UHV Flanges and Fittings - VG Scienta

UHV Flanges and Fittings - VG Scienta

UHV Flanges and Fittings - VG Scienta

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

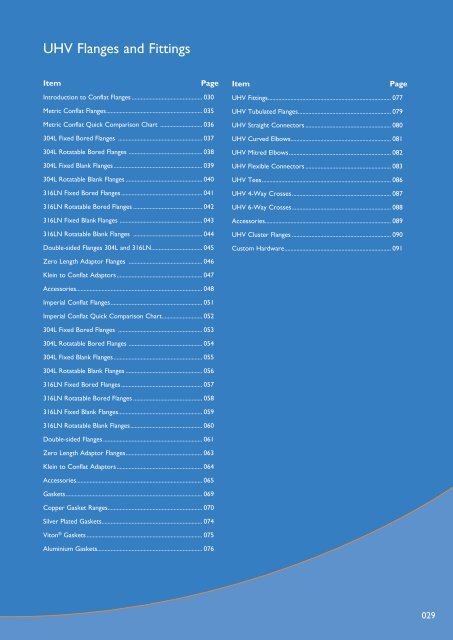

<strong>UHV</strong> <strong>Flanges</strong> <strong>and</strong> <strong>Fittings</strong><br />

Item Page<br />

Introduction to Conflat <strong>Flanges</strong> ............................................... 030<br />

Metric Conflat <strong>Flanges</strong> ................................................................ 035<br />

Metric Conflat Quick Comparison Chart ............................ 036<br />

304L Fixed Bored <strong>Flanges</strong> ........................................................ 037<br />

304L Rotatable Bored <strong>Flanges</strong> ................................................. 038<br />

304L Fixed Blank <strong>Flanges</strong> ........................................................... 039<br />

304L Rotatable Blank <strong>Flanges</strong> ................................................... 040<br />

316LN Fixed Bored <strong>Flanges</strong> ...................................................... 041<br />

316LN Rotatable Bored <strong>Flanges</strong> .............................................. 042<br />

316LN Fixed Blank <strong>Flanges</strong> ....................................................... 043<br />

316LN Rotatable Blank <strong>Flanges</strong> .............................................. 044<br />

Double-sided <strong>Flanges</strong> 304L <strong>and</strong> 316LN .................................. 045<br />

Zero Length Adaptor <strong>Flanges</strong> ................................................. 046<br />

Klein to Conflat Adaptors ......................................................... 047<br />

Accessories .................................................................................... 048<br />

Imperial Conflat <strong>Flanges</strong> ............................................................. 051<br />

Imperial Conflat Quick Comparison Chart ........................... 052<br />

304L Fixed Bored <strong>Flanges</strong> ........................................................ 053<br />

304L Rotatable Bored <strong>Flanges</strong> ................................................. 054<br />

304L Fixed Blank <strong>Flanges</strong> ........................................................... 055<br />

304L Rotatable Blank <strong>Flanges</strong> ................................................... 056<br />

316LN Fixed Bored <strong>Flanges</strong> ...................................................... 057<br />

316LN Rotatable Bored <strong>Flanges</strong> .............................................. 058<br />

316LN Fixed Blank <strong>Flanges</strong> ........................................................ 059<br />

316LN Rotatable Blank <strong>Flanges</strong> ................................................ 060<br />

Double-sided <strong>Flanges</strong> .................................................................. 061<br />

Zero Length Adaptor <strong>Flanges</strong> ................................................... 063<br />

Klein to Conflat Adaptors ......................................................... 064<br />

Accessories .................................................................................... 065<br />

Gaskets ........................................................................................... 069<br />

Copper Gasket Ranges ............................................................... 070<br />

Silver Plated Gaskets ................................................................... 074<br />

Viton ® Gaskets ............................................................................. 075<br />

Aluminium Gaskets...................................................................... 076<br />

Item Page<br />

<strong>UHV</strong> <strong>Fittings</strong> .................................................................................. 077<br />

<strong>UHV</strong> Tubulated <strong>Flanges</strong> .............................................................. 079<br />

<strong>UHV</strong> Straight Connectors ......................................................... 080<br />

<strong>UHV</strong> Curved Elbows................................................................... 081<br />

<strong>UHV</strong> Mitred Elbows .................................................................... 082<br />

<strong>UHV</strong> Flexible Connectors ......................................................... 083<br />

<strong>UHV</strong> Tees ...................................................................................... 086<br />

<strong>UHV</strong> 4-Way Crosses .................................................................. 087<br />

<strong>UHV</strong> 6-Way Crosses .................................................................. 088<br />

Accessories .................................................................................... 089<br />

<strong>UHV</strong> Cluster <strong>Flanges</strong> .................................................................. 090<br />

Custom Hardware ....................................................................... 091<br />

029

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

Conflat <strong>Flanges</strong><br />

From Commercial Grade 304L to High<br />

Quality 316LN stainless steel<br />

<strong>VG</strong> <strong>Scienta</strong> is probably the only manufacturer to<br />

offer a range of flange material grades throughout<br />

the entire product range, to cover both the<br />

st<strong>and</strong>ard <strong>and</strong> high performance requirements<br />

of <strong>UHV</strong> technology. With commercial 304L<br />

<strong>and</strong> 316LN stainless steels it is possible to cover<br />

the operational temperature range of -190 ºC<br />

to +450 ºC. This can be extended when using<br />

vacuum firing to +950 ºC with our st<strong>and</strong>ard<br />

316LN grade of flange material. All flanges<br />

are manufactured on dedicated CNC machines<br />

to ensure excellent product consistency. Every<br />

stage of production is carefully quality controlled<br />

to ISO9001 specifications <strong>and</strong> each flange<br />

is code stamped with a material cast number<br />

to allow full material traceability. Each flange is<br />

processed through an automated aqueous cleaning<br />

procedure <strong>and</strong> individually sealed <strong>and</strong> packed<br />

so that the product is in perfect condition for<br />

use on <strong>UHV</strong> equipment.<br />

<strong>VG</strong> <strong>Scienta</strong>’s st<strong>and</strong>ard range of flanges (ZFC<br />

<strong>and</strong> ZFCR series) are manufactured from specially<br />

selected commercial grade 304L steel of<br />

high cleanliness <strong>and</strong> carefully controlled chemistry.<br />

These flanges are suitable for the every<br />

day vacuum user who wants a reliable, but cost<br />

effective, <strong>UHV</strong> material. 316LN flanges on the<br />

other h<strong>and</strong> (ZFCL <strong>and</strong> ZFCRL series) are specially<br />

produced for more dem<strong>and</strong>ing applications<br />

including the need for greater hardness (at high<br />

temperatures) <strong>and</strong> low magnetic permeability.<br />

This grade of austenitic stainless steel has nitrogen<br />

added, increasing the overall hardness <strong>and</strong><br />

strength. Hardness value of 316LN is typically<br />

160-180 Brinell <strong>and</strong> generally higher than 304<br />

series steels. More importantly, 316LN retains<br />

the hardness at elevated temperatures, especially<br />

after repeated bakeouts or high temperature system<br />

degassing procedures.<br />

The 316LN steel is electroslag refined (ESR) to<br />

eliminate gross macro segregation <strong>and</strong> improve<br />

grain homogeneity resulting in an excellent uniform<br />

structure. The ESR process substantially<br />

reduces the total inclusion content <strong>and</strong> removes<br />

impurities, producing a very clean material. This<br />

minimises any risk of leakage paths due to inclusions.<br />

316LN steel produced by this route is<br />

virtually ferrite free <strong>and</strong> flanges produced from<br />

this material have a very low magnetic permeability<br />

(

Why Two Materials?<br />

It is important to note that there are several<br />

grades of material available in the market place.<br />

In increasing order of cost, these materials are:<br />

1 Flame cut flange blanks (the part used before<br />

it is machined into a flange) are cut with an<br />

industrial laser or similar from large sheets of<br />

rolled stainless steel.<br />

2 Forged flange blanks are made from individually<br />

forged pieces of stainless steel. It has the<br />

same basic properties as flame cut.<br />

3 Cross forged flange blanks are made from<br />

individually forged pieces of stainless steel,<br />

they are then forged in several directions to<br />

break up any microscopic stingers (formed<br />

during manufacture of the billet) that may be<br />

present. This process is now only used for the<br />

316LN material. Advances in steel manufacture<br />

have meant that this is no longer such a<br />

significant problem as it was 20 years ago.<br />

316LN <strong>Flanges</strong> - Material Certification<br />

A commonly asked question about 316LN relates<br />

to the various levels of certification that we can<br />

supply.<br />

There are two levels of certificates that we can<br />

provide:<br />

1 Certificates of Conformity (C of C's)<br />

These are issued internally by <strong>VG</strong> <strong>Scienta</strong> <strong>and</strong><br />

effectively qualify that the item in question<br />

conforms to our published specification. i.e.<br />

it is made from 304L stainless steel, or it can<br />

be baked to 250 ºC etc.<br />

These Certificates of Conformity can apply<br />

to items other than just flanges. As regards<br />

the actual stainless steels involved in the<br />

manufacture of our flanges, we can also provide<br />

(at extra cost) the following additional<br />

certification.<br />

2 Material Certificates<br />

When the stainless steel is manufactured, a<br />

chemical analysis of the resultant material is<br />

performed, <strong>and</strong> samples are taken from the<br />

top, the middle, <strong>and</strong> the bottom of the ingot<br />

<strong>and</strong> averaged to give the figures. The cast is<br />

www.vgscienta.com<br />

Conflat <strong>Flanges</strong><br />

individually numbered <strong>and</strong> is identified by<br />

this number. These certificates are available<br />

to customers for a small charge as they are<br />

normally supplied with the material. This<br />

certificate tells you what different chemicals<br />

are present in the steel <strong>and</strong> what mechanical<br />

properties the steel has.<br />

Typical 316LN Chemical Composition %<br />

Cr 16.0 to 18.5 % Ni 12.0 to 14 %<br />

C < 0.03 % Si 0.7 to 1.0 %<br />

Mn 1.5 to 2.0 % Mo 2.0 to 3.0 %<br />

N 0.14 to 0.20 % P 0.045 % max<br />

S 0.030 % max<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

031

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

Basic Flange Types<br />

Blank Flange Blank Rotatable<br />

Bored Bored Rotatable<br />

Stepped Adaptor Zero Length Adaptor<br />

032 www.vgscienta.com

FC <strong>Flanges</strong> - 304L <strong>and</strong> 316LN Features<br />

<strong>and</strong> Benefits<br />

• Made to international flange st<strong>and</strong>ards. Fits<br />

to customers existing flange dimensions<br />

• Two materials available, 304L <strong>and</strong> 316LN<br />

• Quick delivery - extensive stock<br />

• High quality control<br />

• Competitive prices<br />

• Wide range of sizes <strong>and</strong> types suitable for<br />

all customer requirements<br />

• Low outgassing rates. Rapid achievement<br />

of <strong>UHV</strong>, 316LN can be vacuum fired to<br />

remove dissolved (i.e. H 2 ) gases in the flange<br />

material<br />

• Controlled material hardness. Longer life<br />

• High temperature range. Suitable for use<br />

from liquid nitrogen temperatures to<br />

450 °C. 316LN to 1.050 °C vacuum bake<br />

• Good pressure range. 1 Bar to 10e -12 mbar<br />

• Outgassing rates

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

Conflat <strong>Flanges</strong> - Important Product Information<br />

IMPORTANT PRODUCT INFORMATION<br />

<strong>VG</strong> <strong>Scienta</strong> have been manufacturing Conflat flanges<br />

for over 40 years <strong>and</strong> were one of the first suppliers<br />

to the <strong>UHV</strong> industry. We have a very wide range of<br />

sizes <strong>and</strong> types of flanges produced in a number of different<br />

materials. These are fully compatible with other<br />

manufacturers' flanges up to NW250 size in terms of<br />

mating flanges together - thicknesses (dimension B in<br />

the drawing), gasket sizes, bolt hole number, pitch circle<br />

diameter (or PCD, dimension F in the drawing) <strong>and</strong> size<br />

etc., but there are some features of our flanges that you<br />

should be aware of when consulting this catalogue <strong>and</strong><br />

ordering our products<br />

NW versus FC Designations<br />

<strong>VG</strong> <strong>Scienta</strong> has evolved <strong>and</strong> used its own FC designation to describe flange sizes. It is important to note that FC<br />

designation is not the same as the NW designation. FC generally refers to the outside diameter (OD) of a tube<br />

that is fitted to a flange; NW generally refers to the inside diameter (ID) or “clear bore” of the flange.<br />

