SUMMER 2023

Distributor's Link Magazine Summer 2023 / Vol 46 No 3

Distributor's Link Magazine Summer 2023 / Vol 46 No 3

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

In the Summer <strong>2023</strong> issue of<br />

6 DISTRIBUTOR NEWS<br />

8 FASTENER SCIENCE: SPECTROSCOPY – THE ELEMENTAL<br />

CODE BEHIND THE CHEMISTRY OF METAL<br />

Rob LaPointe<br />

10 DIFFICULT FASTENING APPLICATIONS – PART 2:<br />

THIN-WALLED PLASTIC BOSSES<br />

Laurence Claus<br />

12 THREAD-FORMING SCREWS FOR PLASTICS<br />

Bruno Marbacher<br />

14 WHAT DISTRIBUTORS NEED TO KNOW ABOUT<br />

TORQUE IN FASTENERS<br />

Guy Avellon<br />

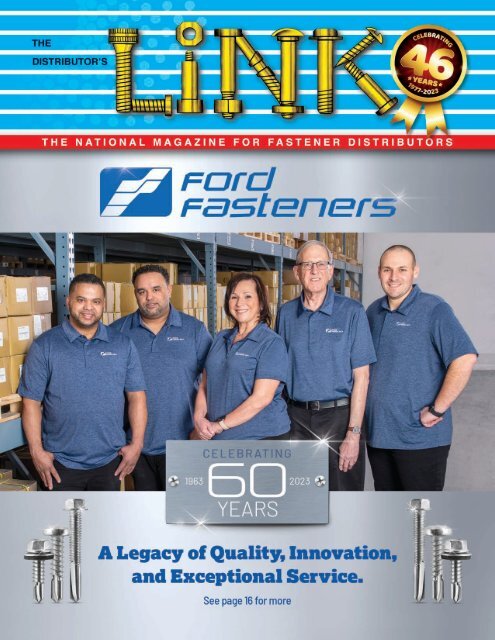

16 [COVER FEATURE] FORD FASTENERS: A LEGACY OF<br />

QUALITY, INNOVATION, AND EXCEPTIONAL SERVICE<br />

26 HIGH PERFORMANCE DISTRIBUTION UPDATE<br />

Robert Footlik<br />

28 FTC SPARKS DEBATE WITH PROPOSED REGULATION<br />

BANNING NON-COMPETES<br />

Jim Truesdell<br />

30 ROTOR CLIP EXPANDS TO TEXAS WAREHOUSE AND<br />

LOGISTICS FACILITY<br />

32 USING AI TO HAVE A CONVERSATION WITH YOUR DATABASE<br />

Joe Dysart<br />

34 THE POWER OF BRAND MESSAGING: UNLEASHING YOUR<br />

POTENTIAL IN THE FASTENER INDUSTRY<br />

Joe Shoemaker<br />

36 IFI ANNOUNCES NEW BOARD AND DIVISION CHAIRS<br />

Dan Walker<br />

38 WE’RE BACK?<br />

Chris Donnell<br />

39 PROSPECT FASTENER: SPIRAL, CONSTANT SECTION &<br />

TAPERED SECTION RETAINING RINGS<br />

40 SETTING ADJUSTABLE THREAD RINGS PART 2: HOW IT’S DONE<br />

Larry Borowski<br />

42 WING-HAMLIN CO. CELEBRATES 33 YEARS IN BUSINESS!<br />

44 ALLIED TITANIUM: GROUNDBREAKING NEW TECHNOLOGY<br />

Tristan Phillips<br />

46 VMI & SIGNATURE CAPTURE<br />

Dennis Cowhey<br />

48 MWFA FSTNR WEEK ’23: FASTENER SHOW, TRAINING,<br />

NETWORKING, RECREATION ALL IN ONE WEEK<br />

Nancy Rich<br />

50 UNVEILING A BIGGER, BOLDER<br />

KINTER: EMBRACING<br />

INNOVATION AND GROWTH<br />

52 SMARTCERT ® ANNOUNCES<br />

NEW FEATURES & UPGRADES<br />

TO FREE STARTER<br />

SUBSCRIPTIONS<br />

54 SPIROL: THE ADVANTAGES OF<br />

CL220 SPLIT SEAM COMPRESSION LIMITERS<br />

Peter Grant<br />

56 THORNBERG TO PAC-WEST: NEXT FEW YEARS<br />

“YOU ARE GOING TO MAKE GREAT MONEY”<br />

John Wolz<br />

57 INTERNATIONAL FASTENERS ADDS TWO DISTRIBUTION<br />

CENTERS TO TOTAL OF EIGHT NATIONWIDE!<br />

58 A & A BOLT & SCREW: BETTER BEATS BIGGER<br />

Dennis Cowhey<br />

60 COMMON DEDUCTIONS FOR SMALL BUSINESS OWNERS<br />

TO TAKE ADVANTAGE OF<br />

Roman Basi<br />

62 FASTENER TRAINING WEEK IS COMING TO CHICAGO!<br />

Jo Morris<br />

64 INAUGURAL FASTENER FAIR USA GOLF OUTING<br />

PRESENTED BY NCFA & MWFA<br />

Marty Nolan<br />

65 NCFA & MWFA FASTENER FAIR USA GOLF OUTING PHOTOS<br />

66 THE FASTENER EXPERTS MENTOR GROUP: I HAVE A<br />

FASTENER QUESTION…..WHAT ARE MY OPTIONS FOR A<br />

BLACK FASTENER FINISH?<br />

Your Expert, Darlene Collis<br />

68 PREVIEW OF STAFDA’S UPCOMING 47TH ANNUAL<br />

CONVENTION & TRADE SHOW<br />

Georgia Foley<br />

70 SETKO FASTENERS: YOUR SOURCE FOR BRASS AND<br />

NYLON TIP SET SCREWS<br />

Kelly Poholarz<br />

72 IMSM LTD: WHY ISO 17025 IS ESSENTIAL FOR THE<br />

FASTENER INDUSTRY<br />

Scott Mersch<br />

74 BLIND RIVET FAILURES & SOLUTIONS<br />

Anthony DiMaio<br />

75 INTERNATIONAL FASTENER EXPO RETURNS TO<br />

LAS VEGAS FOR THEIR <strong>2023</strong> SHOW

volume 46 // issue #3<br />

76 CARMEN VERTULLO AWARDED NFDA’S <strong>2023</strong> FASTENER<br />

PROFESSIONAL OF THE YEAR<br />

78 OPTIMIZING INVENTORY: HOW AI IMPROVES S&OP<br />

Nelson Valderrama<br />

80 FASTENER FAIR USA <strong>2023</strong>: A RESOUNDING SUCCESS<br />

IN NASHVILLE, TN<br />

81 FASTENER FAIR USA <strong>2023</strong> NETWORKING PARTY PHOTOS<br />

83 INTERCONTINENTAL SALES CORP (ISC): NEW<br />

RELATIONSHIP WITH RICK RUDOLPH ASSOCIATES<br />

84 SEFA ANNUAL SPRING <strong>2023</strong> CONFERENCE RECAP<br />

Nancy Rich<br />

85 SEFA SPRING CONFERENCE PHOTOS<br />

91 UNICORP NOW OFFERS RETAINING RINGS<br />

102 MWFA FASCINATION WITH FASTENERS<br />

Nancy Rich<br />

103 MWFA FASCINATION WITH FASTENERS CLASS PHOTOS<br />

115 FASTENER FAIR USA <strong>2023</strong> SHOW PHOTOS<br />

116 SEFA BOARD OF DIRECTORS <strong>2023</strong>/2024<br />

Nancy Rich<br />

120 JOIN PAC-WEST IN COEUR D’ALENE SEPTEMBER 14-16<br />

Amy Nijjar<br />

129 SEFA SPRING CONFERENCE GOLF OUTING PHOTOS<br />

137 NEFDA AWARDS SCHOLARSHIPS<br />

Laura Murphy<br />

137 FASTENER COMPANY FOR SALE<br />

138 FASTENER INDUSTRY WEB LINKS<br />

146 MAFDA’S 20TH ANNUAL GOLF OUTING – TEEING OFF<br />

FOR A GOOD CAUSE<br />

Justin Myers<br />

147 MAFDA GOLF OUTING PHOTOS<br />

151 SUBSCRIPTION FORM<br />

158 NCFA <strong>2023</strong> DISTRIBUTOR SOCIAL RECAP<br />

Marty Nolan<br />

163 PAC-WEST SPRING <strong>2023</strong> CONFERENCE PHOTOS<br />

164 PAC-WEST HOSTS MEL KIRSNER MEMORIAL GOLF OUTING<br />

Amy Nijjar<br />

176 MWFA: A TASTE OF ITALY IN THE MID-WEST<br />

Nancy Rich<br />

183 ADVERTISE IN OUR BIG 2-SHOW FALL ISSUE

6 THE DISTRIBUTOR’S LINK<br />

Brikksen is proud to announce Forrest<br />

Rogers as the newly appointed General Manager<br />

of Brikksen. Forrest is a seasoned professional<br />

who started his fastener career 12 years ago<br />

in domestic and international procurement.<br />

Most recently, he served as the Packaged and<br />

Branded Parts Manager for a national OEM<br />

distributor. Forrest has also been instrumental<br />

in the development and growth of the firm’s<br />

e-commerce platform. He possesses a customercentric<br />

approach to conducting business and<br />

is excited about establishing new customer<br />

relationships in his role as the General Manager<br />

of Brikksen.<br />

¤ Forrest Rogers will assume General Manager<br />

responsibilities June 1, <strong>2023</strong><br />

¤ Emily Morrison will remain Business<br />

Operations Manager<br />

¤ Continue to contact your Business Solutions<br />

representative for assistance or questions.<br />

Brikksen is a master distributor of the<br />

highest quality stainless steel fasteners in the<br />

industry. We have been providing value-added<br />

service and top-quality products to customers<br />

for over 15 years. Working with manufacturers<br />

worldwide and utilizing a state-of-the-art inventory<br />

management system allows us the opportunity<br />

to provide distributors with industry leading<br />

customer service, exceptional quality control, and<br />

