Earning his Spurs - Pitchcare

Earning his Spurs - Pitchcare

Earning his Spurs - Pitchcare

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

cones reels and can damage reel<br />

bearings.<br />

The time spent annually lapping<br />

mowers vastly exceeds the time it takes to<br />

face the bed-knife, with a facer or file<br />

and in-situ spin-grind a reel properly.<br />

Is it a scythe?<br />

When you set a mower as a scythe the<br />

reel becomes a gathering device,<br />

bringing the grass crop to the bed-knife.<br />

The bed-knife is the scythe’s cuttingedge.<br />

Correctly sharpened and angled, it<br />

allows it to present the grass crop for the<br />

reel to pull in against the sharp front<br />

cutting edge.<br />

No contact is required between the reel<br />

and bed-knife when setting as a scythe,<br />

just sharp edges, particularly on the bedknife.<br />

The spiralled helix shape of the<br />

reel blades are designed to provide a<br />

sideways action when drawing the grass<br />

along the bed-knife. The bed-knife has<br />

to be sharp at all times.<br />

Scissors will cut, but a scythe cuts<br />

cleaner. T<strong>his</strong> is precisely why a surgeon<br />

uses a single-blade scalpel (which is<br />

drawn through the flesh) instead of<br />

scissors.<br />

When setting the mower as a scythe,<br />

with zero reel to bed-knife contact, there<br />

is no need for a blade thinning a relief,<br />

100% relief is there all the time, so the<br />

machine runs easier and with less energy<br />

input, less fuel use, lower hydraulic<br />

pressures and so on.<br />

When using an easy to set, in-situ type<br />

spin grinding method with the ability to<br />

set up and sharpen quickly, you can<br />

lightly renew the reel’s edges as needed,<br />

face up the bed-knife and always keep<br />

the “no contact” setting in minutes. T<strong>his</strong><br />

is a scything cut.<br />

To maintain a scything cut the bedknife<br />

is the most important part. The<br />

bed-knife has three functions:<br />

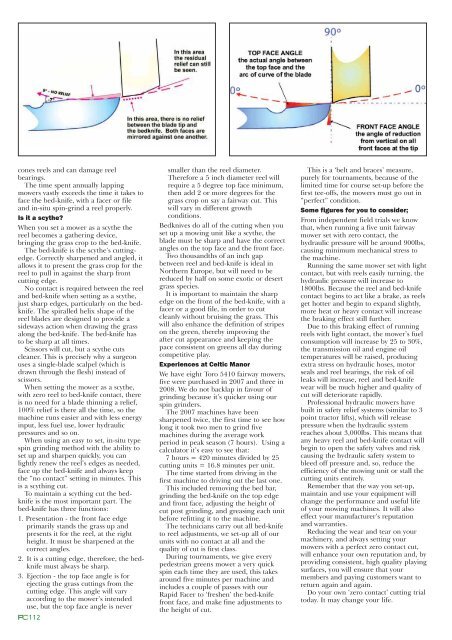

1. Presentation - the front face edge<br />

primarily stands the grass up and<br />

presents it for the reel, at the right<br />

height. It must be sharpened at the<br />

correct angles.<br />

2. It is a cutting edge, therefore, the bedknife<br />

must always be sharp.<br />

3. Ejection - the top face angle is for<br />

ejecting the grass cuttings from the<br />

cutting edge. T<strong>his</strong> angle will vary<br />

according to the mower’s intended<br />

use, but the top face angle is never<br />

112<br />

smaller than the reel diameter.<br />

Therefore a 5 inch diameter reel will<br />

require a 5 degree top face minimum,<br />

then add 2 or more degrees for the<br />

grass crop on say a fairway cut. T<strong>his</strong><br />

will vary in different growth<br />

conditions.<br />

Bedknives do all of the cutting when you<br />

set up a mowing unit like a scythe, the<br />

blade must be sharp and have the correct<br />

angles on the top face and the front face.<br />

Two thousandths of an inch gap<br />

between reel and bed-knife is ideal in<br />

Northern Europe, but will need to be<br />

reduced by half on some exotic or desert<br />

grass species.<br />

It is important to maintain the sharp<br />

edge on the front of the bed-knife, with a<br />

facer or a good file, in order to cut<br />

cleanly without bruising the grass. T<strong>his</strong><br />

will also enhance the definition of stripes<br />

on the green, thereby improving the<br />

after cut appearance and keeping the<br />

pace consistent on greens all day during<br />

competitive play.<br />

Experiences at Celtic Manor<br />

We have eight Toro 5410 fairway mowers,<br />

five were purchased in 2007 and three in<br />