Thus a <strong>VG</strong> <strong>Scienta</strong> FC41 flange has a clear bore of 38 mm <strong>and</strong> is therefore equivalent to an NW38 flange.<br />

Tube sizes - Imperial versus Metric Tube<br />

The tube counterbore diameters (dimension D in the drawing) of our flanges have been primarily governed by the<br />

availability of Imperial (inch) size tube in the UK; the USA still works with Imperial units <strong>and</strong> many of the original<br />

UK tube sizes are still used in the USA.<br />

In many cases there are st<strong>and</strong>ard sizes of metric tube that will fit our st<strong>and</strong>ard flanges - all critical dimensions of our<br />

st<strong>and</strong>ard flanges are quoted in millimetres, so please ensure that you check the tube counterbore diameter before<br />

ordering. In some cases we have included “true metric” versions of our flanges in the flange tables; otherwise the<br />

availability of metric versions is indicated against each flange part code.<br />

Tube Counterbore Depth or “L<strong>and</strong> Thickness”<br />

The l<strong>and</strong> thickness (dimension C in the drawing) or set-back dimension is effectively the distance between the end<br />

of the tube that you insert into the flange, <strong>and</strong> the front face of the flange. For example, if you are fitting flanges to<br />

port tubes on a chamber, then this is the dimension that you need to take into account when calculating the overall<br />

port lengths.<br />

This dimension is not constant for all flanges, <strong>and</strong> varies from manufacturer to manufacturer. It is very important to<br />

take note of this when ordering bored flanges.<br />

034 www.vgscienta.com

Introduction to Conflat <strong>Flanges</strong><br />

• Wide range of Imperial <strong>and</strong> Metric st<strong>and</strong>ard<br />

sizes<br />

• All flanges manufactured on computer<br />

controlled CNC machines for accuracy<br />

• Available in 304L or 316LN stainless steel<br />

• Low outgassing rates, 450 °C) without<br />

leaking.<br />

<strong>VG</strong> <strong>Scienta</strong>’s range of <strong>UHV</strong> flanges is world<br />

renowned both for its quality <strong>and</strong> range of sizes<br />

<strong>and</strong> materials. The complete range of flanges are<br />

fully compatible with the internationally agreed<br />

ISO/Pneurop st<strong>and</strong>ards <strong>and</strong> will connect to any<br />

other flange that also complies with this st<strong>and</strong>ard<br />

(for flanges with a diameter greater than<br />

300 mm no such st<strong>and</strong>ards exist at present). All<br />

flange OD dimensions are nominal.<br />

Method of Sealing<br />

The <strong>UHV</strong> seal is made by trapping a copper gasket<br />

between two sexless flanges that have a sharp<br />

knife-edge profiled onto their operating face.<br />

When joined together with a set of connecting<br />

bolts, the knife-edges cut into the surface of the<br />

copper gasket to make a seal that is <strong>UHV</strong> leak<br />

tight. When exposed to bakeout temperatures<br />

the shape of the knife-edge ensures that the seal<br />

remains leak tight by resisting any differential<br />

movements between the copper gasket <strong>and</strong> the<br />

stainless steel flange parts.<br />

www.vgscienta.com<br />

Metric Conflat <strong>Flanges</strong><br />

Fixed <strong>and</strong> Rotatable <strong>Flanges</strong><br />

To aid the construction of <strong>UHV</strong> chambers <strong>and</strong><br />

components, <strong>VG</strong> <strong>Scienta</strong> flanges are available in<br />

both fixed <strong>and</strong> rotatable configurations. Fixed<br />

flanges are a single machined item with the<br />

bolt hole orientation fixed into position once<br />

they are welded onto a chamber or component.<br />

Rotatable flanges are manufactured in two parts<br />

with the knife-edge part <strong>and</strong> external bolt hole<br />

ring being separate. Once the knife-edge part is<br />

welded in position it is easy to change the orientation<br />

of the bolt holes relative to the axis of the<br />

port. This makes rotatable flanges ideal for the<br />

situations where alignment of a component to<br />

a chamber (or another component) needs to be<br />

set accurately before the flange mounting bolts<br />

are tightened.<br />

Please Note: It is not advisable to have two<br />

rotatable flanges at the same joint.<br />

Internal Weld<br />

Copper Gasket<br />

<strong>Flanges</strong> are bolted together with a copper<br />

gasket between the knife edges.<br />

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

035

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

Metric Conflat Flange Quick Reference Comparison<br />

Chart<br />

Metric Flange Comparison Chart<br />

IMPORTANT PRODUCT INFORMATION<br />

See page 034 concerning FC <strong>and</strong> NW designations<br />

304L 304L 304L 304L 316LN 316LN 316LN 316LN<br />

OD Pneurop Fixed Rotatable Fixed Rotatable Fixed Rotatable Fixed Rotatable<br />

mm inch Equivalent Bored Bored Blank Blank Bored Bored Blank Blank<br />

34 1.33 Blank ZFC90 ZFCR90 ZFCL90 ZFCRL90<br />

34 1.33 Blank ZFC90T ZFCL90T<br />

34 1.33 NW7CF ZFC97 ZFCR97 ZFCL97 ZFCRL97<br />

34 1.33 NW12CF ZFC912 ZFCL912<br />

34 1.33 NW14CF ZFC914 ZFCR914 ZFCL914 ZFCRL914<br />

34 1.33 NW16CF ZFC919 ZFCR919 ZFCL919 ZFCRL919<br />

34 1.33 NW16CF ZFC19NS ZFCL19NS<br />

34 1.33 NW16CF ZFC19NST ZFCL19NT<br />

70 2.75 Blank ZFC2 ZFCR2 ZFCL2 ZFCRL2<br />

70 2.75 Blank Tapped ZFC2T ZFCR2T ZFCL2T ZFCRL2T<br />

70 2.75 NW14CF ZFC14 ZFCR14 ZFCL14 ZFCRL14<br />

70 2.75 NW14CF ZFCR14T ZFCRL14T<br />

70 2.75 NW25CF ZFC25 ZFCR25 ZFCL25 ZFCRL25<br />

70 2.75 NW25CF ZFCR25T ZFCRL25T<br />

70 2.75 NW35CF ZFC38 ZFCR38 ZFCL38 ZFCRL38<br />

70 2.75 NW35CF ZFC38T ZFCR38T ZFCL38T ZFCRL38T<br />

70 2.75 NW38CF ZFC41 ZFCR41 ZFCL41 ZFCRL41<br />

70 2.75 NW38CF ZFC41T ZFCR41T ZFCL41T ZFCRL41T<br />

70 2.75 NW45CF ZFC45 ZFCL45<br />

70 2.75 NW45CF ZFC45T ZFCL45T<br />

85 3.38 Blank ZFC3 ZFCL3<br />

85 3.38 Blank Tapped ZFC3T ZFCL3T<br />

85 3.38 NW54CF ZFC54 ZFCR54 ZFCL54 ZFCRL54<br />

85 3.38 NW54CF ZFC54T ZFCL54T<br />

114 4.50 Blank ZFC4 ZFCR4 ZFCL4 ZFCRL4<br />

114 4.50 Blank Tapped ZFC4T ZFCR4T ZFCL4T ZFCRL4T<br />

114 4.50 NW50CF ZFC50 ZFCR50 ZFCL50 ZFCRL50<br />

114 4.50 NW63CF ZFC64 ZFCR64 ZFCL64 ZFCRL64<br />

114 4.50 NW63CF ZFC64T ZFCR64T ZFCL64T ZFCRL64T<br />

114 4.50 NW68CF ZFC70 ZFCR70 ZFCL70 ZFCRL70<br />

114 4.50 NW68CF ZFC70T ZFCR70T ZFCL70T ZFCRL70T<br />

152 6.00 Blank ZFC6 ZFCR6 ZFCL6 ZFCRL6<br />

152 6.00 Blank Tapped ZFC6T ZFCR6T ZFCL6T ZFCRL6T<br />

152 6.00 NW100CF ZFC100 ZFCR100 ZFCL100 ZFCRL100<br />

152 6.00 NW100CF ZFC100T ZFCR100T ZFCL100T<br />

203 8.00 Blank ZFC8 ZFCR8 ZFCL8 ZFCRL8<br />

203 8.00 Blank Tapped ZFC8T ZFCR8T ZFCL8T ZFCRL8T<br />

203 8.00 NW150CF ZFC150 ZFCR150 ZFCL150 ZFCRL150<br />

203 8.00 NW150CF ZFC150T ZFCR150T ZFCL150T ZFCRL150T<br />

254 10.00 Blank ZFC10 ZFCR10 ZFCL10 ZFCRL10<br />

254 10.00 Blank Tapped ZFC10T ZFCL10T<br />

254 10.00 NW200CF ZFC200 ZFCR200 ZFCL200 ZFCRL200<br />

254 10.00 NW200CF ZFC200T ZFCL200T<br />

Please Note - No accepted international st<strong>and</strong>ard dimensions exist for flanges with an OD of 300 mm or greater.<br />

300 12.00 Blank ZFC12 ZFCL12<br />

300 12.00 NW250CF ZFC250 ZFCL250<br />

362 14.25 Blank ZFC1425 ZFCL1425<br />

362 14.25 NW300CF ZFC300 ZFCL300<br />

indicates clearance bolt holes indicates tapped bolt holes<br />

036 www.vgscienta.com

Fixed bored flanges are available in the full range<br />

of sizes as indicated in the chart below. They<br />

are normally welded on to chamber tubulations<br />

or certain specific sizes of component. Please<br />

note that the smaller sizes of flange can accept a<br />

number of different st<strong>and</strong>ard tube sizes.<br />

(1) Dimension D refers to external tubulation <strong>and</strong> not the recess in<br />

flange body as per rest of range of flanges<br />

(2) Non spigotted flange<br />

(3) Non spigotted flange <strong>and</strong> tapped holes<br />

(M) Metric version available on request. Contact Technical Sales<br />

Department for details.<br />

(T) Tapped version available on request. Contact Technical Sales<br />

Department for details.<br />

www.vgscienta.com<br />

304L Fixed Bored <strong>Flanges</strong> (FC Series)<br />

304L Fixed Bored <strong>Flanges</strong><br />

Tube Bolt Bolt Tube Size<br />

Clear Flange L<strong>and</strong> Counter Hole Hole No. of to Fit Shipping<br />

