Keeping an eye on Sales - Association of Independent Corrugated ...

Keeping an eye on Sales - Association of Independent Corrugated ...

Keeping an eye on Sales - Association of Independent Corrugated ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Folding—R<str<strong>on</strong>g>an</str<strong>on</strong>g>domness C<strong>on</strong>trolled<br />

c<strong>on</strong>tinued from page 19<br />

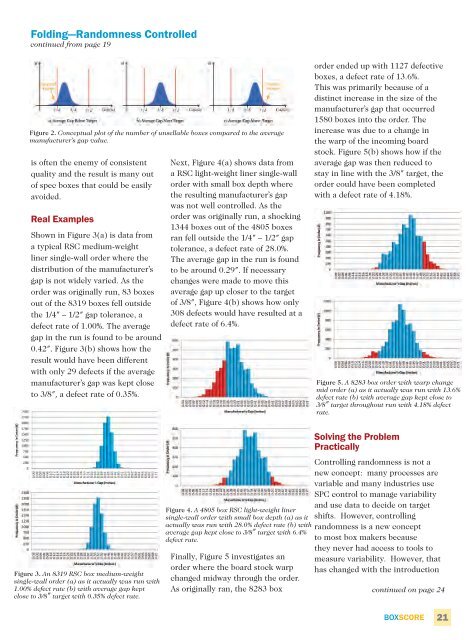

Figure 2. C<strong>on</strong>ceptual plot <strong>of</strong> the number <strong>of</strong> unsellable boxes compared to the average<br />

m<str<strong>on</strong>g>an</str<strong>on</strong>g>ufacturer’s gap value.<br />

is <strong>of</strong>ten the enemy <strong>of</strong> c<strong>on</strong>sistent<br />

quality <str<strong>on</strong>g>an</str<strong>on</strong>g>d the result is m<str<strong>on</strong>g>an</str<strong>on</strong>g>y out<br />

<strong>of</strong> spec boxes that could be easily<br />

avoided.<br />

Real Examples<br />

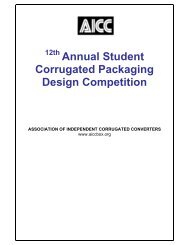

Shown in Figure 3(a) is data from<br />

a typical RSC medium-weight<br />

liner single-wall order where the<br />

distributi<strong>on</strong> <strong>of</strong> the m<str<strong>on</strong>g>an</str<strong>on</strong>g>ufacturer’s<br />

gap is not widely varied. As the<br />

order was originally run, 83 boxes<br />

out <strong>of</strong> the 8319 boxes fell outside<br />

the 1/4” – 1/2” gap toler<str<strong>on</strong>g>an</str<strong>on</strong>g>ce, a<br />

defect rate <strong>of</strong> 1.00%. The average<br />

gap in the run is found to be around<br />

0.42”. Figure 3(b) shows how the<br />

result would have been different<br />

with <strong>on</strong>ly 29 defects if the average<br />

m<str<strong>on</strong>g>an</str<strong>on</strong>g>ufacturer’s gap was kept close<br />

to 3/8”, a defect rate <strong>of</strong> 0.35%.<br />

Figure 3. An 8319 RSC box medium-weight<br />

single-wall order (a) as it actually was run with<br />

1.00% defect rate (b) with average gap kept<br />

close to 3/8” target with 0.35% defect rate.<br />

Next, Figure 4(a) shows data from<br />

a RSC light-weight liner single-wall<br />

order with small box depth where<br />

the resulting m<str<strong>on</strong>g>an</str<strong>on</strong>g>ufacturer’s gap<br />

was not well c<strong>on</strong>trolled. As the<br />

order was originally run, a shocking<br />

1344 boxes out <strong>of</strong> the 4805 boxes<br />

r<str<strong>on</strong>g>an</str<strong>on</strong>g> fell outside the 1/4” – 1/2” gap<br />

toler<str<strong>on</strong>g>an</str<strong>on</strong>g>ce, a defect rate <strong>of</strong> 28.0%.<br />

The average gap in the run is found<br />

to be around 0.29”. If necessary<br />

ch<str<strong>on</strong>g>an</str<strong>on</strong>g>ges were made to move this<br />

average gap up closer to the target<br />

<strong>of</strong> 3/8”, Figure 4(b) shows how <strong>on</strong>ly<br />

308 defects would have resulted at a<br />

defect rate <strong>of</strong> 6.4%.<br />

Figure 4. A 4805 box RSC light-weight liner<br />

single-wall order with small box depth (a) as it<br />

actually was run with 28.0% defect rate (b) with<br />

average gap kept close to 3/8” target with 6.4%<br />

defect rate.<br />

Finally, Figure 5 investigates <str<strong>on</strong>g>an</str<strong>on</strong>g><br />

order where the board stock warp<br />

ch<str<strong>on</strong>g>an</str<strong>on</strong>g>ged midway through the order.<br />

As originally r<str<strong>on</strong>g>an</str<strong>on</strong>g>, the 8283 box<br />

order ended up with 1127 defective<br />

boxes, a defect rate <strong>of</strong> 13.6%.<br />

This was primarily because <strong>of</strong> a<br />

distinct increase in the size <strong>of</strong> the<br />

m<str<strong>on</strong>g>an</str<strong>on</strong>g>ufacturer’s gap that occurred<br />

1580 boxes into the order. The<br />

increase was due to a ch<str<strong>on</strong>g>an</str<strong>on</strong>g>ge in<br />

the warp <strong>of</strong> the incoming board<br />

stock. Figure 5(b) shows how if the<br />

average gap was then reduced to<br />

stay in line with the 3/8” target, the<br />

order could have been completed<br />

with a defect rate <strong>of</strong> 4.18%.<br />

Figure 5. A 8283 box order with warp ch<str<strong>on</strong>g>an</str<strong>on</strong>g>ge<br />

mid order (a) as it actually was run with 13.6%<br />

defect rate (b) with average gap kept close to<br />

3/8” target throughout run with 4.18% defect<br />

rate.<br />

Solving the Problem<br />

Practically<br />

C<strong>on</strong>trolling r<str<strong>on</strong>g>an</str<strong>on</strong>g>domness is not a<br />

new c<strong>on</strong>cept: m<str<strong>on</strong>g>an</str<strong>on</strong>g>y processes are<br />

variable <str<strong>on</strong>g>an</str<strong>on</strong>g>d m<str<strong>on</strong>g>an</str<strong>on</strong>g>y industries use<br />

SPC c<strong>on</strong>trol to m<str<strong>on</strong>g>an</str<strong>on</strong>g>age variability<br />

<str<strong>on</strong>g>an</str<strong>on</strong>g>d use data to decide <strong>on</strong> target<br />

shifts. However, c<strong>on</strong>trolling<br />

r<str<strong>on</strong>g>an</str<strong>on</strong>g>domness is a new c<strong>on</strong>cept<br />

to most box makers because<br />

they never had access to tools to<br />

measure variability. However, that<br />

has ch<str<strong>on</strong>g>an</str<strong>on</strong>g>ged with the introducti<strong>on</strong><br />

c<strong>on</strong>tinued <strong>on</strong> page 24<br />

bOXSCORE<br />

21