Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

”<br />

With determination<br />

14<br />

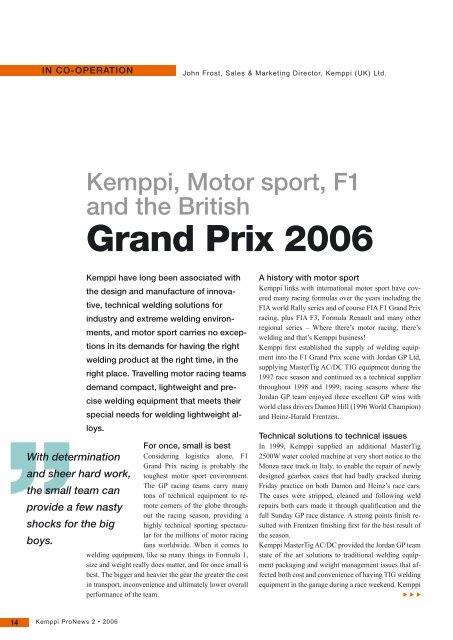

IN CO-OPERATION<br />

and sheer hard work,<br />

the small team can<br />

provide a few nasty<br />

shocks for the big<br />

boys.<br />

<strong>Kemppi</strong> ProNews 2 • 2006<br />

<strong>Kemppi</strong>, Motor sport, F1<br />

and the British<br />

Grand Prix 2006<br />

<strong>Kemppi</strong> have long been associated with<br />

the design and manufacture of innovative,<br />

technical welding solutions for<br />

industry and extreme welding environments,<br />

and motor sport carries no exceptions<br />

in its demands for having the right<br />

welding product at the right time, in the<br />

right place. Travelling motor racing teams<br />

demand compact, lightweight and precise<br />

welding equipment that meets their<br />

special needs for welding lightweight alloys.<br />

For once, small is best<br />

Considering logistics alone, F1<br />

Grand Prix racing is probably the<br />

toughest motor sport environment.<br />

The GP racing teams carry many<br />

tons of technical equipment to remote<br />

corners of the globe throughout<br />

the racing season, providing a<br />

highly technical sporting spectacular<br />

for the millions of motor racing<br />

fans worldwide. When it comes to<br />

welding equipment, like so many things in Formula 1,<br />

size and weight really does matter, and for once small is<br />

best. The bigger and heavier the gear the greater the cost<br />

in transport, inconvenience and ultimately lower overall<br />

performance of the team.<br />

John Frost, Sales & Marketing Director, <strong>Kemppi</strong> (UK) Ltd.<br />

A history with motor sport<br />

<strong>Kemppi</strong> links with international motor sport have covered<br />

many racing formulas over the years including the<br />

FIA world Rally series and of course FIA F1 Grand Prix<br />

racing, plus FIA F3, Formula Renault and many other<br />

regional series – Where there’s motor racing, there’s<br />

welding and that’s <strong>Kemppi</strong> business!<br />

<strong>Kemppi</strong> fi rst established the supply of welding equipment<br />

into the F1 Grand Prix scene with Jordan GP Ltd,<br />

supplying MasterTig AC/DC TIG equipment during the<br />

1997 race season and continued as a technical supplier<br />

throughout 1998 and 1999; racing seasons where the<br />

Jordan GP team enjoyed three excellent GP wins with<br />

world class drivers Damon Hill (1996 World Champion)<br />

and Heinz-Harald Frentzen.<br />

Technical solutions to technical issues<br />

In 1999, <strong>Kemppi</strong> supplied an additional MasterTig<br />

2500W water cooled machine at very short notice to the<br />

Monza race track in Italy, to enable the repair of newly<br />

designed gearbox cases that had badly cracked during<br />

Friday practice on both Damon and Heinz’s race cars.<br />

The cases were stripped, cleaned and following weld<br />

repairs both cars made it through qualifi cation and the<br />

full Sunday GP race distance. A strong points fi nish resulted<br />

with Frentzen fi nishing fi rst for the best result of<br />

the season.<br />

<strong>Kemppi</strong> MasterTig AC/DC provided the Jordan GP team<br />

state of the art solutions to traditional welding equipment<br />

packaging and weight management issues that affected<br />

both cost and convenience of having TIG welding<br />

equipment in the garage during a race weekend. <strong>Kemppi</strong>