unequaled product delivery. At Brikksen, we are<br />

committed to providing ultra-fast purchase order<br />

turnaround, the highest quality stainless product<br />

line, and the most competitive pricing in the<br />

industry.<br />

For more information contact Brikksen at<br />

2152 Martin Luther King Jr Blvd #1060, Sanford,<br />

FL 32771. Tel: 1-800-962-1614, Email: sales@<br />

brikksen.com or online at www.brikksen.com.<br />

* * * * * * * * * * * * * * * * * * * * * * * * *<br />

After 51 years of success operating as a<br />

single location in Spokane, Washington, Empire<br />

Bolt & Screw announced today the opening<br />

of a second warehouse distribution facility in<br />

Summerville, SC.<br />

President and CEO Ron Stanley stated, “After<br />

receiving requests from various customers<br />

needing more localized inventory, we listened and<br />

started the process of setting up a distribution<br />

warehouse in South Carolina. We are already<br />

seeing the advantages of having inventory closer<br />

to our customers due to the logistical challenges<br />

of shipping freight across the country. Under<br />

the direction of Chief Operations Officer, Jennifer<br />

Sturm, our new service facility was established<br />

within four short months at a location 2600 miles<br />

away from our Spokane Headquarters.”<br />

Staffing is complete and Empire expects to<br />

have all the necessary inventory in place to service<br />

existing customers within the next 30 days.<br />

Empire Bolt is an international industrial<br />

distributor of primarily threaded products founded<br />

in 1972 by Larry Stanley and family. They<br />

provide product and customized Vendor Managed<br />

Inventory (VMI) services to Original Equipment<br />

Manufacturers (OEMs) with particular focus on<br />

quality and made-to-print items.<br />

For more information, contact Empire Bolt &<br />

Screw at 1501 E. Trent Avenue, Spokane, WA<br />

99202-2938. Tel: 509-534-0636, Fax: 509-534-<br />

1475, email: sales@empirebolt.com or visit them<br />

online at www.empirebolt.com.

8<br />

THE DISTRIBUTOR’S LINK<br />

Rob LaPointe EXPEDITE TESTING SERVICE<br />

Rob LaPointe is a noted authority in materials and fastener technology. With extensive experience in the<br />

management and science of materials testing laboratories combined with master’s degrees in physics and<br />

education, he excels at bringing solutions to the client. Working specifically in the fastener testing industry,<br />

he has developed expertise in mechanical, nondestructive, metallurgical and chemical testing. With a<br />

background of 20 years in physics education, Rob is effective at communicating complex ideas in a simple<br />

and understandable manner, communicating well with clients enabling them to make informed decisions<br />

about their products and business. Rob is President/CEO of Expedite Testing Service, 11645 Riverside Drive,<br />

Suite 127, Lakeside, CA 92040. Tel: 619-736-7872, Cell: 909-254-1278 or visit www.expeditetest.com.<br />

FASTENER SCIENCE: SPECTROSCOPY - THE ELEMENTAL<br />

CODE BEHIND THE CHEMISTRY OF METAL<br />

The topic of spectroscopy has always fascinated me.<br />

Even before I knew what it was exactly, I was caught by<br />

the name, the word. It was as if it were familiar. Maybe<br />

it’s just the kind of word that you recognize as familiar<br />

because you recognize its parts. Spectro or Spectrum,<br />

meaning an image, apparition, or specter. Even more<br />

fundamental, the root Spec is based in Latin, meaning<br />

to look. The physics use of spectrum means an array of<br />

entities or a broad range of objects. Such is the use of the<br />

word spectrum to describe an array of white light, spread<br />

out into its constituent colors. A rainbow.<br />

The tail-end of the word, scopy, creates an action noun<br />

with the word to which it’s connected, denoting scope. A<br />

common example would be the word used to describe<br />

using a microscope, microscopy. Spectroscopy is used to<br />

describe the use of the spectrum of light that is emitted<br />

by objects to understand the mechanics of how that light<br />

was created or the interactions that the light has had with<br />

other objects on its way to us.<br />

To evaluate what materials are being used to make<br />

fastener products, we must be able to see exactly<br />

what atoms are used to form the mixture of elements<br />

put together by the mill that produced the metal. To<br />

manufacture the common alloys that are used to make<br />

fasteners, producers begin with a base metal and add<br />

other elements, in specific amounts, to create a solid that<br />

has the properties we rely on in our fastener products,<br />

such as hardness and tensile strength. For example, alloy<br />

steel is an iron-based metal that is comprised of a mixture<br />

of iron, carbon, chromium, molybdenum, manganese,<br />

silicon, sulfur, phosphorus, copper, and nickel. There<br />

TECHNICAL ARTICLE<br />

FIGURE 1 A RAINBOW PRODUCED BY WATER DROPLETS<br />

DISPURSING SUNLIGHT<br />

are many variations of this recipe that offer different<br />

mechanical properties to the alloy. Figure 2 shows a<br />

recipe of alloy steel used to make A574 socket-head cap<br />

screws. This recipe is available on the material test report<br />

(MTR) from the mill that produced the material. The MTR<br />

document is fundamental in the certificate package that<br />

is provided to the customer for the products we sell. The<br />

mill uses spectroscopy to determine the exact chemical<br />

breakdown of the material they produced and to certify<br />

that chemistry on the MTR.<br />

CONTINUED ON PAGE 90

10<br />

THE DISTRIBUTOR’S LINK<br />

Laurence Claus<br />

Laurence Claus is the President of NNi Training and Consulting, Inc. He has 25 years of<br />

experience with a medium sized automotive fastener manufacturer, holding positions<br />

including Vice President of Engineering, General Manager, Director of Quality, Director<br />

of New Business Development and Applications Engineer. In 2012 he formed NNi<br />

offering technical and business training courses as well as technical consulting, expert<br />

witness and consultation work. He can be reached at 847-867-7363 or by email:<br />

Lclaus@NNiTraining.com. You can learn more about NNi at www.NNiTraining.com.<br />

