The effect of six polishing systems on the surface roughness of two ...

The effect of six polishing systems on the surface roughness of two ...

The effect of six polishing systems on the surface roughness of two ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>six</str<strong>on</strong>g> <str<strong>on</strong>g>polishing</str<strong>on</strong>g> <str<strong>on</strong>g>systems</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> <strong>surface</strong> <strong>roughness</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>two</strong> packable resin-based composites<br />

ANDREFIGUEIREDOREIS, DOS, MARCELO GIANNINI, DDS, MS, PHO, JOSE ROBERTO Loy ADINO, DDS, MS, PHO,<br />

CARLOSTADEUDOSSANTOSDIAS, PHO<br />

ABSTRACT: Purpose: To evaluate <strong>the</strong> <strong>surface</strong> <strong>roughness</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>two</strong> packable composites after finishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> with<br />

<str<strong>on</strong>g>six</str<strong>on</strong>g> different <str<strong>on</strong>g>systems</str<strong>on</strong>g>. Materials and Methods: Solitaire and Alert composite samples were prepared and polished with<br />

Poli I and Poli II aluminum oxide pastes, Ultralap diam<strong>on</strong>d paste, Enhance finishing points, Politip rubber polishers,<br />

fine and extra fine diam<strong>on</strong>d burs, and 30-blade tungsten carbide burs according to <strong>the</strong> manufacturers' instructi<strong>on</strong>s. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

polished <strong>surface</strong>s were <strong>the</strong>n evaluated with a pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ilometer and a scanning electr<strong>on</strong> microscope. Results: Solitaire composite<br />

resin presented <strong>the</strong> smoo<strong>the</strong>st <strong>surface</strong>s when polished with Poli I and II aluminum oxide pastes, Ultralap diam<strong>on</strong>d<br />

paste, Politip finishing points and 30-blade tungsten carbide burs. <str<strong>on</strong>g>The</str<strong>on</strong>g> smoo<strong>the</strong>st <strong>surface</strong>s for Alert composite were evident<br />

with <strong>the</strong> 30-blade tungsten carbide burs. (Am J Dent 2002; 15: 193-197).<br />

CLINICAL SIGNIFICANCE: Alert displayed a significantly greater <strong>surface</strong> <strong>roughness</strong> than Solitaire for most <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> agents<br />

used. <str<strong>on</strong>g>The</str<strong>on</strong>g> smoo<strong>the</strong>st <strong>surface</strong>s for Solitaire were attained with <str<strong>on</strong>g>polishing</str<strong>on</strong>g> pastes, 30-blade carbide burs and Politip.<br />

Carbide burs provided <strong>the</strong> best finish for Alert.<br />

CORRESPONDENCE: Dr. Andre Figueiredo Reis, Department <str<strong>on</strong>g>of</str<strong>on</strong>g> Restorative Dentistry, Piracicaba School <str<strong>on</strong>g>of</str<strong>on</strong>g> Dentistry,<br />

Campinas State University, Av. Limeira, 901, Piracicaba/SP, Brazil, CEP 13414-018, Fax: 55 194305218, E-mail:<br />

reisandre@yahoo.com<br />

Since resin-based composites were introduced to dentistry,1<br />

no o<strong>the</strong>r restorative material has been modified and<br />

improved at a similar rate. Despite all initial inherent problems<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composites, many dentists attempted to use <strong>the</strong>se<br />

materials to restore posterior teeth, and perhaps <strong>the</strong> greatest<br />

effort to improve composites has been <strong>the</strong> generati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> materials<br />

for occlusal <strong>surface</strong>s. 2 - 4<br />

Problems with <strong>the</strong> early composite formulati<strong>on</strong>s, such as<br />

percentage <str<strong>on</strong>g>of</str<strong>on</strong>g> filler and particle size leading high wear rates,<br />

loss <str<strong>on</strong>g>of</str<strong>on</strong>g> anatomic form and poor polishability c<strong>on</strong>vinced researchers<br />

