NUMBER 02 - Haas Automation, Inc.

NUMBER 02 - Haas Automation, Inc.

NUMBER 02 - Haas Automation, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

“You’re wasting time!” booms Senior, flying out of his office in a<br />

clinched-fist fury. Out on the floor, the prodigal sons respond true to form: Paulie<br />

digs in for a fight, while Mikey backs off with a smirk. The Orange County Choppers<br />

shop is, once again, a certifiable war zone. “It ain’t what you do,” bellows Senior’s<br />

almighty voice of clout, “it’s the way that you do it!”<br />

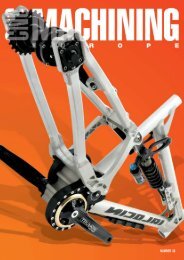

Custom Bikes for All<br />

The well-known management at Orange County<br />

Choppers (OCC) is busy laying the groundwork to make the<br />

company the best-known and most influential bike builder in<br />

the world.<br />

Paul Teutul Senior’s behind-the-scene business<br />

planners, designers, machinists and builders are settling in<br />

to manufacture a new line of standardized production bikes<br />

to support a growing chain of OCC retail dealers. Until now,<br />

each bike has been specifically made to order for each<br />

customer, so the move represents a major shift in the way<br />

everyone at OCC must approach his work. Perhaps no one<br />

faces greater changes than OCC’s machine shop manager<br />

Jim Quinn.<br />

“It’s definitely a challenge,” says Quinn. “In some ways it’s<br />

easier, but in many ways it’s more difficult. Because of the<br />

way we’ve networked our machines, once we’ve made a part<br />

to spec, it’s just a matter of loading the program and we can<br />

duplicate it again without any problems.”<br />

But trying to dedicate machines to manufacturing<br />

production, while building one-off bikes under the pressures<br />

of television deadlines, is no simple matter. “That’s the other<br />

part of it,” says Quinn with a smile. “It never fails. As soon as<br />

I get a machine set up to run production wheels all day, it’s<br />

‘Oops!’ we’ve got to break in and run a special design for one<br />

of the bikes for the show.”<br />

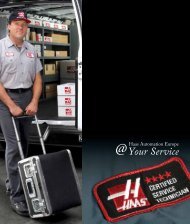

Realizing they suddenly had a lot more irons in the fire,<br />

the OCC gang set out last year to virtually double the size of<br />

the machine shop. Paul Senior and son Mikey, with a full video<br />

crew in tow, dropped in on the one-million-square-foot <strong>Haas</strong><br />

<strong>Automation</strong> factory in Southern California, and humorously<br />

scribed their names on the machines they wanted. Jim Quinn<br />

and many others had thoughtfully coordinated the expansion<br />

and suggested which machines to acquire weeks before the<br />

stars left for the sunny coast; but Senior’s impromptu “This<br />

one’s mine!” scrawl, staged during the factory tour, was much<br />

more entertaining on camera.<br />

Back home, the OCC machine shop began to expand,<br />

spilling over into what had been the warehousing area of the<br />

30,000-square-foot building. This new annex holds a recently<br />

installed <strong>Haas</strong> Mini Mill, TL-1 Toolroom Lathe and EC-500<br />

horizontal machining center – all tied in with the crew’s everbusy<br />

VF-5/50, VM-3 and VF-2SS vertical machining centers<br />

and SL-20 lathe.<br />

CNC MACHINING | 5