DIFFICULT FASTENING APPLICATIONS - PART 2<br />

THIN-WALLED PLASTIC BOSSES<br />

Fasteners are often overlooked and “underconsidered”<br />

when being designed into a product. It is for<br />

this reason that even the simplest fastener can wreak<br />

havoc for the unsuspecting or ill-prepared manufacturer.<br />

The wrong choice can lead to serious headaches in<br />

manufacturing, or worse yet, failures once the product<br />

makes it into service.<br />

Without trying to sound too dramatic, there isn’t<br />

really a single fastener or fastener application that we<br />

can take for granted. Even the screw that holds a cheap<br />

child’s toy together is all important to a harried parent<br />

if it should break leaving a frustrated and cranky child<br />

in its wake. This means that there is no automatic<br />

guarantee that things will work without some preplanning<br />

and forethought. It also means that there are<br />

some applications we must be especially careful with.<br />

This three-part series investigates three particularly<br />

challenging fastener applications. In the first part of this<br />

series, we looked at thread forming into thin sheets. We<br />

learned how thin sheet thickness only allows a couple<br />

of pitches of thread engagement, making them very<br />

vulnerable to threads stripping and placing them near<br />

the top of the list of difficult fastening problems. In<br />

this part of the series, we will investigate fastening into<br />

thin-walled plastic bosses. The final segment will look<br />

at the challenges of connecting two or more dissimilar<br />

materials together.<br />

To consider the challenges of fastening thin-walled<br />

bosses, we must first consider plastics themselves.<br />

There is a wide assortment of different plastic materials<br />

TECHNICAL ARTICLE<br />

available today which provide an even wider assortment<br />

of mechanical and physical properties. Plastics are<br />

polymers, meaning that they are comprised of long<br />

chains of repeating molecules. Plastics broadly fall into<br />

two categories, semi-crystalline and amorphous. Semicrystalline<br />

polymers exhibit regions where these long<br />

molecules arrange themselves in an orderly fashion (a<br />

crystalline structure) and regions where they are simply<br />

randomly intertwined (amorphous structure). Amorphous<br />

plastics are entirely randomly intertwined, like a bowl of<br />

spaghetti noodles.<br />

This different molecular structuring has a dramatic<br />

influence on the material’s performance characteristics.<br />

Amorphous plastics tend to be more like glass. In fact,<br />

the word “glass” is often part of the descriptive terms<br />

associated with this category of plastics, and most<br />

amorphous plastics are clear in their natural state.<br />

Most amorphous plastics are considered “engineering<br />

plastics”, or plastics that offer higher performance and<br />

enhanced capabilities when compared with commodity<br />

plastics. Engineering plastics are what designers choose<br />

and manufacturers use to make high-end plastic parts<br />

for multiple industries including automotive, consumer<br />

products, electronics, aerospace, and medical to<br />

name but a few. Typical engineering plastics that are<br />

amorphous include Polycarbonate (PC), Acrylonitrile-<br />

Butadiene-Styrene (ABS), and Polyphenylene Oxide<br />

(PPO). Of course, not all engineering plastics are<br />

amorphous, the polyamides being an excellent example<br />

of a semi-crystalline engineering plastic.<br />

CONTINUED ON PAGE 92

12<br />

THE DISTRIBUTOR’S LINK<br />

Bruno Marbacher<br />

Bruno Marbacher earned his mechanical engineering degree in Switzerland, he also holds a<br />

business degree. He started out as a tool and die maker (poly-mechanic) and over the years he<br />

has held various management positions in quality and engineering. During his time in America<br />

he has developed and given numerous seminars on topics related to the proper use of mechanical<br />

fasteners and machine elements, and assists engineers in solving fastening/assembly issues. His<br />

has groomed and directed many young engineers in fastening/assembly technology. He now<br />

offers his 40 years of experience through writing and lecturing.<br />

THREAD-FORMING SCREWS FOR PLASTICS<br />

Dear Reader: In this article we cover thread-forming<br />

screws. We will address thread-cutting screws and<br />

threaded insert in another issue. Thread-forming<br />

screws can only be used in pliable plastics, such as<br />

thermoplastics. Fastening items to a plastic part has its<br />

own challenges. Typical choices are using some sort of<br />

inserts or using thread-forming or thread-cutting screws<br />

designed for plastic.<br />

In most instances, using some sort of thread-forming<br />

screws is the most cost-efficient way. However, there are<br />

instances when using a threaded insert is more suitable.<br />

Things To Consider<br />

There are a few things that must be considered when<br />

fastening things to plastic. For example:<br />

¤ Is it a high-volume assembly?<br />

¤ Does the piece of equipment ever have to be<br />

taken apart during the life of the part?<br />

¤ Does it need to be re-assembled for maintenance<br />

and repair?<br />

¤ How often does it need to be reassembled?<br />

¤ Does the consumer need to assemble or<br />

re-assemble parts?<br />

Thread-Forming Screws<br />

Thread-forming screws are screws that can form<br />

their own threads when driven into the material.<br />

Plastic requires a special thread profile, using regular<br />

TECHNICAL ARTICLE<br />

tapping screws can result in residual stresses in the<br />

plastic possibly degrading the structural integrity of the<br />

assembly. The various forming screws for plastic offer<br />

more flexibility to quickly assemble components with<br />

fewer fasteners.<br />

When choosing thread-forming screws, the first step<br />

is to decide what type of thread-forming screws are best<br />

suited for the application. Screws for plastic applications<br />

are classified into two categories: thread-forming and<br />

thread-cutting.<br />

Thread-forming screws, generally, perform best in<br />

thermoplastics. They do not produce waste. The threads<br />

enter the plastic and displace it into the spaces between<br />

the threads. Thus, creating a very tight secure fit.<br />

It’s important to understand the category of plastic one<br />

is fastening into. There are three main categories:<br />

¤ Thermoplastics<br />

¤ Thermosetting plastics<br />

¤ Elastomers<br />

CONTINUED ON PAGE 94

14<br />

THE DISTRIBUTOR’S LINK<br />

Guy Avellon<br />

Guy Avellon has been in MRO and Fastener Distribution for over 30 years, in such positions Sales<br />

Engineer, Chief Engineer, Manager of Product Marketing, Product Engineering & Quality and<br />

Director of Quality & Engineering. He founded GT Technical Consultants where he performs failure<br />

analysis, lectures on fastener safety, works for law firms and designs/audits Quality systems. He is a<br />

member of SAE, is Vice Chairman of the ASTM F16 Fastener Committee, Chairman of the F16.01 Test<br />

Methods Committee and received the ASTM Award of Merit in 2005. Guy can be contacted at 847-<br />

477-5057, Email: ExpertBoltGuy@gmail.com or visit www.BoltFailure.com.<br />

WHAT DISTRIBUTORS NEED TO KNOW<br />

ABOUT TORQUE IN ASSEMBLIES<br />

While torque may seem universal there are three<br />

specific industries that apply torque differently; structural,<br />

maintenance and mass assemblies.<br />

In a bolted joint, torque is measured in two different<br />

planes that are perpendicular to one another. Torque is<br />

a combined relationship between force, times distance<br />

and tension. Torque measures the reaction of rotational<br />

movement of the fastener, while tension measures the<br />

longitudinal movement of the same fastener. There are<br />

many assembly devices that analyze these forces.<br />

The amount of energy that is applied to the bolt from<br />

rotation to create tension is determined by the energy<br />

losses due to the friction between the surfaces of the<br />

rotating parts and the joint. Therefore, the assembled<br />

parts need to be new, no deformities and clean. The<br />

relationship between the applied torque and the tension<br />

generated in the joint is the torque-tension<br />

relationship.<br />

The mass assembly of products include the<br />

automotive, truck and bus industries to name a few,<br />

excluding the electronics industries because vehicles<br />

experience heavy loading, vibration and shock. Also,<br />

vehicles can become very dangerous to life and property<br />

if something breaks or loosens.<br />

Recently Rivian automotive has recalled approximately<br />

13,000 of its vehicles for a loose steering assembly. It<br />

was reported that the fastener connecting the front upper<br />

control arm and steering knuckle “may not have been<br />

sufficiently torqued.”<br />

The question to be asked is, why wasn’t there<br />

CONTRIBUTOR ARTICLE<br />

sufficient torque applied? How was the assembly<br />

tightened? Is there a torque calibration issue? Was the<br />

output data not interpreted correctly?<br />

Automotive assembly lines use a variety of<br />

programmable, digital power tools for assembly that will<br />

transmit data, such as torque and angle, to the data<br />

processor for error-proofing. The torque-angle measurement<br />

is a most accurate tool used for solid and stiff joints. In<br />

most cases the turn will negate friction variables, which is<br />

why a pre-torque is first applied to establish a hard base<br />

without any further joint compression.<br />

Some programmable nut runners and power screw<br />

drivers will operate on an X-Y-Z axis that will locate the<br />

next screw or nut to be tightened and will not allow<br />

another part to be tightened until that prior task has been<br />

completed. This action greatly aids with proper tightening<br />

sequence as the clamp load is criss-crossed so the load<br />

is evenly distributed.<br />

It must be realized that with all of the torque aids, it<br />

will not always mean that the preload has been achieved.<br />

This depends upon how the data is monitored and<br />

interpreted and if the parts tightened are within tolerance.<br />

If the torque and angle have been achieved within a<br />

certain per cent window, then the joint is good.<br />

However, if the torque angle goes significantly<br />

beyond the expected tolerance window to achieve the<br />

proper torque, this means the joint was not solid and<br />

there was interference between the joint, such as a burr,<br />

unexpected lubrication or even a non-conforming part that<br />

produced compression or resistance.<br />

CONTINUED ON PAGE 96

26<br />

THE DISTRIBUTOR’S LINK<br />

Robert Footlik<br />

Robert B. Footlik, PE is a retired Professional Industrial Engineer. With over 50 years’<br />

experience as a Warehouse and Logistics Consultant to a wide variety of clients including<br />

