December 2023

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DECEMBER <strong>2023</strong><br />

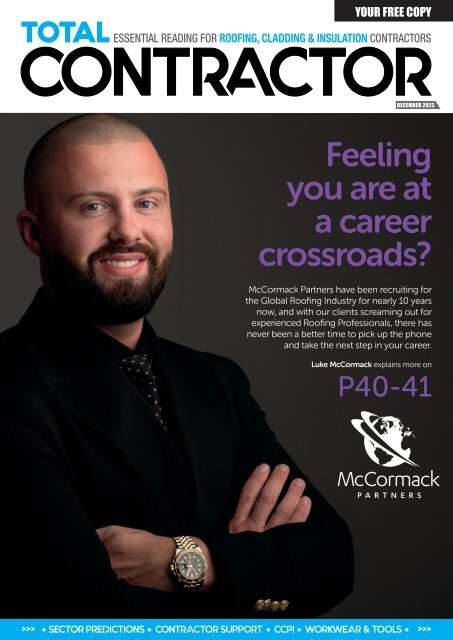

Feeling<br />

you are at<br />

a career<br />

crossroads?<br />

McCormack Partners have been recruiting for<br />

<br />

<br />

<br />

never been a better time to pick up the phone<br />

<br />

Luke McCormack explains more on<br />

P40-41<br />

>>> • SECTOR PREDICTIONS • CONTRACTOR SUPPORT • CCPI • WORKWEAR & TOOLS • >>>

RAINWATER<br />

SYSTEM<br />

ENDCAP<br />

MITRE BOX<br />

BOX GUTTER<br />

RUNNING OUTLET<br />

110° OFFSET<br />

3M DOWNPIPE<br />

LARGE HOPPER<br />

PROJECT OFFSET 110°<br />

Y BRANCH<br />

MANUFACTURER OF ALUMINIUM RAINWATER SYSTEMS<br />

SPECIALISING IN BESPOKE PRODUCTION<br />

GUTTERS DOWNPIPES FASCIA SOFFIT COPING SILLS CLADDING<br />

WISHING ALL OUR CUSTOMERS A HAPPY<br />

CHRISTMAS AND JOYOUS NEW YEAR<br />

SECRET FIX BOX GUTTER COMING SOON !!!<br />

Seamless Aluminium International Ltd<br />

Unit 6b, Solihull Building Trade Centre<br />

Olton Wharf, Olton, West Midlands B92 7RN<br />

Info@seamlessaluminium.co.uk<br />

+44 (0)121 765 4355<br />

www.seamlessaluminium.co.uk

Editor’s Intro<br />

MATT DOWNS<br />

EDITORIAL DIRECTOR<br />

MATTDOWNS@MEDIA-NOW.CO.UK<br />

07963 330774<br />

Feeling<br />

you are at<br />

a career<br />

crossroads?<br />

McCormack Partners have been recruiting for<br />

<br />

<br />

<br />

never been a better time to pick up the phone<br />

<br />

Luke McCormack explains more on<br />

P40-41<br />

If the last few years in construction have taught us anything, it’s that<br />

trying make predictions and forecasts about what lies ahead is a pretty a<br />

futile endeavour...<br />

But despite this, as it’s the <strong>December</strong> issue and we’ve reached the end of<br />

another tricky year, I think it’s always a good opportunity to look back on some<br />

of the key events for the sector, and attempt to highlight some of the trends,<br />

challenges and opportunities for roofers in 2024. With this in mind, we’ve<br />

contacted a whole host of individuals from throughout the roofing and cladding<br />

sector supply chain for their thoughts on <strong>2023</strong>, and what might be in store for<br />

2024. As you’d expect, October’s introduction of the Building Safety Act features<br />

heavily, and the whole focus on competence, increased responsibilities,<br />

improving safety standards and regulatory compliance that stems from this is a<br />

key theme in the responses you can read from page 14. Whilst the importance<br />

of training and the development of knowledge and skills to raise standards<br />

rightly get a big mention, contributors also highlight the opportunities in solar<br />

PV, which look set to continue to grow in 2024.<br />

Elsewhere in this issue, Ruth Scarrott of NFRC outlines the support available to<br />

contractors looking to recruit and retain staff (page 12); Steve Leech of LRWA<br />

explains how contractors can benefit from the association’s new initiatives<br />

(page 24); Daniel Weait of Marley discusses the Code for Construction Product<br />

Information and explains why roofers really need to take note (page 30); we put<br />

the questions on all things fixings to Brian Mack of EJOT UK (page 42); and Mike<br />

Wyles of Siderise Insulation explains why inspecting and recording passive fire<br />

protection installations is so important on page 48, plus much more!<br />

Enjoy the issue, and we’d like to wish all our readers and contributors a Happy<br />

Christmas and prosperous New Year!<br />

Matt<br />

Cover courtesy of McCormack Partners. Head to page 40 for an update<br />

from Luke McCormack. www.mccormack-partners.com<br />

FOLLOW US: TOTAL CONTRACTOR MAGAZINE<br />

SIGN UP FOR YOUR E-NEWSLETTER AT<br />

WWW.TOTAL-CONTRACTOR.CO.UK<br />

Advertising:<br />

Publishing Director: Andy Dunn<br />

DD: 01892 732 047<br />

Mob: 07963 330777<br />

Email: andydunn@media-now.co.uk<br />

Registered office: 1 Forstal Road, Aylesford, Kent, ME20 7AU<br />

Editorial Director Matt Downs<br />

DD: 01892 732 047<br />

Mob: 07963 330774<br />

Email: mattdowns@media-now.co.uk<br />

The content of Total Contractor magazine (and website) does not necessarily reflect the views of the editor or publishers and are<br />

the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or<br />

websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from<br />

information in this publication and do not endorse any advertising or products available from external sources. No part of this<br />

publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.<br />

Supported by:<br />

24<br />

With so much change and innovation<br />

happening in construction, the LRWA has recently<br />

launched regional ‘contractor days.’<br />

Find out more on page 24

Contents<br />

3 KEY FEATURES<br />

30<br />

14 WHAT’S IN STORE<br />

FOR 2024?<br />

We asked individuals from throughout the<br />

roofing and cladding sector supply chain to<br />

look back on the key themes from <strong>2023</strong>, and to<br />

provide their thoughts on what to be aware of in<br />

2024...<br />

30 BUILDING PRODUCT<br />

TRUST & CERTAINTY<br />

Daniel Weait of Marley discusses the Code for<br />

Construction Product Information (CCPI) and<br />

why roofers really need to take notice of the CCPI<br />

48 THE RECORDS SHOW...<br />

Mike Wyles of Siderise Insulation discusses the<br />

importance of inspecting and recording your<br />

passive fire protection installations<br />

FURTHER READING<br />

24 DRIVING GROWTH<br />

Steve Leech of the LRWA looks at some of the<br />

association’s latest initiatives to support contractors<br />

26 ROLLBACK RETENTIONS<br />

Tony Lawther of BriggsAmasco makes the case for<br />

abolishing the outdated retention process<br />

32 A CENTURY & STILL GROWING<br />

Stewart Britton of BMI UK & Ireland looks back on a<br />

century of manufacturing in Manchester for Icopal<br />

34 SOLAR PV: TACKLING DEBRIS<br />

James Robinson of Samac Fixings looks at a solution to<br />

help prevent dirt and debris gathering under solar panels<br />

54<br />

36 INVESTING & INNOVATING<br />

Andrew Hayward of Russell Roof Tiles looks back on a year<br />

of big investment in a tricky period for the sector<br />

50 THE RIGHT NUMBERS<br />

Sunny Lotay of PermaRoof Commercial explains what<br />

contractors really need to know about U-values<br />

54 PLAYING FAST WITH FASHION<br />

What has ‘fast fashion’ got to do with your workwear<br />

choices? Peter Dumigan of Snickers Workwear explains all<br />

4 TC DECEMBER <strong>2023</strong>

REGULARS<br />

12 NFRC ROOFING TALK<br />

Ruth Scarrott explains that the support is there to<br />

help contractors make a success of the<br />

recruitment process<br />

42 TOTAL TALK: BRIAN MACK<br />

We put the questions to Brian Mack of EJOT UK,<br />

discussing his career, the colorfast range of<br />

fixings, the importance of R&D and innovation in<br />

fastening solutions, and a whole lot more...<br />

46 KNAUF INSULATION<br />

TECH TALK<br />

Bradley Hirst outlines his top three tips for<br />

maximising space and storing insulation...<br />

49 QI BY QI<br />

As the experts at Quantum Insulation reach their<br />

final column, the team look back at some of the<br />

key events of the past couple of years<br />

INDUSTRY NEWS<br />

06 CHAMPION CROWNED!<br />

The SkillBuild National Finals took place in late November;<br />

find out who took home the Roof Slating & Tiling trophy!<br />

08 IOR & CIOB TAKE TO THE ROAD<br />

CEOs Kay Rose and Caroline Gumble have been discussing<br />

the benefits of the potential integration of IoR into CIOB<br />

SECTIONS:<br />

TOTAL<br />

ROOFING<br />

24<br />

TOTAL<br />

CLADDING<br />

42<br />

TOTAL<br />

INSULATION<br />

46<br />

10<br />

MCS (the Microgeneration<br />

Certification Scheme), the<br />

standards organisation for<br />

small-scale renewable<br />

energy and heat, has<br />

announced it has<br />

surpassed 4,000 MCS<br />

certified contractors.<br />

VEHICLES, TOOLS<br />

& WORKWEAR<br />

54<br />

DECEMBER <strong>2023</strong> TC 5

Industry News<br />

NFRC VQ ASSESSMENT<br />

SERVICE LAUNCHED<br />

NFRC has announced it has launched a new<br />

assessment service for a range of roofing<br />

and cladding NVQs at Levels 2, 3 and 4.<br />

It says delivery of VQs through the NFRC<br />

Assessment Service is based on the needs of<br />

the individual operative, and assessment can<br />

be done mostly on-site rather than all taking<br />

place at a college or exam centre.<br />

NFRC says on-site assessment means that<br />

the VQ assessor visits learners in the<br />

workplace, completing live assessments with<br />

the team, and this keeps written work to a<br />

minimum, and includes one-on-one<br />

professional discussions alongside witness<br />

testimonies from the operative’s site<br />

manager or colleagues.<br />

NFRC’s Careers Service says it can then<br />

support businesses to understand and access<br />

available CITB funding, to make assessment as<br />

cost neutral as possible, and the association<br />

points out businesses may be eligible to do this<br />

via CITB’s Skills and Training Fund.<br />

Firms can visit the NFRC website to find out<br />

if the NFRC Assessment Service meets their<br />

experienced worker assessment needs and<br />

how to get started. If this service isn’t the<br />

right fit, the NFRC Careers Service says it can<br />

help contractors find the right provider.<br />

Ruth Scarrott, NFRC’s Head of Careers,<br />

explained: “We are delighted to be launching<br />

this service in order to further support the<br />

roofing industry to upskill its experienced<br />

workers. Many experienced workers are now<br />

looking to gain a qualification because of the<br />

upcoming withdrawal of ‘Grandfather Rights’<br />

as a way of obtaining a CSCS card, but even if<br />

this isn’t something your particular workforce<br />

needs, your people are worth investing in, and<br />

gaining proof of competency can be an<br />

immense source of pride and confidence.”<br />

www.nfrc.co.uk/careers/<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

SKILLBUILD ROOF SLATING AND TILING<br />

CHAMPION CROWNED!<br />

The winners of the SkillBuild National Final<br />

<strong>2023</strong> have been announced, after 78<br />

construction trainees went head-to-head over<br />

three days of competition.<br />

SkillBuild, also known as the construction ‘skills<br />

Olympics’, is delivered by the Construction<br />

Industry Training Board (CITB) and showcases<br />

some of the brightest talent in construction. The<br />

prestigious competition brings together highly<br />

skilled learners and apprentices to battle it out to<br />

be crowned winner of their chosen trade.<br />

Following the Regional Qualifiers, which were held<br />

at various colleges across the UK earlier this year,<br />

the National Final took place at the Marshall<br />

Arena in Milton Keynes on 21st–23rd November.<br />

The event attracted around 1,000 visitors,<br />

exhibiting the variety of skills and career<br />

opportunities available within the industry.<br />

Across the three days competitors were tasked<br />

with constructing a project designed by an expert<br />

panel of judges, within an 18-hour timeframe.<br />

CITB says the project tests the individual’s<br />

knowledge and skills, as well as their ability to<br />

work under pressure, ensuring they adhere to<br />

health and safety protocols.<br />

The Roof Slating and Tiling competition was won<br />

by Jacob Blight of South Devon College, with<br />

Hamish Morgan of Edinburgh College taking<br />

Jacob Blight of South Devon College with his SkillBuild trophies<br />

second place and Aeron Murray of Leeds College<br />

of Building finishing third.<br />

Tim Balcon, CITB Chief Executive, said: “I always<br />

look forward to the SkillBuild events and this<br />

year’s final at the Marshall Arena has, once<br />

again, been a brilliant success! It’s fantastic to<br />

meet all the talented individuals and hear about<br />

their career aspirations, and I’m delighted we<br />

were able to welcome so many members of the<br />

public this year, too.<br />

“At a time when the industry is going through a<br />

skills shortage, it’s vital that we support this next<br />

generation of talent and encourage them to<br />

pursue their passions. SkillBuild has the potential<br />

to make a huge difference here, transforming an<br />

interest or a hobby into a full-time career, and I’d<br />

like to thank everyone involved in making this<br />

year’s competition possible. Finally,<br />

congratulations to all the winners and everyone<br />

who competed, you should all be incredibly proud<br />

of yourselves.”<br />

3 winners centre, l-r: Hamish Morgan, Edinburgh College<br />

(2nd place); Jacob Blight, South Devon College (1st place);<br />

Aeron Murray, Leeds College of Building (3rd place).<br />

6 TC DECEMBER <strong>2023</strong>

WestWood Liquid Technologies Limited<br />

31 Morris Road, Nuffi eld Industrial Estate,<br />

Poole, Dorset BH17 0GG<br />

Phone: +44 800 808 5480<br />

Liquid Applied Waterproofi ng Systems<br />

Car Parks • Flat Roofs • Metal Roofs • Gutters • Roof Terraces Balconies

Industry News<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

IOR AND CIOB ROADSHOW SHEDS FURTHER<br />

LIGHT ON POTENTIAL INTEGRATION<br />

QUICKGUIDES<br />

SUPPORT FROM<br />

THE ROOFLIGHT<br />

ASSOCIATION<br />

As the UK’s trade association representing<br />

the rooflight industry, the Rooflight<br />

Association publishes freely available<br />

guidance for specifiers on its website.<br />

With this in mind, details of regulatory<br />

requirements covering rooflights and roof<br />

windows in respect of the conservation of heat<br />

& power have now been assimilated into four<br />

new ‘Quickguides’, each covering the different<br />

recently introduced requirements of the four<br />

devolved nations of the UK.<br />

Rooflight Association Quickguides are<br />

designed to provide specifiers with the salient<br />

facts, in a series of brief and easily digested<br />

documents.<br />

Jeremy Dunn, Rooflight Association Director<br />

and Technical Committee representative,<br />

said:“These changes are another step in<br />

improving the thermal efficiency of buildings<br />

working towards the future homes standard<br />

and achieving net zero.”<br />

The new regulations were introduced at<br />

varying dates across the nations, with the<br />

latest being Approved Document L 2022 for<br />

Wales, Volume 2: Buildings other than<br />

Dwellings, which came into force earlier this<br />

year.<br />

The four new Quickguides 09EN, 09SCO, 09NI<br />

and 09WA, can all be downloaded free of<br />

charge from:<br />

www.rooflightassociation.org<br />

A week-long roadshow of Institute of<br />

Roofing (IoR) events to discuss the<br />

potential integration into the<br />

Chartered Institute of Building<br />

(CIOB) has been hailed a success<br />

by those involved.<br />

Hosted by Kay Rose (FIoR), CEO of the IoR, and<br />

Caroline Gumble, CEO of the CIOB, the five-day<br />

roadshow, which took place between Monday 30<br />

October <strong>2023</strong> and Friday 3 November <strong>2023</strong>, saw IoR<br />

