Spring contact<br />

Plug connectors<br />

Soldering tabs<br />

Parts for switches<br />

Substrate material<br />

For relay contacts<br />

for higher<br />

temperatures<br />

Cu 57 380 – 390 60 – 120 250 – Cu-data for<br />

comparison purposes<br />

Material Thickness in µm Advantages Disadvantages<br />

Au 0,15 – 2,5<br />

Ag 5 – 10<br />

Sn 1 – 10<br />

Comparison between plating materials Au, Ag and Sn for connectors<br />

<strong>Contact</strong> requirements low contact force<br />

– good chemical stability<br />

– low contact force allowed<br />

high thermal conductivity<br />

high electrical conductivity<br />

abrasion resistant<br />

– very good electrical / thermal conductivity<br />

– DRY-CIRCUIT applications, low current and<br />

low voltage<br />

– good soldering characteristics<br />

– excellent electrical conductivity<br />

– excellent thermal conductivity<br />

– easy to form when cold<br />

– for medium and high currents<br />

– low abrasion<br />

– low cost<br />

– easy to plate<br />

– easy to tin at low temperatures<br />

– good soldering characteristics<br />

corrosion resistant<br />

suitable for plating<br />

low cost<br />

– high cost<br />

– relatively soft<br />

– diffusion barrier required<br />

– not free from pores with thin layers<br />

– subject to sulphide tarnishing<br />

– more expensive than Sn<br />

– minimum contact force<br />

– only for low no. of plugging cycles n < 100<br />

– higher plug-in and withdrawal force<br />

– higher contact force necessary 3,5N – 5N<br />

– higher abrasion<br />

– susceptible to oxidation

Advanced <strong>Contact</strong> Technology<br />

Insulation<br />

– insulating<br />

– high dielectric strength<br />

– form stable<br />

– rugged<br />

<strong>Contact</strong> element<br />

– heat resistant<br />

– elasticity<br />

Efficiency of contact<br />

– current capacity<br />

– voltage capacity<br />

– contact resistance<br />

Type of connection<br />

– soldering<br />

– clamping<br />

– AxiClamp<br />

– crimping<br />

– wrapping<br />

<strong>Contact</strong> area<br />

– plugging cycles<br />

– plating thickness<br />

– material<br />

– abrasion<br />

<strong>Contact</strong> failure<br />

– corrosion<br />

– oxide film<br />

– environment condition<br />

– misalignment<br />

Basic requirements for the design of connectors<br />

Vibration<br />

– vibration proof<br />

– shock proof<br />

plug-in force<br />

sliding force<br />

withdrawal force<br />

<strong>Contact</strong> characteristics<br />

– contact resistance<br />

– insulation resistance<br />

Standardization<br />

– assembly dimensions<br />

– contact spacing<br />

– specifications<br />

– number of poles<br />

<strong>Contact</strong> pressure<br />

– adequate<br />

– constant<br />

Frequency characteristics<br />

– capacitance<br />

– reflection factor<br />

– shield<br />

– surge impedance<br />

Price of contact<br />

– contact plating<br />

– insulation<br />

– termination type<br />

– contact elements<br />

<strong>Contact</strong> heat<br />

– thermal resistance<br />

– power dissipation<br />

– thermal conductivity<br />

<strong>Contact</strong> testing<br />

– electrical<br />

– dimensions<br />

– mechanical<br />

– thermal<br />

– climatic<br />

www.multi-contact.com 11

Advanced <strong>Contact</strong> Technology<br />

Fields of application of <strong><strong>Multi</strong>lam</strong>s<br />

<strong>The</strong>re is now a range of some 50 different <strong><strong>Multi</strong>lam</strong>s, each of<br />

which is designed for a specific application. <strong><strong>Multi</strong>lam</strong>s with a<br />

very thin � strip thickness of 0,8mm to 0,125mm are used<br />

where many plugging cycles are required. Connectors for few<br />

plugging cycles and permanent contacts for press-fitting are<br />

equipped with thicker <strong><strong>Multi</strong>lam</strong>s, e.g. 0,3mm to 0,5mm. For<br />

extreme load conditions such as in switchgear, which are characterised<br />

by a large number of plugging or sliding operations<br />

and high short-time currents, it is recommended to have the<br />

connector fitted with guide rings.<br />

Temperatures<br />

<strong>The</strong> <strong><strong>Multi</strong>lam</strong>s (Cu-Be alloy) are suitable for use at temperatures<br />

up to 180°C. In case of short circuits, temperatures up to<br />

250°C can be tolerated for a short time. <strong>The</strong> use of other alloys<br />

