FORGED: Making a Knife with Traditional Blacksmith Skills

This book will teach you to hand build a knife using the traditional method of blacksmiths of old — FORGING. Traditional forging of a knife blade is a process which uses the ancient techniques of moving hot steel with hammer and anvil alone into a knife-form that is ready for filing, heat treating and sharpening with no or very minimal electric grinding. This book also teaches traditional fit-and-finish skills using only hand tools. It explains an ancient riveted full-tang handle construction system that surpasses modern methods. In the author's words; "In my early blacksmithing years, I was lucky to get to know some old smiths who wrangled hot iron every day just to make a living. They unselfishly taught me traditional blacksmithing skills and knife forging methods. Every time I use those skills and methods, I honor their friendships, and by teaching you, the reader, we keep alive the memory of those old-time iron pounders." Hardcover, 132 pages, 150 photos and illustrations, $29.95.

This book will teach you to hand build a knife using the traditional method of blacksmiths of old — FORGING.

Traditional forging of a knife blade is a process which uses the ancient techniques of moving hot steel with hammer and anvil alone into a knife-form that is ready for filing, heat treating and sharpening with no or very minimal electric grinding.

This book also teaches traditional fit-and-finish skills using only hand tools. It explains an ancient riveted full-tang handle construction system that surpasses modern methods.

In the author's words; "In my early blacksmithing years, I was lucky to get to know some old smiths who wrangled hot iron every day just to make a living. They unselfishly taught me traditional blacksmithing skills and knife forging methods. Every time I use those skills and methods, I honor their friendships, and by teaching you, the reader, we keep alive the memory of those old-time iron pounders."

Hardcover, 132 pages, 150 photos and illustrations, $29.95.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Don’t attempt to drill or file steel that has not been annealed; it’s bad on the steel,<br />

the equipment, and the smith.<br />

Normalizing: (Note: the terms and chemical reactions mentioned here are<br />

explained in more detail in the following chapter). The last normalization is<br />

done just before the hardening quench after you have finished shaping your<br />

blade <strong>with</strong> file and sandpaper. When normalizing you first bring the entire blade<br />

to critical heat (1500° F) then set it aside to cool at room temperature. This allows<br />

the trapped carbon atoms to slowly diffuse out of the ferrite structure and form<br />

into cementite, then line themselves up <strong>with</strong> the remaining ferrite structure.<br />

These two formations together are now called pearlite. Pearlite is a fine grained<br />

structure that is extremely ductile. The most important result of normalization is<br />

that it homogenizes the internal microstructure, thereby equalizing the crystalline<br />

size and “normalizing” the consistency of the blade’s steel. This process prepares<br />

the steel for an even hardening and tempering, <strong>with</strong> a reduced chance of bending<br />

or cracking. Most smiths normalize one to three times over the course of blade<br />

construction. More than three times is unnecessary.<br />

Filing and Sanding<br />

If I were grinding the final shape, I would turn on my Grizzly. I have nothing<br />

against 2 x 72 belt sanders. I like mine. But… I also like the forging process that<br />

brings a blade to near completion, then doing the final shaping and finishing<br />

<strong>with</strong> file and sandpaper sticks. That’s how Gus did it.<br />

Forging and filing can be almost as fast as grinding and buffing. That’s because we<br />

have forged the knife closer to its final form and have less to remove. After forgebeveling<br />

there is way less, hardly any, stock to be removed. Also, there are fewer<br />

high-speed grinding mistakes resulting in half finished blades on the floor at the<br />

end of the day. I do it old and slow. For me slow is more enjoyable and a lot quieter.<br />

Secure a collection of files. New files are expensive. Old half-used files are just<br />

fine and available in used tool and pawn shops, farm auctions and yard sales.<br />

When you buy a new file purchase the best quality you can. Learn to sharpen<br />

the old ones, they come out almost new. Half of your work will be done <strong>with</strong><br />

two or three flat, cross tooth and single cut large files, the other half will be <strong>with</strong><br />

sanding sticks.<br />

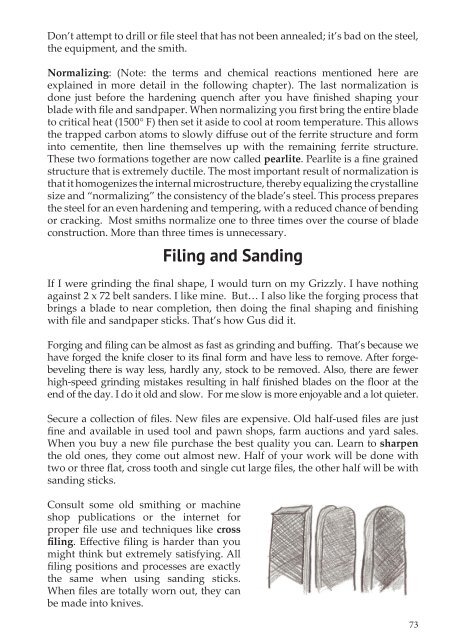

Consult some old smithing or machine<br />

shop publications or the internet for<br />

proper file use and techniques like cross<br />

filing. Effective filing is harder than you<br />

might think but extremely satisfying. All<br />

filing positions and processes are exactly<br />

the same when using sanding sticks.<br />

When files are totally worn out, they can<br />

be made into knives.<br />

73