THE YEAR-BOOK OF THE COKE OVEN - Coke-oven-managers.org

THE YEAR-BOOK OF THE COKE OVEN - Coke-oven-managers.org

THE YEAR-BOOK OF THE COKE OVEN - Coke-oven-managers.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Environmental issues<br />

The comparison in table 1 indicates a general better environmental situation<br />

with the application of high-capacity <strong>oven</strong>s, generated by less pushing and<br />

charging per day as well as by a reduced total length of sealing elements at<br />

the <strong>oven</strong> closures, followed by less visible emissions.<br />

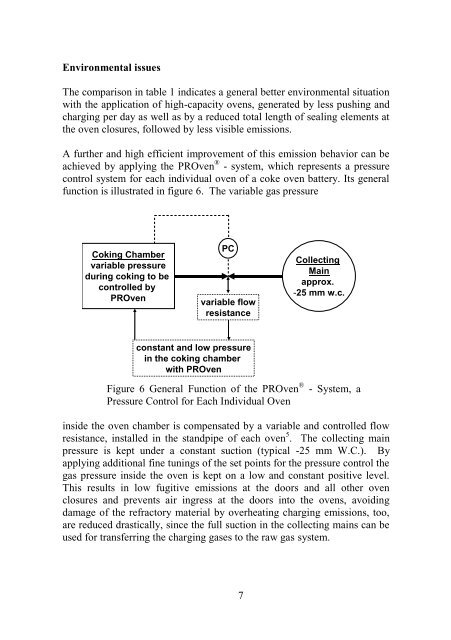

A further and high efficient improvement of this emission behavior can be<br />

achieved by applying the PROven ® - system, which represents a pressure<br />

control system for each individual <strong>oven</strong> of a coke <strong>oven</strong> battery. Its general<br />

function is illustrated in figure 6. The variable gas pressure<br />

Coking Chamber<br />

variable pressure<br />

during coking to be<br />

controlled by<br />

PROven<br />

PC<br />

variable flow<br />

resistance<br />

constant and low pressure<br />

in the coking chamber<br />

with PROven<br />

7<br />

Collecting<br />

Main<br />

approx.<br />

-25 mm w.c.<br />

Figure 6 General Function of the PROven ® - System, a<br />

Pressure Control for Each Individual Oven<br />

inside the <strong>oven</strong> chamber is compensated by a variable and controlled flow<br />

resistance, installed in the standpipe of each <strong>oven</strong> 5 . The collecting main<br />

pressure is kept under a constant suction (typical -25 mm W.C.). By<br />

applying additional fine tunings of the set points for the pressure control the<br />

gas pressure inside the <strong>oven</strong> is kept on a low and constant positive level.<br />

This results in low fugitive emissions at the doors and all other <strong>oven</strong><br />

closures and prevents air ingress at the doors into the <strong>oven</strong>s, avoiding<br />

damage of the refractory material by overheating charging emissions, too,<br />

are reduced drastically, since the full suction in the collecting mains can be<br />

used for transferring the charging gases to the raw gas system.