OD Pneurop Bore Thickness Thickness Bore PCD Diameter Bolt Flange Weight<br />

mm inch Equivalent A B C D F (or thread) Holes Bore kg Order Code<br />

34 1.33 NW7CF 6.4 7.6 N/A 6.4 27.0 4.3 6 6.35 0.1 ZFC97 (T)<br />

34 1.33 NW12CF 12.0 7.6 N/A 12.7 27.0 4.3 6 12.70 0.1 ZFC912 (T)<br />

34 1.33 NW14CF 13.2 7.6 4.8 14.4 27.0 4.3 6 14.29 0.1 ZFC914(T)<br />

34 1.33 NW16CF 16.6 7.6 12.7 19.1 27.0 4.3 6 19.05 0.1 ZFC919 (1)(T)(M)<br />

34 1.33 NW16CF 16.6 7.6 4.8 19.1 27.0 4.3 6 19.05 0.1 ZFC19NS (2)<br />

34 1.33 NW16CF 16.6 7.6 4.8 19.1 27.0 (M4) 6 19.05 0.1 ZFC19NST (3)<br />

70 2.75 NW14CF 13.2 13.0 4.8 14.4 58.7 6.8 6 14.29 0.3 ZFC14<br />

70 2.75 NW25CF 24.2 13.0 4.8 25.5 58.7 6.8 6 25.40 0.3 ZFC25 (T)<br />

70 2.75 NW35CF 36.9 13.0 4.8 38.3 58.7 6.8 6 38.10 0.3 ZFC38 (M)<br />

70 2.75 NW35CF 36.9 13.0 4.8 38.3 58.7 (M6) 6 38.10 0.3 ZFC38T (M)<br />

70 2.75 NW40CF 40.0 13.0 4.8 41.3 58.7 6.8 6 41.27 0.3 ZFC41<br />

70 2.75 NW40CF 40.0 13.0 4.8 41.3 58.7 (M6) 6 41.27 0.3 ZFC41T<br />

70 2.75 NW40CF 40.0 13.0 10.2 44.5 58.7 6.8 6 44.45 0.3 ZFC45<br />

70 2.75 NW40CF 40.0 13.0 10.2 44.5 58.7 (M6) 6 44.45 0.3 ZFC45T<br />

85 3.38 NW54CF 49.0 16.0 8.0 51.1 72.4 8.4 8 50.80 0.7 ZFC54 (M)<br />

85 3.38 NW54CF 49.0 16.0 8.0 51.1 72.4 (M8) 8 50.80 0.7 ZFC54T (M)<br />

114 4.50 NW50CF 49.6 17.5 8.0 51.1 92.1 8.4 8 50.80 1.0 ZFC50 (M)(T)<br />

114 4.50 NW61CF 61.2 17.5 8.0 63.7 92.1 8.4 8 63.50 0.9 ZFC64<br />

114 4.50 NW61CF 61.2 17.5 8.0 63.7 92.1 (M8) 8 63.50 0.9 ZFC64T<br />

114 4.50 NW68CF 68.0 17.5 8.0 70.0 92.1 8.4 8 69.80 0.9 ZFC70<br />

114 4.50 NW68CF 68.0 17.5 8.0 70.0 92.1 (M8) 8 69.80 0.9 ZFC70T<br />

152 6.00 NW100CF 99.4 20.0 9.5 101.9 130.2 8.4 16 101.60 1.7 ZFC100 (M)<br />

152 6.00 NW100CF 99.4 20.0 9.5 101.9 130.2 (M8) 16 101.60 1.7 ZFC100T (M)<br />

203 8.00 NW150CF 149.7 22.0 9.5 152.6 181.0 8.4 20 152.40 2.6 ZFC150 (M)<br />

203 8.00 NW150CF 149.7 22.0 9.5 152.6 181.0 (M8) 20 152.40 2.6 ZFC150T (M)<br />

254 10.00 NW200CF 200.4 24.5 9.5 203.5 231.8 8.4 24 203.20 3.7 ZFC200 (M)<br />

254 10.00 NW200CF 200.4 24.5 9.5 203.5 231.8 (M8) 24 203.20 3.7 ZFC200T (M)<br />

Please Note - No accepted international st<strong>and</strong>ard dimensions exist for flanges with an OD of 300 mm or greater.<br />

305 12.00 NW250CF 250.7 27.0 9.5 254.4 283.0 10.5 32 254.00 6.3 ZFC250<br />

305 12.00 NW250CF 250.7 27.0 9.5 254.4 283.0 (M10) 32 254.00 6.3 ZFC250T<br />

305 12.00 NW250CF 250.0 26.0 13.0 256.4 284.0 8.5 32 256.00 6.3 ZFC250M<br />

305 12.00 NW250CF 250.0 26.0 13.0 256.4 284.0 (M8) 32 256.00 6.3 ZFC250MT<br />

362 14.25 NW300CF 302.0 30.0 16.0 305.2 334.0 10.5 36 304.80 9.0 ZFC300<br />

362 14.25 NW300CF 302.0 30.0 16.0 305.2 334.0 (M10) 36 304.80 9.0 ZFC300T<br />

All dimensions in mm unless otherwise stated.<br />

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

037

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

304L Rotatable Bored <strong>Flanges</strong> (FCR Series)<br />

304L Rotatable Bored <strong>Flanges</strong><br />

Rotatable bored flanges are available in the full<br />

range of sizes as indicated in the chart below.<br />

They are normally welded onto chamber tubulations<br />

or certain specific sizes of component.<br />

The rotatable nature of the flange allows any<br />

bolt hole angle variation to be easily accommodated.<br />

Please note that the smaller sizes of<br />

flange can accept a number of different st<strong>and</strong>ard<br />

tube sizes.<br />

Tube Rot Bolt Bolt Tube Size<br />

Clear Flange L<strong>and</strong> Counter Tube Hole Hole No. of to Fit Shipping<br />

OD Pneurop Bore Thickness Thickness Bore Bore PCD Diameter Bolt Flange Weight<br />

mm inch Equivalent A B C D E F (or thread) Holes Bore kg Order Code<br />

34 1.33 NW7CF 6.4 7.6 N/A 6.4 19.3 27.0 4.3 6 6.35 0.1 ZFCR97<br />

34 1.33 NW14CF 13.2 7.6 4.8 14.4 19.3 27.0 4.3 6 14.29 0.1 ZFCR914 (T)<br />

34 1.33 NW16CF 16.6 7.6 12.7 19.1 19.3 27.0 4.3 6 19.05 0.1 ZFCR919 (1)(M)(T)<br />

70 2.75 NW14CF 13.2 13.0 4.8 14.4 41.9 58.7 6.8 6 14.29 0.3 ZFCR14<br />

70 2.75 NW14CF 13.2 13.0 4.8 14.4 41.9 58.7 (M6) 6 14.29 0.3 ZFCR14T<br />

70 2.75 NW25CF 24.2 13.0 4.8 25.5 41.9 58.7 6.8 6 25.40 0.3 ZFCR25<br />

70 2.75 NW25CF 24.2 13.0 4.8 25.5 41.9 58.7 (M6) 6 25.40 0.3 ZFCR25T<br />

70 2.75 NW35CF 36.9 13.0 4.8 38.3 41.9 58.7 6.8 6 38.10 0.3 ZFCR38 (M)<br />

70 2.75 NW35CF 36.9 13.0 4.8 38.3 41.9 58.7 (M6) 6 38.10 0.3 ZFCR38T (M)<br />

70 2.75 NW40CF 40.0 13.0 4.8 41.3 41.9 58.7 6.8 6 41.27 0.3 ZFCR41<br />

70 2.75 NW40CF 40.0 13.0 4.8 41.3 41.9 58.7 (M6) 6 41.27 0.3 ZFCR41T<br />

85 3.38 NW54CF 49.0 16.0 9.7 51.1 52.6 72.4 8.4 8 50.80 0.7 ZFCR54<br />

114 4.50 NW50CF 49.6 17.5 8.0 51.1 68.0 92.1 8.4 8 50.80 1.0 ZFCR50<br />

114 4.50 NW61CF 61.2 17.5 8.0 63.7 68.0 92.1 8.4 8 63.50 0.9 ZFCR64 (M)(T)<br />

114 4.50 NW61CF 61.2 17.5 8.0 63.7 68.0 92.1 (M8) 8 63.50 0.9 ZFCR64T<br />

114 4.50 NW68CF 68.0 17.5 8.0 70.0 71.0 92.1 8.4 8 69.80 0.9 ZFCR70<br />

114 4.50 NW68CF 68.0 17.5 8.0 70.0 71.0 92.1 (M8) 8 69.80 0.9 ZFCR70T<br />

152 6.00 NW100CF 99.4 20.0 9.5 101.9 104.9 130.2 8.4 16 101.60 1.7 ZFCR100 (M)(T)<br />

152 6.00 NW100CF 99.4 20.0 9.5 101.9 104.9 130.2 (M8) 16 101.60 1.7 ZFCR100T<br />

152 6.00 NW100CF 100.0 20.0 9.5 104.5 105.0 130.2 8.4 16 104.00 1.7 ZFCR100M<br />

152 6.00 NW100CF 100.0 20.0 9.5 104.5 105.0 130.2 (M8) 16 104.00 1.7 ZFCR10MT<br />

203 8.00 NW150CF 149.7 22.0 9.5 152.6 155.7 181.0 8.4 20 152.40 2.6 ZFCR150<br />

203 8.00 NW150CF 149.7 22.0 9.5 152.6 155.7 181.0 (M8) 20 152.40 2.6 ZFCR150T<br />

203 8.00 NW150CF 150.0 22.0 9.5 154.6 155.7 181.0 8.4 20 154.00 2.6 ZFCR150M<br />

203 8.00 NW150CF 150.0 22.0 9.5 154.6 155.7 181.0 (M8) 20 154.00 2.6 ZFCR15MT<br />

254 10.00 NW200CF 200.4 24.5 9.5 203.5 206.4 231.8 8.4 24 203.20 3.7 ZFCR200 (M)<br />

All dimensions in mm unless otherwise stated.<br />

(1) Dimension D refers to external tubulation <strong>and</strong> not the recess in flange body as per rest of range of flanges.<br />

(M) Metric version of flanges available on request. Contact Technical Sales Department for details.<br />

(T) Tapped version of flanges available on request. Contact Technical Sales Department for details.<br />

038 www.vgscienta.com

Fixed blank flanges are available in the full range<br />

of sizes as indicated in the chart below. They<br />

are normally used to blank off unused chamber<br />

ports to create a leak-tight assembly. It is also<br />

possible to machine them as required for the fixing<br />

of special tube sizes or components that are<br />

not covered by the st<strong>and</strong>ard range of sizes.<br />

All dimensions in mm unless otherwise stated.<br />

www.vgscienta.com<br />

304 Fixed Blank <strong>Flanges</strong> (FC Series)<br />

304L Fixed Blank <strong>Flanges</strong><br />

Flange Bolt Hole Bolt Hole Number Shipping<br />

OD Pneurop Thickness PCD Diameter of Bolt Weight<br />

mm inch Equivalent B F (or thread) Holes kg Order Code<br />

34 1.33 NW16CF 7.6 27.0 4.3 6 0.1 ZFC90<br />

34 1.33 NW16CF 7.6 27.0 (M4) 6 0.1 ZFC90T<br />

70 2.75 NW35CF 13.0 58.7 6.8 6 0.4 ZFC2<br />

70 2.75 NW35CF 13.0 58.7 (M6) 6 0.4 ZFC2T<br />

85 3.38 NW54CF 16.0 72.4 8.4 8 0.7 ZFC3<br />

85 3.38 NW54CF 16.0 72.4 (M8) 8 0.7 ZFC3T<br />

114 4.50 NW63CF 17.5 92.1 8.4 8 1.3 ZFC4<br />

114 4.50 NW63CF 17.5 92.1 (M8) 8 1.3 ZFC4T<br />

152 6.00 NW100CF 20.0 130.2 8.4 16 3.0 ZFC6<br />

152 6.00 NW100CF 20.0 130.2 (M8) 16 3.0 ZFC6T<br />

203 8.00 NW150CF 22.0 181.2 8.4 20 5.5 ZFC8<br />

203 8.00 NW150CF 22.0 181.2 (M8) 20 5.5 ZFC8T<br />

254 10.00 NW200CF 24.5 231.8 8.4 24 9.7 ZFC10<br />

254 10.00 NW200CF 24.5 231.8 (M8) 24 9.7 ZFC10T<br />

Please Note - No accepted international st<strong>and</strong>ard dimensions exist for flanges with an OD of 300 mm or greater.<br />