for <strong><strong>Multi</strong>lam</strong>s – e.g. NiBe – results in reduced current-carrying<br />

capacity and conductivity. High-temperature connectors for<br />

temperatures from 350°C – 400°C can be supplied with<br />

<strong><strong>Multi</strong>lam</strong>s made of NiBe alloy. <strong><strong>Multi</strong>lam</strong>s can also be used at<br />

extremely low temperatures. Experiments in liquid helium at<br />

4,2K have been successfully carried out.<br />

Plugging cycle<br />

<strong>The</strong> sliding forces of our connectors depend on several parameters<br />

such as the type of <strong><strong>Multi</strong>lam</strong>, plating, the base materials<br />

of the contact parts, the applied � lubricant etc. <strong>The</strong> data provided<br />

here can be regarded as typical values. <strong>The</strong> coefficients<br />

of friction typically vary around 0,35.<br />

In the technical data we state the � sliding force per louver for<br />

a mean friction coefficient of µr = 0,35. As a general rule the<br />

following equation applies:<br />

F �n���F s r k<br />

Standard high-current connectors are silver-plated to 5 – 10µm.<br />

<strong>The</strong>se platings are suitable for approximately 5,000 plugging<br />

cycles, provided they are coated with a thin film of lubricant<br />

before being used for the first time. For larger numbers of up<br />

to 30,000 plugging cycles, the <strong><strong>Multi</strong>lam</strong>s and the contact surface<br />

which slides over them can be plated with a thicker layer<br />

of silver and a thin film of lubricant applied before their first<br />

use. Plugging cycles up to 100,000 or more require special silver<br />

plating on both the <strong>Multi</strong>la’s and the contact surfaces.<br />

If more than 5,000 plugging cycles are required, MC recommends<br />

special � guide rings and “soft” (thin strip material)<br />

<strong><strong>Multi</strong>lam</strong>s. Since “soft” <strong><strong>Multi</strong>lam</strong>s have a reduced current-carrying<br />

capacity, it may be necessary to fit several <strong><strong>Multi</strong>lam</strong>s in<br />

parallel.<br />

12 www.multi-contact.com<br />

See<br />

Example<br />

See<br />

See<br />

See<br />

Example<br />

Strip thickness (Thickness of the <strong><strong>Multi</strong>lam</strong> strip)<br />

pages 14, 16, 18, 22<br />

2-pole high temperature contact for an ambient<br />

temperature of 350°C.<br />

Lubricant, page 22<br />

Sliding force per louver / medium spring deflection,<br />

pages 14, 16, 18, 22<br />

Fs = Sliding force of a contact<br />

n = Number of louvers<br />

µr = Friction coefficient<br />

Fk = <strong>Contact</strong> force per louver accord. to table<br />

pages 14, 16, 18<br />

<strong><strong>Multi</strong>lam</strong> contact with guide rings

Advanced <strong>Contact</strong> Technology<br />

Current-carrying capacity<br />

<strong>The</strong> current-carrying capacity of connections with <strong><strong>Multi</strong>lam</strong>s<br />

depends upon a number of factors which can essentially be assigned<br />

to two categories: contact resistance and environmental<br />

conditions. Below the categories are further subdivided and<br />

the relevant factors are named.<br />

1. Internal resistance of the <strong><strong>Multi</strong>lam</strong><br />

Material resistance depends on the length and the conductive<br />

cross-section<br />

Material of the louvers<br />

2. <strong>Contact</strong> resistance between the louver and<br />

the contact parts<br />

<strong>Contact</strong> force Fk<br />

Size of the contact points<br />

Coating of the <strong><strong>Multi</strong>lam</strong> and the contact parts<br />

Oxidation, pollution layers<br />

Surface roughness of the contact parts<br />

3. Resistance of the contact parts<br />

Material<br />

Cross section of the contact parts<br />

4. Environmental conditions<br />

Ambient temperature<br />

External temperature influences<br />

Environmental conditions<br />

<strong>The</strong> electrical values for <strong><strong>Multi</strong>lam</strong>s stated in the table on pages<br />

14 – 19 are based on optimum conditions. That means, for instance,<br />

that contact surfaces with a roughness of N6 must be<br />

provided with suitable and clean coatings, not oxidised or polluted.<br />

<strong>The</strong> ambient temperature is 20°C and the electrically<br />

conducting cross-sections of the contact parts must be<br />

adequate.<br />

Approximative calculation of the<br />

current-carrying capacity<br />

(Calculated with the values from tables on pages 14 – 19)<br />

Number of louvers n<br />

for round contacts:<br />

Number of louvers n<br />

for flat contacts:<br />

Total resistance Rg<br />

of a contact:<br />

n d ��<br />

�<br />

r<br />

<strong>The</strong> rated continuous current In and the short-circuit currents Ik<br />