Fastener Distributors, Bob has a wealth of valuable information for our industry and he is<br />

willing to share it. While Footlik & Associates is now closed, his expertise is still available<br />

to his friends and our readers. For friendly advice, a second opinion or just to start a<br />

conversation, he can be reached at robert@footlik.net.<br />

HIGH PERFORMANCE DISTRIBUTION UPDATE<br />

When it comes to warehouse improvement, every<br />

Fastener Distributor is looking for the elusive “silver<br />

bullet” that will raise productivity, quality, morale,<br />

customer satisfaction and profits without a high cost in<br />

terms of both dollars and time.<br />

The latest media craze to achieve this goal is<br />

“Artificial Intelligence”, which was once known as<br />

“Machine Learning,” by an earlier generation as “Data<br />

Mining” and by those who are old enough to have<br />

some as, “Common Sense.” The differences over the<br />

years can be measured in the amount of information or<br />

data analyzed and the time required to reach a viable<br />

conclusion. Good managers have been doing this since<br />

ancient times and great managers have exploited the<br />

process for both profit and advantage.<br />

Let us examine new technologies based on what you<br />

can do now, what you can do better and what you will<br />

be doing in the not too distant future. The objective is<br />

to prepare your operation for optimization in every area<br />

and then apply technical enhancements as they become<br />

available. Along the way, there is a ton of money to be<br />

made/saved without having to invest very much time<br />

and capital. There is plenty of “low hanging fruit” to be<br />

harvested if you know where to look.<br />

Filling The Warehouse Using Enlightened<br />

AI Purchasing<br />

Marketing in the front office should know what the<br />

customers want to purchase, but all too often, it is<br />

the warehouse that suffers the consequences of inept<br />

CONTRIBUTOR ARTICLE<br />

ordering. At the very least, there should be a feedback<br />

mechanism in place to facilitate communication. This can<br />

be as simple as a prominent pallet rack or floor storage<br />

area labeled, “Buyers Boo-Boos” or as sophisticated<br />

as a daily or weekly listing of product movement by<br />

family group, vendor or even individual Stock Keeping<br />

Units (SKU). With the amount of inventory management<br />

sophistication now available to the Fastener Industry,<br />

one could easily become inundated by the data, but<br />

Artificial Intelligence (AI) programs offer a way to analyze<br />

massive amounts of data looking for usable patterns<br />

and presenting the information graphically as well as<br />

charted.<br />

Using AI to identify and eliminate old inventory is<br />

never wrong unless your business model is to be the<br />

warehouse of last resort. Just like ChatBot and other<br />

programs, human intervention must be used to define<br />

the parameters, identify the proper metrics and review<br />

the results. Whitworth thread fasteners for example are<br />

probably not coming back, especially in countries that<br />

have embraced metrics. Nevertheless, if these fasteners<br />

are the basis of your business eliminating this family<br />

means oblivion.<br />

The objective of any AI program should be to analyze<br />

continuously the data required to actually know what is<br />

going on with every product you sell. The first innovator<br />

who puts this in place ill have a significant marketing and<br />

warehousing advantage. Unfortunately, an AI inventory<br />

module for your Warehouse Management System (WMS)<br />

probably is not yet available.<br />

CONTINUED ON PAGE 98

28<br />

THE DISTRIBUTOR’S LINK<br />

Jim Truesdell<br />

James Truesdell is President of Brauer Supply Company, a distributor of specialty<br />

fasteners, insulation, air filtration, and air conditioning with headquarters in St. Louis.<br />

Mr. Truesdell is adjunct professor at Saint Louis University and Webster University.<br />

An attorney and frequently published writer, he is the author of “Total Quality<br />

Management: Reports From the Front Lines”.<br />

FTC SPARKS DEBATE WITH PROPOSED<br />

REGULATION BANNING NON-COMPETES<br />

For many decades wholesaler-distributors and other<br />

businesses have utilized “non-compete” agreements with<br />

key employees as a means of protecting confidential<br />

business information such as pricing, key relationships,<br />

marketing strategy, and proprietary matters from unfair<br />

disclosure to competitors. They have put a brake on efforts<br />

of some employees to parlay their insider knowledge into<br />

bigger compensation from competitive companies who<br />

might wish to “harvest” that knowledge from new workers<br />

coming on board. Within the confines of reasonableness<br />

(limitations in time and geographic markets) the courts<br />

have been supportive of these agreements. Recent years,<br />

however, have seen many states chip away at these<br />

“contracts” as an unreasonable restraint on trade and an<br />

unfair curb on workers’ freedom due to perceived unequal<br />

bargaining situations.<br />

This year, the Federal Trade Commission (FTC)<br />

launched a broad attack on such agreements with a<br />

regulation, proposed in January, that would outlaw noncompetes<br />

in a large segment of instances and would<br />

even invalidate existing agreements with employers<br />

being obligated to inform their workers that existing<br />

agreements would no longer be valid. The implications<br />

of this, if enacted, will be widespread in affecting the<br />

way companies approach the labor market and how<br />

they define and protect their critical information. It may<br />

accentuate the current problems companies face in<br />

stabilizing work forces and might well lead to inflationary<br />

CONTRIBUTOR ARTICLE<br />

wage pressures. It might, however, be confirming a<br />

trend towards recognizing that these agreements and<br />

the uncertainty of workers’ options could be in need of<br />

overdue reform. People and organizations on all sides<br />

of the debate have been weighing in during the FTC’s<br />

comment period. Reportedly, the FTC received more than<br />

17,000 comments on the proposed changes during the<br />

open period which ended April 19. The rule will go into<br />

effect 180 days after it is finalized. Observers such as<br />

the Council of Insurance Agents and Brokers (CIAB) say<br />

they do expect it to be finalized. After all, it is being<br />

strongly pushed as an accomplishment that the Biden<br />

Administration can tout in the upcoming election.<br />

A non-compete is a restrictive covenant agreement<br />

that limits a worker’s ability to work in a specific job<br />

To be valid it has traditionally only been enforceable if<br />

limited to a particular industry, for a limited time (which<br />

generally is less than a year), and within a limited<br />

geographic market. The whole idea is that a person<br />

should not be prevented from earning a living. This<br />

limiting principle has found strong backing amongst<br />

worker advocates, labor unions, and people who<br />

themselves find themselves subject to such restrictions.<br />

As millennials and Gen Z people begin to populate the<br />

workplace they bring a stronger orientation to work-life<br />

balance and assertiveness against employer control<br />

which gives opponents of these agreements more<br />

political leverage.<br />

CONTINUED ON PAGE 100

30<br />

THE DISTRIBUTOR’S LINK<br />

ROTOR CLIP COMPANY INC.<br />

187 Davidson Avenue, Somerset, NJ 08873<br />

TEL 1-800-557-6867 FAX 732-469-7898 EMAIL sales@rotorclip.com WEB www.rotorclip.com<br />

ROTOR CLIP EXPANDS TO TEXAS WAREHOUSE<br />

AND LOGISTICS FACILITY<br />

With over 65 years of manufacturing and hundreds<br />

of years of combined engineered experience, Rotor<br />

Clip has been the global leader in the manufacture of<br />

retaining rings, wave springs and hose clamps. With<br />

manufacturing in the United States and Europe and an<br />

extensive network of global warehouses and distribution<br />

partners, we’re able to supply and meet customers’<br />

production requirements and timelines worldwide.<br />

In order to serve a global market, Rotor Clip<br />

continues to invest in strategically aligning distribution<br />

and sales efforts to support our customers. We have<br />

the systems in place to react to our customers’ needs<br />

by having the right people, equipment, and resources to<br />

supply products when and where they are needed.<br />

Headquartered in Somerset, New Jersey at our<br />

vertically integrated manufacturing<br />

facility and engineering offices,<br />

Rotor Clip has five additional<br />

locations including:<br />

¤ Czech Republic:<br />

Manufacturing, Sales,<br />

Engineering, Quality and<br />

Customer Service<br />

¤ United Kingdom: Sales,<br />

Engineering, Customer<br />

Service & Warehouse<br />

¤ Germany: Sales Engineering and<br />

Customer Service<br />

¤ China: Sales, Engineering, Quality,<br />

Customer Service and Warehouse<br />

Rotor Clip recently expanded operations to include<br />

a new logistics distribution center in Fort Worth, Texas.<br />

The new 50,000 sq ft warehouse will expand our global<br />

finished product storage capabilities, accommodating<br />

our customers in a more centralized location near global<br />

carrier and transportation distribution hubs. “We’re a<br />

global company that literally holds the world together,<br />

one ring at a time. We’ll continue to invest in equipment<br />

and facilities to ensure the expanding global marketplace<br />

has access to the highest quality rings and springs in the<br />

world,” states Craig Slass, Co-President of Rotor Clip.<br />

BUSINESS FOCUS ARTICLE<br />

ROTOR CLIP COMPANY INC.