that early composite formulati<strong>on</strong>s were unacceptable<br />

for restoring posterior teeth. 5 - 7 <str<strong>on</strong>g>The</str<strong>on</strong>g> increase <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> filler<br />

loading percentage, <strong>the</strong> modificati<strong>on</strong> and reducti<strong>on</strong> <strong>on</strong> <strong>the</strong><br />

particles size, that initially had 12 11m,and <strong>the</strong>ir better distributi<strong>on</strong><br />

in <strong>the</strong> resin matrix, c<strong>on</strong>tributed to reduce <strong>the</strong> wear<br />

rates 8 - 1O and to improve <strong>the</strong> <strong>surface</strong> smoothness <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong>se restorative<br />

materials. ,11,12<br />

Numerous studies have been developed and notable progress<br />

has been achieved in <strong>the</strong> attempt to improve <strong>the</strong> physical<br />

and handling characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> posterior composites. New<br />

formulati<strong>on</strong>s possess packable characteristics similar to amalgam<br />

manipulative properties, due to new filler types, which<br />

c<strong>on</strong>sist <str<strong>on</strong>g>of</str<strong>on</strong>g> micro filament glass fibers or more coarse and textured<br />

fillers than c<strong>on</strong>venti<strong>on</strong>al <strong>on</strong>es. 3 ,13 <str<strong>on</strong>g>The</str<strong>on</strong>g> use <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong>se composites,<br />

in c<strong>on</strong>juncti<strong>on</strong> with b<strong>on</strong>ding agents and following<br />

correct clinical techniques, has allowed dentists to place reli-<br />

abl e postenor . resm- . b<strong>on</strong>d ed restorati<strong>on</strong>s.' . 3 13-15H owever, <strong>the</strong>re<br />

is no c<strong>on</strong>.;ensus <strong>on</strong> which finishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> materials<br />

provide <strong>the</strong> smoo<strong>the</strong>st <strong>surface</strong>s for packable composites.<br />

Proper fmishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> posterior composite<br />

restorati<strong>on</strong>s are important steps that enhance both es<strong>the</strong>tics<br />

and l<strong>on</strong>gevity <str<strong>on</strong>g>of</str<strong>on</strong>g> restored teeth. 16.17Surface <strong>roughness</strong>, associated<br />

with improper fmishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> can result in ex-<br />

cessive <strong>surface</strong> stammg, increased wear rates and plaque<br />

accumulati<strong>on</strong>, which compromise <strong>the</strong> clinical performance <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> restorati<strong>on</strong>. 18-22<br />

Most investigators agree that <strong>the</strong> aluminum oxide discs are<br />

<strong>the</strong> fmishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> agents that produce <strong>the</strong> lowest<br />

<strong>surface</strong> <strong>roughness</strong> average (Ra) <strong>on</strong> resin-based composites;23-<br />

28however, -<strong>the</strong>ir use is restricted to anterior teeth. Regarding<br />

this limitati<strong>on</strong>, a wide variety <str<strong>on</strong>g>of</str<strong>on</strong>g> finishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> devices<br />

are available to <strong>the</strong> clinician: multifluted tungsten carbide<br />

burs, diam<strong>on</strong>d burs, white st<strong>on</strong>es, rubber points, aluminum<br />

oxide pastes, and diam<strong>on</strong>d pastes. 16,17<br />

This study compared <strong>the</strong> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>six</str<strong>on</strong>g> different finishing<br />

and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> agents <strong>on</strong> <strong>the</strong> <strong>surface</strong> <strong>roughness</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>two</strong> packable<br />

resin-based composites and to observe <strong>the</strong>ir polished<br />

<strong>surface</strong>s with a scanning electr<strong>on</strong> microscope.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> packable resin-based composites used in this study<br />

were Solitaire" and Alert, b and <strong>the</strong> <str<strong>on</strong>g>polishing</str<strong>on</strong>g> <str<strong>on</strong>g>systems</str<strong>on</strong>g> were<br />

aluminum oxide pastes (Poli I and Poli lIe), diam<strong>on</strong>d paste<br />