(for 1s, 2s and 3s) and the rated peak withstand current are all<br />

calculated in the same manner with the appropriate values:<br />

R<br />

n �<br />

r<br />

�<br />

Iwhole <strong><strong>Multi</strong>lam</strong> �n�Iper louver<br />

g<br />

Rk<br />

�<br />

n<br />

Plug assembly<br />

Nominal diameter<br />

= socket diameter<br />

Socket assembly<br />

Nominal diameter<br />

= plug diameter<br />

Flat assembly<br />

n = Number of louvers<br />

d = Ø of contact<br />

� = 3,1415...<br />

r = <strong>Contact</strong> spacing<br />

(according to table pages 14,16,18)<br />

n = Number of louvers<br />

� = Length of flat contact<br />

r = <strong>Contact</strong> spacing<br />

(according to table pages 14,16,18)<br />

Rg = Overall resistance of contact assembly<br />

Rk = Average contact resistance per louver<br />

n = Number of louvers<br />

n = Number of louvers<br />

I = currents<br />

www.multi-contact.com 13

Advanced <strong>Contact</strong> Technology<br />

LA0/...<br />

LA0-G<br />

LAIA/...<br />

LAIB/...<br />

LAII/...<br />

1) <strong>The</strong> sliding force is normally determined on the end product<br />

2) see catalogue 1 Powerline<br />

Technical data and typical applications of MC <strong><strong>Multi</strong>lam</strong>s<br />

<strong><strong>Multi</strong>lam</strong> type Typical Sizes Applications Dimensions Mechanical data<br />