32<br />

THE DISTRIBUTOR’S LINK<br />

Joe Dysart<br />

Joe Dysart is an Internet speaker and business consultant based in Thousand Oaks,<br />

California. A journalist for 20 years, his articles have appeared in more than 40<br />

publications, including The New York Times and The Financial Times of London.<br />

During the past decade, his work has focused exclusively on ecommerce.<br />

Telephone: 631-256-6602; web: www.joedysart.com; email: joe@dysartnewsfeatures.com<br />

USING AI TO HAVE A CONVERSATION<br />

WITH YOUR DATABASE<br />

Early adopters are using AI to have daily conversations<br />

with their databases to mine business insights -- freeing<br />

them up from keyboards forevermore.<br />

The capability -- for workers at a fastener distributor<br />

to talk with their company database each morning to<br />

glean insights on how to further maximize business<br />

profits each day -- may seem like sci-fi to some.<br />

But for those in the know, chatting daily with their<br />

databases -- as if they’re talking with Siri, Alexa, Google<br />

Assistant, or a similar voice interface system -- has<br />

become second nature.<br />

“As consumers, we’ve grown accustomed to simply<br />

asking our smart speakers or mobile assistants to<br />

authoritatively resolve any factual questions or trivia<br />

disputes, because it’s that much faster,” says Chen<br />

Zhang, chief technology officer, RAIN, a voice tech<br />

company.<br />

“Alexa, Google Assistant, and Siri have grown<br />

incredibly robust in the knowledge graphs they consult<br />

to perform these tricks of effortless data access -- and<br />

clever in how they return results that balance brevity with<br />

some helpful context.<br />

“This affordance of voice tech as a rapid, convenient<br />

gateway to knowledge can be even more transformational<br />

for employees, for whom knowledge access is not a<br />

trivial matter of exploring a curiosity, but a fundamental<br />

part of doing their jobs.<br />

“This is especially true for members of the deskless<br />

workforce, employees whose hands and eyes are<br />

CONTRIBUTOR ARTICLE<br />

EARLY ADOPTERS ARE USING AI TO HAVE CONVERSATIONS<br />

WITH THEIR DATABASES<br />

frequently tied up with their work.”<br />

Abhishek Shanbhag, AI and automation practice<br />

head at Acuvate, agrees: “A few years back, voice<br />

search and voice-based assistants were more a novelty<br />

than common parlance.<br />

“With the advent of more powerful AI, natural language<br />

processing and speech recognition technologies, AI-based<br />

voice search and voice support have come to the forefront<br />

in various industrial use cases.”<br />

In practice, such voice-enabled systems allow<br />

fastener distributor workers to grab a quick, business<br />

data insight before, during, or after a meeting.<br />

And they also enable workers to converse with<br />

their databases on a specific facet of their business<br />

-- enabling them drill-down with follow-up questions<br />

and what-ifs to retrieve specific solutions for specific<br />

challenges.<br />

CONTINUED ON PAGE 104

34<br />

THE DISTRIBUTOR’S LINK<br />

Joe Shoemaker<br />

Joe is an accomplished strategic marketing leader with over 20 years of executive<br />

leadership experience in industrial manufacturing and B2B sectors. Joe’s expertise<br />

includes brand leadership, product development, demand generation, digital and<br />

social media strategy, messaging and communications strategies, and market<br />

intelligence. He has built global brand strategies for multi-brand market leaders<br />

driving them to prominent positions in their respective markets. Joe can be reached at<br />

36shoe@gmail.com or 330-720-0552.<br />

THE POWER OF BRAND MESSAGING: UNLEASHING<br />

YOUR POTENTIAL IN THE FASTENER INDUSTRY<br />

In today’s increasingly competitive fastener industry,<br />

the importance of crafting a powerful and consistent<br />

brand message cannot be understated. A robust brand<br />

message is a narrative that permeates your company,<br />

product line, and customer interactions. It’s not just about<br />

what you do, but why you do it - the unique value you bring<br />

to your customers. So, how do you shape this message,<br />

and more importantly, how do you convey it effectively?<br />

Develop Your Core Message<br />

First, understand your Unique Selling Proposition<br />

(USP) and translate it into a compelling narrative that<br />

speaks to your customers. What sets you apart from your<br />

competitors? Perhaps it’s your fast delivery times, your<br />

experienced team, or a patented feature of your fasteners.<br />

Your USP should be a central part of your brand message.<br />

This narrative should encapsulate what sets you<br />

apart from the competition. Whether it’s your superior<br />

quality, innovative designs, or exceptional customer<br />

service, your brand message should resonate with your<br />

customers’ needs and aspirations.<br />

Balance Of Print And Digital<br />

Once you have a solid brand message, the next step<br />

is to disseminate it effectively across various platforms.<br />

In today’s digital age, it’s easy to spread yourself across<br />

various online channels. However, print media still has<br />

significant value, particularly in the B2B industrial sector.<br />

A well-executed print campaign, in magazines like LINK,<br />

can offer visibility, credibility, and lasting impact that a<br />

CONTRIBUTOR ARTICLE<br />

digital ad may struggle to match.<br />

Social media, email newsletters, and website content<br />

can be great for delivering regular, timely updates and<br />

engaging with your customers. But print advertising adds<br />

a tactile, personal touch that digital can’t replicate. It<br />

shows that you’re invested in your brand and willing to put<br />

it out there, quite literally, in your customers’ hands.<br />

Moreover, combining print and digital channels can<br />

reinforce your brand message. A striking print ad can<br />

create an initial impression, while targeted digital content<br />

can further educate and engage potential customers. A<br />

consistent message across these platforms ensures that<br />

whether a customer finds you through a magazine ad or a<br />

LinkedIn post, they immediately understand who you are<br />

and what you stand for.<br />

Consistency Is Key<br />

Consistency, both in content and design, is crucial in<br />

brand messaging. This helps build brand recognition and<br />

trust. Whether it’s a print ad in a trade magazine, a blog<br />

post, or a social media update, your message should be<br />

consistent.<br />

In conclusion, while crafting your brand message<br />

takes time and thoughtful consideration, the payoff<br />

can be significant. A well-articulated and consistently<br />

applied brand message, disseminated via a balanced<br />

mix of print and digital media, can elevate your visibility,<br />

credibility, and connection with customers in the fastener<br />

industry. It’s not just about being seen—it’s about being<br />

remembered.<br />

JOE SHOEMAKER

36<br />

THE DISTRIBUTOR’S LINK<br />

INDUSTRIAL FASTENERS INSTITUTE<br />

6363 Oak Tree Boulevard, Independence, OH 44131<br />

TEL 216-241-1482 FAX 216-241-5901 EMAIL info@indfast.org WEB www.indfast.org<br />

IFI ANNOUNCES NEW BOARD LEADERSHIP AND<br />

DIVISION CHAIRS by Dan Walker, Managing Director<br />

¤ Vice-Chairmain - Doug Carlton - Click-Bond, Inc.<br />

¤ Tech. Chairman - Mike Mowins - IFI<br />

¤ ALMA Tech. Chair - David Roberto - Bristol Industries, LLC<br />

Board Representatives<br />

¤ Devin Wilson - Parker Fasteners<br />

¤ Bob Gurrola - Howmet Fastening Systems<br />

¤ Wayne Drysol - CAM Aerospace<br />

GENE SIMPSON<br />

IFI BOARD CHAIRMAN<br />

The Industrial Fasteners Institute (IFI), has elected<br />

new leadership for the organization’s Board of Directors<br />

for the <strong>2023</strong>-2024 term. Gene Simpson of Semblex<br />

Corporation was selected to lead the board as Chairman,<br />

along with Dan Curtis of MacLean-Fogg Company as the<br />

new Vice Chairman, and Jeff Liter of Wrought Washer<br />

Mfg., Inc. as Ex-Officio Chair.<br />

In addition to the Board leadership, the following Board<br />

Representatives and Division chairs have been installed:<br />

Division 1 - Industrial Products<br />

Officers<br />

¤ Chairman - Rob Kocian - Auto Bolt<br />

¤ Vice-Chairman - Attsie Hashimoto - Unytite, Inc.<br />

Board Representatives<br />

¤ Brian Prodoehl - Valley Fastener Group, LLC<br />

¤ Steve Sherman - Industrial Rivet & Nut<br />

¤ Michele Clarke - Valley Forge & Bolt Mfg. Co.<br />

Division II - Aerospace Products<br />

Officers<br />

DAN CURTIS<br />

IFI BOARD VICE CHAIRMAN<br />

¤ Chairman - Jim Erbs - Safety Socket LLC<br />

Division III - Automotive Products<br />

Officers<br />

¤ Chairman - Steve Dixon - Camcar Innovations<br />

¤ Vice-Chairman - John Medcalf - Agrati, Inc.<br />

Board Representatives<br />

¤ Kevin Vollmert - ITW Shakeproof Automotive<br />

¤ Greg Rawlings - Nylok, LLC<br />

¤ Ryan Surber - ATF, Inc.<br />

Associate Suppliers Division (ASD)<br />

¤ Chairman- Jerry Bupp - National Machinery LLC<br />

¤ Vice-Chairman - Herb Gottelt - Metal Resource Solutions<br />

About IFI<br />

IFI is the leading voice representing the interests of the<br />

North American manufacturers of mechanical fasteners and<br />

formed parts, as well as the key suppliers to the industry,<br />

fostering their working together to shape the future of<br />

the industry. IFI represents the industry to its suppliers,<br />

customers, the government, and the public-at-large to advance<br />

the competitiveness, products, and innovative technology of<br />

the Member Companies in a global marketplace.<br />

To inquire about IFI membership, contact Dan Walker,<br />

Managing Director at dwalker@indfast.org or call 216-241-<br />

1482 for details on eligibility and benefits.<br />

TECHNICAL ARTICLE<br />

INDUSTRIAL FASTENERS INSTITUTE

THE DISTRIBUTOR’S LINK 37

38<br />

THE DISTRIBUTOR’S LINK<br />

Chris Donnell<br />

Chris Donnell is the National Sales Director for Scanwell Logistics International (CHI)<br />