305 12.00 NW250CF 27.0 283.0 10.5 32 16.0 ZFC12<br />

305 12.00 NW250CF 27.0 283.0 (M10) 32 16.0 ZFC12T<br />

305 12.00 NW250CF 27.0 284.0 8.5 32 16.0 ZFC12M<br />

305 12.00 NW250CF 27.0 284.0 (M8) 32 16.0 ZFC12MT<br />

362 14.25 NW300CF 30.0 334.0 10.5 36 22.0 ZFC1425<br />

Note: <strong>Flanges</strong> in size 114-362 mm OD (4.50-14.25 inch) have an additional 0.5 mm recess on the back face.<br />

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

039

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

304L Rotatable Blank <strong>Flanges</strong> (FCR Series)<br />

304L Rotatable Blank <strong>Flanges</strong><br />

All dimensions in mm unless otherwise is stated.<br />

(T) Tapped version of flanges available on request. Contact Technical Sales Department for details.<br />

Rotatable blank flanges are available in the full<br />

range of sizes as indicated in the chart below.<br />

The rotatable nature of the flange allows any<br />

bolt hole angle variations to be easily accommodated.<br />

These flanges are not normally used<br />

to blank off unused chamber ports, but are<br />

machined as required for the mounting of special<br />

tube sizes or components that are not covered<br />

by the st<strong>and</strong>ard range of sizes.<br />

Flange Rotatable Bolt Hole Bolt Hole Number Shipping<br />

OD Pneurop Thickness Tube Bore PCD Diameter of Bolt Weight<br />

mm inch Equivalent B E F (or thread) Holes kg Order Code<br />

34 1.33 NW16CF 7.6 19.3 27.0 4.3 6 0.1 ZFCR90<br />

34 1.33 NW16CF 7.6 19.3 27.0 (M4) 6 0.1 ZFCR90T<br />

70 2.75 NW35CF 13.0 41.9 58.7 6.8 6 0.4 ZFCR2<br />

70 2.75 NW35CF 13.0 41.9 58.7 (M6) 6 0.4 ZFCR2T<br />

114 4.50 NW63CF 17.5 68.0 92.1 8.4 8 1.3 ZFCR4<br />

114 4.50 NW63CF 17.5 68.0 92.1 (M8) 8 1.3 ZFCR4T<br />

152 6.00 NW100CF 20.0 104.9 130.2 8.4 16 3.0 ZFCR6 (T)<br />

203 8.00 NW150CF 22.0 155.7 181.2 8.4 20 5.5 ZFCR8 (T)<br />

254 10.00 NW200CF 24.5 206.4 231.8 8.4 24 9.7 ZFCR10 (T)<br />

040 www.vgscienta.com

Fixed bored flanges are available in the full range<br />

of sizes as indicated in the chart below. They are<br />

normally welded onto chamber tubulations or<br />

certain specific sizes of component. Please note<br />

that for the smaller sizes of flange there are a<br />

number of different st<strong>and</strong>ard tube sizes that<br />

they can accept.<br />

(1) Non spigotted flange<br />

(2) Non spigotted flange <strong>and</strong> tapped holes<br />

(3) Dimension D refers to external tubulation <strong>and</strong> not the recess in<br />

flange body as per rest of range of flanges<br />

(M) Metric version available on request.<br />

Contact Technical Sales Department for details.<br />

(T) Tapped version available on request.<br />

Contact Technical Sales Department for details.<br />

www.vgscienta.com<br />

316LN Fixed Bored <strong>Flanges</strong> (FCL Series)<br />

316LN Fixed Bored <strong>Flanges</strong><br />

Tube Bolt Bolt Tube Size<br />

Clear Flange L<strong>and</strong> Counter Hole Hole No. of to Fit Shipping<br />

OD Pneurop Bore Thickness Thickness Bore PCD Diameter Bolt Flange Weight<br />

mm inch Equivalent A B C D F (or thread) Holes Bore kg Order Code<br />

34 1.33 NW7CF 6.4 7.6 N/A 6.4 27.0 4.3 6 6.35 0.1 ZFCL97 (T)<br />

34 1.33 NW12CF 6.4 7.6 N/A 12.7 27.0 4.3 6 12.7 0.1 ZFCL912 (T)<br />

34 1.33 NW14CF 13.2 7.6 4.8 14.4 27.0 4.3 6 14.29 0.1 ZFCL914 (T)<br />

34 1.33 NW16CF 16.6 7.6 12.7 19.1 27.0 4.3 6 19.05 0.1 ZFCL919 (3)<br />

34 1.33 NW16CF 16.6 7.6 4.8 19.1 27.0 4.3 6 19.05 0.1 ZFCL19NS (1)<br />

34 1.33 NW16CF 16.6 7.6 4.8 19.1 27.0 (M4) 6 19.05 0.1 ZFCL19NT (2)<br />

70 2.75 NW14CF 13.2 13.0 4.8 14.4 58.7 6.8 6 14.29 0.3 ZFCL14<br />

70 2.75 NW25CF 24.2 13.0 4.8 25.5 58.7 6.8 6 25.40 0.3 ZFCL25 (T)<br />

70 2.75 NW35CF 36.9 13.0 4.8 38.3 58.7 6.8 6 38.10 0.3 ZFCL38 (M)<br />

70 2.75 NW35CF 36.9 13.0 4.8 38.3 58.7 (M6) 6 38.10 0.3 ZFCL38T (M)<br />

70 2.75 NW40CF 40.0 13.0 4.8 41.3 58.7 6.8 6 41.27 0.3 ZFCL41<br />

70 2.75 NW40CF 40.0 13.0 4.8 41.3 58.7 (M6) 6 41.27 0.3 ZFCL41T<br />

70 2.75 NW40CF 40.0 13.0 10.2 44.5 58.7 6.8 6 44.45 0.3 ZFCL45<br />

70 2.75 NW40CF 40.0 13.0 10.2 44.5 58.7 (M6) 6 44.45 0.3 FCL45T<br />

114 4.50 NW50CF 49.6 17.5 8.0 51.1 92.1 8.4 8 50.80 1.0 ZFCL50<br />

114 4.50 NW63CF 61.2 17.5 8.0 63.7 92.1 8.4 8 63.50 0.9 ZFCL64<br />

114 4.50 NW63CF 61.2 17.5 8.0 63.7 92.1 (M8) 8 63.50 0.9 ZFCL64T<br />

114 4.50 NW63CF 68.0 17.5 8.0 70.0 92.1 8.4 8 69.80 0.9 ZFCL70<br />

114 4.50 NW63CF 68.0 17.5 8.0 70.0 92.1 (M8) 8 69.80 0.9 ZFCL70T<br />

152 6.00 NW100CF 99.4 20.0 9.5 101.9 130.2 8.4 16 101.60 1.7 ZFCL100 (M)<br />

152 6.00 NW100CF 99.4 20.0 9.5 101.9 130.2 (M8) 16 101.60 1.7 ZFCL100T (M)<br />

203 8.00 NW150CF 149.7 22.0 9.5 152.6 181.0 8.4 20 152.40 2.6 ZFCL150 (M)<br />

203 8.00 NW150CF 149.7 22.0 9.5 152.6 181.0 (M8) 20 152.40 2.6 ZFCL150T (M)<br />

254 10.00 NW200CF 200.4 24.5 9.5 203.5 231.8 8.4 24 203.20 3. 7 ZFCL200 (M)<br />

254 10.00 NW200CF 200.4 24.5 9.5 203.5 231.8 (M8) 24 203.20 3.7 ZFCL200T (M)<br />

Please Note - No accepted international st<strong>and</strong>ard dimensions exist for flanges with an OD of 300 mm or greater.<br />

305 12.00 NW250CF 250.7 27.0 9.5 254.4 283.0 10.5 32 254.00 6.3 ZFCL250<br />

305 12.00 NW250CF 250.7 27.0 9.5 254.4 283.0 (M10) 32 254.00 6.3 ZFCL250T<br />

305 12.00 NW250CF 250.0 26.0 13.0 256.4 284.0 8.5 32 256.00 6.3 ZFCL250M<br />

305 12.00 NW250CF 250.0 26.0 13.0 256.4 284.0 (M8) 32 256.00 6.3 ZFCL25MT<br />

362 14.25 NW300CF 302.0 30.0 16.0 305.2 334.0 10.5 36 304.80 9.0 ZFCL300<br />

362 14.25 NW300CF 302.0 30.0 16.0 305.2 334.0 (M10) 36 304.80 9.0 ZFCL300T<br />

All dimensions in mm unless otherwise stated.<br />

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

041

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

316LN Rotatable Bored <strong>Flanges</strong> (FCRL Series)<br />

316LN Rotatable Bored <strong>Flanges</strong><br />

All dimensions in mm unless otherwise stated.<br />

(M) Metric version of flanges available on request. Contact Technical Sales Department for details.<br />

(T) Tapped version of flanges available on request. Contact Technical Sales Department for details.<br />

Rotatable bored flanges are available in the full<br />

range of sizes as indicated in the chart below.<br />

They are normally welded onto chamber tubulations<br />

or to certain specific sizes of component.<br />

The rotatable nature of the flange allows any<br />

bolt hole angle variation to be easily accommodated.<br />

Please note that the smaller sizes of<br />

flange can accept a number of different st<strong>and</strong>ard<br />

tube sizes.<br />

Tube Rotatable Bolt Bolt Tube Size<br />

Clear Flange L<strong>and</strong> Counter Tube Hole Hole No. of to Fit Shipping<br />

OD Pneurop Bore Thickness Thickness Bore Bore PCD Diameter Bolt Flange Weight<br />