LA0/0,15<br />

LA0/0,20<br />

LA0/0,25<br />

LA0/0,30<br />

14 www.multi-contact.com<br />

Width of <strong><strong>Multi</strong>lam</strong><br />

mm b<br />

mm<br />

> Ø 25<br />

> Ø 25<br />

> Ø 25<br />

> Ø 25<br />

LA0-G/0,25 > Ø 25<br />

LAIA/0,08<br />

LAIA/0,10<br />

LAIA/0,125<br />

LAIA/0,15<br />

LAIA/0,20<br />

LAIA/0,25<br />

LAIA/0,30<br />

LAIA/0,40<br />

LAIA/0,50<br />

LAIB/0,08<br />

LAIB/0,10<br />

LAIB/0,125<br />

LAIB/0,15<br />

LAIB/0,20<br />

LAIB/0,25<br />

LAIB/0,30<br />

LAII/0,15<br />

LAII/0,20<br />

Ø 8 – Ø 20<br />

Ø 8 – Ø 20<br />

Ø 8 – Ø 20<br />

Ø 8 – Ø 20<br />

Ø 8 – Ø 20<br />

Ø 8 – Ø 20<br />

Ø 15 – Ø 20<br />

Ø 20 – Ø 70<br />

Ø 20 – Ø 70<br />

Ø 25 – Ø 70<br />

Ø 25 – Ø 70<br />

Ø 25 – Ø 70<br />

Ø 25 – Ø 70<br />

Ø 25 – Ø 70<br />

Ø 25 – Ø 70<br />

Ø 25 – Ø 70<br />

Ø 3,5 – Ø 20<br />

Ø 3,5 – Ø 20<br />

Switches,<br />

disconnectors<br />

earth connectors<br />

sliding and rotary<br />

connectors<br />

Switches,<br />

disconnectors<br />

earth connectors<br />

sliding contacts<br />

Round contacts<br />

as in B8N to<br />

B20N 2) ,<br />

Flat contacts,<br />

as in fork plugs<br />

Round contacts<br />

as in B25N to<br />

B40N 2) ,<br />

switches,<br />

disconnectors,<br />

earth connectors,<br />

sliding and rotary<br />

contacts<br />

Transformers<br />

and fork plugs<br />

26<br />

26<br />

26<br />

26<br />

Thickness of<br />

<strong><strong>Multi</strong>lam</strong> strip<br />

s<br />

mm<br />

0,15<br />

0,2<br />

0,25<br />

0,3<br />

<strong>Contact</strong> spacing<br />

r<br />

mm<br />

5<br />

5<br />

5<br />

5<br />

<strong>Contact</strong> force per<br />

louver with medium<br />

spring deflection<br />

Fk<br />

N<br />

3<br />

8,5<br />

15<br />

17<br />

Sliding force per<br />

louver with medium<br />

spring defl. µr =0,35<br />

Fs<br />

N<br />

1,05<br />

3<br />

5,25<br />

6<br />

25 0,25 2,5 9 3,15<br />

17,5<br />

17,5<br />

17,5<br />

17,5<br />

17,5<br />

17,5<br />

17,5<br />

17,5<br />

17,5<br />

17,6<br />

17,6<br />

17,6<br />

17,6<br />

17,6<br />

17,6<br />

17,6<br />

14<br />

14<br />

0,08<br />

0,1<br />

0,125<br />

0,15<br />

0,2<br />

0,25<br />

0,3<br />

0,4<br />

0,5<br />

0,08<br />

0,1<br />

0,125<br />

0,15<br />

0,2<br />

0,25<br />

0,3<br />

0,15<br />

0,2<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

1,5<br />

1,5<br />

1<br />

3<br />

4<br />

7<br />

15<br />

20<br />

32,5<br />

68<br />

105<br />

1<br />

3<br />

4<br />

7<br />

15<br />

20<br />

32,5<br />

10<br />

16<br />

0,35<br />

1,05<br />

1,4<br />

2,5<br />

5,25<br />

7<br />

11,4<br />

23,8<br />

37<br />

0,35<br />

1,05<br />

1,4<br />

2,5<br />

5,25<br />

7<br />

11,4<br />

3,5<br />

5,6

Advanced <strong>Contact</strong> Technology<br />

Rated current (A)<br />

per louver<br />

l<br />

n<br />

A<br />

<strong>Contact</strong> resistance (m�)<br />

per louver<br />

R<br />

k<br />

m�<br />

Electrical data 1)<br />

Short circuit current (kA)<br />

per louver at<br />

lk11s kA<br />

( ) lk2( 2s)<br />

lk3( 3s)<br />

kA kA<br />

Rated peak withstand current (kA)<br />

per louver<br />

0 7 14 21 28 35 42 49 56 63 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0 0 0,2 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 0 0,7 1,4 2,1 2,8 3,5 4,2 4,9 5,6 6,3<br />

1) valid for <strong><strong>Multi</strong>lam</strong>s made from hard copper, silver-plated (mating part Cu, silver-plated)<br />

www.multi-contact.com 15<br />

l<br />

p<br />

kA

Advanced <strong>Contact</strong> Technology<br />

LA-CU<br />

LA-CUT<br />

Technical data and typical applications of MC <strong><strong>Multi</strong>lam</strong>s<br />

<strong><strong>Multi</strong>lam</strong> type Typical Sizes Applications Dimensions Mechanical data <strong>The</strong>rmal data<br />

LA-CU/0,15-0,5 Ø 12 – Ø 400<br />

LA-CUT/0,25 > Ø 50<br />

LA-CUT/0,25/0 > Ø 50<br />

1) <strong>The</strong> sliding force is normally determined on the end product<br />

16 www.multi-contact.com<br />

Width of <strong><strong>Multi</strong>lam</strong><br />

mm b<br />

mm<br />

Switches<br />

disconnectors<br />

earth,<br />

connectors<br />

sliding and rotary<br />

contacts<br />

Switches<br />

disconnectors<br />

earth,<br />

connectors<br />

sliding and rotary<br />

contacts<br />

Switches<br />

disconnectors<br />

earth,<br />

connectors<br />

sliding and rotary<br />

contacts<br />

Thickness of<br />

<strong><strong>Multi</strong>lam</strong> strip<br />

s<br />

mm<br />

<strong>Contact</strong> spacing<br />

r<br />

mm<br />

<strong>Contact</strong> force per<br />

louver with medium<br />

spring deflection<br />

Fk<br />

N<br />

Sliding force per<br />

louver with medium<br />

spring defl. µr =0,35<br />

Fs<br />

N<br />

Continuous using<br />

temperature<br />

Short time<br />

temperature<br />

<strong>The</strong>rmal resistance<br />

per louver<br />

°C °C K/W<br />

12 0,15 (Cu 0,5) 3,5 7 2,5 180 250 25<br />

26 0,25 (Cu 1) 4 10 1 – 2 1) 150 250 25 – 30<br />

30 0,25 (Cu 1) 4 10 1 – 2 1) 150 250 25 – 30

Advanced <strong>Contact</strong> Technology<br />

Rated current (A)<br />

per louver<br />

l<br />

n1 l n 2<br />

A<br />

A<br />

<strong>Contact</strong> resistance (m�)<br />

per louver<br />

R<br />

k<br />

m�<br />

Electrical data 1)<br />

Short circuit current (kA)<br />

per louver at<br />

l ( s)<br />

l ( s)<br />

l ( s)<br />

k1 1<br />

kA<br />

k 2 2<br />

kA<br />

k 3 3<br />

kA<br />

Rated peak withstand current (kA)<br />

per louver<br />

0 10 20 30 40 50 60 70 80 90 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0 0 0,2 0,4 0,6 0,8 1,0 1,2 1,4 1,6 0 0,6 1,2 1,8 2,4 3,0 3,6 4,2 4,8 5,4<br />

