Repair to BT roads at Jaggayyapet Lime Stone Mines. - Vizag Steel

Repair to BT roads at Jaggayyapet Lime Stone Mines. - Vizag Steel

Repair to BT roads at Jaggayyapet Lime Stone Mines. - Vizag Steel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Engineer. Should a change in the source of m<strong>at</strong>erials be proposed, a new job mix formula<br />

shall be established and got approved from the Engineer before actually using the<br />

m<strong>at</strong>erials.<br />

2.10.4 Construction Oper<strong>at</strong>ions:<br />

2.10.4.1 We<strong>at</strong>her and seasonal limit<strong>at</strong>ions<br />

Clause 2.7.3.1. shall apply.<br />

2.10.4.2 Prepar<strong>at</strong>ion of base:<br />

The base on which bituminous concrete is <strong>to</strong> be laid shall be prepared, shaped and<br />

conditioned <strong>to</strong> the specified levels, grade and crossfall (camber) in accordance with clause<br />

2.4 or as directed by the Engineer. The surface shall be thoroughly swept and scraped clean<br />

and free of dust and other foreign m<strong>at</strong>ter.<br />

2.10.4.3 Tack co<strong>at</strong>: A tack co<strong>at</strong> complying with clause 2.6 shall be applied over the base.<br />

2.10.4.4 Prepar<strong>at</strong>ion of mix:<br />

Hot mix plant of adequ<strong>at</strong>e capacity and capable of producing a proper and uniform quality<br />

mix shall be used for preparing the mix. The plant may be either a weigh b<strong>at</strong>ch type of<br />

volumetric proportioning continuous or drum mix type.<br />

The temper<strong>at</strong>ure of binder <strong>at</strong> the time of mixing shall be in the range of 150°C - 177°C and<br />

of aggreg<strong>at</strong>es in the range of 155°C - 163°C provided also th<strong>at</strong> <strong>at</strong> no time shall the<br />

difference in temper<strong>at</strong>ure between the aggreg<strong>at</strong>es and binder exceed 14°C.<br />

Mixing shall be thorough <strong>to</strong> ensure th<strong>at</strong> homogeneous mixture is obtained in which all<br />

particles of the mineral aggreg<strong>at</strong>es the co<strong>at</strong>ed uniformly.<br />

The mix shall be transported from the mixing plant <strong>to</strong> the point of use in suitable tipper<br />

vehicles. The vehicles employed for transport shall be clean and be covered in transit if<br />

sodirected by the Engineer.<br />

2.10.4.5 Spreading:<br />

The mix transported from the hot mix plant <strong>to</strong> the site shall be spread by means of a selfpropelled<br />

mechanical paver with suitable screeds capable of spreading, tamping and<br />

finishing the mix <strong>to</strong> specified grade, lines and cross section.<br />

However, in restricted loc<strong>at</strong>ions and in narrow width where the available equipment cannot<br />

be oper<strong>at</strong>ed in the opinion of the Engineer, he may permit manual laying of the mix.<br />

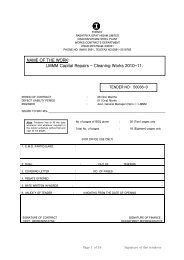

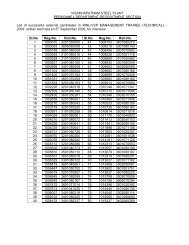

TABLE – 17<br />

REQUIREMENTS OF BITUMINOUS CONCRETE MIX<br />

SNO. DESCRIPTION REQUIREMENT<br />

01<br />

02<br />

03<br />

04<br />

05<br />

Marshall stability (ASTM design<strong>at</strong>ion: D1559) determined on<br />

Marshall specimens compacted by 50 compaction blows on<br />

Each end.<br />

Marshall flow (mm)<br />

Percent voids in mix<br />

Percent voids in mineral aggreg<strong>at</strong>e filled with bitumen<br />

Binder content percent by weight of mix<br />

340 Kg.<br />

(Minimum)<br />

2 - 4<br />

3 – 5<br />

75 - 85<br />

5 - 7.5<br />

2.10.4.6 Permissible vari<strong>at</strong>ions from the job mix formula:<br />

The contrac<strong>to</strong>r shall have the responsibility of ensuring proper proportioning of m<strong>at</strong>erials in<br />

accordance with the approved job mix formula and producing a uniform mix. The<br />

permissible vari<strong>at</strong>ions of the individual percentages of the various ingredients in the actual<br />

mix from the job mix formula may be within the limits as specified in Table 18. These<br />

vari<strong>at</strong>ions are intended <strong>to</strong> apply <strong>to</strong> individual specimens taken for quality control tests.<br />

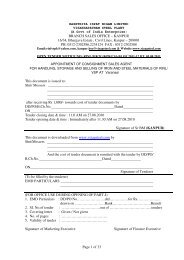

TABLE – 18<br />

PERMISSIBLE VARIATIONS FROM THE JOB MIX FORMULA