mm inch Equivalent A B C D E F (or thread)Holes Bore kg Order Code<br />

34 1.33 NW7CF 6.4 7.6 N/A 6.4 19.3 27.0 4.3 6 6.35 0.1 ZFCRL97<br />

34 1.33 NW14CF 13.2 7.6 4.8 14.4 19.3 27.0 4.3 6 14.29 0.1 ZFCRL914(T)<br />

34 1.33 NW16CF 16.6 7.6 12.7 19.1 19.3 27.0 4.3 6 19.05 0.1 ZFCRL919 (M)(T)<br />

70 2.75 NW14CF 13.2 13.0 4.8 14.4 41.9 58.7 6.8 6 14.29 0.3 ZFCRL14<br />

70 2.75 NW14CF 13.2 13.0 4.8 14.4 41.9 58.7 (M6) 6 14.29 0.3 ZFCRL14T<br />

70 2.75 NW25CF 24.2 13.0 4.8 25.5 41.9 58.7 6.8 6 25.40 0.3 ZFCRL25<br />

70 2.75 NW25CF 24.2 13.0 4.8 25.5 41.9 58.7 (M6) 6 25.40 0.3 ZFCRL25T<br />

70 2.75 NW35CF 36.9 13.0 4.8 38.3 41.9 58.7 6.8 6 38.10 0.3 ZFCRL38 (M)<br />

70 2.75 NW35CF 36.9 13.0 4.8 38.3 41.9 58.7 (M6) 6 38.10 0.3 ZFCRL38T (M)<br />

70 2.75 NW38CF 40.0 13.0 4.8 41.3 41.9 58.7 6.8 6 41.27 0.3 ZFCRL41<br />

70 2.75 NW38CF 40.0 13.0 4.8 41.3 41.9 58.7 (M6) 6 41.27 0.3 ZFCRL41T<br />

114 4.50 NW50CF 49.6 17.5 8.0 51.1 68.0 92.1 8.4 8 50.80 1.0 ZFCRL50<br />

114 4.50 NW63CF 61.2 17.5 8.0 63.7 68.0 92.1 8.4 8 63.50 0.9 ZFCRL64<br />

114 4.50 NW61CF 61.2 17.5 8.0 63.7 68.0 92.1 (M8) 8 63.50 0.9 ZFCRL64T<br />

114 4.50 NW68CF 68.0 17.5 8.0 70.0 71.0 92.1 8.4 8 69.80 0.9 ZFCRL70<br />

114 4.50 NW68CF 68.0 17.5 8.0 70.0 71.0 92.1 (M8) 8 69.80 0.9 ZFCRL70T<br />

152 6.00 NW100CF 99.4 20.0 9.5 101.9 104.9 130.2 8.4 16 101.60 1.7 ZFCRL100<br />

152 6.00 NW100CF 99.4 20.0 9.5 101.9 104.0 130.2 (M8) 16 101.60 1.7 ZFCRL10T<br />

152 6.00 NW100CF 100.0 20.0 9.5 104.5 105.0 130.2 8.4 16 104.00 1.7 ZFCRL10M (T)<br />

203 8.00 NW150CF 149.7 22.0 9.5 152.6 155.7 181.0 8.4 20 152.40 2.6 ZFCRL150 (M)(T)<br />

203 8.00 NW150CF 149.7 22.0 9.5 152.6 155.7 181.0 (M8) 20 152.40 2.6 ZFCRL15T<br />

203 8.00 NW150CF 150.0 22.0 9.5 152.6 155.7 181.0 8.4 20 154.00 2.6 ZFCRL15M (T)<br />

254 10.00 NW200CF 200.4 24.5 9.5 203.5 206.4 231.8 8.4 24 203.20 3.7 ZFCRL200 (M)(T)<br />

042 www.vgscienta.com

Fixed blank flanges are available in the full range<br />

of sizes as indicated in the chart below. They<br />

are normally used to blank off unused chamber<br />

ports to create a leak-tight assembly. It is also<br />

possible to machine them as required for the fixing<br />

of special tube sizes or components that are<br />

not covered by the st<strong>and</strong>ard range of sizes.<br />

All dimensions in mm unless otherwise stated.<br />

www.vgscienta.com<br />

316LN Fixed Blank <strong>Flanges</strong> (FCL Series)<br />

316LN Fixed Blank <strong>Flanges</strong><br />

Flange Bolt Hole Bolt Hole Number Shipping<br />

OD Pneurop Thickness PCD Diameter of Bolt Weight<br />

mm inch Equivalent B F (or thread) Holes kg Order Code<br />

34 1.33 NW16CF 7.6 27.0 4.3 6 0.1 ZFCL90<br />

34 1.33 NW16CF 7.6 27.0 (M4) 6 0.1 ZFCL90T<br />

70 2.75 NW35CF 13.0 58.7 6.8 6 0.4 ZFCL2<br />

70 2.75 NW35CF 13.0 58.7 (M6) 6 0.4 ZFCL2T<br />

114 4.50 NW63CF 17.5 92.1 8.4 8 1.3 ZFCL4<br />

114 4.50 NW63CF 17.5 92.1 (M8) 8 1.3 ZFCL4T<br />

152 6.00 NW100CF 20.0 130.2 8.4 16 3.0 ZFCL6<br />

152 6.00 NW100CF 20.0 130.2 (M8) 16 3.0 ZFCL6T<br />

203 8.00 NW150CF 22.0 181.2 8.4 20 5.5 ZFCL8<br />

203 8.00 NW150CF 22.0 181.2 (M8) 20 5.5 ZFCL8T<br />

254 10.00 NW200CF 24.5 231.8 8.4 24 9.7 ZFCL10<br />

254 10.00 NW200CF 24.5 231.8 (M8) 24 9.7 ZFCL10T<br />

Please note - No accepted international st<strong>and</strong>ard dimensions exist for flanges with an OD of 300 mm or greater<br />

305 12.00 NW250CF 27.0 283.0 10.3 32 16.0 ZFCL12<br />

305 12.00 NW250CF 27.0 283.0 (M10) 32 16.0 ZFCL12T<br />

305 12.00 NW250CF 26.0 284.0 8.5 32 16.0 ZFCL12M<br />

305 12.00 NW250CF 26.0 284.0 (M8) 32 16 ZFCL12MT<br />

362 14.25 NW300CF 30.0 334.0 10.5 36 22.0 ZFCL1425<br />

Note: <strong>Flanges</strong> in sizes 114-362 mm OD (4.50-14.25 inch) have an additional 0.5 mm recess on the back face.<br />

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

043

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

316LN Rotatable Blank <strong>Flanges</strong> (FCRL Series)<br />

316LN Rotatable Blank <strong>Flanges</strong><br />

Flange Rotatable Bolt Hole Bolt Hole Number Shipping<br />

OD Pneurop Thickness Tube bore PCD Diameter of Bolt Weight<br />

mm inch Equivalent B E F (or thread) Holes kg Order Code<br />

34 1.33 NW16CF 7.6 19.3 27.0 4.3 6 0.1 ZFCRL90<br />

34 1.33 NW16CF 7.6 19.3 27.0 (M4) 6 0.1 ZFCRL90T<br />

70 2.75 NW35CF 13.0 41.9 58.7 6.8 6 0.4 ZFCRL2<br />

70 2.75 NW35CF 13.0 41.9 58.7 (M6) 6 0.4 ZFCRL2T<br />

114 4.50 NW63CF 17.5 68.0 92.1 8.4 8 1.3 ZFCRL4<br />

114 4.50 NW63CF 17.5 68.0 92.1 (M8) 8 1.3 ZFCRL4T<br />

150 6.00 NW100CF 20.0 104.9 130.2 8.4 16 3.0 ZFCRL6 (T)<br />

200 8.00 NW150CF 22.0 155.7 181.2 8.4 20 5.5 ZFCRL8 (T)<br />

250 10.00 NW200CF 24.5 206.4 231.8 8.4 24 9.7 ZFCRL10<br />

All dimensions in mm unless otherwise stated.<br />

(T) Tapped version of flanges available on request. Contact Technical Sales Department for details.<br />

Rotatable blank flanges are available in the full<br />

range of sizes as indicated in the chart below.<br />

The rotatable nature of the flange allows any<br />

bolt hole angle variations to be easily accommodated.<br />

These flanges are not normally used<br />

to blank off unused chamber ports, but are<br />

machined as required for the mounting of special<br />

tube sizes or components that are not covered<br />

by the st<strong>and</strong>ard range of sizes.<br />

044 www.vgscienta.com

Double-sided <strong>Flanges</strong> 304L (FC Series) <strong>and</strong> 316LN<br />

(FCL Series)<br />

Double-sided flanges are used for several different<br />

purposes including the spacing out of components<br />

from a flange. It is also possible to drill<br />

a hole from the outside diameter of the flange to<br />

the inside. If a thin tube <strong>and</strong> flange assembly are<br />

then welded in place, it allows you to introduce<br />

gases or have extra pumping around a component<br />

that either does not have any free ports or<br />

is limited on space. There is a version of the 70<br />

mm flange that has two KF ports added into<br />

its OD to permit this. Special versions of these<br />

flanges can be supplied on request. For doublesided<br />

blank flanges please see page 062.<br />

www.vgscienta.com<br />

Double-sided <strong>Flanges</strong> in 304L <strong>and</strong> 316LN<br />

Clear <strong>Flanges</strong> Thickness Shipping<br />

OD Bore B B Weight<br />

mm inch A Material mm inch kg Order Code<br />

FC Series 304L<br />

34 1.33 14.4 304L 10.0 0.39 0.1 ZFC914D<br />

34 1.33 Blank 304L 10.0 0.39 0.1 ZFC90D<br />

70 2.75 38.0 304L 16.0 0.63 0.3 ZFC38D<br />

70 2.75 38.0 304L 16.0 0.63 0.3 ZFC38DKF (1)<br />

70 2.75 Blank 304L 16.0 0.63 0.4 ZFC2D<br />

114 4.50 64.4 304L 17.5 0.69 0.9 ZFC64D<br />

114 4.50 Blank 304L 17.5 0.69 1.3 ZFC4D<br />

152 6.00 102.4 304L 20.0 0.79 1.7 ZFC100D<br />

152 6.00 Blank 304L 20.0 0.79 3.0 ZFC6D<br />

203 8.00 153.3 304L 22.0 0.87 2.6 ZFC150D<br />

203 8.00 Blank 304L 22.0 0.87 5.5 ZFC8D<br />

FCL Series 316LN<br />

34 1.33 14.4 316LN 10.0 0.39 0.1 ZFCL914D<br />

34 1.33 Blank 316LN 10.0 0.39 0.1 ZFCL90D<br />

70 2.75 38.0 316LN 16.0 0.63 0.3 ZFCL38D<br />

70 2.75 Blank 316LN 16.0 0.63 0.4 ZFCL2D<br />

114 4.50 64.4 316LN 17.5 0.69 0.9 ZFCL64D<br />

114 4.50 Blank 316LN 17.5 0.69 1.3 ZFCL4D<br />

152 6.00 102.4 316LN 20.0 0.79 1.7 ZFCL100D<br />

152 6.00 Blank 316LN 20.0 0.79 3.0 ZFCL6D<br />

203 8.00 153.3 316LN 22.0 0.87 2.6 ZFCL150D<br />

203 8.00 Blank 316LN 22.0 0.87 5.5 ZFCL8D<br />

All dimensions in mm unless otherwise stated.<br />

(1) ZFC38DKF has two radial KF ports as described above.<br />

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

045

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

Zero Length Adaptor <strong>Flanges</strong> 304L <strong>and</strong> 316LN<br />

Zero Length Adaptor <strong>Flanges</strong>, 304L <strong>and</strong> 316LN<br />

This type of flange is used to adapt from one<br />

flange size to another. The zero length indicates<br />

that it is no thicker than a st<strong>and</strong>ard flange<br />

(except the 34 mm to 70 mm OD adaptor). The<br />

larger flange OD has through bolt holes enabling<br />

ordinary nut <strong>and</strong> bolt kits to be used. The<br />

smaller flange OD has tapped holes so the bolts<br />

that are used must be shorter than normal. We<br />

offer bolt kits for both sizes of flange.<br />

Flange 1 Flange 2<br />

Major Bolt Minor Clear Thickness Shipping<br />

OD Holes OD Bolt Bore B B Weight<br />

mm inch mm to mm inch Holes A Material mm inch kg Order Code<br />

AZ Series 304L<br />

70 2.75 Clear 6.8 to 34 1.33 Tapped M4 16.0 304L 20.0 0.79 0.4 ZAZ3470<br />

114 4.50 Clear 8.4 to 34 1.33 Tapped M4 16.0 304L 17.5 0.69 1.3 ZAZ34114<br />

114 4.50 Clear 8.4 to 70 2.75 Tapped M6 38.0 304L 24.0 0.94 1.6 ZAZ70114<br />

152 6.00 Clear 8.4 to 70 2.75 Tapped M6 38.0 304L 24.0 0.94 3.0 ZAZ7015<br />

203 8.00 Clear 8.4 to 70 2.75 Tapped M6 38.0 304L 24.0 0.94 5.5 ZAZ7020<br />

254 10.00 Clear 8.4 to 70 2.75 Tapped M6 38.0 304L 24.0 0.94 8.8 ZAZ7025<br />

152 6.00 Clear 8.4 to 114 4.50 Tapped M8 63.7 304L 24.0 0.94 2.6 ZAZ11415<br />

203 8.00 Clear 8.4 to 114 4.50 Tapped M8 63.7 304L 24.0 0.94 5.2 ZAZ11420<br />

254 10.00 Clear 8.4 to 114 4.50 Tapped M8 63.7 304L 24.0 0.94 8.4 ZAZ11425<br />

203 8.00 Clear 8.4 to 152 6.00 Tapped M8 101.8 304L 24.0 0.94 4.2 ZAZ15020<br />

254 10.00 Clear 8.4 to 152 6.00 Tapped M8 101.8 304L 24.0 0.94 7.5 ZAZ15025<br />

254 10.00 Clear 8.4 to 203 8.00 Tapped M8 152.6 304L 24.0 0.94 5.6 ZAZ20025<br />

