Repair to BT roads at Jaggayyapet Lime Stone Mines. - Vizag Steel

Repair to BT roads at Jaggayyapet Lime Stone Mines. - Vizag Steel

Repair to BT roads at Jaggayyapet Lime Stone Mines. - Vizag Steel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

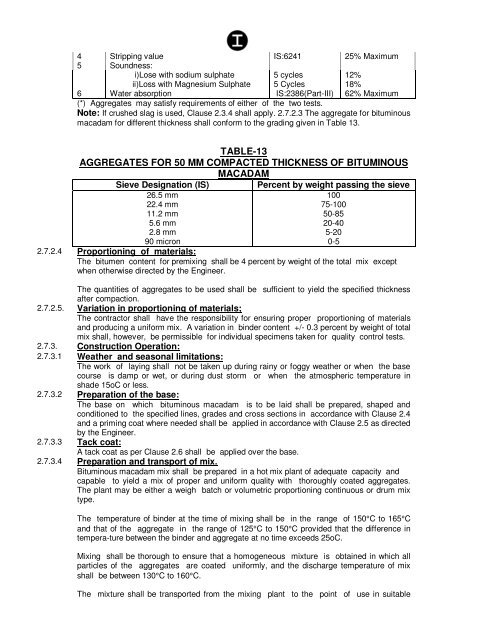

4<br />

5<br />

6<br />

Stripping value<br />

Soundness:<br />

i)Lose with sodium sulph<strong>at</strong>e<br />

ii)Loss with Magnesium Sulph<strong>at</strong>e<br />

W<strong>at</strong>er absorption<br />

IS:6241<br />

5 cycles<br />

5 Cycles<br />

IS:2386(Part-III)<br />

25% Maximum<br />

12%<br />

18%<br />

62% Maximum<br />

(*) Aggreg<strong>at</strong>es may s<strong>at</strong>isfy requirements of either of the two tests.<br />

Note: If crushed slag is used, Clause 2.3.4 shall apply. 2.7.2.3 The aggreg<strong>at</strong>e for bituminous<br />

macadam for different thickness shall conform <strong>to</strong> the grading given in Table 13.<br />

TABLE-13<br />

AGGREGATES FOR 50 MM COMPACTED THICKNESS OF BITUMINOUS<br />

MACADAM<br />

Sieve Design<strong>at</strong>ion (IS) Percent by weight passing the sieve<br />

26.5 mm<br />

22.4 mm<br />

11.2 mm<br />

5.6 mm<br />

2.8 mm<br />

90 micron<br />

100<br />

75-100<br />

50-85<br />

20-40<br />

5-20<br />

0-5<br />

2.7.2.4 Proportioning of m<strong>at</strong>erials:<br />

The bitumen content for premixing shall be 4 percent by weight of the <strong>to</strong>tal mix except<br />

when otherwise directed by the Engineer.<br />

The quantities of aggreg<strong>at</strong>es <strong>to</strong> be used shall be sufficient <strong>to</strong> yield the specified thickness<br />

after compaction.<br />

2.7.2.5. Vari<strong>at</strong>ion in proportioning of m<strong>at</strong>erials;<br />

The contrac<strong>to</strong>r shall have the responsibility for ensuring proper proportioning of m<strong>at</strong>erials<br />

and producing a uniform mix. A vari<strong>at</strong>ion in binder content +/- 0.3 percent by weight of <strong>to</strong>tal<br />

mix shall, however, be permissible for individual specimens taken for quality control tests.<br />

2.7.3. Construction Oper<strong>at</strong>ion:<br />

2.7.3.1 We<strong>at</strong>her and seasonal limit<strong>at</strong>ions:<br />

The work of laying shall not be taken up during rainy or foggy we<strong>at</strong>her or when the base<br />

course is damp or wet, or during dust s<strong>to</strong>rm or when the <strong>at</strong>mospheric temper<strong>at</strong>ure in<br />

shade 15oC or less.<br />

2.7.3.2 Prepar<strong>at</strong>ion of the base:<br />

The base on which bituminous macadam is <strong>to</strong> be laid shall be prepared, shaped and<br />

conditioned <strong>to</strong> the specified lines, grades and cross sections in accordance with Clause 2.4<br />

and a priming co<strong>at</strong> where needed shall be applied in accordance with Clause 2.5 as directed<br />

by the Engineer.<br />

2.7.3.3 Tack co<strong>at</strong>:<br />

A tack co<strong>at</strong> as per Clause 2.6 shall be applied over the base.<br />

2.7.3.4 Prepar<strong>at</strong>ion and transport of mix.<br />

Bituminous macadam mix shall be prepared in a hot mix plant of adequ<strong>at</strong>e capacity and<br />

capable <strong>to</strong> yield a mix of proper and uniform quality with thoroughly co<strong>at</strong>ed aggreg<strong>at</strong>es.<br />

The plant may be either a weigh b<strong>at</strong>ch or volumetric proportioning continuous or drum mix<br />

type.<br />

The temper<strong>at</strong>ure of binder <strong>at</strong> the time of mixing shall be in the range of 150°C <strong>to</strong> 165°C<br />

and th<strong>at</strong> of the aggreg<strong>at</strong>e in the range of 125°C <strong>to</strong> 150°C provided th<strong>at</strong> the difference in<br />

tempera-ture between the binder and aggreg<strong>at</strong>e <strong>at</strong> no time exceeds 25oC.<br />

Mixing shall be thorough <strong>to</strong> ensure th<strong>at</strong> a homogeneous mixture is obtained in which all<br />

particles of the aggreg<strong>at</strong>es are co<strong>at</strong>ed uniformly, and the discharge temper<strong>at</strong>ure of mix<br />

shall be between 130°C <strong>to</strong> 160°C.<br />

The mixture shall be transported from the mixing plant <strong>to</strong> the point of use in suitable