Air Conditioning Compressors - Delphi

Air Conditioning Compressors - Delphi

Air Conditioning Compressors - Delphi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

e q u i r e d c o o l i n g i s t h u s a ch i eve d b ut at the<br />

ex p e n s e o f t h e wo r k n e cessar y t o drive the<br />

c o m p r e s s o r.<br />

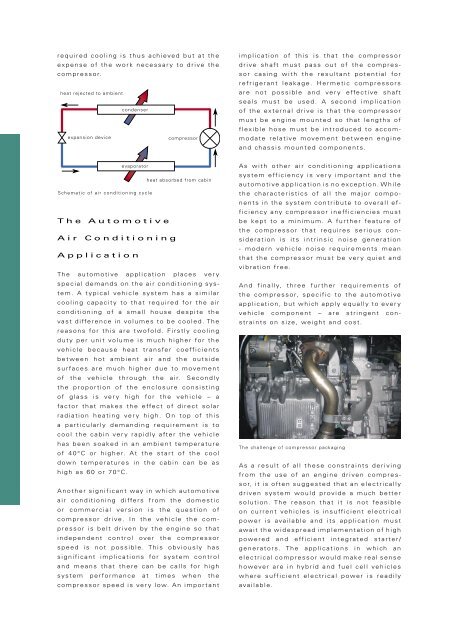

heat rejected to ambient<br />

expansion device<br />

T h e A u t o m o t i v e<br />

A i r C o n d i t i o n i n g<br />

A p p l i c a t i o n<br />

Th e a u t o m o t i ve a p p l i c ation places ver y<br />

s p e c i a l d e m a n d s o n t h e air c o n ditioning sys-<br />

t e m . A t y p i c a l ve h i c l e s ys t em has a similar<br />

c o o l i n g c a p a c i t y t o t h a t r e q uired for the air<br />

c o n d i t i o n i n g o f a s m a l l h o use d e spite the<br />

va s t d i ffe r e n c e i n vo l u m e s t o b e c ooled. The<br />

r e a s o n s fo r t h i s a r e t wo fold. Firstly cooling<br />

d u t y p e r u n i t vo l u m e i s m u ch higher for the<br />

ve h i c l e b e c a u s e h e a t t ransfe r c o efficients<br />

b e t we e n h o t a m b i e n t a ir a n d t h e outside<br />

s u r fa c e s a r e m u ch h i g h e r d u e t o movement<br />

o f t h e ve h i c l e t h r o u g h t h e a i r. Secondly<br />

t h e p r o p ortion o f t h e e nclosure consisting<br />

o f g l a s s i s ve r y h i g h fo r t h e vehicle – a<br />

fa c t o r t h a t m a ke s t h e e ffe c t o f direct solar<br />

r a d i a t i o n h e a t i n g ve r y h i g h. O n t op of this<br />

a p a r t i c u l a r l y d e m a n d i n g r e q u i r ement is to<br />

c o o l t h e cabin ve r y r a p i d l y a ft e r t he vehicle<br />

h a s b e e n s o a ke d i n a n a m bient t e mperature<br />

o f 4 0 ° C or h i g h e r. A t t h e s t a r t o f the cool<br />

d ow n t e mperatu r e s i n t he c a bin c an be as<br />

h i g h a s 6 0 o r 7 0 ° C .<br />

condenser<br />

evaporator<br />

S ch e m a t i c o f a i r c o n d i t i o n i n g c yc l e<br />

compressor<br />

heat absorbed from cabin<br />

A n o t h e r s i g n i f i c a n t way i n w h ich a utomotive<br />

a i r c o n d i t i o n i n g d i ffe r s from t h e domestic<br />

o r c o m m e r c i a l ve r s i o n is t h e q u estion of<br />

c o m p r e s s o r d r i ve . I n t he ve h icle the com-<br />

p r e s s o r i s b e l t d r i ve n by t h e e n g i ne so that<br />

i n d e p e n d e n t c o n t r o l over t h e c ompressor<br />

s p e e d i s n o t p o s s i b l e . This o bv i ously has<br />

s i g n i f i c a n t i m p l i c a t i o n s fo r sys t e m control<br />

a n d m e a n s t h a t t h e r e c an b e calls for high<br />

s ys t e m perfo r m a n c e a t t imes when the<br />

c o m p r e s s o r s p e e d i s ve r y l ow. A n import ant<br />

implication of this is that the compressor<br />

drive shaft must pass out of the compres-<br />

sor casing with the result ant potential for<br />

refrigerant leakage. Hermetic compressors<br />

are not possible and ver y effective shaft<br />

seals must be used. A second implication<br />

of the external drive is that the compressor<br />

must be engine mounted so that lengths of<br />

flexible hose must be introduced to accom-<br />

modate relative movement bet ween engine<br />

and chassis mounted components.<br />

As with other air conditioning applications<br />

system efficiency is ver y import ant and the<br />

automotive application is no exception. While<br />

the characteristics of all the major compo-<br />

nents in the system contribute to overall ef-<br />

ficiency any compressor inefficiencies must<br />

be kept to a minimum. A further feature of<br />

the compressor that requires serious con-<br />

sideration is its intrinsic noise generation<br />

- modern vehicle noise requirements mean<br />

that the compressor must be ver y quiet and<br />

vibration free.<br />

And finally, three further requirements of<br />

the compressor, specific to the automotive<br />

application, but which apply equally to ever y<br />

vehicle component – are stringent con-<br />

straints on size, weight and cost.<br />

Th e ch a l l e n g e o f c o m p r e s s o r p a ck a g i n g<br />

As a result of all these constraints deriving<br />

from the use of an engine driven compres-<br />

sor, it is often suggested that an electrically<br />

driven system would provide a much better<br />

solution. The reason that it is not feasible<br />

on current vehicles is insufficient electrical<br />

power is available and its application must<br />

await the widespread implement ation of high<br />

powered and efficient integrated st arter/<br />

generators. The applications in which an<br />

electrical compressor would make real sense<br />

however are in hybrid and fuel cell vehicles<br />

where sufficient electrical power is readily<br />

available.