AZL Series 316LN<br />

70 2.75 Clear 6.8 to 34 1.33 Tapped M4 16.0 316LN 20.0 0.79 0.4 ZAZL3470<br />

114 4.50 Clear 8.4 to 34 1.33 Tapped M4 16.0 316LN 17.5 0.69 1.3 ZAZL3414<br />

114 4.50 Clear 8.4 to 70 2.75 Tapped M6 38.0 316LN 24.0 0.94 1.6 ZAZL7014<br />

152 6.00 Clear 8.4 to 70 2.75 Tapped M6 38.0 316LN 24.0 0.94 3.0 ZAZL7015<br />

203 8.00 Clear 8.4 to 70 2.75 Tapped M6 38.0 316LN 24.0 0.94 5.5 ZAZL7020<br />

254 10.00 Clear 8.4 to 70 2.75 Tapped M6 38.0 316LN 24.0 0.94 8.8 ZAZL7025<br />

152 6.00 Clear 8.4 to 114 4.50 Tapped M8 63.7 316LN 24.0 0.94 2.6 ZAZL1415<br />

203 8.00 Clear 8.4 to 114 4.50 Tapped M8 63.7 316LN 24.0 0.94 5.2 ZAZL1420<br />

254 10.00 Clear 8.4 to 114 4.50 Tapped M8 63.7 316LN 24.0 0.94 8.4 ZAZL1425<br />

203 8.00 Clear 8.4 to 152 6.00 Tapped M8 101.8 316LN 24.0 0.94 4.2 ZAZL1520<br />

254 10.00 Clear 8.4 to 152 6.00 Tapped M8 101.8 316LN 24.0 0.94 7.5 ZAZL1525<br />

254 10.00 Clear 8.4 to 203 8.00 Tapped M8 152.6 316LN 24.0 0.94 5.6 ZAZL2025<br />

All dimensions in mm unless otherwise stated.<br />

046 www.vgscienta.com

Klein Flange to Conflat Flange Adaptors (KA Series)<br />

It is often necessary to join a Conflat flange to<br />

a Klein flange. This can be achieved easily by<br />

using an adaptor. Please note that some of the<br />

Conflat flanges have tapped holes instead of<br />

through holes, which means that the connecting<br />

bolts cannot be inserted from the KF side of the<br />

flange when making the connection. The table<br />

also includes the order codes for the copper<br />

gasket, Viton ® o-ring <strong>and</strong> carrier, together with<br />

the flange clamp that is required to complete<br />

the seal.<br />

(1) Please Note - Where bolt holes are tapped, bolts cannot be inserted from KF side of flange.<br />

www.vgscienta.com<br />

Klein to Conflat <strong>Flanges</strong> Adaptors<br />

Conflat Length of Shipping<br />

OD Use Use Fitting L Weight<br />

mm inch Holes (1) Gasket to Klein O-ring Clamp mm inch kg Order Code<br />

34 1.33 Tapped M4 ZCU19 to NW10KF KK10VCS KKF16CA 21 0.83 0.2 ZKA3410T<br />

34 1.33 Tapped M4 ZCU19 to NW16KF KK16VCS KKF16CA 21 0.83 0.2 ZKA3416T<br />

70 2.75 Clear hole ZCU38 to NW10KF KK10VCS KKF16CA 31 1.22 0.5 ZKA7010<br />

70 2.75 Clear hole ZCU38 to NW16KF KK16VCS KKF16CA 30 1.18 0.5 ZKA7016<br />

70 2.75 Clear hole ZCU38 to NW25KF KK25VCS KKF25CA 31 1.22 0.5 ZKA7025<br />

70 2.75 Tapped M6 ZCU38 to NW32KF KK32VCS KKF40CA 31 1.22 0.5 ZKA7032T<br />

70 2.75 Tapped M6 ZCU38 to NW40KF KK40VCS KKF40CA 31 1.22 0.5 ZKA7040T<br />

114 4.50 Clear hole ZCU64 to NW40KF KK40VCS KKF40CA 33 1.30 1.5 ZKA11440<br />

114 4.50 Clear hole ZCU64 to NW50KF KK50VCS KKF50CA 33 1.30 1.5 ZKA11450<br />

152 6.00 Clear hole ZCU100 to NW40KF KK40VCS KKF50CA 33 1.30 3.0 ZKA15040<br />

Metric<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

047

Metric<br />

Flange<br />

Accessories<br />

Accessories<br />

Nut Plates<br />

Flange<br />

OD Nut No. of No. of<br />

mm inch Plates Bolts Washers Order Code<br />

34 1.33 2 6 6 ZNPS133<br />

70 2.75 2 6 6 ZNPS2<br />

114 4.50 2 8 8 ZNPS4<br />

Nut, Bolt <strong>and</strong> Washer Sets<br />

For reliable <strong>UHV</strong> seals, specially selected stainless<br />

steel bolt sets are recommended; see table<br />

on page 050. The materials are selected to match<br />

the expansion <strong>and</strong> contraction of the Conflat<br />

flanges during bakeout. This minimises the risk<br />

of vacuum leaks by differential expansion.<br />

We always recommend that bolts are lightly<br />

coated with an anti-seize thread lubricant during<br />

construction. This prevents seizure after a<br />

system bakeout. Be careful not to introduce any<br />

of this compound into the vacuum system as it<br />

will cause contamination.<br />

Anti-seize thread lubricant order code is ZTL<br />

(28 g tube).<br />

Alternatively we can supply silver-plated bolt<br />

sets.<br />

Nut Plate Sets<br />

Where access behind a flange is limited, or<br />

tapped flanges are required but not preferred, it<br />

is possible to use a nut plate set instead. Each set<br />

consists of two half-moon shaped metal pieces<br />

with tapped holes <strong>and</strong> set of bolt <strong>and</strong> washers.<br />

Access with a spanner is only required from the<br />

top as the plates are self locating behind the<br />

flange. If the threads become damaged, it is<br />

easy enough to replace the plate without having<br />

to touch the flange to which it is mounted.<br />

Nut plate sets are available for 34 mm (1.33"),<br />

70 mm (2.75"), <strong>and</strong> 114 mm (4.5") OD Conflat<br />

flanges. We always recommend that bolts are<br />

lightly coated with an anti-seize thread lubricant<br />

during construction. This prevents seizure after<br />

a system bakeout. Be careful not to introduce<br />

any of this compound into the vacuum system<br />

as it will cause contamination.<br />

048 www.vgscienta.com

Thread Lubricant<br />

This may be used on external nuts <strong>and</strong> bolts; it<br />

is used to stop the nuts seizing to the bolts when<br />

the system is baked. It should be applied sparingly<br />

to the thread of the bolts during assembly.<br />

A small brush is an ideal way of applying the<br />

lubricant.<br />

Important - This lubricant is not <strong>UHV</strong> compatible<br />

so use it carefully, ensuring that no lubricant<br />

enters into the vacuum system.<br />

Order Code<br />

ZTL (28 g (1 oz) tube).<br />

Nylon Gloves<br />

To stop greasy fingers contaminating parts<br />

that are going inside the <strong>UHV</strong> system, we supply<br />

packs of clean nylon gloves. These should<br />

always be used when h<strong>and</strong>ling items. They<br />

should be regularly changed.<br />

Order Code<br />

ZNG10 (pack of 5 pairs)<br />

www.vgscienta.com<br />

General Accessories<br />

Metric<br />

Flange<br />

Accessories<br />

049

Metric<br />

Flange<br />

Accessories<br />

Conflat Flange Accessories<br />

Conflat Flange Accessories<br />

OD Comm- High<br />

Copper Gaskets<br />

Silver Alumin- Bolt<br />

mm Flange Type ercial Quality Annealed Plated Blank Viton ® ium Set(*)<br />

34 St<strong>and</strong>ard Fixed or Rotatable ZCUC19 ZCU19 ZCUA19 ZCUSP19 ZCUB19 ZVIT19 ZAL19 ZM4B20 (1)<br />

34 Double Sided ZCUC19 ZCU19 ZCUA19 ZCUSP19 ZCUB19 ZVIT19 ZAL19 ZM4B35 (1)<br />

34 Tapped M4 ZCUC19 ZCU19 ZCUA19 ZCUSP19 ZCUB19 ZVIT19 ZAL19 ZM4B16 (1)<br />

70 St<strong>and</strong>ard Fixed or Rotatable ZCUC38 ZCU38 ZCUA38 ZCUSP38 ZCUB38 ZVIT38 ZAL38 ZM6B35 (2)<br />

70 Double Sided ZCUC38 ZCU38 ZCUA38 ZCUSP38 ZCUB38 ZVIT38 ZAL38 ZM6B50 (2)<br />

70 Tapped M6 ZCUC38 ZCU38 ZCUA38 ZCUSP38 ZCUB38 ZVIT38 ZAL38 ZM6S25 (2)<br />

85 St<strong>and</strong>ard Fixed or Rotatable ZCUC54 ZCU54 ZM8B50<br />

85 Tapped M8 ZCUC54 ZCU54 ZM8B50<br />

114 St<strong>and</strong>ard Fixed or Rotatable ZCUC64 ZCU64 ZCUA64 ZCUSP64 ZVIT64 ZAL64 ZM8B45 (3)<br />

114 Double Sided ZCUC64 ZCU64 ZCUA64 ZCUSP64 ZVIT64 ZAL64 ZM8B60 (3)<br />

114 Tapped M8 ZCUC64 ZCU64 ZCUA64 ZCUSP64 ZVIT64 ZAL64 ZM8S35 (3)<br />

152 St<strong>and</strong>ard Fixed or Rotatable ZCUC100 ZCU100 ZCUA100 ZCUSP100 ZVIT100 ZAL100 ZM8B50<br />

152 Double Sided ZCUC100 ZCU100 ZCUA100 ZCUSP100 ZVIT100 ZAL100 ZM8B70<br />

152 Tapped M8 ZCUC100 ZCU100 ZCUA100 ZCUSP100 ZVIT100 ZAL100 ZM8S40<br />

203 St<strong>and</strong>ard Fixed or Rotatable ZCUC150 ZCU150 ZCUA150 ZCUSP150 ZVIT150 ZAL150 ZM8B60<br />

203 Double Sided ZCUC150 ZCU150 ZCUA150 ZCUSP150 ZVIT150 ZAL150 ZM8B80<br />

203 Tapped M8 ZCUC150 ZCU150 ZCUA150 ZCUSP150 ZVIT150 ZAL150 ZM8S40<br />

254 St<strong>and</strong>ard Fixed or Rotatable ZCUC200 ZCU200 ZCUA200 ZCUSP200 ZVIT200 ZAL200 ZM8B60<br />

254 Double Sided ZCUC200 ZCU200 ZCUA200 ZCUSP200 ZVIT200 ZAL200 ZM8B85<br />

254 Tapped M8 ZCUC200 ZCU200 ZCUA200 ZCUSP200 ZVIT200 ZAL200 ZM8S45<br />

305 St<strong>and</strong>ard Fixed ZCUC250 ZCU250 ZCUSP250 ZAL250 ZM10B65<br />

305 Double Sided ZCUC250 ZCU250 ZCUSP250 ZAL250 ZM10B90<br />

305 Tapped M10 ZCUC250 ZCU250 ZCUSP250 ZAL250 ZM10S50<br />

362 St<strong>and</strong>ard Fixed ZCUC300 ZCU300 ZM10B75<br />

(*) Most bolt kits come in packs of 25 except the ZM10B65, ZM10B90, ZM10S50 which are in 35’s <strong>and</strong> ZM10B75 which is a pack of<br />

40. Bolts for tapped flanges with UNC threads are available upon request. Contact the Sales Office for details.<br />

(1) Nut plate set for this flange = ZNPS133 (2) Nut plate set for this flange = ZNPS2 (3) Nut plate set for this flange = ZNPS4<br />

For more information on the full range of Conflat gaskets see pages 069 to 076.<br />