(Ultralapd), rubber polishers (Enhance e and Politipf), diam<strong>on</strong>d<br />

fmishing burs (fme and extra fme g ), and 30-blade tungsten<br />

carbide burs. h <str<strong>on</strong>g>The</str<strong>on</strong>g> compositi<strong>on</strong> and characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

resins and fmishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> <str<strong>on</strong>g>systems</str<strong>on</strong>g> are listed in Tables<br />

1 and 2, respectively.<br />

Thirty cylindrical specimens (3 mm thick and 5 mm in<br />

diameter) <str<strong>on</strong>g>of</str<strong>on</strong>g> each composite were prepared in a polytetrafluorethylene<br />

split mold. <str<strong>on</strong>g>The</str<strong>on</strong>g> cavity was filled, using an amalgam<br />

plugger, and cured for 40 sec<strong>on</strong>ds with a visible light-curing<br />

unit.' <str<strong>on</strong>g>The</str<strong>on</strong>g> specimens were stored in distilled water at 37°C for<br />

24 hours and <strong>the</strong>n randomly assigned to <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> <str<strong>on</strong>g>six</str<strong>on</strong>g> test<br />

groups (n=5), fmished and polished by a single investigator.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> pastes (Ultralap and Poli IIPoli II) and rubber polishers<br />

(Enhance and Politip) were applied using a low-speed

6 in diameter and 60-80 in<br />

length (glass fiber),<br />

0.8 (irregular-shaped filler)<br />

Product Type Abrasive<br />

Poli I and Poli II Paste Aluminum oxide<br />

Ultralap Paste Ultrafine diam<strong>on</strong>ds<br />

Silic<strong>on</strong> dioxide, fluoride-bariumaluminum-borosilicate<br />

glass,<br />

fluoride aluminumsilicate glass<br />

Micr<str<strong>on</strong>g>of</str<strong>on</strong>g>ilamentous glass fiber,<br />

silic<strong>on</strong> dioxide, barium-borosilicate<br />

glass, micr<str<strong>on</strong>g>of</str<strong>on</strong>g>ine silica<br />

Enhance Rubber point Aluminum oxide, silanized<br />

pyrolytic silica<br />

Politip Rubber point Silic<strong>on</strong> dioxide<br />

Diam<strong>on</strong>d bur Diam<strong>on</strong>d bur UltTafine diam<strong>on</strong>ds<br />

F and FF<br />

30-blade multi fluted Carbide bur Tungsten carbides<br />

carbide bur<br />

handpiece for 30 sec<strong>on</strong>ds, and felt wheels were used for <strong>the</strong><br />

applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> pastes. High-speed 30-blade tungsten carbide<br />

burs and diam<strong>on</strong>d fmishing burs were applied for 15<br />

sec<strong>on</strong>ds with water coolant.<br />

After all specimens were polished, <strong>the</strong>y were thorougWy<br />

rinsed with water and allowed to dry for 24 hours before<br />

measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> average <strong>surface</strong> <strong>roughness</strong> (Ra). To measure<br />

<strong>the</strong> <strong>surface</strong> <strong>roughness</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> specimens a pr<str<strong>on</strong>g>of</str<strong>on</strong>g>Jlometeri was<br />

used. Three measurements in different directi<strong>on</strong>s were recorded<br />

for <strong>the</strong> five specimens in each group, <strong>the</strong> mean Ra value was<br />

determined for each specimen, and an overall Ra was<br />

determined for <strong>the</strong> total sample. <str<strong>on</strong>g>The</str<strong>on</strong>g> results were analyzed<br />

statistically by 2 x 6 factorial ANaVA and Duncan's multiple<br />

range test at <strong>the</strong> 0.05 level <str<strong>on</strong>g>of</str<strong>on</strong>g> significance (Tables 3, 4).<br />