members gather in London, the midlands, Scotland<br />

and the North West.<br />

The organisers say it gave IoR members the chance<br />

to discuss what the integration into CIOB would<br />

mean for them, enabled them to find out more on<br />

the proposals and learn about the CIOB and what it<br />

would offer.<br />

Commenting on the success of the events, Kay Rose<br />

(FIoR), CEO of the IoR, said: “We’d like to thank<br />

everyone who attended these important meetings,<br />

which gave us an opportunity to answer some key<br />

questions. I’d also like to personally thank Caroline<br />

Gumble for her unwavering support and for making<br />

the week enjoyable and successful.<br />

“The feedback from all of our members was<br />

generally positive, as they can see the benefits of<br />

joining a chartered, global organisation. The CIOB<br />

can offer our members great opportunities to<br />

network, develop knowledge and qualifications,<br />

increase their wider reach within the construction<br />

industry and achieve professional recognition within<br />

roofing and beyond.”<br />

Kay continued: “The IoR saw the need to change, to<br />

provide our members with a clear progression of<br />

opportunities in the future. Being part of the CIOB<br />

can offer positive growth, which will be a huge<br />

benefit for our members.”<br />

Kay also said the integration would not be “watering<br />

down” the qualifications, experience and knowledge<br />

already achieved by IoR members.<br />

Left to Right - Caroline Gumble, CEO of the CIOB<br />

and Kay Rose (FIoR) CEO of the IoR, travelled<br />

around the UK to discuss the benefits of a<br />

potential integration of IoR into the CIOB.<br />

She added: “This will not wipe clean<br />

the years of effort and dedication our<br />

members have already put into their<br />

profession. It will be enhancing this and opening<br />

doors to a wider network of contacts, more<br />

opportunities, professional training, support and<br />

guidance, which we believe can only be a positive<br />

move for us.<br />

“We encourage our members to take this<br />

opportunity with both hands and demonstrate your<br />

professionalism within a bigger organisation such as<br />

the CIOB, where we can really make our mark within<br />

roofing.”<br />

Caroline Gumble, CEO of the CIOB, added: “The<br />

week was hugely beneficial. We have been talking<br />

about our shared mission to improve the built<br />

environment for many months, and it was useful to<br />

hear the thoughts of current IoR members about the<br />

plans, to get their perspectives and insights, and<br />

explain how the integration might work for them.<br />

“CIOB has the broadest membership base of any<br />

professional body in the built environment sector<br />

with more than 47,000 members worldwide in a<br />

number of sectors, and we want to involve the IoR<br />

as experts in roofing and strengthen our community<br />

of modern professionals. The integration is an open<br />

conversation between us and the IoR, and we hope<br />

that, subject to approval by our respective boards, it<br />

will be a smooth process to complete next year.”<br />

Further discussions about the IoR and CIOB<br />

integration continue, and are expected to conclude<br />

in 2024. The organisations say a number of virtual<br />

Q&A sessions will take place early next year for IoR<br />

members to discuss the potential integration, as<br />

well as engagement opportunities for CIOB<br />

members. For more information about these, you<br />

can contact Kay Rose (FIoR), CEO of the IoR, at<br />

KayRose@instituteofroofing.org.<br />

8 TC DECEMBER <strong>2023</strong>

STILL<br />

THE<br />

MARKET<br />

LEADER<br />

PRICE<br />

DROP<br />

Multi-award winning aluminium<br />

roof lantern<br />

70,000+ installs<br />

National brand exhibitions<br />

Sales lead generation for Trade customers<br />

Fast KwikQuote service<br />

2.5m x 1.5m lantern, when ordered<br />

with glass, delivered from only<br />

£ 1292*<br />

+VAT<br />

* Price based on a standard range anthracite grey on white, 2.5m x 1.5m roof lantern ordered with glass. Delivery restrictions apply.<br />

madefortrade.co<br />

sales@madefortrade.co<br />

01642 610799

Industry News<br />

BIG BENEFITS FOR<br />

BURTON IRVINE<br />

BRANCH<br />

Burton Roofing Merchants has relocated and<br />

invested in a more extensive Irvine branch to<br />

enhance its product range and service<br />

offering in Ayrshire and the wider East<br />

Scotland.<br />

The new branch, which also<br />

carries the latest energy-efficient<br />

green technologies to help reduce its<br />

carbon footprint, sees over £200,000 invested<br />

to more than quadruple capacity from 18,400<br />

sq. ft. to 80,358 sq. ft. compared to the<br />

previous branch.<br />

The additional space means more product<br />

lines will be stocked to facilitate increased<br />

demand, particularly for solar and flat roof<br />

products, and it is the largest branch that the<br />

company has opened this year.<br />

The new Burton Roofing Merchants branch on<br />

Auchengate Business Park replaces the<br />

former Rinus branch, which Burton Roofing<br />

Merchants acquired in 2021 and was located<br />

at Mackintosh Place. The company aims for<br />

the expansion to lead to additional jobs within<br />

the year.<br />

Jon Smith, Operations Director at Burton<br />

Roofing, commented on the investment: “As a<br />

business, we have a purpose centred around<br />

helping customers enhance their businesses.<br />

The enlarged branch will help us deliver our<br />

promise by giving access to innovative roofing<br />

products combined with our Irvine team’s<br />

expert and friendly service.”<br />

More news, updates and interviews at www.total-contractor.co.uk<br />

CERTIFIED CONTRACTOR GROWTH AT MCS<br />

MCS (the Microgeneration Certification years of the scheme combined.<br />

Scheme), the standards organisation for<br />

At the end of 2022, MCS says it had fewer than<br />

small-scale renewable energy and heat, has<br />

2,000 solar PV contractors – whereas today, they<br />

announced it has surpassed 4,000 MCS<br />

have over 3,200. This growth mirrors the rapid<br />

certified contractors.<br />

rise in certified solar PV installations across the<br />

The organisation says the growth in the number UK and the growing demand amongst<br />

of certified companies installing low-carbon homeowners to generate their own home-grown<br />

technology highlights the growth in consumer electricity, reducing energy bills, claiming energy<br />

confidence in home-grown energy across the UK, independence, and decreasing their carbon<br />

and reflects the growing demand for MCS<br />

footprint.<br />

certified contractors across the nation.<br />

The scheme has also recorded over 200,000<br />

In October, MCS certified its 4,000th contractor, certified installations of small-scale technologies<br />

as the number of homeowners looking for<br />

in <strong>2023</strong>.<br />

certified installers to retrofit their homes with<br />

Ian Rippin, MCS CEO, explained: “MCS is<br />

solar panels, heat pumps and other renewable<br />

extremely proud to have certified more than 4,000<br />

technologies continued to grow. MCS says its<br />

contractors. It is extremely encouraging to see our<br />

certification is a mark of quality providing<br />

certified contractor base continuing to grow at<br />

assurance to consumers, and being MCS certified<br />

pace in support of the ever-growing demand for<br />

demonstrates that a contractor installs renewable<br />

small-scale renewable technologies.<br />

energy and heating systems to industry-expected<br />

levels of quality every time.<br />

“Our mission is to give people confidence in<br />

home-grown energy, and this enormous growth<br />

The organisation says <strong>2023</strong> has been a recordbreaking<br />

year for MCS so far as the scheme has<br />

in our contractor base shows that UK<br />

consumers have more and more confidence<br />

seen over 1,700 new contractors becoming<br />

every day.”<br />

certified in the last 11 months, a 70% growth in<br />

the contractor base since the end of 2022. In You can hear from the Installer community here -<br />

fact, MCS says more contractors have joined the https://www.youtube.com/watch?v=-X03YHscheme<br />

in <strong>2023</strong> so far than in the previous six EV7E<br />

Branch Manager Jim Finnegan added:<br />

“Customers that have already been to the new<br />

branch have been impressed with the product<br />

range, and it will help cement our ambition to<br />

be a centre of excellence in new roofing<br />

technologies and products.”<br />

www.burtonroofing.co.uk<br />

10 TC DECEMBER <strong>2023</strong>

UNROLL<br />

YOUR<br />

POTENTIAL<br />

Become accredited with<br />

ICB Waterproofing Ltd<br />

alwitra.co.uk

NFRC Roofing Talk<br />

ECO PROJECT: ACCESS SUPPORT<br />

FOR THE RECRUITMENT PROCESS<br />

Ruth Scarrott, Head of Careers at NFRC, tells readers that the support is there to help make<br />

a success of the recruitment process, as well as those crucial first months for new recruits…<br />