Zero Length Flange Accessories<br />

Zero Length Adaptor Accessories<br />

Zero Length Adaptor Order Code Flange 1 Gaskets Flange 2 Gaskets<br />

304L 316LN Copper Viton ® Bolt Set Copper Viton ® Bolt Set<br />

ZAZ3470 or ZAZL3470 ZCU38 ZVIT38 ZM6B35 ZCUA19 ZVIT19 ZM4S16<br />

ZAZ34114 or ZAZL3414 ZCU64 ZVIT64 ZM8B45 ZCUA19 ZVIT19 ZM4S16<br />

ZAZ70114 or ZAZL7014 ZCU64 ZVIT64 ZM8B45 ZCUA38 ZVIT38 ZM6S25<br />

ZAZ7015 or ZAZL7015 ZCU100 ZVIT100 ZM8B50 ZCUA38 ZVIT38 ZM6S25<br />

ZAZ7020 or ZAZL7020 ZCU150 ZVIT150 ZM8B60 ZCUA38 ZVIT38 ZM6S25<br />

ZAZ7025 or ZAZL7025 ZCU200 ZVIT200 ZM8B60 ZCUA38 ZVIT38 ZM6S25<br />

ZAZ11415 or ZAZL1415 ZCU100 ZVIT100 ZM8B45 ZCUA64 ZVIT64 ZM8S35<br />

ZAZ11420 or ZAZL1420 ZCU150 ZVIT150 ZM8B60 ZCUA64 ZVIT64 ZM8S35<br />

ZAZ11425 or ZAZL1425 ZCU200 ZVIT200 ZM8B60 ZCUA64 ZVIT64 ZM8S35<br />

ZAZ15020 or ZAZL1520 ZCU150 ZVIT150 ZM8B60 ZCUA100 ZVIT100 ZM8S40<br />

ZAZ15025 or ZAZL1525 ZCU200 ZVIT200 ZM8B60 ZCUA100 ZVIT100 ZM8S40<br />

ZAZ20025 or ZAZL2025 ZCU200 ZVIT200 ZM8B60 ZCUA150 ZVIT150 ZM8S40<br />

050 www.vgscienta.com

Introduction to Conflat <strong>Flanges</strong><br />

• Wide range of Imperial <strong>and</strong> Metric st<strong>and</strong>ard<br />

sizes<br />

• All flanges manufactured on computer<br />

controlled CNC machines for accuracy<br />

• Available in 304L or 316LN stainless steel<br />

• Low outgassing rates, 450 °C) without<br />

leaking.<br />

<strong>VG</strong> <strong>Scienta</strong>’s range of <strong>UHV</strong> flanges is world<br />

renowned both for its quality <strong>and</strong> range of sizes<br />

<strong>and</strong> materials. The complete range of flanges are<br />

fully compatible with the internationally agreed<br />

ISO/Pneurop st<strong>and</strong>ards <strong>and</strong> will connect to any<br />

other flange that also complies with this st<strong>and</strong>ard<br />

(for flanges with a diameter greater than<br />

300 mm no such st<strong>and</strong>ards exist at present). All<br />

flange OD dimensions are nominal.<br />

Method of Sealing<br />

The <strong>UHV</strong> seal is made by trapping a copper gasket<br />

between two sexless flanges that have a sharp<br />

knife-edge profiled onto their operating face.<br />

When joined together with a set of connecting<br />

bolts, the knife-edges cut into the surface of the<br />

copper gasket to make a seal that is <strong>UHV</strong> leak<br />

tight. When exposed to bakeout temperatures<br />

the shape of the knife-edge ensures that the seal<br />

remains leak tight by resisting any differential<br />

movements between the copper gasket <strong>and</strong> the<br />

stainless steel flange parts.<br />

IMPORTANT PRODUCT INFORMATION<br />

For full information on:<br />

i) NW versus FC Designations<br />

ii) Tube Sizes - Imperial versus Metric Tube<br />

iii) Tube Counterbore Depth<br />

please refer to page 034.<br />

www.vgscienta.com<br />

Imperial Flange Range<br />

Fixed <strong>and</strong> Rotatable <strong>Flanges</strong><br />

To aid the construction of <strong>UHV</strong> chambers <strong>and</strong><br />

components, <strong>VG</strong> <strong>Scienta</strong> flanges are available in<br />

both fixed <strong>and</strong> rotatable configurations. Fixed<br />

flanges are a single machined item with the<br />

bolt hole orientation fixed into position once<br />

they are welded onto a chamber or component.<br />

Rotatable flanges are manufactured in two parts<br />

with the knife-edge part <strong>and</strong> external bolt hole<br />

ring being separate. Once the knife-edge part is<br />

welded in position it is easy to change the orientation<br />

of the bolt holes relative to the axis of the<br />

port. This makes rotatable flanges ideal for the<br />

situations where alignment of a component to<br />

a chamber (or another component) needs to be<br />

set accurately before the flange mounting bolts<br />

are tightened.<br />

Please Note: It is not advisable to have two<br />

rotatable flanges at the same joint.<br />

Internal Weld<br />

Copper Gasket<br />

<strong>Flanges</strong> are bolted together with a copper<br />

gasket between the knife edges.<br />

Imperial<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

051

Imperial<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

Imperial Conflat Flange Type Quick Reference<br />

Comparison Chart IMPORTANT PRODUCT INFORMATION<br />

See page 034 concerning FC <strong>and</strong> NW designations<br />

Imperial Flange Comparison Chart<br />

304L 304L 304L 304L 316LN 316LN 316LN 316LN<br />

OD Pneurop Fixed Rotatable Fixed Rotatable Fixed Rotatable Fixed Rotatable<br />

mm inch Equivalent Bored Bored Blank Blank Bored Bored Blank Blank<br />

34 1.33 Blank ZF90A ZFR90A ZFL90A ZFRL90A<br />

34 1.33 Blank ZF90TA ZFL90TA<br />

34 1.33 NW7CF ZF97A ZFR97A ZFL97A ZFRL97A<br />

34 1.33 NW12CF ZF912A ZFL912A<br />

34 1.33 NW14CF ZF914A ZFR914A ZFL914A ZFRL914A<br />

34 1.33 NW16CF ZF919A ZFR919A ZFL919A ZFRL919A<br />

34 1.33 NW16CF ZF19NSA ZFL19NSA<br />

34 1.33 NW16CF ZF19NSTA ZFL19NTA<br />

70 2.75 Blank ZF2A ZFR2A ZFL2 ZFRL2A<br />

70 2.75 Blank Tapped ZF2TA ZFR2TA ZFL2TA ZFRL2TA<br />

70 2.75 NW14CF ZF14A ZFR14A ZFL14A ZFRL14A<br />

70 2.75 NW14CF ZFR14TA ZFRL14TA<br />

70 2.75 NW25CF ZF25A ZFR25A ZFL25A ZFRL25A<br />

70 2.75 NW25CF ZFR25TA ZFRL25TA<br />

70 2.75 NW35CF ZF38A ZFR38A ZFL38A ZFRL38A<br />

70 2.75 NW35CF ZF38TA ZFR38TA ZFL38TA ZFRL38TA<br />

70 2.75 NW38CF ZF41A ZFR41A ZFL41A ZFRL41A<br />

70 2.75 NW38CF ZF41TA ZFR41TA ZFL41TA ZFRL41TA<br />

70 2.75 NW45CF ZF45A ZFL45A<br />

70 2.75 NW45CF ZF45TA ZFL45TA<br />

85 3.38 Blank ZF3A ZFL3A<br />

85 3.38 Blank Tapped ZF3TA ZFL3TA<br />

85 3.38 NW54CF ZF54A ZFR54A ZFL54A ZFRL54A<br />

85 3.38 NW54CF ZF54TA ZFL54TA<br />

114 4.50 Blank ZF4A ZFR4A ZFL4A ZFRL4A<br />

114 4.50 Blank Tapped ZF4TA ZFR4TA ZFL4TA ZFRL4TA<br />

114 4.50 NW50CF ZF50A ZFR50A ZFL50A ZFRL50A<br />

114 4.50 NW63CF ZF64A ZFR64A ZFL64A ZFRL64A<br />

114 4.50 NW63CF ZF64TA ZFR64TA ZFL64TA ZFRL64TA<br />

152 6.00 Blank ZF6A ZFR6A ZFL6A ZFRL6A<br />

152 6.00 Blank Tapped ZF6TA ZFR6TA ZFL6TA ZFRL6TA<br />

152 6.00 NW100CF ZF100A ZFR100A ZFL100A ZFRL100A<br />

152 6.00 NW100CF ZF100TA ZFR100TA ZFL100TA<br />

203 8.00 Blank ZF8A ZFR8A ZFL8A ZFRL8A<br />

203 8.00 Blank Tapped ZF8TA ZFR8TA ZFL8TA ZFRL8TA<br />

203 8.00 NW150CF ZF150A ZFR150A ZFL150A ZFRL150A<br />

203 8.00 NW150CF ZF150TA ZFR150TA ZFL150TA ZFRL150TA<br />

254 10.00 Blank ZFL10A ZFRL10A<br />

254 10.00 Blank Tapped ZF10TA ZFL10TA<br />

254 10.00 NW200CF ZF200A ZFR200A ZFL200A ZFRL200A<br />

254 10.00 NW200CF ZF200TA ZFL200TA<br />

Please Note - No accepted international st<strong>and</strong>ard dimensions exist for flanges with an OD of 300mm or greater.<br />

