Colour Chronicle - April 2012 - Clariant

Colour Chronicle - April 2012 - Clariant

Colour Chronicle - April 2012 - Clariant

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Experimental<br />

Trial fabrics<br />

Cotton denim, indigo dyed, 345 g/m 2<br />

Desized and scoured<br />

Fabric pH 8.1 and alkalinity 0.10%<br />

(as NaOH)<br />

Procedure<br />

Foam Eco Care:<br />

400 g/l Arkofix ® ELF liq c<br />

100 g/l Catalyst NKC liq<br />

80 g/l Ceralube ® SVN liq<br />

40 g/l Solusoft ® MW liq<br />

30 g/l nonionic foaming agent<br />

Foam at 30% wet pick-up<br />

Top and bottom foam applicators<br />

Dry – 110°C, 90 seconds dwell time<br />

Cure – 130°C, 3 minutes<br />

Reference (pad process – Premium LT –<br />

Cure):<br />

200 g/l Arkofix ® ELF liq c<br />

50 g/l Catalyst NKC liq<br />

40 g/l Ceralube ® SVN liq<br />

20 g/l Solusoft ® MW liq<br />

2 g/l nonionic wetting agent<br />

Pad with 60% wet pick-up<br />

Dry – 110°C, 120 seconds dwell time<br />

Cure – 130°C, 3 minutes<br />

Remark: Premium LT-Cure is already improved in respect<br />

of curing temperature : 130°C instead of 170°C<br />

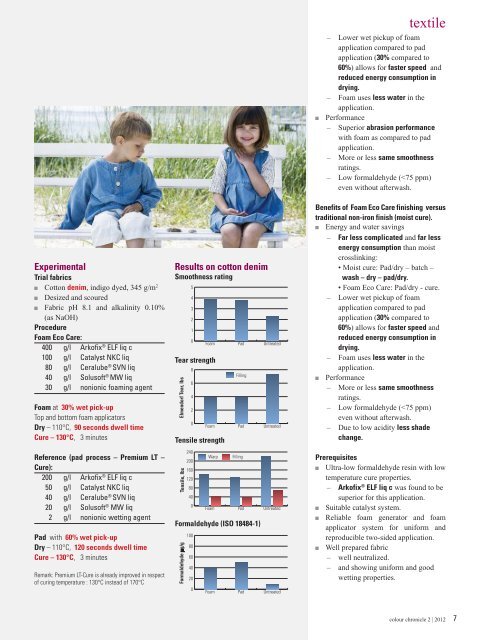

Results on cotton denim<br />

Smoothness rating<br />

Elmendorf Tear, lbs<br />

Tensile, lbs<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

8<br />

6<br />

4<br />

2<br />

0<br />

240<br />

200<br />

160<br />

120<br />

80<br />

40<br />

0<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Foam<br />

Tear strength<br />

Foam<br />

Tensile strength<br />

Warp Filling<br />

Foam<br />

Foam<br />

Pad<br />

Filling<br />

Pad<br />

Pad<br />

Formaldehyde (ISO 18484-1)<br />

Pad<br />

Untreated<br />

Untreated<br />

Untreated<br />

Untreated<br />

textile<br />

– Lower wet pickup of foam<br />

application compared to pad<br />

application (30% compared to<br />

60%) allows for faster speed and<br />

reduced energy consumption in<br />

drying.<br />

– Foam uses less water in the<br />

application.<br />

Performance<br />

– Superior abrasion performance<br />

with foam as compared to pad<br />

application.<br />

– More or less same smoothness<br />

ratings.<br />

– Low formaldehyde (