Making roofing and cladding<br />

a desirable and rewarding<br />

career is central to<br />

ensuring the industry can recruit and<br />

retain enough staff – that is, bringing<br />

people on board and then keeping<br />

them on for a significant period of<br />

time.<br />

NFRC now has an offering to help all<br />

roofing and cladding<br />

contractors meet this<br />

challenge. Via CITB<br />

funding, the ‘ECO’<br />

Project enables us to<br />

guide employers in<br />

England through the<br />

entire recruitment process,<br />

from the first job advert until your new<br />

team member is six months in post. We are now<br />

also able to help employers of roofing apprentices<br />

in Scotland with the equivalent programme.<br />

To be eligible for us to provide this support, your<br />

new starter needs to be new to construction, or<br />

returning to the industry after some time away.<br />

So, what will this actually look like?<br />

Taking on someone new<br />

We can start by helping you plan your recruitment<br />

and interview process. This can include talking<br />

with you to help define what you’re looking for,<br />

and give pointers on the best way to advertise<br />

and find the right person.<br />

It may also be planning what’s best to ask in the<br />

interview, and then getting a contract of<br />

employment in place when you have found your<br />

new starter and they have accepted a job offer.<br />

We can also link you up with organisations that<br />

“This programme means that<br />

if there is a point in the<br />

hiring process where you are<br />

not sure what to do, you have<br />

help on hand” – Ruth Scarrott<br />

source candidates, like Jobcentres. Essentially,<br />

this programme means that if there is a point in<br />

the hiring process where you are not sure what to<br />

do, you have help on hand.<br />

The first few months<br />

The journey doesn’t end once someone has been<br />

employed. Your first day on site or in the office<br />

will have been scary, and you won’t have got<br />

everything right first time.<br />

Once you have secured a new starter, we can<br />

help you offer them one-on-one support, for<br />

example by giving you or other experienced<br />

colleagues some support to become great<br />

informal mentors for newcomers.<br />

The new starter can access pastoral support<br />

through this programme, meaning that if they are<br />

feeling worried about starting work, what’s<br />

expected of them, or their ability in their new role,<br />

they can speak to someone outside the workplace<br />

and be guided in the right direction.<br />

Equally, if they are struggling with<br />

behaviour or are not recognising the<br />

standards they need to meet at work,<br />

that can be addressed. More broadly,<br />

if they have a training need, we can<br />

help you source that learning, for<br />

example finding a local site-readiness<br />

course.<br />

Preparing for progression<br />

It can be helpful to show a new starter<br />

what their trajectory will be once<br />

they’re in your business. We can<br />

assist you to draft an ongoing training<br />

plan for them: having a short<br />

document that points out how you<br />

plan to develop their skills and<br />

qualifications means that you can keep on track<br />

with making sure that they are maximising their<br />

potential, and your employee knows that your<br />

company is a place they will learn and progress,<br />

not see a dead end.<br />

This could be as simple as setting out that your<br />

employee will gain a specific qualification and<br />

complete particular short courses in a set period<br />

of time.<br />

Even if you have hired new people before and just<br />

want to know what you can do better with your<br />

next staff member, it’s worth a chat. If you’d like<br />

more information or to access this support,<br />

please get in touch with me directly at<br />

careers@nfrc.co.uk.<br />

Contact NFRC<br />

020 7638 7663<br />

www.nfrc.co.uk<br />

NFRC<br />

12 TC DECEMBER <strong>2023</strong>

TAKE YOUR<br />

ROOFING BUSINESS<br />

TO THE NEXT LEVEL WITH NFRC<br />

Technical advice, the industry quality stamp and fantastic<br />

profile-raising opportunities—for all roofing disciplines<br />

NFRC sets the highest<br />

standards for work across<br />

all roofing and cladding<br />

disciplines. But we’re much<br />

more than the industry’s quality<br />

assurance stamp. Membership<br />

of the trade association offers<br />

contractors and suppliers a<br />

range of powerful technical<br />

and commercial advantages.<br />

These include a profile on our website<br />

and directory listing, making your<br />

business easier for clients to find. Plus<br />

exclusive access to technical support and<br />

updates, an exclusive health and safety<br />

app, and advice on training provision.<br />

For suppliers, key benefits include<br />

numerous opportunities to engage with<br />

roofing contractors all over the country.<br />

And as the voice of the roofing sector,<br />

NFRC makes our members’ views<br />

heard where it matters most. We work<br />

with government, standards bodies<br />

and training providers to promote the<br />

interests of the industry, and of the<br />

construction market as a whole.<br />

<strong>2023</strong> UK Roofing Awards<br />

Fully-supported Metal winner<br />

Roles Broderick Roofing Limited<br />

3 | Working Towards Zero Avoidable Waste in the Roofing Sector<br />

NFRC trade<br />

membership benefits<br />

WHAT BEING AN NFRC MEMBER MEANS FOR YOU<br />

3 | Working Towards Zero Avoidable Waste in the Roofing Sector<br />

NFRC supplier<br />

membership benefits<br />

EXCLUSIVE ACCESS TO OUR ROOFING<br />

CONTRACTOR MEMBERS<br />

Call 020 7638 7663 or visit<br />

nfrc.co.uk/TCbenefits to request our<br />

benefits brochure—and find out more<br />

about what NFRC membership can do<br />

for your business.<br />

Have you heard about NFRC’s NEW regional NVQ Assessment<br />

Service dedicated to roofing and cladding?<br />

This service offers the opportunity to get qualified,<br />

on-site in a real working environment.<br />

Like to find out more?<br />

Email careers@nfrc.co.uk

Viewpoints & Predictions<br />

A LOOK BACK AT <strong>2023</strong>, PLUS<br />

WHAT’S IN STORE FOR 2024?<br />

If the last few years have shown anything for those operating in the roofing, cladding and<br />

wider construction industry, it’s that making predictions and forecasting is a thankless task<br />

and quite possibly a complete waste of time! But it’s still good to try and learn from the past<br />

and plan for the future, so we asked individuals from throughout the supply chain to give<br />

their views on the past year, and thoughts on what to look out for in 2024...<br />