1) Valid for MC <strong><strong>Multi</strong>lam</strong> <strong>Contact</strong>s, silver-plated (mating part Cu, silver-plated)<br />

www.multi-contact.com 17<br />

l<br />

p<br />

kA

Advanced <strong>Contact</strong> Technology<br />

LAIII<br />

LAIV<br />

LAV<br />

LAVII<br />

Technical data and typical applications of MC <strong><strong>Multi</strong>lam</strong>s<br />

<strong><strong>Multi</strong>lam</strong> type Typical Sizes Applications Dimensions Mechanical data<br />

LAIII/0,125<br />

LASIII/0,15<br />

LAIII/0,20<br />

LAIII/0,30<br />

LAIV/0,10<br />

LAIV/0,125<br />

LAIV/0,15<br />

LAV/0,10<br />

LAV/0,125<br />

LAV/0,15<br />

18 www.multi-contact.com<br />

Width of <strong><strong>Multi</strong>lam</strong><br />

mm b<br />

mm<br />

Ø 2 – Ø 20<br />

Ø 2 – Ø 20<br />

Ø 2 – Ø 20<br />

Ø 2 – Ø 20<br />

Ø 0,5 – Ø 4<br />

Ø 0,5 – Ø 4<br />

Ø 0,5 – Ø 4<br />

Ø 0,5 – Ø 4<br />

Ø 0,5 – Ø 4<br />

Ø 0,5 – Ø 4<br />

Test cables,<br />

probes<br />

Test cables,<br />

probes,<br />

miniature<br />

sockets<br />

Miniature<br />

sockets<br />

12<br />

12<br />

12<br />

12<br />

8<br />

8<br />

8<br />

5<br />

5<br />

5<br />

Thickness of<br />

<strong><strong>Multi</strong>lam</strong> strip<br />

s<br />

mm<br />

0,125<br />

0,150<br />

0,200<br />

0,300<br />

0,100<br />

0,125<br />

0,150<br />

0,100<br />

0,125<br />

0,150<br />

<strong>Contact</strong> spacing<br />

r<br />

mm<br />

0,8 – 1,0<br />

0,8 – 1,0<br />

0,8 – 1,0<br />

0,8 – 1,0<br />

0,6 – 0,8<br />

0,6 – 0,8<br />

0,6 – 0,8<br />

0,6 – 0,8<br />

0,6 – 0,8<br />

0,6 – 0,8<br />

<strong>Contact</strong> force per<br />

louver with medium<br />

spring deflection<br />

LAVII/0,125 Ø 0,8 – Ø 2,36 Miniature<br />

sockets 3 0,125 0,6 – 0,8 – –<br />

1) <strong>The</strong> sliding force will be determined by the end product<br />

2) No indication of guide values possible, these values depend on the final use<br />

Fk<br />

N<br />

3,5<br />

7<br />

2)<br />

–<br />

–<br />

–<br />

10<br />

–<br />

–<br />

3<br />

Sliding force per<br />

louver with medium<br />

spring defl. µr =0,35<br />

Fs<br />

N<br />

1,25<br />

2,5<br />

2)<br />

–<br />

–<br />

–<br />

3,5<br />

–<br />

–<br />

1,05

Advanced <strong>Contact</strong> Technology<br />

Rated current (A)<br />

per louver<br />

l<br />

n1<br />

A<br />

<strong>Contact</strong> resistance (m�)<br />

per louver<br />

R<br />

k<br />

m�<br />

Electrical data 1)<br />

Short circuit current (kA)<br />

per louver at<br />

lk11s kA<br />

( ) lk2( 2s)<br />

lk3( 3s)<br />

kA kA<br />

Rated peak withstand current (kA)<br />

per louver<br />

0 1,5 3,0 4,5 6,0 7,5 9,0 10,5 12,0 13,5 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0 0 0,04 0,08 0,12 0,16 0,20 0,24 0,28 0,32 0,36 0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9<br />

