Air Conditioning Compressors - Delphi

Air Conditioning Compressors - Delphi

Air Conditioning Compressors - Delphi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Th e h i g h e ff i c i e n c y o f m o d e r n e n g ines can<br />

l e a d t o t h e s i tu a t i o n i n which i n s u ff icient re-<br />

j e c t e d h e a t i s ava i l a b l e fo r comfo r t heating .<br />

Th i s fa c t h a s p r o m p t e d t h e s u g g estion that<br />

t h e a i r c onditioning s ys tem b e o p erated in<br />

r eve r s e a s a h e a t p u m p t o s u p p l e ment the<br />

e n g i n e h e a t a n d t h e v i a b i lit y o f the concept<br />

h a s b e e n d e m o n s t r a t e d o n a n u m b er of plat-<br />

fo r m s . Th e i m p l i c a t i o n s fo r t h e c o mpressor<br />

a r e t h a t t h e r e q u i r e d o perating life can be<br />

n e a r l y d o u b l e d a n d t h e c ompressor ambient<br />

s a fe o p e r a t i n g t e m p e r a tu r e r a n g e must be<br />

ex t e n d e d d ow nwa r d s t o minus 20°C.<br />

D e l p h i ve h i c l e w i t h H e a t Pu m p s u p p l e m e n t a r y h e a t i n g<br />

R e f r i g e r a n t I s s u e s<br />

Th e a u t o m o t i ve a i r c o n ditioning industr y<br />

r e s p o n d e d p r o - a c t i ve l y t o t h e d emands of<br />

t h e 19 8 7 M o n t r e a l Pr o tocol a n d by 1994,<br />

2 ye a r s e a r l y, t h e ch a n g e ove r f r o m R12 to<br />

R 13 4 a wa s c o m p l e t e fo r a ll ve h icle produc-<br />

t i o n l i n e s i n t h e d eve l oped wo rld. It soon<br />

b e c a m e a p p a r e n t t h a t t h is m ay n ot be the<br />

e n d o f t h e s t o r y a n d w i th i ncreasing pene-<br />

t r a t i o n o f a i r c o n d i t i o n i n g i n t h e European<br />

m a r ke t t ogether w i t h t he d e mands of the<br />

Kyo t o Pr o t o c o l p r e s s u r e has b u ilt to make<br />

ch a n g e s t o s t i l l f u r t h e r r e d uce the potential<br />

c o n t r i b u t i o n o f a i r c o nditioning systems<br />

t o g l o b a l wa r m i n g . A n ew D i r ective has<br />

r e c e n t l y c o m p l e t e d i t s p r o g r ess t h r ough the<br />

E u r o p e a n l e g i s l a t i ve p r o cess. I t r e q uires the<br />

e l i m i n a t i o n o f R 13 4 a f r om a ll n ew models<br />

f r o m 2 011 a n d f r o m a l l n ew ve h icles by 2017.<br />

Th e c u rrently c o n s i d e r ed alternatives are<br />

R 15 2 a w i th a g l o b a l wa rming p o t e ntial less<br />

t h a n 10 % o f t h a t o f R 13 4 a, o r t h e so-called<br />

‘ n a tu r a l ’ r e f r i g e r a n t R 744 ( carbon dioxide).<br />

R 15 2 a h a s t h e r m o d y n amic characteristics<br />

ve r y s i m i l a r t o t h o s e o f R 13 4a a nd will be<br />

d i r e c t l y u s a b l e w i t h current c ompressor<br />

t e ch n o l o g y. I t s p o t e n t i a l d r aw back is a<br />

d e g r e e o f f l a m m a b i l i t y that h as made the<br />

i n d u s t r y reluct a n t t o c onsider i t. More re-<br />

c e n t l y o t h e r l a r g e ch e m i c al c o m panies have<br />

a n n o u n c e d t h e p o t e n t i a l ava ilabilit y of new<br />

a l t e r n a t i ve s . L i tt l e i s k n ow n a b o u t them at<br />

t h i s s t a g e b u t i t i s a s s u m e d t hat they too<br />

wo u l d f u n c t i o n w i t h c u rrent c ompressor<br />

t e ch n o l o g y. Th e r e m u s t b e a q u estion as to<br />

w h e t h e r t h e n e c e s s a r y d eve l o pment and<br />

testing and then implement ation of the<br />

necessar y manufacturing capacit y can be<br />

completed in time to meet the requirements<br />

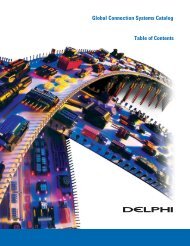

of the European legislation. If R744 becomes<br />

the chosen route the implications for com-<br />

pressor technology are ver y far-reaching . <strong>Air</strong><br />

conditioning systems with R744 need com-<br />

pressors with displacement of only a fifth<br />

of that required for R134a but operating at<br />

much higher pressures. Discharge pressures<br />

of 120 bar are normal compared with a t ypi-<br />

cal 18 bar for an R134a system. As can be<br />

imagined, these factors have big implications<br />

for the compressor layout and structural<br />

strength requirements and also represent a<br />

particularly severe shaft seal challenge.<br />

Pressure - MPa<br />

100<br />

10<br />

1<br />

100<br />

-40°C<br />

0°C<br />

200<br />

40°C<br />

80°C 120°C 160°C 200°C<br />

0°C<br />

40°C<br />

300 400<br />

Enthalpy - kJ/kg<br />

500<br />

I d e a l i ze d p r e s s u r e e n t h a l py d i a g r a m o f C O 2 c yc l e<br />

C o m p r e s s o r<br />

Te c h n o l o g i e s<br />

<strong>Air</strong> conditioning began to become available<br />

for vehicles in the early 1950s. From the<br />

beginning a number of different compressor<br />

technologies have been used. The earliest<br />

systems used piston compressors in various<br />

configurations. The Frigidaire F5, a five pis-<br />

ton wobble plate configuration, used in the<br />

earliest GM vehicles with air conditioning<br />

was first produced in 1956 – it weighed in at<br />

18kg! The R4 compressor with a scotch yoke<br />

mechanism was first produced by Harrison<br />

(now <strong>Delphi</strong>) in 1974 and remained in pro-<br />

duction until 1995. It was 190mm in overall<br />

diameter and weighed 9kg .<br />

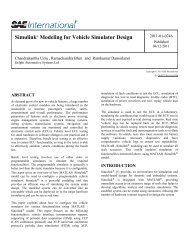

A n e a r l y<br />

c o m p r e s s o r,<br />

t h e D e l p h i R 4<br />

80°C<br />

120°C<br />

600<br />

160°C<br />

200°C<br />

700