After <strong>the</strong> pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ilometric examinati<strong>on</strong>, <strong>two</strong> samples <str<strong>on</strong>g>of</str<strong>on</strong>g> each<br />

group were prepared for <strong>the</strong> scanning electr<strong>on</strong> microscope<br />

(DSM-940A k ). Samples were sputter coated with gold to a<br />

thickness <str<strong>on</strong>g>of</str<strong>on</strong>g> approximately 50A in a vacuum evaporator<br />

(MED 010'). <str<strong>on</strong>g>The</str<strong>on</strong>g> samples were observed and photographs <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<strong>the</strong> most representative regi<strong>on</strong>s were taken.<br />

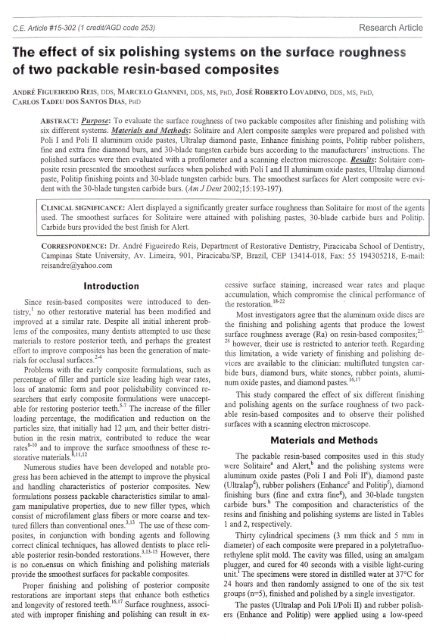

<str<strong>on</strong>g>The</str<strong>on</strong>g> average Ra measurements for combinati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

composites and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> instruments are presented in Fig. 1<br />

and Table 4, respectively. <str<strong>on</strong>g>The</str<strong>on</strong>g> smoo<strong>the</strong>st <strong>surface</strong>s for Solitaire<br />

resin were recorded with Poli I and Poli II aluminum oxide<br />

pastes, Ultralap diam<strong>on</strong>d paste, Politip finishing point, and 30blade<br />

tungsten carbide bur. No statistically significant<br />

differences were observed am<strong>on</strong>g <strong>the</strong>m (P>0.05). Regarding<br />

Alert composite, <strong>the</strong> smoo<strong>the</strong>st <strong>surface</strong>s were evident with 30blade<br />

tungsten carbide burs (P

Aluminum oxide<br />

pastes<br />

Fig. 1. Surface <strong>roughness</strong> average (Ra-~m) produced by <strong>the</strong> finishing and<br />

<str<strong>on</strong>g>polishing</str<strong>on</strong>g> instruments.<br />

Fig. 3. Alert composite and an aluminum oxide paste-produced <strong>surface</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

bar denotes 20 ~m. (SEM x500.)<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> differences in <strong>surface</strong> topography between Solitaire<br />

and Alert may be attributed to differences in <strong>the</strong>ir interparticle<br />

spacing and <strong>the</strong>ir filler particle· size. Solitaire composite resin,<br />

in which particle size varies from 0.7 to 2.0 ~m, presented <strong>the</strong><br />

lowest <strong>surface</strong> <strong>roughness</strong> averages, whereas Alert composite,<br />

which is composed <str<strong>on</strong>g>of</str<strong>on</strong>g> bigger particles, varying from 0.8 to 80<br />

11m,recorded <strong>the</strong> greatest <strong>roughness</strong>.<br />

For a composite finishing system to be <str<strong>on</strong>g>effect</str<strong>on</strong>g>ive, <strong>the</strong> cutting<br />

particles (abrasive) must be relatively harder than <strong>the</strong><br />

filler materials. 34 O<strong>the</strong>rwise, <strong>the</strong> <str<strong>on</strong>g>polishing</str<strong>on</strong>g> agent will <strong>on</strong>ly<br />

remove <strong>the</strong> s<str<strong>on</strong>g>of</str<strong>on</strong>g>t resin matrix and leave <strong>the</strong> filler particles<br />