2008. We do not backlap in favour of<br />

grinding because it’s quicker using our<br />

spin grinders.<br />

The 2007 machines have been<br />

sharpened twice, the first time to see how<br />

long it took two men to grind five<br />

machines during the average work<br />

period in peak season (7 hours). Using a<br />

calculator it’s easy to see that:<br />

7 hours = 420 minutes divided by 25<br />

cutting units = 16.8 minutes per unit.<br />

The time started from driving in the<br />

first machine to driving out the last one.<br />

T<strong>his</strong> included removing the bed bar,<br />

grinding the bed-knife on the top edge<br />

and front face, adjusting the height of<br />

cut post grinding, and greasing each unit<br />

before refitting it to the machine.<br />

The technicians carry out all bed-knife<br />

to reel adjustments, we set-up all of our<br />

units with no contact at all and the<br />

quality of cut is first class.<br />

During tournaments, we give every<br />

pedestrian greens mower a very quick<br />

spin each time they are used, t<strong>his</strong> takes<br />

around five minutes per machine and<br />

includes a couple of passes with our<br />

Rapid Facer to ‘freshen’ the bed-knife<br />

front face, and make fine adjustments to<br />

the height of cut.<br />

T<strong>his</strong> is a ‘belt and braces’ measure,<br />

purely for tournaments, because of the<br />

limited time for course set-up before the<br />

first tee-offs, the mowers must go out in<br />

“perfect” condition.<br />

Some figures for you to consider;<br />

From independent field trials we know<br />

that, when running a five unit fairway<br />

mower set with zero contact, the<br />

hydraulic pressure will be around 900lbs,<br />

causing minimum mechanical stress to<br />

the machine.<br />

Running the same mower set with light<br />

contact, but with reels easily turning, the<br />

hydraulic pressure will increase to<br />

1800lbs. Because the reel and bed-knife<br />

contact begins to act like a brake, as reels<br />

get hotter and begin to expand slightly,<br />

more heat or heavy contact will increase<br />

the braking effect still further.<br />

Due to t<strong>his</strong> braking effect of running<br />

reels with light contact, the mower’s fuel<br />

consumption will increase by 25 to 30%,<br />

the transmission oil and engine oil<br />

temperatures will be raised, producing<br />

extra stress on hydraulic hoses, motor<br />

seals and reel bearings, the risk of oil<br />

leaks will increase, reel and bed-knife<br />

wear will be much higher and quality of<br />

cut will deteriorate rapidly.<br />

Professional hydraulic mowers have<br />

built in safety relief systems (similar to 3<br />

point tractor lifts), which will release<br />

pressure when the hydraulic system<br />

reaches about 3,000lbs. T<strong>his</strong> means that<br />

any heavy reel and bed-knife contact will<br />

begin to open the safety valves and risk<br />

causing the hydraulic safety system to<br />

bleed off pressure and, so, reduce the<br />

efficiency of the mowing unit or stall the<br />

cutting units entirely.<br />

Remember that the way you set-up,<br />

maintain and use your equipment will<br />

change the performance and useful life<br />

of your mowing machines. It will also<br />

effect your manufacturer’s reputation<br />

and warranties.<br />

Reducing the wear and tear on your<br />

machinery, and always setting your<br />

mowers with a perfect zero contact cut,<br />

will enhance your own reputation and, by<br />

providing consistent, high quality playing<br />

surfaces, you will ensure that your<br />

members and paying customers want to<br />

return again and again.<br />

Do your own ‘zero contact’ cutting trial<br />

today. It may change your life.