1) Valid for <strong><strong>Multi</strong>lam</strong>s made from hard copper, gold-plated<br />

2) No indication of guide values possible, these values depend on the final use<br />

www.multi-contact.com 19<br />

l<br />

p<br />

kA

Advanced <strong>Contact</strong> Technology<br />

Cylindrical contacts<br />

<strong>The</strong> <strong><strong>Multi</strong>lam</strong>s are fitted on cylindrical<br />

contact rings. Either in a socket (female),<br />

the mating part being a rigid pin,<br />

or on a pin (male) and the mating part a<br />

rigid socket. Also for dynamic applications<br />

(axial movement or rotatable).<br />

Spherical contacts<br />

Accommodate angular misalignments<br />

and axial movements (sliding).<br />

Special design features<br />

With MC <strong><strong>Multi</strong>lam</strong> technology, users have available an extremely<br />

flexible and individually adaptable contact interface.<br />

20 www.multi-contact.com<br />

Flat contacts<br />

are suitable for connecting busbars, either<br />

as a connector or a clamping unit.<br />

This allows connection and disconnection<br />

with large busbars.<br />

Fork contacts<br />

are suitable for connecting busbars to<br />

the plug-in module system. Connections<br />

to parallel busbars can easily be made<br />

with “floating” fork contacts.

Advanced <strong>Contact</strong> Technology<br />

MC <strong><strong>Multi</strong>lam</strong>s<br />

Countless applications and a basis for new developments<br />

<strong>The</strong> first step to a solution for<br />

your own contact<br />

is a simple form to be filled in online with your contact requirements<br />

You will find this form under:<br />

www.multi-contact.com > Downloads > Online Forms ><br />

Checklist / Inquiry Form<br />

Send the generated pdf-form, together with possible additions<br />

or additional requirements by mail to:<br />

basel@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong><br />

www.multi-contact.com 21

Advanced <strong>Contact</strong> Technology<br />

Strip thickness s<br />

Thickness of the <strong><strong>Multi</strong>lam</strong> strip without plating.<br />

Leaf spring <strong><strong>Multi</strong>lam</strong><br />

Individual louvers have a spring action as a result of their<br />

curved shape. Leaf spring <strong><strong>Multi</strong>lam</strong> bands are usually gold or<br />

nickel plated.<br />

Torsion spring <strong><strong>Multi</strong>lam</strong><br />

MC <strong><strong>Multi</strong>lam</strong> type with individual louvers which deflect under<br />

torsion. <strong>The</strong>y are made from copper alloy and are usually silver<br />

plated.<br />

Definition In1, In2<br />

In1 = Nominal current under normal environmental conditions<br />

and good contact quality according to table, page 9. In1 is the<br />

basis for MC design.<br />

In2 = Nominal current under optimal environmental conditions<br />

and sufficient contact quality according to table, page 9.<br />

Internal resistance of the louver<br />

results from the specific resistance of the louver material, the<br />

distance the current must travel through the louver and the active<br />

cross-section.<br />

Standards<br />

IEC 61984 (VDE 0627):<br />

Safety requirements and tests for plug connectors.<br />

IEC 61010-031 (VDE 0411-031):<br />

Safety regulations and hand-held accessories for test and measurement.<br />

IEC 62271-1 (VDE 0671-1):<br />

High voltage switchgear and switch devices – general definitions.<br />

<strong>Contact</strong> force Fk<br />

is defined as the spring force of a louver at medium deflection.<br />

<strong>Contact</strong> resistance<br />

is the resistance of the point of contact between the <strong><strong>Multi</strong>lam</strong><br />

and the contact parts.<br />

<strong><strong>Multi</strong>lam</strong> recess<br />

Groove milled into the contact part for the “floating” mounting<br />

of a <strong><strong>Multi</strong>lam</strong> louver.<br />

RoHS – 2002/95/EC<br />

European Directive 2002/95/EC (“RoHS” for short) restricts the<br />

use of certain hazardous substances in household equipment.<br />

<strong><strong>Multi</strong>lam</strong> strips are component parts, and as such are not directly<br />

affected by this directive. <strong>The</strong>y also contain none of the<br />

substances which are scheduled under the directive and can<br />

therefore be safely incorporated in devices to which the<br />

directive applies.<br />

Glossary<br />

22 www.multi-contact.com<br />

<strong><strong>Multi</strong>lam</strong> louver<br />

Individual contact element of a <strong><strong>Multi</strong>lam</strong> strip; there are either<br />

