Copper Chromium (CuCr) Contact Materials for Vacuum ... - Plansee

Copper Chromium (CuCr) Contact Materials for Vacuum ... - Plansee

Copper Chromium (CuCr) Contact Materials for Vacuum ... - Plansee

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

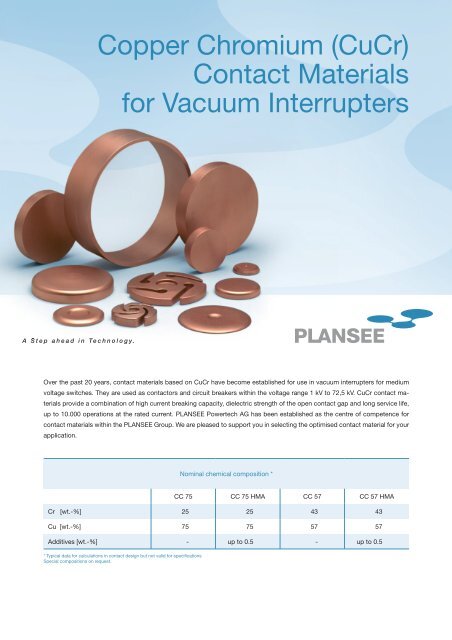

<strong>Copper</strong> <strong>Chromium</strong> (<strong>CuCr</strong>)<br />

<strong>Contact</strong> <strong>Materials</strong><br />

<strong>for</strong> <strong>Vacuum</strong> Interrupters<br />

Over the past 20 years, contact materials based on <strong>CuCr</strong> have become established <strong>for</strong> use in vacuum interrupters <strong>for</strong> medium<br />

voltage switches. They are used as contactors and circuit breakers within the voltage range 1 kV to 72,5 kV. <strong>CuCr</strong> contact ma-<br />

terials provide a combination of high current breaking capacity, dielectric strength of the open contact gap and long service life,<br />

up to 10.000 operations at the rated current. PLANSEE Powertech AG has been established as the centre of competence <strong>for</strong><br />

contact materials within the PLANSEE Group. We are pleased to support you in selecting the optimised contact material <strong>for</strong> your<br />

application.<br />

Nominal chemical composition *<br />

CC 75 CC 75 HMA CC 57 CC 57 HMA<br />

Cr [wt.-%] 25 25 43 43<br />

Cu [wt.-%] 75 75 57 57<br />

Additives [wt.-%] - up to 0.5 - up to 0.5<br />

* Typical data <strong>for</strong> calculations in contact design but not valid <strong>for</strong> specifications<br />

Special compositions on request.

* Typical data <strong>for</strong> calculations in contact design but not valid <strong>for</strong> specifications<br />

••••• excellent, •••• good, ••• satisfactory, •• sufficient<br />

* Typical data <strong>for</strong> calculations in contact design but not valid <strong>for</strong> specifications<br />

Impurities*<br />

CC 75 CC 75 HMA CC 57 CC 57 HMA<br />

O [ppm] 650 650 700 700<br />

H [ppm] 5 5 10 10<br />

N [ppm] 100 100 110 110<br />

Physical properties*<br />

CC 75 CC 75 HMA CC 57 CC 57 HMA<br />

Density [g/cm³] 8.05 8.15 7.60 7.65<br />

Hardness [HV30] 70 85 85 90<br />

Electrical conductivity [m/Ωmm 2 ] 31 32 21 22<br />

Welding tendency •• ••• •••• •••••<br />

Operating principle<br />

For practical applications the Cr content varies between 25 and<br />

60 wt.-%. For applications where arc quenching at low and high<br />

frequencies and low current chopping values are significant, <strong>CuCr</strong><br />

contact materials with 25 wt.-% Cr provide the best results. For<br />

applications where erosion resistance and welding behaviour is im-<br />

portant, <strong>CuCr</strong> contact materials with 40 to 60 wt.-% Cr are used.<br />

Besides the optimum Cr content, the contact geometry also has<br />

a significant influence on the per<strong>for</strong>mance of the contacts, <strong>for</strong> the<br />

different switching applications.

Microstructure of PLANSEE <strong>CuCr</strong> <strong>Materials</strong> <strong>for</strong> Vaccum Interrupters<br />

Microstructure of <strong>CuCr</strong> contact material<br />

with 25 wt.-% Cr<br />

Microstructure of <strong>CuCr</strong> contact material<br />

with 43 wt.-% Cr<br />

A benefit of the <strong>CuCr</strong> contact material is<br />

the high oxygen affinity of the Cr, which<br />

acts as a getter <strong>for</strong> any oxygen released<br />

by the switching process. Special pro-<br />

duction processes based on powder<br />

metallurgical techniques are employed<br />

<strong>for</strong> production of high purity contact<br />

materials.<br />

<strong>CuCr</strong> contact materials are produced by a powder metallurgical<br />

process which includes mixing of the Cu and Cr powders, pressing<br />

and sintering below the melting point of copper. The microstructure<br />

of the contact material is influenced by the grain size of the Cr pow-<br />

der used. The use of fine grained Cr powders has beneficial effects<br />

on the chopping behaviour and breakdown voltage of the contact.<br />

<strong>CuCr</strong> contact materials produced by sintering may exhibit a small<br />

amount of retained porosity which leads to an improvment of the<br />

LBD behaviour at higher Voltage ranges. In some applications this<br />

can influence the breaking capacity of a circuit breaker. By subse-<br />

quent reduction of porosity after sintering i.e. by repressing, the<br />

electrical and thermal conductivity can be increased. The reduced<br />

porosity also leads to an improvement in breaking capacity.<br />

All contact materials from PLANSEE Powertech AG are produced in accordance with ISO 9001 and are designed to meet detai-<br />

led customer specifications. We are pleased to support you in selecting the optimum contact material.

