paroc panel system magazine

paroc panel system magazine

paroc panel system magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

16 THE MAGAZINE<br />

A technical qua<br />

Advanced structural technology represents the highest<br />

quality standard in structural sandwich <strong>panel</strong>s in terms<br />

of strength, durability and fire safety. AST is a visible<br />

sign guaranteeing a high, defined quality level of these<br />

invisible characters and making the choice of reliable<br />

sandwich <strong>panel</strong>s easier.<br />

AST SETS THE STANDARD BASED ON 3 PARTS CRITERIA<br />

Strength - optimised and controlled properties<br />

The use of the best properties of each material and the interaction between them is the basis in<br />

structural sandwich <strong>panel</strong> design, providing optimal strength properties. Without this interaction<br />

there is no sandwich structure, that is why the bonding technique is the most essential part in the<br />

manufacturing process. A measure of the interactive quality is the tensile strength of a <strong>panel</strong>. For<br />

AST <strong>panel</strong>s the threshold value is 100 kN/m 2<br />

. A <strong>panel</strong> that fulfils the AST demands ensures reliable<br />

strength properties and minimises the risk with window openings and suspensions in the facings.<br />

Durability - long term performance property<br />

Sandwich <strong>panel</strong>s have to maintain their strength and insulating properties, and to remain weather<br />

resistant over their expected service life. For industrial buildings a lifetime of 25 years can be sufficient<br />

but in other cases, the requirements can be 50 years or more. The durability of a sandwich <strong>panel</strong><br />

describes its ability to fulfil this requirement. The lifetime of a structural material can be estimated<br />

by using accelerated test methods. For structural sandwich <strong>panel</strong>s methods and classification can<br />

be found in the new ECCS/CIB European Recommendations for Sandwich Panels. An AST <strong>panel</strong><br />

must fulfil the highest class for durability to guarantee the properties during the lifetime of a building.<br />

Fire safety – minimised risk for people and property<br />

The global fire safety design objectives are to ensure safety for people in the building, to prevent<br />

losses in terms of properties and business activities and to protect the environment from hazardous<br />

materials. An AST core is a non-combustible material, which means that it is impossible to ignite and<br />

it will not contribute heat to the fire. It will neither produce smoke nor toxic irritant products. The<br />

<strong>panel</strong> joint in an AST <strong>panel</strong> must be tight against hot gases and flames.<br />

AST - a reliable value for clients<br />

AST is a major step forward in defining a quality standard for structural sandwich. The hidden<br />

characteristics that distinguish AST <strong>panel</strong>s from other <strong>panel</strong> products are made visible by the AST<br />

logo stamped on each <strong>panel</strong>. It is a sign specifiers and building owners can rely on.<br />

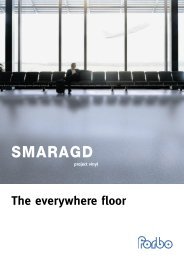

Applied<br />

bending<br />

forces<br />

Compression<br />

Tension<br />

Sandwich <strong>panel</strong>s are of complicated nature.<br />

Core<br />

compression<br />

Core shear