� leaf spring louvers or � torsion spring louvers.<br />

<strong>Contact</strong> spacing r<br />

is the distance between the centres of two � <strong><strong>Multi</strong>lam</strong> louvers.<br />

Sliding force FS<br />

is the purely frictional force of the deflected <strong><strong>Multi</strong>lam</strong>.<br />

<strong>The</strong> stated figures are average values obtained with a thin lubricant<br />

film and after 20 – 30 mating cycles. <strong>The</strong> values are<br />

higher in new connectors. <strong>The</strong> sliding force is determined in<br />

the end product, since its value is not determined solely by the<br />

<strong><strong>Multi</strong>lam</strong>.<br />

Plug-in force FSt<br />

is the maximum force needed in order to deflect the <strong><strong>Multi</strong>lam</strong><br />

when mating the connector. It is made up of the spring force<br />

and the frictional force.<br />

<strong>The</strong> plug-in force is determined in the end product, since its<br />

value is not determined solely by the <strong><strong>Multi</strong>lam</strong>.<br />

It should be noted that the plug-in force is always greater than<br />

the sliding force. <strong>The</strong> plug-in force is usually not indicated.<br />

Force<br />

Difference between plug-in force and sliding force<br />

F St<br />

Mating way<br />

Lubricants<br />

MC recommends the following lubricants:<br />

Grease (general electrical contacts):<br />

METALON HT-1,5-50ML (73.1052)<br />

KONTASYNTH BA100 SPRAY (73.1051)*<br />

Sliding grease:<br />

in SF6-Gas: Barrierta I EL-102*<br />

Press-fitting and sealing grease:<br />

Barrierta I S-402 or Barrierta I MI-202*<br />

* from Klüber Lubrication, Munich.<br />

FS

Advanced <strong>Contact</strong> Technology<br />

www.multi-contact.com 23

Advanced <strong>Contact</strong> Technology<br />

Headquarters:<br />

<strong>Multi</strong>-<strong>Contact</strong> AG<br />

Stockbrunnenrain 8<br />

CH – 4123 Allschwil<br />

Tel. +41/61/306 55 55<br />

Fax +41/61/306 55 56<br />

mail basel@multi-contact.com<br />

www.multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Deutschland GmbH<br />

Hegenheimer Strasse 19<br />

Postfach 1606<br />

DE – 79551 Weil am Rhein<br />

Tel. +49/76 21/6 67 - 0<br />

Fax +49/76 21/6 67 - 100<br />

mail weil@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong><br />

Handelsges.m.b.H. Austria<br />

Hauptplatz 8<br />

AT – 3452 Heiligeneich<br />

Tel. +43/2275/56 56<br />

Fax +43/2275/56 56 4<br />

mail austria@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Benelux<br />

c/o Stäubli Benelux N.V.<br />

Meensesteenweg 407<br />

BE – 8501 Bissegem<br />

Tel. +32/56 36 41 00<br />

Fax +32/56 36 41 10<br />

mail benelux@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Czech<br />

c/o Stäubli Systems, s.r.o.<br />

Hradecká 536<br />

CZ – 53009 Pardubice<br />

Tel. +420/466/616 126<br />

Fax +420/466/616 127<br />

mail connectors.cz@staubli.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Española<br />

c/o Stäubli Española S.A.<br />

C/Marià Aguiló, 4 – 1°<br />

ES – 08205 Sabadell<br />

Tel. +34/93/720 65 50<br />

Fax +34/93/712 42 56<br />

mail spain@multi-contact.com<br />

Ihre <strong>Multi</strong>-<strong>Contact</strong> Vertretung:<br />

Your <strong>Multi</strong>-<strong>Contact</strong> representative:<br />

Votre représentant <strong>Multi</strong>-<strong>Contact</strong>:<br />

<strong>Multi</strong>-<strong>Contact</strong> Essen GmbH<br />

Westendstrasse 10<br />

Postfach 102 527<br />

DE – 45025 Essen<br />

Tel. +49/2 01/8 31 05 - 0<br />

Fax +49/2 01/8 31 05 - 99<br />

mail essen@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> (UK) Ltd.<br />