Inc., specializing in Supply Chain Management, Inventory Control, Logistics Sales and<br />

Management. Chris excels at selling the “Solution” to advanced program analysis and<br />

implementation. A highly ambitious and effective team leader who thrives on the challenges<br />

of this industry, Chris currently oversees a National Sales and Partnership Program consisting<br />

of more than 100 Sales executives who focus primarily on SCM and Logistics development in<br />

most vertical markets. Contact Chris at 847-228-6789 or email: chrisdonnell@scanwell.com.<br />

WE’RE BACK?<br />

The world of logistics and supply chain management<br />

has certainly calmed down over the past year. It’s crazy<br />

to think but this time last year we were all trotting<br />

through massive manufacturing and service-related<br />

disruptions. Everyone was fearful of a potential west<br />

coast port strike, inflation was climbing at record levels,<br />

and ocean rates started to take a tumble due to poor<br />

import volumes from the Pacific Rim.<br />

Rather than rehash what we all went through during<br />

the pandemic, I wanted to review the past 6 months of<br />

<strong>2023</strong> and provide you with some insight into what we<br />

expect to happen over the next 6 months.<br />

Overall, the past 6 months have been relatively<br />

calm. Most service-related disruptions have subsided<br />

and congestion on the west coast has been eliminated.<br />

Rates have plummeted to near pre-pandemic levels and<br />

importers now have a more consistent data set from<br />

which to effectively manage their supply chain. Between<br />

the months of January and June, we saw ocean rates<br />

drop almost 70% year over year. We saw dwell time at<br />

the ports and most rail depots fall by more than 85%<br />

and overall carrier on-time performance rebound, albeit<br />

still taking into account their stance on “Blank Sailings”.<br />

So, what changed? How did a market which was ravaged<br />

for more than three years do an about-face within a few<br />

short months to return to a more manageable time?<br />

One reason (and I think I might have had a small<br />

CONTRIBUTOR ARTICLE<br />

part in this) is because importers and exporters became<br />

more aware of their supply chains and were able to<br />

bypass some of the existing disruptions and roadblocks.<br />

Supply chains became more resilient. Everyone started<br />

to really focus on exiting troublesome areas and adapted<br />

to the market resulting in the growth of quantifiable<br />

data. As an example, a year ago everyone was talking<br />

about the potential port strike between the ILWU and<br />

PMA; there was also talk about the rail situation and<br />

their union members looking to walk out; and what did<br />

importers and exporters do? They simply made subtle<br />

changes to their supply chain, re-routed cargo to avoid<br />

any potential issues, and followed the data. Instead of<br />

being reactive, we as an industry became proactive.<br />

Thankfully, for the most part, both crisis’ were avoided.<br />

Another reason the market changed so quickly was<br />

due to inflation. Make no mistake about it, this has<br />

made a lasting impact on the global trade market and<br />

there isn’t a country on the face of the earth that hasn’t<br />

been impacted in one way or another by the US market.<br />

For the first six months of <strong>2023</strong> purchasing fell off a cliff,<br />

