NUMBER 02 - Haas Automation, Inc.

NUMBER 02 - Haas Automation, Inc.

NUMBER 02 - Haas Automation, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

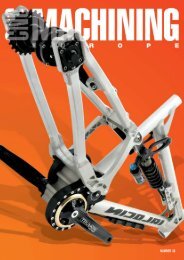

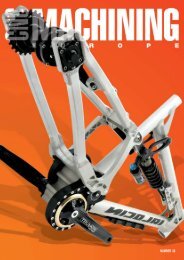

One of the main advantages of in-house machining is the<br />

speed with which new ideas can go from the drawing board<br />

– make that computer screen – to a finished prototype.<br />

Karlheinz says, “We design primarily in SolidWorks, and<br />

use both ESPRIT and VisualMill on the CAM side.” Design,<br />

programming and production are under one roof, and<br />

seamlessly integrate in an environment where designers,<br />

programmers and machine operators work closely together.<br />

The VF-2SS fit in perfectly.<br />

“With the <strong>Haas</strong> machine, we can have a prototype<br />

finished in the time it would take just to communicate with<br />

| www.<strong>Haas</strong>CNC.com<br />

vendors and get a price quote on making the part outside,”<br />

Karlheinz explains.<br />

Nicolai GmbH selects employees carefully, preferring to<br />

train motivated individuals with conventional machine shop<br />

experience onsite. And with only 15 full-time employees and<br />

a backlog of orders, it’s important that each person and every<br />

machine is productive from the start. The logical, user-friendly<br />

<strong>Haas</strong> control makes CNC machining easier to understand,<br />

reducing operator error and training time. Nicolai feels this<br />

has been a great advantage to his firm.