Panels & Furniture Asia September/October 2022

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Panels & Furniture Asia (PFA) is a leading regional trade magazine dedicated to the woodbased panel, furniture and flooring processing industry. Published bi-monthly since 2000, PFA delivers authentic journalism to cover the latest news, technology, machinery, projects, products and trade events throughout the sector. With a hardcopy and digital readership comprising manufacturers, designers and specifiers, among others, PFA is the platform of choice for connecting brands across the global woodworking landscape.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PANEL MANUFACTURING<br />

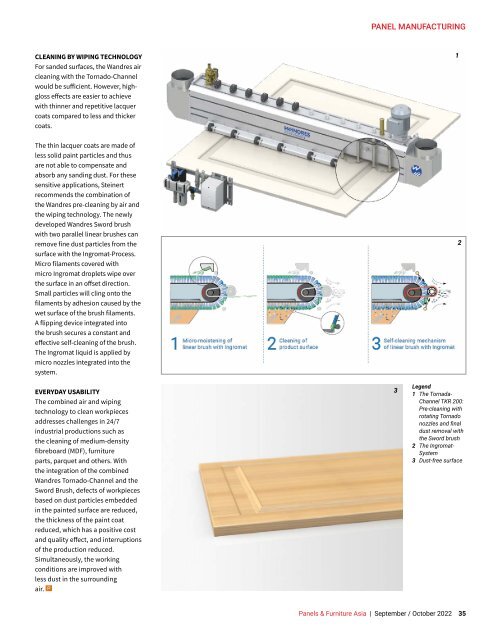

CLEANING BY WIPING TECHNOLOGY<br />

For sanded surfaces, the Wandres air<br />

cleaning with the Tornado-Channel<br />

would be sufficient. However, highgloss<br />

effects are easier to achieve<br />

with thinner and repetitive lacquer<br />

coats compared to less and thicker<br />

coats.<br />

1<br />

The thin lacquer coats are made of<br />

less solid paint particles and thus<br />

are not able to compensate and<br />

absorb any sanding dust. For these<br />

sensitive applications, Steinert<br />

recommends the combination of<br />

the Wandres pre-cleaning by air and<br />

the wiping technology. The newly<br />

developed Wandres Sword brush<br />

with two parallel linear brushes can<br />

remove fine dust particles from the<br />

surface with the Ingromat-Process.<br />

Micro filaments covered with<br />

micro Ingromat droplets wipe over<br />

the surface in an offset direction.<br />

Small particles will cling onto the<br />

filaments by adhesion caused by the<br />

wet surface of the brush filaments.<br />

A flipping device integrated into<br />

the brush secures a constant and<br />

effective self-cleaning of the brush.<br />

The Ingromat liquid is applied by<br />

micro nozzles integrated into the<br />

system.<br />

EVERYDAY USABILITY<br />

The combined air and wiping<br />

technology to clean workpieces<br />

addresses challenges in 24/7<br />

industrial productions such as<br />

the cleaning of medium-density<br />

fibreboard (MDF), furniture<br />

parts, parquet and others. With<br />

the integration of the combined<br />

Wandres Tornado-Channel and the<br />

Sword Brush, defects of workpieces<br />

based on dust particles embedded<br />

in the painted surface are reduced,<br />

the thickness of the paint coat<br />

reduced, which has a positive cost<br />

and quality effect, and interruptions<br />

of the production reduced.<br />

Simultaneously, the working<br />

conditions are improved with<br />

less dust in the surrounding<br />

air. P<br />

3<br />

2<br />

Legend<br />

1 The Tornada-<br />

Channel TKR 200:<br />

Pre-cleaning with<br />

rotating Tornado<br />

nozzles and final<br />

dust removal with<br />

the Sword brush<br />

2 The Ingromat-<br />

System<br />

3 Dust-free surface<br />

<strong>Panels</strong> & <strong>Furniture</strong> <strong>Asia</strong> | <strong>September</strong> / <strong>October</strong> <strong>2022</strong> 35