we saw decreases in global trade fall some 55% overall,<br />

none more surprising than the 47% from China to<br />

North America. Consumer spending plummeted, causing<br />

inventories to skyrocket nationwide. In short, we went<br />

from one extreme to another in a matter of less than a<br />

year.<br />

CONTINUED ON PAGE 106

PROSPECT FASTENER<br />

THE DISTRIBUTOR’S LINK 39<br />

1295 Kyle Ct, Wauconda, IL 60084 TEL 1-800-822-6080<br />

EMAIL sales@prospectfastener.com WEB www.prospectfastener.com<br />

SPIRAL, CONSTANT SECTION & TAPERED SECTION RETAINING RINGS<br />

BUSINESS FOCUS ARTICLE<br />

Since the founding of the Rotor<br />

Express distribution partnership<br />

program in 2005, Prospect<br />

Fastener has been the master<br />

distributor for Rotor Clip. We<br />

stock in anticipation of your<br />

next order, so your supply chain<br />

experience remains consistent<br />

and reliable.<br />

Rotor Clip is the only manufacturer<br />

of every style of retaining ring,<br />

ensuring the most optimal solution<br />

for your application. Compared<br />

to traditional fasteners requiring<br />

threading, tapping, and other<br />

machining operations, retaining<br />

rings are installed into a groove on a shaft or in a bore<br />

creating a shoulder that resists thrust loading and keeps the<br />

assembly together.<br />

There are three main types of retaining rings:<br />

• Constant Section - features a uniform, constant<br />

section that makes a 3-point contact with the groove.<br />

• Tapered Section - gripping the entire periphery of<br />

the groove along the ring’s edge; easily installed<br />

with special pliers and applicators<br />

• Spiral Rings - wound from a single section of flat<br />

wire and providing 360-degree axial contact.<br />

Spiral retaining rings are an advanced solution for<br />

applications that require 360-degree contact with<br />

the groove and shoulder of the assembly. They<br />

are designed to allow expansion (unwind) to slip<br />

over shafts and contraction (wind) to squeeze into<br />

bores. These rings are manufactured by coiling a<br />

single flat wire and can be single or multi-turn in<br />

construction.<br />

PROSPECT FASTENER

40<br />

THE DISTRIBUTOR’S LINK<br />

Larry Borowski President<br />

GREENSLADE & COMPANY INC.<br />

2234 Wenneca Avenue, Fort Worth, TX 76102<br />

TEL 817-870-8888 FAX 817-870-9199<br />

EMAIL sales1@greensladeandcompany.com WEB www.greensladeandcompany.com<br />

SETTING ADJUSTABLE THREAD RINGS PART 2:<br />

HOW IT IS DONE<br />

In the last issue we laid the groundwork as to what<br />

the thread standards require for calibration or setting<br />

of adjustable thread ring gages. In this issue, we will<br />

get into the “nuts and bolts” of the calibration/setting<br />

procedure.<br />

The first thing you want to do is either choose a<br />

set plug style or familiarize yourself with what you are<br />

currently using. There are (2) main types, truncated and<br />

progressive.<br />

common, so we will be focusing on how they are used.<br />

As a point of information, a Progressive setting plug<br />

has a Hi pitch diameter section and a Lo pitch diameter<br />

section separated by an interruption in the thread form.<br />

The basic concept is to set on the Lo (front) end, and the<br />

ring should not go onto the Hi (back) end.<br />

Next, you want to either choose a style of adjustable<br />

ring or familiarize yourself with what you are currently<br />

using. There are (2) normal types, and both have locking<br />

screws and adjustment screws. These are called AGD<br />

or American Gage Design as defined in the ASME B47<br />

standard on Gage Blanks, and there is the Southern<br />

Style.<br />

Since the American Gage Design (AGD) is the most<br />

popular style, this is what we will be covering.<br />

TRUNCATED SETTING PLUG<br />

PROGRESSIVE SETTING PLUG<br />

Truncated setting plugs have a full form and a<br />

truncated section with a continuous thread and Pitch<br />

Diameter across both. Truncated set plugs are the most<br />

TECHNICAL ARTICLE<br />

AMERICAN GAGE DESIGN (AGD)<br />

CONTINUED ON PAGE 108

42<br />

THE DISTRIBUTOR’S LINK<br />

WING-HAMLIN COMPANY, INC.<br />

568 S Spring Rd, Suite C, Elmhurst IL 60126<br />

TEL 630-279-6161 EMAIL quotes@wing-hamlin.com WEB www.wing-hamlin.com<br />

WING-HAMLIN COMPANY CELEBRATES<br />

33 YEARS IN BUSINESS!<br />

The Wing-Hamlin Company was founded in 1990 by<br />

Terry Wing and Mike Hamlin. The handshake partnership<br />

between two career nut & bolt salesman has led to<br />

33 years of success built on core values of Integrity,<br />

Communication, and Professionalism. Over that time,<br />

Mike, Terry, and Terry’s son Cory Wing, have built Wing-<br />

Hamlin into a seven-person Manufacturer’s Representative<br />

firm located in Elmhurst, IL and servicing fastener and<br />

industrial distributors in the Midwest.<br />

Wing-Hamlin has five outside Sales Representatives<br />

and two inside support personnel. Mike Hoffman services<br />

Minnesota, Iowa, Nebraska, and the Dakotas. Mike joined<br />

the firm in 1998. Nicole Korb covers Wisconsin and<br />

Northern Illinois and has been with Wing-Hamlin since<br />

2007. Jeff Adams joined Wing-Hamlin in 2014 and covers<br />

Michigan and Illinois. Cory Wing started at the firm in<br />

2011 and services Illinois and Indiana. Mike Hamlin now<br />

specializes in MRO customers and company initiatives.<br />

Wing-Hamlin services the distribution marketplace<br />

supporting general distribution, MRO distribution, and<br />

VMI providers. Their long-term success and reputation<br />

in the industry can be attributed to decades of strong<br />

communication and follow-up with customers and principals<br />

to develop profitable and sustainable partnerships.<br />

They collaborate closely with every customer to help<br />

solve problems and develop sales opportunities through<br />

specialized inventory programs, custom packaging, kitting,<br />

and assortments. In addition, Wing-Hamlin works with<br />

engineers and product development specialists to develop<br />

custom per-print components with their manufacturing<br />

partners.<br />

Wing-Hamlin represents the highest quality suppliers<br />

LEFT TO RIGHT: MIKE HAMLIN, NICOLE KORB, MIKE HOFFMAN,<br />

CORY WING AND JEFF ADAMS<br />

in the fastener marketplace. Products sold include<br />

domestic and imported internally and externally threaded<br />

fasteners, washers, stampings, retaining rings, pins,<br />

clamps, anchors, rivets, sealants, fittings, and electrical<br />

components. Products are available in inch and metric<br />

dimensions made from ferrous, non-ferrous, and plastic<br />

materials.<br />

The Wing-Hamlin team has over 120 years of combined<br />

fastener industry experience and active members of<br />

MWFA and NFDA. They support each other to bring<br />

continued long-term success to customers and principals.<br />

Their value proposition of Integrity, Communication and<br />

Professionalism has carried them for 33 years and will<br />

continue to carry them in <strong>2023</strong> and beyond!<br />

BUSINESS FOCUS ARTICLE<br />

WING-HAMLIN COMPANY

THE DISTRIBUTOR’S LINK 43<br />

SPIROL is pleased to<br />

announce that Ford Aerospace<br />

Ltd based in South Shields,<br />

UK will be joining the SPIROL<br />

group of companies.<br />

Ford Aerospace was<br />

founded at Tyne Dock in 1910<br />

by Robert Ford, and the family<br />

business has most recently<br />

been led by the founder’s<br />

great-grandson, Chris Ford.<br />

The company specializes in<br />

manufacturing high precision<br />

metal components and subassemblies<br />

for the aerospace,<br />

industrial, and high-technology<br />

sectors.<br />

SPIROL’s well-established<br />

global footprint will take the<br />

UK based Ford Aerospace’s<br />

products to a wider<br />

international market. In<br />

addition, one of SPIROL’s core<br />

principles is to continuously<br />

reinvest back into the<br />

business to ensure long-term,<br />

enhanced success and better<br />

serve its customers.<br />

Speaking about the<br />

sale, Chris Ford said, “Ford<br />

Aerospace is, and always has<br />

been, here for the people,<br />

especially our dedicated<br />

and skilled team, and it was<br />

important that any new Ford<br />

Aerospace owner share the<br />

values that have been at the<br />

heart of the company for over<br />

100 years. Our two companies<br />

have a long history of working<br />

together, dating back to<br />

1980 where SPIROL licensed<br />

a specialized manufacturing<br />

process from Ford Aerospace,<br />

which is still in use today.<br />

SPIROL respects Ford’s strong<br />

position in the UK market and<br />

our product manufacturing<br />

knowledge.<br />

SPIROL and Ford’s approach to its<br />

employees and its customers align<br />

wonderfully, and I am excited to see<br />

our strong business carry on as part<br />

of the successful SPIROL group.”<br />

Ford Aerospace’s technical skills in<br />

‘space compensating’ management<br />

– the production of laminated and<br />

solid shims which ensures fast,<br />

precision tolerance compensation<br />

used on products such as fuselages,<br />

gearboxes and movable components<br />

– was a key offering that attracted<br />

SPIROL. These solid and laminated<br />

shims enable clients to reduce stock<br />

of individual shims and offers the<br />

option of “sizing” a particular shim<br />

by adjusting the shim pack to the<br />

desired thickness on assembly.<br />

These products simplify the assembly<br />

process while simultaneously reducing<br />

the overall cost of the assembly.<br />

Ken Hagan, a Division President<br />

at SPIROL said, “SPIROL is an<br />

engineering, manufacturing and sales<br />

driven company, and as such we seek<br />

to grow and expand in our product<br />

space. This includes acquiring and<br />

holding exceptional companies which<br />

fit well with our overall business, global<br />

strategy and culture of excellence. We<br />

are excited to have Ford Aerospace<br />

join SPIROL and to be able to offer<br />

a more complete solution to our<br />

customers in Europe and beyond. We<br />

anticipate running Ford as a standalone<br />

business unit within the SPIROL group<br />

of companies. By combining the<br />

capabilities of both companies, our<br />

objective is to enhance our valueadded<br />

offering to our customers both<br />

in technical expertise and products.”<br />

For more information contact<br />

SPIROL at Tel: 1-860-774-8571,<br />

Email: info@spirol.com online at<br />

www.spirol.com.