“WE SEE GOOD GROWTH PROSPECTS FOR HIGH QUALITY<br />

RAINSCREEN CLADDING”<br />

Peter Johnson, Founder of Vivalda Group<br />

<strong>2023</strong> saw its fair share of unexpected news<br />

in the construction sector. First, we saw<br />

sobering trading updates on consecutive<br />

days from two well-known FT250-listed<br />

building materials distributors, both admitting<br />

that sustained hikes in interest rates were<br />

having a negative impact on turnover and<br />

profits.<br />

Following this trend, we’ve witnessed just about<br />

every major housebuilder laying off staff and<br />

reducing the number of new builds for the<br />

foreseeable future. In another tell-tale sign of the<br />

sector’s woes, homes are taking longer to sell, with<br />

some developers even offering free fridges and<br />

washing machines to lure buyers – a phenomenon<br />

we thought had disappeared with the 1990s.<br />

The last year has also seen a lot of highly<br />

regarded, small to medium-sized contractors<br />

going out of business, victims of the insidious<br />

nature of fixed priced contracts in an inflationary<br />

environment, as well as retrospective cost<br />

reduction strategies from developers and<br />

housebuilders. With interest rates at 5.25%, the<br />

cold winds of sluggish construction activity<br />

appear to be with us for the next few months,<br />

although there are tentative signs rates may have<br />

now peaked; here’s hoping.<br />

Vivalda Group takes pride in its unswerving<br />

contribution to safe cladding,<br />

historically having been priced out of<br />

many large supply contracts after<br />

refusing to join a race to the bottom, the tragic<br />

result of which was Grenfell. The absolute<br />

necessity to avoid a similar tragedy means my<br />

company has cladding safety in its DNA. Safety is<br />

inbuilt into every component – fire barriers,<br />

substrate boards, fireproof insulation, aluminium<br />

fixing systems and, of course, fire-resistant<br />

cladding panels. If only others had given a similar<br />

priority pre-Grenfell. If only.<br />

On the upside, we take pride in our contribution to<br />

making life more tolerable for the thousands of<br />

families who live in the towers we’ve helped to<br />

remediate; not only that, we’re working flat out to<br />

supply the thousands of others where the cost is<br />

similarly borne by the Building Safety Fund. While<br />

it’s fair to say commencement of work in this<br />

regard has sometimes been slow due to planning,<br />

application complexities or insurance issues, this<br />

absolutely vital activity now accounts for a<br />

significant proportion of our turnover. And with<br />

buildings over 11m tall soon to be eligible under the<br />

new Medium-Rise Scheme, this should continue to<br />

keep us busy for several more years to come.<br />

Looking ahead to 2024, the final chapter of the<br />

Grenfell Tower Inquiry final report is widely<br />

expected to be published.<br />

In terms of economic pain, I think the high<br />

watermark of inflation is behind us; in fact we’re<br />

likely to see discounting as the market re-aligns<br />

itself. Even to this day my eyes water when I’m<br />

reminded of some façade brands increasing<br />

prices by as much as 45% in 2021/22 in an<br />

attempt to defray their raw material costs.<br />

However, they may need to row back by offering<br />

project rates – or run the risk of losing market<br />

share to comparable (my italics) products that<br />

are more competitively priced. It’s the iron law of<br />

economics: products price themselves into the<br />

market; products price themselves out.<br />

With Andy McEwan, our CEO now at the helm,<br />

2024 is shaping up to be a great year for Vivalda<br />

Group. With 11 branches UK-wide, unrivalled<br />

fabrication capabilities and a well-established<br />

team of highly skilled people, we continue to<br />

invest in the business.<br />

This year (2024) will see us launching our own,<br />

UK-manufactured solid aluminium cladding<br />

system, MetSkin, which will provide much needed<br />

additional capacity to the non-flammable<br />

cassette market. Recent times have not been<br />

easy for the construction sector but we’re<br />

optimistic about bucking the trend. In summary,<br />

we see good growth prospects for high quality<br />

rainscreen cladding.<br />

www.vivalda.co.uk<br />

14 TC DECEMBER <strong>2023</strong>

“THE NEW COMPETENCE REQUIREMENTS COME INTO FORCE IN APRIL,<br />

SO ‘DOING NOTHING’ IS NOT AN OPTION”<br />

Carlton J Jones, Director MCRMA (Metal Cladding & Roofing Manufacturers Association)<br />

Over the past 12 months, the construction<br />

industry has taken important steps to adapt<br />

to the requirements of the 2022 Building<br />

Safety Act.<br />

Despite the current challenging economic<br />

backdrop, organisations including the MCRMA<br />

have remained focused on supporting businesses<br />

working at all points in the building envelope<br />

supply chain to understand, and respond to, the<br />

competence and compliance demands of the new<br />

building safety regime.<br />

One of the most important developments of the<br />

last 12 months is undoubtedly the publication of<br />

the white paper by the JCI (Joint Competence<br />

Initiative), ‘Achieving Competence in the Building<br />

Envelope Sector’. This was a breakthrough as it<br />

provides a benchmark standard relating to<br />

competencies for all Individuals working in, or<br />

for, specialist sub-contractors and<br />

consultants, as well as material and system<br />

manufacturers within the building envelope<br />

sector.<br />

Our role in the JCI has been to ensure the voices<br />

of businesses involved in metal cladding and<br />

roofing are heard so the new ways of working are<br />

feasible and achievable. And this has been one of<br />

the reasons why many of our members have<br />

derived greater value from their MCRMA<br />

membership in <strong>2023</strong>.<br />

Looking ahead to 2024, it is likely that many more<br />

businesses in our sector will be investing time<br />

and resources in training and implementing new<br />

processes, if required, to align with the JCI<br />

framework and meet client expectations from a<br />

regulatory perspective. This<br />

investment will pay dividends<br />

because demonstrating competence at<br />

both an individual and company level will be key<br />

to winning contracts and delivering projects in<br />

future.<br />

In recent months we have already seen a huge<br />

increase in bookings for our 3-day training<br />

programme and individuals taking our online<br />

CPDs, and we expect the demand for specialist<br />

training to increase further over the next year.<br />

Remember, the new competence requirements<br />

come into force in April, so ‘doing nothing’ is not<br />

an option. Hence why there has never been a<br />

more important time to prioritise knowledge and<br />

skills development through training!<br />

www.mcrma.co.uk<br />

“WE’RE ALL TOO AWARE OF THE POTENTIAL FOR REPLACEMENT CLADDING”<br />

John Park-Davies, Group Managing Director at Vertik-Al<br />

This time last year, even the most<br />

insightful individual would have<br />

struggled to predict how <strong>2023</strong> would<br />

unfold. We have seen multiple conflicts<br />

around the world, rampant inflation in the UK,<br />

material price volatility, and firms – both large<br />

and small – in distress. It’s safe to say that<br />

we’ve experienced turmoil across all areas –<br />

social, political and economic.<br />

My personal outlook has always been – ‘what<br />

doesn’t hurt you, makes you stronger’, and it’s a<br />

view that I bring to the business. I am pleased to<br />

say that we have grown stronger over this<br />

challenging year.<br />

I have made sure that during one of the most<br />

challenging times in my 37 year career, our<br />

business has maintained its exceptional standards<br />

and service. For example, we have continued to<br />

invest in industry leading accreditations<br />

such as Qualicoat and the GSB<br />

International Master Seal; standards we<br />

have upheld for almost 30 years. Our sister<br />

company, IKON Aluminium, also achieved the<br />

revised PAS 24 certification on its louvre doorsets.<br />

All too often we see businesses compromise on<br />

quality when things are difficult. This is not how we<br />

run a business. We want to support our customers,<br />

to help them thrive and emerge resilient.<br />

Our core business is powder coating architectural<br />

aluminium, this sees us dealing with global paint<br />

suppliers and serving many sectors of British<br />

industry. Our customers deal with both the domestic<br />

and commercial markets, so we coat everything<br />

from components through to bar length, often this is<br />

destined for prestigious building facades.<br />

While some larger commercial projects have stalled<br />

this year, we have a strong order book for 2024.<br />

Demand for coated aluminium products is high – its<br />

recyclability and lightweight properties makes it a<br />

material of choice for many specifiers and façade<br />

consultants. Plus, we’re all too aware of the<br />

potential for replacement cladding.<br />

The home improvement market has also proven to<br />

be more resilient than we first thought at the start of<br />

the year. While some homeowners are feeling the<br />

pinch there are others who are using savings and<br />

investing in their homes. This state of the housing<br />

market has triggered this ‘improve don’t move’<br />

reaction. Rising consumer awareness and the<br />

growing popularity of aluminium fenestration<br />

products and clad extensions means this has, and<br />

continues to be, a fairly buoyant market for our<br />

customers, and in turn, us. We don’t see this<br />

changing in 2024. www.vertik-al.com<br />

DECEMBER <strong>2023</strong> TC 15

Viewpoints & Predictions<br />

“<strong>2023</strong> HAS BEEN PIVOTAL IN TERMS OF INDUSTRY REGULATIONS, WITH THE<br />

