Eclipse Engineering Guide

Eclipse Engineering Guide

Eclipse Engineering Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

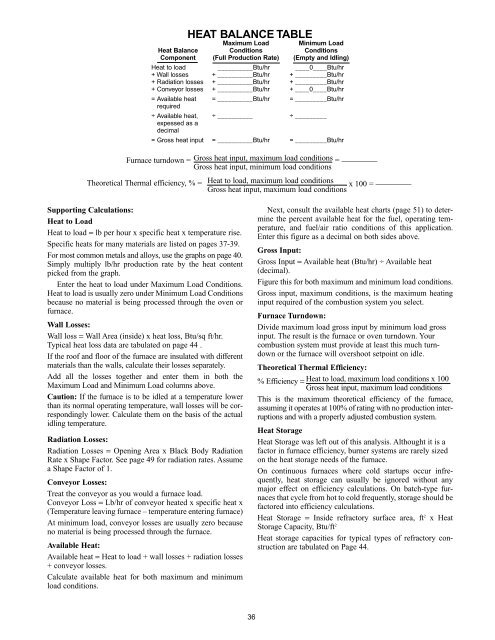

HEAT BALANCE TABLE<br />

Maximum Load Minimum Load<br />

Heat Balance Conditions Conditions<br />

Component (Full Production Rate) (Empty and Idling)<br />

Heat to load __________Btu/hr ____0____Btu/hr<br />

+ Wall losses + __________Btu/hr + _________Btu/hr<br />

+ Radiation losses + __________Btu/hr + _________Btu/hr<br />

+ Conveyor losses + __________Btu/hr + ____0____Btu/hr<br />

= Available heat = __________Btu/hr = _________Btu/hr<br />

required<br />

÷ Available heat, ÷ __________ ÷ _________<br />

expessed as a<br />

decimal<br />

= Gross heat input = __________Btu/hr = _________Btu/hr<br />

Furnace turndown = Gross heat input, maximum load conditions = _________<br />

Gross heat input, minimum load conditions<br />

Theoretical Thermal efficiency, % =<br />

Supporting Calculations:<br />

Heat to Load<br />

Heat to load = lb per hour x specific heat x temperature rise.<br />

Specific heats for many materials are listed on pages 37-39.<br />

For most common metals and alloys, use the graphs on page 40.<br />

Simply multiply lb/hr production rate by the heat content<br />

picked from the graph.<br />

Enter the heat to load under Maximum Load Conditions.<br />

Heat to load is usually zero under Minimum Load Conditions<br />

because no material is being processed through the oven or<br />

furnace.<br />

Wall Losses:<br />

Wall loss = Wall Area (inside) x heat loss, Btu/sq ft/hr.<br />

Typical heat loss data are tabulated on page 44 .<br />

If the roof and floor of the furnace are insulated with different<br />

materials than the walls, calculate their losses separately.<br />

Add all the losses together and enter them in both the<br />

Maximum Load and Minimum Load columns above.<br />

Caution: If the furnace is to be idled at a temperature lower<br />

than its normal operating temperature, wall losses will be correspondingly<br />

lower. Calculate them on the basis of the actual<br />

idling temperature.<br />

Radiation Losses:<br />

Radiation Losses = Opening Area x Black Body Radiation<br />

Rate x Shape Factor. See page 49 for radiation rates. Assume<br />

a Shape Factor of 1.<br />

Conveyor Losses:<br />

Treat the conveyor as you would a furnace load.<br />

Conveyor Loss = Lb/hr of conveyor heated x specific heat x<br />

(Temperature leaving furnace – temperature entering furnace)<br />

At minimum load, conveyor losses are usually zero because<br />

no material is being processed through the furnace.<br />

Available Heat:<br />

Available heat = Heat to load + wall losses + radiation losses<br />

+ conveyor losses.<br />

Calculate available heat for both maximum and minimum<br />

load conditions.<br />

Heat to load, maximum load conditions<br />

x 100 = _________<br />

Gross heat input, maximum load conditions<br />

36<br />

Next, consult the available heat charts (page 51) to determine<br />

the percent available heat for the fuel, operating temperature,<br />

and fuel/air ratio conditions of this application.<br />

Enter this figure as a decimal on both sides above.<br />

Gross Input:<br />

Gross Input = Available heat (Btu/hr) ÷ Available heat<br />

(decimal).<br />

Figure this for both maximum and minimum load conditions.<br />

Gross input, maximum conditions, is the maximum heating<br />

input required of the combustion system you select.<br />

Furnace Turndown:<br />

Divide maximum load gross input by minimum load gross<br />

input. The result is the furnace or oven turndown. Your<br />

combustion system must provide at least this much turndown<br />

or the furnace will overshoot setpoint on idle.<br />

Theoretical Thermal Efficiency:<br />

% Efficiency = Heat to load, maximum load conditions x 100<br />

Gross heat input, maximum load conditions<br />

This is the maximum theoretical efficiency of the furnace,<br />

assuming it operates at 100% of rating with no production interruptions<br />

and with a properly adjusted combustion system.<br />

Heat Storage<br />

Heat Storage was left out of this analysis. Althought it is a<br />

factor in furnace efficiency, burner systems are rarely sized<br />

on the heat storage needs of the furnace.<br />

On continuous furnaces where cold startups occur infrequently,<br />

heat storage can usually be ignored without any<br />

major effect on efficiency calculations. On batch-type furnaces<br />

that cycle from hot to cold frequently, storage should be<br />

factored into efficiency calculations.<br />

Heat Storage = Inside refractory surface area, ft 2 x Heat<br />

Storage Capacity, Btu/ft 2<br />

Heat storage capacities for typical types of refractory construction<br />

are tabulated on Page 44.