44<br />

THE DISTRIBUTOR’S LINK<br />

ALLIED TITANIUM, INC.<br />

1400 East Washington Street Sequim WA, 98382 TEL 1-800-725-8143<br />

EMAIL tristan@alliedtitanium.com WEB www.alliedtitanium.com<br />

ALLIED TITANIUM: GROUNDBREAKING NEW TECHNOLOGY<br />

By Tristan Phillips, Account Manager<br />

Allied Titanium was Founded by Christopher<br />

Greimes our CEO, in 2007. Christopher spent many<br />

years in the marine industry which inspired him to<br />

start Allied Titanium after witnessing relentless crevice<br />

corrosion in marine components made from stainless<br />

steel, especially chainplate corrosion on sailboats<br />

resulting in mast failure and the loss of life.<br />

Allied Titanium is a Delaware corporation with its<br />

manufacturing and sales facilities located in Sequim<br />

Washington. Allied Titanium is ISO9001 and AS9100D<br />

certified for both the design and manufacture of<br />

titanium products and has additional factories located<br />

in Taiwan, Thailand and China.<br />

Groundbreaking New Technology<br />

Christopher Greimes working with Allied Titanium<br />

board member Dr. Craig Feied has developed a new<br />

patent pending manufacturing process that dramatically<br />

lowers manufacturing time and cost. Using our process,<br />

a large bolt that takes a competitor 4-6 minutes to<br />

create can be done in just under a minute. As more<br />

of these new machines come online, Allied Titanium<br />

expects to reduce the end cost to buyers considerably.<br />

Why Titanium?<br />

Titanium is an impressive metal that offers<br />

tremendous benefits and has become highly valued in<br />

many industries. The following are some reasons why<br />

titanium is superior to other metals, especially in the<br />

maritime industry:<br />

Corrosion resistance:<br />

Titanium has a high<br />

resistance to corrosion, making it highly resistant to<br />

seawater, marine environments, and harsh chemicals.<br />

Unlike other metals such as steel and aluminum, it<br />

does not rust or corrode when exposed to saltwater<br />

or seawater, making it a valuable material for ocean<br />

components.<br />

TITANIUM CHAINPLATE – HANS CHRISTIAN 43 SAILBOAT<br />

TECHNICAL ARTICLE CONTINUED ON PAGE 110

46<br />

THE DISTRIBUTOR’S LINK<br />

COMPUTER INSIGHTS, INC.<br />

108 Third Street, Bloomingdale, IL 60108<br />

TEL 1-800-539-1233 EMAIL sales@ci-inc.com WEB www.ci-inc.com<br />

VMI & SIGNATURE CAPTURE<br />

by Dennis Cowhey<br />

Enhance Efficiency & Customer<br />

Service<br />

In today’s fast-paced business<br />

environment, efficient inventory<br />

management and seamless order<br />

processing are crucial for the success<br />

of fastener distributors. Computer<br />

Insights, Inc. has revolutionized the<br />

industry with its ERP system, The<br />

Business Edge TM , offering powerful<br />

features such as Vendor Managed<br />

Inventory (VMI) and Signature<br />

Capture. These functionalities have<br />

garnered immense praise from industry leaders who<br />

have experienced firsthand the transformative impact<br />

on their businesses. Let’s explore how these features<br />

have helped fastener distributors optimize operations and<br />

elevate customer service.<br />

Streamlined Inventory Management With VMI<br />

The Business Edge TM<br />

mobile programs are designed<br />

to run on various devices, including iOS or Android<br />

smartphones, tablets, and notebooks. This flexibility<br />

ensures that users can leverage the power of TBE Mobile<br />

on any device, regardless of their location. The system<br />

facilitates real-time two-way communication between<br />

mobile users and the main system, empowering remote<br />

users to stay connected and productive. The intuitive<br />

interface, like any other app on the device, enables users<br />

to navigate effortlessly and maximize efficiency.<br />

The VMI Mobile App from The Business Edge TM<br />

has<br />

proven to be a game-changer for companies like Ababa<br />

Bolt, A & A Bolt & Screw, and Epco Sales. Larry Lockshaw<br />

from Ababa Bolt lauds the user-friendly interface, simplified<br />

processes, and instant access to inventory information. The<br />

VMI system empowers distributors to track usage, control<br />

inventory levels, and offer extensive customer service<br />

options, as Andy Rodick from A & A Bolt & Screw highlighted.<br />

This comprehensive solution saves valuable time and<br />

resources, driving cost savings and improved efficiency.<br />

Real-Time Data Capture And Transfer<br />

TBE Mobile capabilities are native to The Business<br />

Edge TM<br />

system, resulting in an unparalleled speed of<br />

access. Field personnel can leverage various features,<br />

and Computer Insights, Inc. continuously adds new<br />

capabilities to meet evolving needs.<br />

BUSINESS FOCUS ARTICLE CONTINUED ON PAGE 112

48<br />

THE DISTRIBUTOR’S LINK<br />

MID-WEST FASTENER ASSOCIATION<br />

PO Box 5, Lake Zurich, IL 60047<br />

TOLL-FREE 1-800-753-8338 TEL 847-438-8338 EMAIL mwfa@ameritech.com WEB www.mwfa.net<br />

MWFA ANNOUNCES NEW VENUE FOR<br />

<strong>2023</strong> FSTNR WEEK By Nancy Rich<br />

Fastener Show, Training, Networking,<br />

Recreation All In One Week<br />

MWFA will hold FSTNR Week August 20th - August<br />

24th. This event has proven to be a significant week of<br />

opportunities bringing the fastener industry together. This<br />

year’s show and golf will be at Lincolnshire Marriott Resort in<br />

Lincolnshire, IL. This venue offers attendees the opportunity<br />

to stay on site for both events, saving on travel time and<br />

allowing for more networking! This upscale conference hotel<br />

is 18 miles from O’Hare International Airport. The resort has<br />

several areas for dining, indoor and outdoor pools, a gym,<br />

spa, theatre, and several other amenities.<br />

The week will kick off on Sunday (August 20th ) when<br />

the MWFA again will partner with Sleep in Heavenly Peace.<br />

SHP works with groups/communities to build beds for<br />

kids who don’t have their own. This event will take place<br />

at Abbott Interfast in Wheeling, IL. On Monday (August<br />

21st) Plant Tours, throughout the Chicago area, will be<br />

offered. Various companies will open their doors to tours.<br />

A schedule for each company will be posted allowing<br />

you to plan your day. Tuesday (August 22nd) morning a<br />

Print Reading Seminar will be held, taught by Sean Collis<br />

of Solution Industries. Sean will be teaching the basics<br />

to assist your employees in reading prints and avoiding<br />

costly mistakes.<br />

ASSOCIATION ARTICLE<br />

The 41st MWFA Fastener Show will be featured<br />

Tuesday afternoon. This show will be a Table Top format<br />

allowing for easy, economic exhibits. The show will be<br />

the Fastener Bash with an 80’s theme. Grab your 80’s<br />

outfit, there will be a prize for the best 80’s attire. On<br />

Wednesday (August 23rd) the 70th MWFA Golf Outing<br />

will be held at Crane’s Landing located at Lincolnshire<br />

Marriott Resort. The week doesn’t end there as a MWFA<br />

Mixer will be held August 24th at Real Time Sports in Elk<br />

Grove, IL.<br />

Fastener Training Institute will be participating in<br />

FSTNR Week by providing their Fastener Week program<br />

(August 21st-25th) for those desiring to achieve their<br />

Certified Fastener Specialist certificate. This week class<br />

offers intense education and plant tours. Students may<br />

then take a final exam to be eligible for the Certified<br />

Fastener Specialist (CCFS) designation. Registration<br />

available at www.fastenertrainingevents.com/fastenertraining-chicago.<br />

If you’d like to be on the plant tour schedule for<br />

August 21st, contact Nancy Rich mwfa@ameritech.<br />

net. You select the hours you’d like to allow<br />

industry friends to stop by. We will publish, ask for<br />

registrations but not require registration. Visitors<br />

must adhere to the published schedule.<br />

MID-WEST FASTENER ASSOCIATION

50<br />

THE DISTRIBUTOR’S LINK<br />

KINTER<br />

3333 Oak Grove Ave, Waukegan, IL 60087<br />

TEL 1-800-323-2389 FAX 847-623-0105 EMAIL sales@kinter.com WEB www.kinter.com<br />

UNVEILING A BIGGER, BOLDER KINTER:<br />

EMBRACING INNOVATION AND GROWTH<br />

You know Kinter as a manufacturer and distributor<br />

of niche fastener items, but behind the scenes, we’re<br />

amplifying our capabilities to accommodate the increasing<br />

needs of our valued customers.<br />

But we’re not just expanding in terms of physical space;<br />

we’re pushing the boundaries of innovation, too.<br />

Our relentless pursuit of solving customer problems,<br />

dedicated service support and custom-engineered solutions<br />

brings us to a bigger and bolder Kinter.<br />

We Are Growing!<br />

Kinter has experienced significant growth and facility<br />

expansion in the last ten years. In 2012, the company<br />

moved its headquarters from Gurnee, Illinois, to a new<br />

115,000-square-foot facility on Oak Grove Avenue in<br />

Waukegan. In 2018, further expansion resulted in the<br />

building of a 75,000-square-foot facility designed and<br />

constructed from the ground up located on the same street<br />

as the company headquarters, and is now used solely for<br />

warehousing, storage, and distribution.<br />

In 2022, the newest facility opened at 3211 Oak Grove<br />

Avenue with 95,000 square feet of warehouse space and<br />

an additional 17,000 square feet for office expansion and<br />

additional team members.<br />

“The opening of our newest facility increases our<br />

capacity and reflects our commitment to helping solve<br />

customer’s problems, regardless of project size.” - Paul<br />

White, president of Kinter<br />

The new facility will allow for further growth of Kinter’s<br />

campus, made up of three buildings that serve as the<br />

company’s worldwide headquarters, including leadership<br />

team and administrative functions, research and<br />

development, engineering, design and 3D prototyping, and<br />

product supply storage and fulfillment.<br />

BUSINESS FOCUS ARTICLE<br />

Engineering Lab<br />

This year, another area of expansion for Kinter has been<br />

the addition of an engineering lab located in the company’s<br />

headquarters building. The lab acts as an innovation<br />

center, supporting customers who need custom-engineered<br />

solutions and 3-D printed prototype validation. The new<br />

engineering lab represents increasing customer demand<br />

and the Kinter team’s technical and production expertise,<br />

knowledge of design and development programs, design<br />

validation, custom injection molding capabilities, reverse<br />

engineering, and more.<br />

“It’s exciting to see the growth of our design and<br />

engineering offerings, and having a dedicated space for<br />

innovation will allow for continued advancement into the<br />

future. From same-day prototype or injection molding to<br />

unique materials such as flexible resins, and more, we<br />

are able to create remarkable solutions for our customers’<br />

most challenging needs.” - Ryan Masek lead engineer<br />

Beyond our renowned reputation as a manufacturer and<br />

distributor of fasteners and display hardware, we’ve ignited<br />

a spark of growth and innovation that fuels our dedication<br />

to solving customer problems. Whether you are looking<br />

for X-Mas tree clips, binder posts and screws or unique<br />

fasteners, Kinter remains your dedicated partner for your<br />

niche hardware needs.<br />

Discover what Kinter can do for your business by visiting<br />

our website or contacting our team today to learn more.<br />

KINTER

52<br />

THE DISTRIBUTOR’S LINK<br />

ARAMID TECHNOLOGIES<br />

2200 E Williams Field Rd, Ste 200, Gilbert AZ 85295<br />

TEL 480-680-7242 EMAIL info@smartcert.tech WEB www.smartcert.tech<br />

SMARTCERT ANNOUNCES NEW FEATURES AND<br />

UPGRADES TO FREE STARTER SUBSCRIPTIONS<br />

Aramid Technologies, the developer of SmartCert®,<br />

announces its new SmartCert Request and SmartCert<br />

Packages features designed to enable subscribers to<br />

request certs from vendors and combine SmartCerts<br />

for multiple line items into one SmartCert for the entire<br />

shipment. This latest update supports SmartCert’s vision<br />

to create a centralized platform that simplifies all aspects<br />

of sharing quality documents between a company and<br />

its customers and vendors. In support of this update,<br />

the company will now offer free, full-featured Starter<br />

subscriptions for companies to try SmartCert before<br />

subscribing.<br />