TRAJECTORY CONTINUING INTO 2024”<br />

Michael Anaxagorou, Sales Director, Axter Ltd<br />

This year has revealed the pivotal role of<br />

technology in shaping the future of<br />

construction.<br />

Its increased utilisation has significantly<br />

enhanced survey efficiency and opened new<br />

avenues in specification. Notably, the impact is<br />

substantial in the realm of sustainability, with a<br />

heightened focus on net-zero goals and escalating<br />

energy costs prompting a drive toward enhancing<br />

the energy and thermal efficiency of buildings. This<br />

surge in interest has also led to increased<br />

exploration of energy generation possibilities.<br />

In the domain of Climate Map Technology, fieldbased<br />

and desktop tools are revolutionising the<br />

assessment of the impact of well-designed roofs,<br />

enabling digital modelling of existing structures<br />

against proposed alterations. Moreover, these tools<br />

facilitate showcasing the assets’ value beyond<br />

compliance, highlighting the potential for carbon<br />

reduction, long-term savings, and a more<br />

sustainable future.<br />

The year <strong>2023</strong> has been pivotal in terms of<br />

industry regulations, with the trajectory<br />

continuing into 2024. Notably, the Building<br />

Safety Act introduced the concept of 'duty<br />

holders', including clients, designers, and<br />

contractors, emphasizing the necessity for<br />

assessing competence and declining work that<br />

exceeds one's skills, knowledge, or experience.<br />

These regulations serve as a starting point for<br />

substantial change, with further developments<br />

expected, including updated rules on product<br />

standards.<br />

As a manufacturer and roofing design company, we<br />

advocate for voluntary schemes like the Code for<br />

Construction Product Information (CCPI) and<br />

Building a Safer Future. CCPI, emphasising building<br />

safety and higher standards in presenting<br />

construction product information, has validated our<br />

Wilotekt-Plus system as one of the first CCPIverified<br />

hot melt systems in the industry.<br />

Looking ahead to the next year, Biodiversity Net<br />

Gain (BNG) requirements and Sustainable Urban<br />

Drainage (SuDs) will transition to mandatory status<br />

for most new constructions. This shift highlights the<br />

crucial role of design, construction methods, and<br />

materials in project sustainability. There’s an<br />

emerging expectation not only to meet regulatory<br />

standards but also to exceed them.<br />

In 2024, upskilling the labour force emerges as a<br />

primary trend. Addressing the ongoing shortages,<br />

particularly in roofing, entails enhancing digital<br />

proficiency and driving modernisation through<br />

workforce development for both existing and<br />

incoming personnel.<br />

Amidst the influx of information, investing in CPD for<br />

teams becomes paramount. This investment<br />

ensures familiarity with new methodologies and<br />

approaches, thereby maintaining high standards<br />

and quality of work. Moreover, advancing digital<br />

skills across the industry is imperative to fully<br />

harness the potential of technologies like Building<br />

Information Modeling (BIM) and collaborative online<br />

platforms for building specification and design.<br />

www.axter.co.uk<br />

“WE’RE ANTICIPATING A PIVOTAL YEAR FOR COMPLIANCE”<br />

Joan Ferrer – UK & Ireland Commercial Director, Ravago Building Solutions UK<br />