Parent Company<br />

Austria<br />

PLANSEE SE<br />

E-Mail: info@plansee.com<br />

www.plansee.com<br />

Production Refractory Metals<br />

Austria<br />

PLANSEE Metall GmbH<br />

E-Mail: info@plansee.com<br />

www.plansee.com<br />

Werk Liezen<br />

E-mail: liezen@plansee.com<br />

Japan<br />

VACS PRECISION K.K.<br />

E-Mail: info.vp@vacs-precision.com<br />

PLANSEE Bondingshop K.K.<br />

E-Mail: japan@pbkk.co.jp<br />

USA<br />

E/G Electro-Graph, Inc.<br />

E-Mail: sales@egraph.com<br />

www.egraph.com<br />

PLANSEE USA LLC.<br />

E-Mail: usa@plansee.com<br />

www.plansee-usa.com<br />

Production Composite <strong>Materials</strong><br />

France<br />

PLANSEE Tungsten Alloys<br />

E-Mail: plansee-ta@plansee.com<br />

www.plansee-ta.com<br />

Germany<br />

PLANSEE Composite <strong>Materials</strong> GmbH<br />

E-Mail: plansee-cm@plansee.com<br />

www.plansee-cm.com<br />

Switzerland<br />

PLANSEE Powertech AG<br />

E-Mail: powertech@plansee.com<br />

www.plansee-powertech.com<br />

USA<br />

PLANSEE Thermal Management Solutions<br />

E-Mail: sales@plansee-tms.com<br />

www.plansee-tms.com<br />

www.plansee.com<br />

Sales subsidiaries<br />

Austria<br />

PLANSEE Metall GmbH<br />

E-Mail: info@plansee.com<br />

www.plansee.com<br />

Baltic States (Estonia, Latvia, Lithuania)<br />

PLANSEE Nordic AB<br />

E-Mail: info@plansee.se<br />

Brasil<br />

PLANSEE Brasil Ltda<br />

E-mail: plansee@plansee.com.br<br />

www.plansee.com.br<br />

Canada<br />

PLANSEE USA LLC.<br />

E-Mail: usa@plansee.com<br />

www.plansee-usa.com<br />

China<br />

PLANSEE China Ltd.<br />

E-Mail: info@plansee.cn<br />

PLANSEE Beijing Office<br />

E-Mail: info@plansee.cn<br />

PLANSEE Guangzhou Office<br />

E-Mail: info@plansee.cn<br />

PLANSEE Shanghai Office<br />

E-Mail: info@plansee.cn<br />

Czech Republic<br />

PLANSEE SE<br />

E-Mail: cz@plansee.com<br />

France<br />

PLANSEE SE Succursale Française<br />

E-Mail: plansee.france@plansee.com<br />

Germany<br />

PLANSEE SE Vertriebsniederlassung Deutschland<br />

E-Mail: plansee.deutschland@plansee.com<br />

Great Britain<br />

PLANSEE SE Sales Office UK<br />

E-Mail: uk@plansee.com<br />

India<br />

PLANSEE SE Liaison Office India<br />

New Delhi Office<br />

E-Mail: delhi@plansee.com<br />

Bangalore Office India<br />

E-Mail: bangalore@plansee.com<br />

Italy<br />

PLANSEE SE Sales Office Italy<br />

E-Mail: italy@plansee.com<br />

Japan<br />

PLANSEE Japan Ltd.<br />

Tokyo Office<br />

E-Mail: tokyo@plansee.co.jp<br />

www.plansee.co.jp<br />

Osaka Office<br />

E-Mail: osaka@plansee.co.jp<br />

JAPAN VACS METAL Co., Ltd.<br />

E-Mail: info@vacsmetal.co.jp<br />

www.vacsmetal.co.jp<br />

Korea<br />

PLANSEE Korea Co., Ltd.<br />

E-Mail: service@plansee.co.kr<br />

www.plansee.co.kr<br />

Mexico<br />

PLANSEE Mexico S.A. de C.V.<br />

E-Mail: mexico@plansee.com<br />

Netherlands<br />

PLANSEE Nederland<br />

E-Mail: verkoop@plansee.com<br />

Scandinavia<br />

(Norway, Sweden, Finland)<br />

PLANSEE Nordic AB<br />

E-Mail: info@plansee.se<br />

Slovak Republic<br />

PLANSEE SE<br />

E-Mail: slovakia@plansee.com<br />

Spain<br />

PLANSEE SE<br />

E-Mail: spain@plansee.com<br />

Taiwan<br />

PLANSEE Taiwan Co. Ltd.<br />

E-Mail: service@plansee.com.tw<br />

USA<br />

E/G Electro-Graph, Inc.<br />

E-Mail: sales@egraph.com<br />

www.egraph.com<br />

PLANSEE Thermal Management Solutions<br />

E-Mail: sales@plansee-tms.com<br />

www.plansee-tms.com<br />

PLANSEE USA LLC.<br />

E-Mail: usa@plansee.com<br />

www.plansee-usa.com<br />

Sales Partners and Distributors<br />

Australia, Argentina, Belgium, Denmark, Egypt,<br />

Israel, Malaysia, Singapore, Pakistan, Poland,<br />

South Africa, Thailand, Turkey<br />

7000764 - TI-E 018 E 09.08 (1500) Artpress