NUMBER 02 - Haas Automation, Inc.

NUMBER 02 - Haas Automation, Inc.

NUMBER 02 - Haas Automation, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Real Time<br />

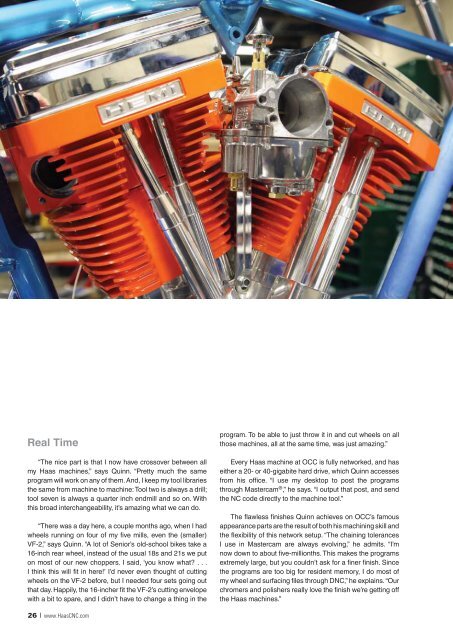

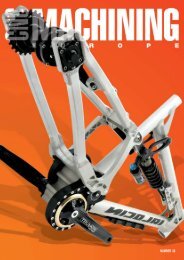

“The nice part is that I now have crossover between all<br />

my <strong>Haas</strong> machines,” says Quinn. “Pretty much the same<br />

program will work on any of them. And, I keep my tool libraries<br />

the same from machine to machine: Tool two is always a drill;<br />

tool seven is always a quarter inch endmill and so on. With<br />

this broad interchangeability, it’s amazing what we can do.<br />

“There was a day here, a couple months ago, when I had<br />

wheels running on four of my five mills, even the (smaller)<br />

VF-2,” says Quinn. “A lot of Senior’s old-school bikes take a<br />

16-inch rear wheel, instead of the usual 18s and 21s we put<br />

on most of our new choppers. I said, ‘you know what? . . .<br />

I think this will fit in here!’ I’d never even thought of cutting<br />

wheels on the VF-2 before, but I needed four sets going out<br />

that day. Happily, the 16-incher fit the VF-2’s cutting envelope<br />

with a bit to spare, and I didn’t have to change a thing in the<br />

| www.<strong>Haas</strong>CNC.com<br />

program. To be able to just throw it in and cut wheels on all<br />

those machines, all at the same time, was just amazing.”<br />

Every <strong>Haas</strong> machine at OCC is fully networked, and has<br />

either a 20- or 40-gigabite hard drive, which Quinn accesses<br />

from his office. “I use my desktop to post the programs<br />

through Mastercam ® ,” he says. “I output that post, and send<br />

the NC code directly to the machine tool.”<br />

The flawless finishes Quinn achieves on OCC’s famous<br />

appearance parts are the result of both his machining skill and<br />

the flexibility of this network setup. “The chaining tolerances<br />

I use in Mastercam are always evolving,” he admits. “I’m<br />

now down to about five-millionths. This makes the programs<br />

extremely large, but you couldn’t ask for a finer finish. Since<br />

the programs are too big for resident memory, I do most of<br />

my wheel and surfacing files through DNC,” he explains. “Our<br />

chromers and polishers really love the finish we’re getting off<br />

the <strong>Haas</strong> machines.”