The most recent CPA forecast has highlighted<br />

a global slowdown of construction output,<br />

driven predominantly by a sharp decline in<br />

residential housebuilding. We’re fortunate not<br />

to be directly impacted by this as a business,<br />

but it will be sure to cause knock-on effects if<br />

not urgently addressed.<br />

I’d like to see the Government continue to develop<br />

a range of funding schemes for first-time buyers<br />

across the next year, as this would revitalise the<br />

private construction sector to counteract<br />

stagnation in this respect.<br />

At Ravago Building Solutions UK, we’re expecting<br />

2024 to bring fierce competition when securing<br />

projects, largely from the perspective of product<br />

pricing. Cheap, uncertified materials<br />

from abroad significantly influence<br />

price expectations, catalysed by the highly<br />

competitive construction markets. Although<br />

infrastructure activity is currently stable, a<br />

slowdown in the number of active projects could<br />

further impact competition throughout the next<br />

year, especially considering looming delays to<br />

road works.<br />

Finally, we’re anticipating a pivotal year for<br />

compliance, especially with the roll-out of CCPI –<br />

of which we are enthusiastic proponents. It’s a<br />

positive step for rebuilding trust in the<br />

construction industry, and we are embracing the<br />

new measures to demonstrate that our technical<br />

materials and processes are robust. Netzero<br />

targets and a greater emphasis on<br />

sustainability measures are inevitable – not<br />

just for 2024, but for the foreseeable future. At<br />

Ravago Building Solutions UK, we’ve been taking<br />

excellent steps towards our own sustainability<br />

goals – including making use of new Cube20<br />

compactors to recycle fine excess XPS dust into<br />

pellets for producing new product, reducing waste<br />

to landfill. We subscribe to the three pillars of<br />

construction; quality, sustainability and<br />

compliance – it’s crucial that we continue to<br />

preserve those pillars to avoid undermining the<br />

progress and resilience we’ve displayed as a<br />

collective over the past few years.<br />

www.ravagobuildingsolutions.com<br />

16 TC DECEMBER <strong>2023</strong>

Maximum reliability. Minimum fuss.<br />

Secure from Substrate to Skin<br />

A complete system of support<br />

W: fixfast.com / T: +44 1732 882387 / E: sales@fixfast.com

Viewpoints & Predictions<br />

“THE GOOD NEWS IS THAT 2024 IS SET TO BRING GROWTH WITH A<br />

PREDICTED 12% INCREASE IN CONSTRUCTION PROJECTS”<br />

Ken Lynes, Managing Director of Fixfast<br />

It’s fair to say that <strong>2023</strong> brought<br />

choppy waters for construction.<br />

Energy prices remain high, inflation<br />

has increased and there’s been an 18%<br />

reduction in construction projects.<br />

Despite this, Fixfast has not only weathered the<br />

storm but continued to grow. There are a number<br />

of factors that have contributed to this success.<br />

We’re known for our ‘Maximum Reliability,<br />

Minimum Fuss’ brand promise. For our contractor<br />

customers, this means we deliver the products<br />

they need when they need them. It’s a simple<br />

philosophy, but it’s why we consistently have the<br />

best customer satisfaction rates in the industry.<br />

We’ve also forged strong partnerships with the<br />

major OEM manufacturers and design fasteners<br />

for their systems at our UK manufacturing site.<br />

And we’re seeing the growth of the façade side of<br />

our business, thanks to the introduction of the<br />

Fixfast façade support system.<br />

Our teams have been busy delivering on our<br />

digital transformation. This has included<br />

the launch of our new website which is<br />

underpinned by technology that creates<br />

seamless integration with all our internal<br />

processes. It’s supported by a Product<br />

Information Management (PIM) system, which<br />

allows us to update all our technical, commercial<br />

and marketing information, related to each of our<br />

thousands of products at the touch of a button –<br />

wherever it’s held. So, whether it’s on our own<br />

systems or those of our partners, it’s always<br />

accurate and up to date.<br />

This is important because the Building Safety Act<br />

will bring greater accountability across the supply<br />

chain and increased scrutiny of product choice. It<br />

means specifiers need to be confident that the<br />

information they use is accurate and that the<br />

products they specify will perform as they are<br />

designed to. For this reason, Fixfast is also<br />

amongst the first in the UK to have achieved the<br />

Code for Construction Product Information (CCPI)<br />

verification for our DrillFast, MatchFast and<br />

TapFast ranges.<br />

The good news is that 2024 is set to bring growth<br />

with a predicted 12% increase in construction<br />

projects. To help us meet customer demand,<br />

Fixfast will be moving to new, larger premises,<br />

which will allow us to further expand our UK<br />

manufacturing capability. The building itself is<br />

also much more environmentally friendly. It will<br />

be built using clean, inert and ACM free recycled<br />

aggregates and hardcore where practical, and<br />

features low-carbon technologies such as a VRF<br />

heat pump for heating and cooling, and solar<br />

panels to achieve an EPC A+ rating.<br />

The foundations we’ve laid in <strong>2023</strong> mean that we<br />

will be able to support our customers and OEM<br />

partners by providing the products they need to<br />

support the creation of better, safer buildings –<br />

backed up by the accurate information needed for<br />

specification. Not just in 2024, but for many<br />

years to come.<br />

www.fixfast.com<br />

“A FOCUS ON DEVELOPING SOFT SKILLS IS CRUCIAL”<br />

Kay Rose (FIoR), CEO of the Institute of Roofing<br />

As we reflect on the past year in roofing<br />

and construction, it’s evident that the<br />

industry is undergoing significant<br />

transformations. At the Institute of<br />

Roofing (IoR), our focus on soft skills training<br />

has become increasingly vital.<br />

The integration discussions with the Chartered<br />

Institute of Building (CIOB) underscore the<br />

industry’s recognition that professional skills<br />

extend beyond qualifications. The emphasis is now<br />

on holistic individual development, including<br />

crucial soft skills such as communication,<br />

presentation, organisation, time management, and<br />

professionalism. It’s not just about what you<br />

know, but how you apply that knowledge in a<br />

professional setting.<br />

Professionalism is a foundation into which<br />

wider skills feed into. Skills such as<br />

delivering on commitments, managing<br />

workloads effectively, and avoiding<br />

overcommitment to prevent disappointments.<br />

Addressing these basic requirements is essential<br />

for anyone in the industry, promoting reliability and<br />

trustworthiness not only as an individual, but as<br />

part of a wider organisation.<br />

The challenges of the past year, which include the<br />

continual preferences to virtual meetings, can<br />

often expose deficiencies in professional<br />

communication and behaviour. This highlights the<br />

importance of fostering a respectful and<br />

committed attitude within the industry.<br />

Looking ahead to 2024, I think a focus on<br />

developing soft skills is crucial for anyone entering<br />

the roofing profession – but particularly the<br />

younger generations. Handling crises, effective<br />

communication, and navigating difficult<br />

conversations are ‘skills for life’ that should be<br />

integral to education and training. While technical<br />

expertise is crucial, companies must also invest in<br />

cultivating well-rounded individuals.<br />

Having a positive attitude toward training is key to<br />

equipping the industry with the necessary skills for<br />

the future. As we look to the future, embracing a<br />

holistic approach to education and training will<br />

ensure a robust and competitive roofing industry.<br />

www.instituteofroofing.org<br />

18 TC DECEMBER <strong>2023</strong>

“<strong>2023</strong> HAS BEEN A YEAR OF REGULATORY CHANGE”<br />

Bradley Hirst, Technical Services Manager for Knauf Insulation<br />

<strong>2023</strong> has been a year of regulatory<br />

change. Significant uplifts to Parts L<br />

(thermal performance) and B (fire<br />

safety), which both affect the specification<br />

of insulation, came into full force bringing in<br />

stricter standards for the design and<br />

construction of buildings in England and Wales.<br />

Similar updates have been made in Scotland<br />

and Ireland.<br />

Then there’s the Building Safety Act, which is<br />

placing greater accountability across the supply<br />

chain. As a result, we’re likely to see the<br />

specification of construction products for higher risk<br />

buildings undertaken much earlier in the design and<br />

build process.<br />

The key takeaways from these changes are that<br />

buildings must achieve much higher performance<br />

standards, the products and systems specified<br />

must be used (and any substitutions approved and<br />

signed off). And ultimately, the finished building<br />

must perform the way it’s designed to.<br />

So, what does this mean for insulation? Well,<br />

firstly we’re seeing greater thermal<br />

efficiency of the building fabric, which<br />

means clients are moving to lower lambda<br />

products and using much more insulation than<br />

before. For example, contractors are being asked by<br />

housebuilders to install loft insulation to depths of<br />

400mm or 500mm. They’re also increasing<br />

masonry cavity widths to 150mm with an<br />

equivalent depth of insulation to improve energy<br />

efficiency and provide greater flexibility – a move<br />

that’s only set to increase as we get closer to the<br />

introduction of the Future Homes Standard.<br />

The focus on fire safety we’ve seen over the last<br />

few years will also continue to be a priority in<br />

2024. So, my message is that the best way to<br />

minimise risk and ensure compliance is to use<br />

non-combustible materials such as Knauf<br />

Insulation rock and glass mineral wool for all<br />

projects, regardless of height or use.<br />

Added to that is the issue of real performance.<br />

The regulations have brought in much greater<br />

scrutiny of product choice and standards of<br />

workmanship. Where insulation is concerned,<br />

good installation can make or break real thermal,<br />

fire safety and acoustic performance – and that’s<br />

affected by the material used.<br />

It’s important contractors and installers choose a<br />

product that’s easy to install correctly. It can be<br />

difficult to get a good fit with materials such as rigid<br />

boards as they’re inflexible and cannot adapt to<br />

imperfections in the substrate. This introduces gaps<br />

that reduce performance. But it’s easy to get a good<br />

fit with mineral wool because it adapts to the<br />

substrate and knits together at the joints.<br />

Ultimately, by focusing on the real-world benefits<br />

of better thermal efficiency, enhanced fire safety,<br />

acoustic performance and materials that are easy<br />

to install correctly, your insulation is more likely to<br />

deliver the performance that’s needed in 2024<br />

and beyond.<br />

www.knaufinsulation.co.uk<br />

“BUSINESSES THAT EXCEL IN DELIVERING PRECISELY WHAT THE CUSTOMER<br />

WANTS WILL STAND APART FROM ANY BUSINESSES THAT DO NOT”<br />

James Chillman, UK Country Manager, Fergus<br />

At Fergus, <strong>2023</strong> saw even more roofing<br />

business owners opt for job<br />

management software – for good<br />

reason. It automates much of their work,<br />

removes paperwork and reduces inefficiency.<br />

In short, it gives them more time back.<br />

By automating a lot of business processes you can<br />

also look to take advantage of some of 2024’s<br />

biggest business trends, one of which includes<br />

adopting new techniques to improve customer<br />

experience. Those businesses that excel in<br />

delivering precisely what the customer wants,<br />

promptly and stress free, while efficiently resolving<br />

any issues, will stand apart from any businesses<br />