300 12.00 Blank ZF12A ZFL12A<br />

300 12.00 NW250CF ZF250A ZFL250A<br />

336 13.25 Blank ZF1325A<br />

336 13.25 Blank Tapped ZF1325TA<br />

336 13.25 ZF1310A<br />

336 13.25 ZF1310TA<br />

336 13.25 ZF1375A<br />

336 13.25 ZF1375TA<br />

355 14.00 ZF1400A<br />

355 14.00 ZF1412A<br />

362 14.25 Blank ZF1425A ZFL1425A<br />

362 14.25 NW300CF ZF300A ZFL300A<br />

indicates clearance bolt holes indicates tapped bolt holes<br />

052 www.vgscienta.com

Fixed bored flanges are available in the full range<br />

of sizes as indicated in the chart below. They<br />

are normally welded on to chamber tubulations<br />

or certain specific sizes of component. Please<br />

note that the smaller sizes of flange can accept a<br />

number of different st<strong>and</strong>ard tube sizes.<br />

Tapped version available for all sizes.<br />

Example ZF2150A (plain bolt holes) becomes<br />

ZF2150TA (tapped bolt holes).<br />

Tapped Holes<br />

1.33 in = Tapped .160-32UNC<br />

2.125 - 2.75 in = Tapped .250-28UNF<br />

3.375 - 10 in = Tapped .312-24UNF<br />

13.25 - 14 in = Tapped .375-24UNF<br />

www.vgscienta.com<br />

304L Fixed Bored <strong>Flanges</strong> (F Series)<br />

304L Fixed Bored <strong>Flanges</strong><br />

Tube Bolt<br />

Clear Flange L<strong>and</strong> Counter Hole Bolt No. of Shipping<br />

OD Bore Thickness Thickness Bore PCD Hole Bolt Weight<br />

inch mm A B C D F Diameter Holes lb Order Code<br />

1.33 34 0.26 0.29 N/A 0.26 1.06 0.17 6 0.25 ZF97A<br />

1.33 34 0.50 0.29 N/A 0.50 1.06 0.17 6 0.25 ZF912A<br />

1.33 34 0.52 0.29 0.17 0.56 1.06 0.17 6 0.25 ZF914A<br />

1.33 34 0.65 0.50 0.50 N/A 1.06 0.17 6 0.25 ZF919A<br />

1.33 34 0.65 0.29 0.17 0.75 1.06 0.17 6 0.25 ZF19NSA<br />

2.125 54 0.51 0.47 N/A N/A 1.63 0.27 4 0.50 ZF2150A<br />

2.125 54 0.70 0.47 0.17 0.76 1.63 0.27 4 0.50 ZF2175A<br />

2.125 54 0.95 0.47 0.17 1.00 1.63 0.27 4 0.50 ZF2110A<br />

2.75 70 0.52 0.50 0.21 0.57 2.31 0.27 6 0.75 ZF14A<br />

2.75 70 0.96 0.50 0.21 1.01 2.31 0.27 6 0.75 ZF25A<br />

2.75 70 1.46 0.50 0.21 1.50 2.31 0.27 6 0.75 ZF38A<br />

2.75 70 1.58 0.50 0.21 1.63 2.31 0.27 6 0.75 ZF41A<br />

2.75 70 1.58 0.50 0.39 1.75 2.31 0.27 6 0.75 ZF45A<br />

3.375 86 1.44 0.63 0.22 1.51 2.85 0.34 8 1.00 ZF3315A<br />

3.375 86 1.94 0.63 0.22 2.00 2.85 0.34 8 1.00 ZF3320A<br />

4.5 114 2.00 0.69 0.37 1.96 3.63 0.34 8 2.00 ZF50A<br />

4.5 114 2.41 0.69 0.37 2.50 3.63 0.34 8 2.00 ZF64A<br />

4.5 114 2.68 0.69 0.37 2.76 3.63 0.34 8 2.00 ZF70A<br />

4.625 117.5 2.44 0.75 0.37 2.51 4.03 0.34 10 2.50 ZF4625A<br />

4.625 117.5 2.94 0.75 0.37 3.00 4.03 0.34 10 2.50 ZF463A<br />

6 151.5 3.91 0.78 0.44 4.00 5.13 0.34 16 3.50 ZF100A<br />

6.75 171.5 3.87 0.84 0.46 4.00 5.97 0.34 18 5.00 ZF6740A<br />

6.75 171.5 4.93 0.84 0.46 5.00 5.97 0.34 18 5.00 ZF6750A<br />

8 202.5 5.89 0.88 0.50 6.00 7.12 0.34 20 5.50 ZF150A<br />

10 254 7.89 0.97 0.50 8.01 9.13 0.34 24 7.50 ZF200A<br />

12 305 9.87 1.02 0.50 10.02 11.18 0.34 32 10.00 ZF250A<br />

13.25 337 9.86 1.12 0.50 10.02 12.06 0.39 30 18.00 ZF1310A<br />

13.25 337 10.63 1.12 0.50 12.02 12.06 0.39 30 14.00 ZF1375A<br />

14 356 11.75 1.12 0.50 12.02 12.81 0.39 30 13.00 ZF1412A<br />

14.25 362 11.89 1.18 0.63 12.01 13.15 0.41 36 19.80 ZF300A<br />

All dimensions in inches unless otherwise stated.<br />

Imperial<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

053

Imperial<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

304L Rotatable Bored <strong>Flanges</strong> (FR Series)<br />

304L Rotatable Bored <strong>Flanges</strong><br />

Rotatable bored flanges are available in the full<br />

range of sizes as indicated in the chart below.<br />

They are normally welded onto chamber tubulations<br />

or certain specific sizes of component.<br />

The rotatable nature of the flange allows any<br />

bolt hole angle variation to be easily accommodated.<br />

Please note that the smaller sizes of<br />

flange can accept a number of different st<strong>and</strong>ard<br />

tube sizes.<br />

Tapped version available for all sizes.<br />

Example ZF2150A (plain bolt holes) becomes<br />

ZF2150TA (tapped bolt holes).<br />

Tapped Holes<br />

1.33 in = Tapped .160-32UNC<br />

2.125 - 2.75 in = Tapped .250-28UNF<br />

3.375 - 10 in = Tapped .312-24UNF<br />

13.25 - 14 in = Tapped .375-24UNF<br />

Tube Rot' Tube Bolt<br />

Clear Flange L<strong>and</strong> Counter Counter Hole Bolt No. of Shipping<br />

OD Bore Thickness Thickness Bore Bore PCD Hole Bolt Weight<br />

inch mm A B C D E F Diameter Holes lb Order Code<br />

1.33 34 0.26 0.29 N/A 0.26 0.76 1.06 0.17 6 0.25 ZFR97A<br />

1.33 34 0.52 0.29 0.17 0.56 0.76 1.06 0.17 6 0.25 ZFR914A<br />

1.33 34 0.65 0.50 0.50 N/A 0.76 1.06 0.17 6 0.25 ZFR919A<br />

2.125 54 0.51 0.47 N/A N/A 1.10 1.63 0.27 4 0.50 ZFR2150A<br />

2.125 54 0.70 0.47 0.17 0.76 1.10 1.63 0.27 4 0.50 ZFR2175A<br />

2.125 54 0.95 0.47 0.17 1.00 1.10 1.63 0.27 4 0.50 ZFR2110A<br />

2.75 70 0.52 0.50 0.21 0.57 1.69 2.31 0.27 6 0.75 ZFR14A<br />

2.75 70 0.96 0.50 0.21 1.01 1.69 2.31 0.27 6 0.75 ZFR25A<br />

2.75 70 1.46 0.50 0.21 1.50 1.69 2.31 0.27 6 0.75 ZFR38A<br />

2.75 70 1.58 0.50 0.21 1.63 1.69 2.31 0.27 6 0.75 ZFR41A<br />

3.375 86 1.44 0.63 0.22 1.51 2.07 2.85 0.34 8 1.00 ZFR3315A<br />

3.375 86 1.94 0.63 0.22 2.00 2.07 2.85 0.34 8 1.00 ZFR3320A<br />

4.5 114 2.00 0.69 0.37 1.96 2.80 3.63 0.34 8 2.00 ZFR50A<br />

4.5 114 2.41 0.69 0.37 2.50 2.80 3.63 0.34 8 2.00 ZFR64A<br />

4.5 114 2.68 0.69 0.37 2.76 2.80 3.63 0.34 8 2.00 ZFR70A<br />

4.625 117.5 2.44 0.75 0.37 2.51 3.10 4.03 0.34 10 2.50 ZFR4625A<br />

4.625 117.5 2.94 0.75 0.37 3.00 3.10 4.03 0.34 10 2.50 ZFR463A<br />

6 151.5 3.91 0.78 0.44 4.00 4.13 5.13 0.34 16 3.50 ZFR100A<br />

6.75 171.5 3.87 0.84 0.46 4.00 5.10 5.97 0.34 18 4.50 ZFR6740A<br />

6.75 171.5 4.93 0.84 0.46 5.00 5.10 5.97 0.34 18 4.50 ZFR675A<br />

8 202.5 5.89 0.88 0.50 6.00 6.13 7.13 0.34 20 5.50 ZFR150A<br />

10 254 7.89 0.97 0.50 8.01 8.15 9.13 0.34 24 7.50 ZFR200A<br />

All dimensions in inches unless otherwise stated.<br />

054 www.vgscienta.com

Fixed blank flanges are available in the full range<br />

of sizes as indicated in the chart below. They<br />

are normally used to blank off unused chamber<br />

ports to create a leak-tight assembly. It is also<br />

possible to machine them as required for the fixing<br />

of special tube sizes or components that are<br />

not covered by the st<strong>and</strong>ard range of sizes.<br />

Tapped version available for all sizes.<br />

Example ZF1325A (plain bolt holes) becomes<br />

ZF1325TA (tapped bolt holes).<br />

Tapped Holes<br />

1.33 in = Tapped .160-32UNC<br />

2.125 - 2.75 in = Tapped .250-28UNF<br />

3.375 - 10 in = Tapped .312-24UNF<br />

13.25 - 14 in = Tapped .375-24UNF<br />

www.vgscienta.com<br />

304L Fixed Blank <strong>Flanges</strong> (F Series)<br />

304L Fixed Blank Flange<br />

Flange Bolt Hole No. of Shipping<br />

OD Thickness PCD Bolt Hole Bolt Weight<br />

inch mm B F Diameter Holes lb Order Code<br />

1.33 34 0.29 1.06 0.17 6 0.2 ZF90A<br />

2.125 54 0.47 1.63 0.27 4 0.5 ZF21A<br />

2.75 70 0.50 2.31 0.27 6 0.9 ZF2A<br />

3.375 86 0.63 2.85 0.34 8 1.5 ZF3A<br />

4.5 114 0.68 3.63 0.34 8 2.9 ZF4A<br />

4.625 117.5 0.75 4.03 0.34 10 5.5 ZF46A<br />

6 151.5 0.78 5.13 0.34 16 6.6 ZF6A<br />

6.75 171.5 0.84 5.97 0.34 18 10.0 ZF675A<br />

8 202.5 0.88 7.13 0.34 20 12.0 ZF8A<br />

10 254 0.97 9.13 0.34 24 21.0 ZF10A<br />

12 305 1.02 11.18 0.34 32 35.0 ZF12A<br />

13.25 337 1.12 12.06 0.39 30 40.0 ZF1325A<br />

14 356 1.12 12.81 0.39 30 44.0 ZF1400A<br />

14.25 362 1.18 13.15 0.41 36 48.0 ZF1425A<br />

All dimensions in inches unless otherwise stated.<br />

NB: Sizes 4.5 - 14.25 inch have an additional 0.5 inch recess on the back face<br />

Imperial<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

055

Imperial<br />

<strong>UHV</strong><br />

<strong>Flanges</strong><br />

304L Rotatable Blank <strong>Flanges</strong> (FR Series)<br />

304L Rotatable Blank <strong>Flanges</strong><br />

Rotatable blank flanges are available in the full<br />

range of sizes as indicated in the chart below.<br />

The rotatable nature of the flange allows any<br />

bolt hole angle variations to be easily accommodated.<br />

These flanges are not normally used<br />

to blank off unused chamber ports, but are<br />

machined as required for the mounting of special<br />

tube sizes or components that are not covered<br />

by the st<strong>and</strong>ard range of sizes.<br />

Tapped version available for all sizes.<br />

Example ZFR46A (plain bolt holes) becomes<br />

ZFR46TA (tapped bolt holes).<br />

Tapped Holes<br />

1.33 in = Tapped .160-32UNC<br />

2.125 - 2.75 in = Tapped .250-28UNF<br />

3.375 - 10 in = Tapped .312-24UNF<br />

13.25 - 14 in = Tapped .375-24UNF<br />

Rotat' Tube Bolt<br />

Flange Counter Hole No. of Shipping<br />

OD Thickness Bore PCD Bolt Hole Bolt Weight<br />

inch mm B E F Diameter Holes lb Order Code<br />

1.33 34 0.29 0.76 1.06 0.17 6 0.2 ZFR90A<br />

2.125 54 0.47 1.10 1.63 0.27 4 0.5 ZFR21A<br />

2.75 70 0.5 1.69 2.31 0.27 6 0.9 ZFR2A<br />

3.375 86 0.63 2.07 2.85 0.34 8 1.5 ZFR3A<br />

4.5 114 0.69 2.80 3.63 0.34 8 2.9 ZFR4A<br />

4.625 117.5 0.75 3.10 4.03 0.34 10 5.5 ZFR46A<br />

6 151.5 0.78 4.13 5.13 0.34 16 6.6 ZFR6A<br />

6.75 171.5 0.84 5.10 5.97 0.34 18 10.0 ZFR67A<br />

8 202.5 0.88 6.13 7.13 0.34 20 12.0 ZFR8A<br />

10 254 0.97 8.15 9.13 0.34 24 21.0 ZFR10A<br />

All dimensions in inches unless otherwise is stated.<br />

056 www.vgscienta.com

Fixed bored flanges are available in the full range<br />

of sizes as indicated in the chart below. They are<br />

normally welded onto chamber tubulations or<br />

certain specific sizes of component. Please note<br />

that for the smaller sizes of flange there are a<br />

number of different st<strong>and</strong>ard tube sizes that<br />

they can accept.<br />