3 Presley Way<br />

Crownhill, Milton Keynes<br />

GB – Buckinghamshire MK8 0ES<br />

Tel. +44/1908 26 55 44<br />

Fax +44/1908 26 20 80<br />

mail uk@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Italia<br />

c/o Stäubli Italia S.p.A.<br />

Via Rivera, 55<br />

IT – 20841 Carate Brianza (MB)<br />

Tel. +39/0362/94 45 01<br />

Fax +39/0362/94 45 80<br />

mail italy@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Portugal<br />

c/o Stäubli Portugal<br />

Representações Lda<br />

Via Central de Milheirós, 171-A<br />

PT – 4475-330 Milheirós / Maia<br />

Tel. +351/229 783 956<br />

Fax +351/229 783 959<br />

mail portugal@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Türkiye<br />

c/o Stäubli Sanayi Makine ve<br />

Aksesuarlari Ticaret Ltd. ¸Sti.<br />

Atatürk Mahallesi, Marmara<br />

Sanayi Sitesi, B Blok No: 28 Ikitelli<br />

TR – 34306 Istanbul<br />

Tel. +90/212/472 13 00<br />

Fax +90/212/472 12 30<br />

mail turkey@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> France SAS<br />

4 rue de l’Industrie<br />

BP 37<br />

FR – 68221 Hésingue Cedex<br />

Tel. +33/3/89 67 65 70<br />

Fax +33/3/89 69 27 96<br />

mail france@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Russia<br />

OOO STAUBLI RUS<br />

ul.Startovaya 8a<br />

RU – 196210 Saint Petersburg<br />

Tel. +7/812/334 46 30<br />

Fax +7/812/334 46 36<br />

mail russia@multi-contact.com<br />

www.multi-contact-russia.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Brazil<br />

c/o Stäubli Comércio, Importação,<br />

Exportação e Representações Ltda.<br />

Rua Henri Dunant, 137 - Conj. D<br />

BR – 04709-110 São Paulo<br />

Tel. +55/11/2348 7400<br />

Fax +55/11/5181 8334<br />

mail brazil@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> China<br />

c/o Stäubli Mechatronic Co. Ltd.<br />

Hangzhou Economic and<br />

Technological Development Zone<br />

No. 5, 4 th Street<br />

CN – 310018 Hangzhou<br />

Tel. +86/571/869 121 61<br />

Fax +86/571/869 125 22<br />

mail hangzhou@staubli.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Hongkong<br />

c/o Stäubli (H.K.) Ltd.<br />

Unit 87, 12/F, HITEC<br />

No. 1 Trademart Drive<br />

Kowloon Bay<br />

HK – Hong Kong<br />

Tel. +852/2366 0660<br />

Fax +852/2311 4677<br />

mail connectors.hk@staubli.com<br />

<strong>Multi</strong>-<strong>Contact</strong> USA<br />

100 Market Street<br />

US – Windsor, CA 95492<br />

Tel. +1/707/838 - 0530<br />

Fax +1/707/838 - 2474<br />

mail usa@multi-contact.com<br />

www.multi-contact-usa.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Taiwan<br />

c/o Stäubli (H.K.) Ltd.<br />

Taiwan Branch<br />

6/F-3, No. 21, Lane 583<br />

Ruiguang Road, Neihu Dist.<br />

TW – Taipei City 11466<br />

Tel. +886/2/8797 7795<br />

Fax +886/2/8797 8895<br />

mail connectors.tw@staubli.com<br />

<strong>Multi</strong>-<strong>Contact</strong> Korea<br />

c/o Stäubli Korea Co., Ltd.<br />

2F, DCCI, 107-2,<br />

Shincheon-dong, Dong-gu,<br />

ROK – 701-702 Daegu<br />

Tel. +82/53/753/0075<br />

Fax +82/53/753/0072<br />

mail korea@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong><br />

(South East Asia) Pte. Ltd.<br />

215 Henderson Road #01-02<br />

Henderson Industrial Park<br />

SG – Singapore 159554<br />

Tel. +65/626 609 00<br />

Fax +65/626 610 66<br />

mail singapore@multi-contact.com<br />

<strong>Multi</strong>-<strong>Contact</strong> (Thailand) Co., Ltd.<br />

160/865-866 Silom Road<br />

ITF-Silom Palace 33 rd Floor<br />

Suriyawong, Bangrak<br />

TH – Bangkok 10500<br />

Tel. +66/2/266 78 79; 268 08 04<br />

Fax +66/2/267 76 80<br />

mail thailand@multi-contact.com<br />

Sie finden Ihren Ansprechpartner unter:<br />

You will find your local partner at:<br />

Trouvez vos contacts sous:<br />

www.multi-contact.com<br />

© <strong>Multi</strong>-<strong>Contact</strong> AG, Switzerland, 12.2009 (1) 11.2011/1000/WD – <strong><strong><strong>Multi</strong>lam</strong>Technology</strong> – Global Communications – Änderungen vorbehalten / Subject to alterations / Sous réserve de modifications.