that do not. If you’re looking to develop top notch<br />

customer care, then job management software<br />

Fergus can help you quickly get ahead of the<br />

trend. It helps you to:<br />

Be speedy: with custom templates, you<br />

can quickly generate accurate quotes and<br />

invoices, sending them directly to clients via email<br />

or SMS.<br />

Be informative: set reminders and send automatic<br />

confirmations and updates to your clients, so every<br />

appointment runs smoothly and customers are<br />

always kept in the loop about any adjustments.<br />

Be ultra-reliable: thanks to smartphones and GPS,<br />

you can track your team members’ exact location<br />

and route, which means you can let clients know<br />

an ETA without disturbing a driver while they’re on<br />

the road.<br />

In October <strong>2023</strong> we launched Fergus Essentials so<br />

that businesses of any size can afford to adopt job<br />

management software. Designed specifically for<br />

sole traders or small teams in the trades industry,<br />

Fergus Essentials offers a range of features that<br />

help streamline day-to-day operations and improve<br />

your customer interactions. It can track jobs,<br />

create quotes and estimates, manage invoices and<br />

keep your calendar and timesheets in order.<br />

For larger companies and those wanting to drive<br />

growth, Fergus Pro provides a full suite of powerful<br />

job management services with features like<br />

advanced project management, team collaboration<br />

tools, real-time reporting and enhanced<br />

customisation options.<br />

www.fergus.com<br />

DECEMBER <strong>2023</strong> TC 19

Viewpoints & Predictions<br />

“CORDLESS IS FAST BECOMING THE PREFERRED<br />

PLATFORM FOR MANY IN THE INDUSTRY”<br />

Simon Miller, Managing Director, HiKOKI Power Tools<br />

When it comes to which tools are going<br />

to be a hit in 2024 with roofing and<br />

cladding installers, it will almost<br />

certainly be cordless nailers.<br />

Advances in cordless nailer performance,<br />

enhanced by Lithium-ion battery technology and<br />

highly efficient brushless motors, means that<br />

cordless is fast becoming the preferred platform<br />

for many in the industry. There are no trailing<br />

power cords that pose trip hazards, no keeping<br />

gas cells warm in pockets on cold winter days –<br />

just consistent, awesome performance.<br />

In <strong>2023</strong> we launched the NT1850DFJXZ 18V<br />

Compact 18 Gauge Cordless Brad Nailer, which<br />

allows users to easily move around the jobsite<br />

without hoses or compressors, and can get a<br />

whopping 1,650 nails per charge with the<br />

included 3.0Ah compact battery. The<br />

Two words may be even more prevalent in<br />

the roofing contracting industry in 2024;<br />

safety and sustainability.<br />

NT1850DFJXZ employs a unique Air Spring<br />

Drive system that uses compressed air to<br />

drive each nail, resulting in zero ramp up<br />

time, increased driving speed and recoil<br />

that feels like a pneumatic nailer.<br />

So, expect cordless power tools to keep<br />

transforming the way we work on construction sites.<br />

By 2027 it is estimated that 90 per cent of all power<br />

tools sold will be cordless – if you haven’t done so<br />

already, maybe it’s time to make that switch!<br />

www.hikoki-powertools.co.uk<br />

“Expect cordless power<br />

tools to keep<br />

transforming the way<br />

we work”<br />

“RENEWABLE TECHNOLOGIES SUCH AS SOLAR<br />

PANELS ARE STILL BEING INSTALLED IN NUMBER”<br />

James Robinson, Sales and Marketing Director, Samac Fixings<br />

1st Fix collated nails continue to be a<br />

popular choice amongst roofers who want<br />

safety and quality in their nailers.<br />

“<strong>2023</strong> SAW ALARMING<br />

THEFT STATS”<br />

Devin Chawda CEO ARMD<br />

As we edge into 2024, it’s the<br />

perfect time for hard-working<br />

roofing and cladding contractors<br />

to take control and get their kit insured, their<br />

vans protected against tool thefts and keep<br />

their livelihood safe.<br />

<strong>2023</strong> saw some alarming stats on theft. There is<br />

one tool theft every 23 minutes which is over<br />

around 23,000 a year – and that’s only those<br />

that are reported. Settlement of these claims can<br />

take weeks or sometimes months, so something<br />

had to change. And it has. With ARMD, in just a<br />

few clicks you can have the peace of mind that<br />

should the worst happen, you will be back on the<br />

tools in days or even hours, rather than weeks.<br />

You can you register your tool inventory for free<br />

within the ARMD app, and the ARMD Guard<br />

Smart Van Alarm and Tracker is engineered to<br />

safeguard your tools and equipment. The “Plug<br />

and Play” alarm can be set up within a few<br />

minutes, with no technical knowledge required.<br />

You simply plug it into the OBD port in your van.<br />

The alarm is powered via your vehicle’s OBD<br />

port, ensuring that it remains operational without<br />

draining your van’s battery and the passive<br />

infrared sensor goes in the back and watches<br />

over your tools looking for movement.<br />

From 1st October <strong>2023</strong>, the Building Safety<br />

Act has been in force and places strict<br />

requirements on the roofing contractor to comply<br />

with the Act. Similarly, although much was made<br />

in the news headlines around Net Zero in<br />

September <strong>2023</strong>, renewable technologies such as<br />

solar panels are still being installed in number.<br />

The industry also has to ensure it is installing<br />

sustainable materials – often at the demand of<br />

environmentally conscious clients.<br />

For Samac Fixings, <strong>2023</strong> saw these trends<br />

reflected in our product range. Our Performance<br />

Range of wood screws was expanded to meet the<br />

demands of more applications, while our Viper<br />

Recognising the amount of solar panelling in<br />

the UK today, we launched the SolarGuard Pro,<br />

which you can retrofit to protect the panels from<br />

the build-up of debris under the panels, which<br />

can compromise the structure of the roof itself.<br />

We also launched Coloured Slate Hooks, the<br />

simple solution for fixing natural slate to pitched<br />

roofs and they are an alternative to copper clout<br />

nails. They come in light grey, dark grey and<br />

green, and provide an unobtrusive fixing solution,<br />

matching the colours against the colour of the<br />

slate itself, allowing the beauty of the roofing<br />

material to take centre stage.<br />

www.samacfixings.co.uk<br />

One of ARMD Guard’s standout features is its<br />

silent alert system. In the unfortunate event of a<br />

break-in, where your van is out of sight or is<br />

masked in darkness, the ARMD Guard discreetly<br />

calls you while the criminals are in action,<br />

without them knowing. This allows you to take<br />

swift action and call the police, potentially<br />

leading to the capture of the culprits in the act<br />

and the recovery of your stolen tools.<br />

In just a few clicks you can have the peace of<br />

mind that should the worst happen, you will be<br />

back on the tools in days or even hours.<br />

www.armd.uk<br />

20 TC DECEMBER <strong>2023</strong>

“THE LRWA IS POISED TO COLLABORATE WITH CONTRACTOR MEMBERS”<br />

Sarah Spink, CEO of Liquid Roofing and Waterproofing Association (LRWA)<br />

Reflecting on the past 12 months, the liquid<br />

roofing industry has weathered a challenging<br />

landscape marked by high inflation rates,<br />

strikes in the transport, health and education<br />

sectors, as well as governmental instability.<br />

The uncertainties of the year were further<br />

compounded by the ongoing impact of the Grenfellrelated<br />

initiatives. Despite these hurdles, the sector<br />

has shown resilience, with construction product<br />

availability stabilising at pre-COVID levels. This<br />

brought much-needed equilibrium to pricing.<br />

A significant milestone this year was in September<br />

(<strong>2023</strong>), the UK saw the first construction products<br />

to achieve verification with the Code for<br />

Construction Product Information (CCPI). These<br />

products will become the first on the market to carry<br />

the CCPI mark; offering reassurance to users that<br />

product information from manufacturers is not only<br />

clear, accurate, and accessible, but is also up-todate<br />

and unambiguous. Amongst some of the first<br />

of these product systems to receive this<br />

validation are liquid applied membranes, from<br />

LRWA members. This is a fantastic<br />

accomplishment from companies represented<br />

within our association.<br />

The implementation of new responsibilities and<br />

systems under the Building Safety Act on<br />

October 1st, <strong>2023</strong>, signalled a pivotal moment for<br />

those engaged in projects involving higher-risk<br />

buildings. These changes underscore the industry's<br />

commitment to enhancing safety standards and<br />

regulatory compliance.<br />

Looking ahead to 2024, the liquid roofing sector<br />

anticipates the cessation of Grandfather Rights on<br />

<strong>December</strong> 31st. This has prompted a surge in<br />

contractor membership as professionals strive to<br />

demonstrate competence in their specialised<br />

disciplines. The LRWA is poised to collaborate with<br />

contractor members, facilitating comprehensive<br />

plans to qualify their workforce in liquid roofing. This<br />

involves leveraging On-Site<br />

Assessment and Training (OSAT) for<br />

experienced workers and Specialist-<br />

Applied Skills Programmes (SAP) for<br />

apprentices, ultimately leading to the attainment of<br />

a blue skilled worker CSCS card.<br />

While 2024 is expected to present market<br />

challenges, liquid roofing and our association is<br />

experiencing a period of growth. This aligns with the<br />

anticipation of a buoyant refurbishment sector amid<br />

the backdrop of a general election and higher<br />

interest rates, further showcasing the adaptability<br />

and dynamism of the liquid applied membrane<br />

industry.<br />

As we embark on the upcoming year, the LRWA<br />

remains committed to supporting excellence,<br />

promoting workforce development, and steering<br />

the sector towards sustainable growth despite the<br />

prevailing uncertainties.<br />

www.lrwa.org.uk<br />

“PV WILL PLAY A GREATER ROLE IN UNLOCKING THE POTENTIAL OF ROOFS”<br />

Damien Pooley, Portfolio Manager for Pitched Roofing at BMI UK & Ireland<br />

Sustainability is a word we’re all hearing<br />

more frequently, and it’s having a direct<br />

impact on every industry – including<br />

roofing. Overarching ambitions such as<br />

net-zero are shaping the requirements of our<br />

built environment, often requiring buildings to<br />

work harder to become more efficient and<br />

underpin sustainability.<br />

Roofs are a fantastic example of how the fabric of<br />

buildings can evolve to do so much more than offer<br />

protection from the elements. As we head into<br />

2024, PV will play a greater role in unlocking the<br />

potential of roofs, helping to reduce carbon<br />

emissions and facilitate the creation of renewable<br />

energy.<br />

The past year has seen record increases in the<br />

number of installations as housebuilders and<br />

building owners look to renewable energy to<br />

improve efficiency. The changes to Part L of<br />

the Building Regulations in 2022 played a<br />

key role in this transition, requiring new<br />

homes to reduce carbon emissions by 31%<br />

and non-domestic buildings by 27%.<br />

With a wide variety of PV panels now in the<br />

marketplace and PV technology changing so rapidly,<br />

the emphasis will be on investing wisely by<br />

choosing the best system for the building. Elements<br />

to consider include power output, manufacturer<br />

support and guarantees, and the reliability of the<br />

panels as part of the full roof system.<br />

Our BMI Redland PV InDaX Adapt system features a<br />

half cut cell module technology to deliver high<br />

output performance and maximum energy yield<br />

throughout the day, even when the panels are in<br />

partial shade. Half-cut cells are also more<br />

physically durable than their traditional<br />

counterparts, being smaller in size, so more<br />

resistant to cracking.<br />