Food & Beverage Asia Jun/July 2021

Food & Beverage Asia (FBA) is the leading source of food and beverage news in Asia since 2002. FBA delivers a comprehensive view of the food and beverage landscape, spanning across the latest health and nutrition trends and industry innovations in ingredients, recipe formulations, food science, sustainability, packaging, and automation, as well as advancements in agri and food-tech.

Food & Beverage Asia (FBA) is the leading source of food and beverage news in Asia since 2002. FBA delivers a comprehensive view of the food and beverage landscape, spanning across the latest health and nutrition trends and industry innovations in ingredients, recipe formulations, food science, sustainability, packaging, and automation, as well as advancements in agri and food-tech.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PROCESSING AND PACKAGING 45<br />

But even so, the contract award wasn’t<br />

a done deal: “We’re almost an entirely<br />

Krones-built operation, but Krones still<br />

has to prove itself with each bid.”<br />

FLEXIBLE, TROUBLE-FREE<br />

PRODUCTION<br />

PET line number 7:<br />

• Contiform 3 Speed stretch blowmolder<br />

with PET-View inspection<br />

system<br />

• AirCo air conveyor<br />

• Contiflow mixer<br />

• Modulfill VFS filler in a cleanroom<br />

• The latest-generation Accutable<br />

dynamic buffer system<br />

• Linadry container dryer<br />

• Contiroll labeler<br />

• Variopac Pro FS-7 packer<br />

• Modulpal Pro 1AD palletizer with<br />

a Robobox T-GS grouping system<br />

with high-level infeed<br />

The new turnkey line bottles both<br />

still and carbonated water as well as<br />

carbonated soft drinks (CSDs) and went<br />

into operation in mid-2019. A number of<br />

unique points are worth noting.<br />

At Vitaqua, the blow-molder on each line<br />

is linked to the filler via an air conveyor.<br />

“It’s our ‘house philosophy’ and it has<br />

worked well for us so far,” explained<br />

Thöne.<br />

Besides trouble-free operation, flexibility<br />

is a priority: “Since we run four different<br />

containers on this line, it was important<br />

that the Contiform blow-molder be<br />

equipped with quick-change capability.<br />

We can now change over from the<br />

smallest bottle size to the largest in just<br />

75 minutes.”<br />

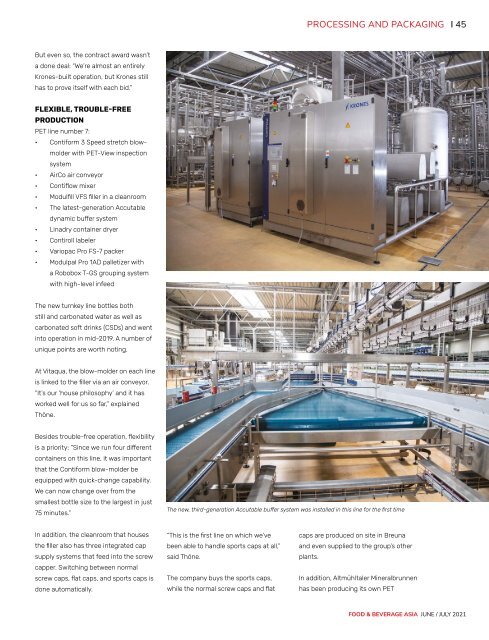

The new, third-generation Accutable buffer system was installed in this line for the first time<br />

In addition, the cleanroom that houses<br />

the filler also has three integrated cap<br />

supply systems that feed into the screw<br />

capper. Switching between normal<br />

screw caps, flat caps, and sports caps is<br />

done automatically.<br />

“This is the first line on which we’ve<br />

been able to handle sports caps at all,”<br />

said Thöne.<br />

The company buys the sports caps,<br />

while the normal screw caps and flat<br />

caps are produced on site in Breuna<br />

and even supplied to the group’s other<br />

plants.<br />

In addition, Altmühltaler Mineralbrunnen<br />

has been producing its own PET<br />

FOOD & BEVERAGE ASIA JUNE / JULY <strong>2021</strong>