protruding from <strong>the</strong> <strong>surface</strong>. 25 <str<strong>on</strong>g>The</str<strong>on</strong>g> hardness <str<strong>on</strong>g>of</str<strong>on</strong>g> aluminum<br />

oxide is significantly higher than that <str<strong>on</strong>g>of</str<strong>on</strong>g> silic<strong>on</strong> dioxide, and<br />

generally, higher than most filler materials used in composite<br />

formulati<strong>on</strong>s. 38 ,39<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> aluminum oxide and diam<strong>on</strong>d pastes produced<br />

smooth <strong>surface</strong>s <strong>on</strong> <strong>the</strong> Solitaire composite. However, <strong>the</strong><br />

<strong>surface</strong> <strong>roughness</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Alert composite was c<strong>on</strong>siderably<br />

greater when <strong>the</strong>se pastes were used. Thus, <str<strong>on</strong>g>polishing</str<strong>on</strong>g> pastes<br />

were unsatisfactory for <str<strong>on</strong>g>polishing</str<strong>on</strong>g> <strong>the</strong> Alert composite, as <strong>the</strong>y<br />

Fig. 2. Solitaire composite and an aluminum oxide paste-produced <strong>surface</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

bar denotes 20 ~m. (SEM x500.).<br />

Fig. 4. Solitaire composite and a diam<strong>on</strong>d bur-produced <strong>surface</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g> bar denotes<br />

20 ~m. (SEM XSOO.)<br />

caused preferential removal <str<strong>on</strong>g>of</str<strong>on</strong>g> resin matrix, resulting in exposure<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> micr<str<strong>on</strong>g>of</str<strong>on</strong>g>ilamentous glass fibers, which have about 6<br />

11min diameter and 60 to 80 11min length (Figs. 2, 3).<br />

As expected, <strong>the</strong> diam<strong>on</strong>d finishing points and <strong>the</strong> Enhance<br />

finishing system produced rough <strong>surface</strong>s <strong>on</strong> both composites.1<br />

7 ,23,38,40 When diam<strong>on</strong>d points were applied, scratches<br />

were observed <strong>on</strong> <strong>the</strong> <strong>surface</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composites (Fig. 4). <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

<strong>surface</strong>s polished v.ith <strong>the</strong> Enhance finishing points presented<br />

some pitting, which may have been due to plucking <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

filler particles during <str<strong>on</strong>g>polishing</str<strong>on</strong>g>. <str<strong>on</strong>g>The</str<strong>on</strong>g> pits were proporti<strong>on</strong>al to<br />

filler sizes (Fig. 5).<br />

Thirty-fluted tungsten carbide burs are c<strong>on</strong>sidered to be<br />

intermediate finishing devices. 16,41 Never<strong>the</strong>less, <strong>the</strong>y were<br />

<strong>the</strong> finishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> devices that recorded <strong>the</strong> best<br />

results for Alert (Fig. 6) and were am<strong>on</strong>g <strong>the</strong> best polishers<br />

for Solitaire, showing no need <str<strong>on</strong>g>of</str<strong>on</strong>g> fmal <str<strong>on</strong>g>polishing</str<strong>on</strong>g> with any<br />

o<strong>the</strong>r device. As <strong>the</strong>y are used in high speed, <strong>the</strong> clinician<br />

must be attentive to <strong>the</strong> pressure applied and to use water<br />

cooling not to damage <strong>the</strong> anatomic form <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> restorati<strong>on</strong><br />

nor <strong>the</strong> adjacent sound enamel.

Fig. 5. Alert composite and an Enhance-produced <strong>surface</strong>. <str<strong>on</strong>g>The</str<strong>on</strong>g> bar denotes 20<br />

11m.(SEM x500.)<br />

Silic<strong>on</strong> dioxide, <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> filler types <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> packable<br />

composites studied in this paper, is also present <strong>on</strong> <strong>the</strong><br />

Politip's compositi<strong>on</strong>. According to Tjan & Chan,25 <strong>the</strong>se<br />

rubber polishers were found to be <str<strong>on</strong>g>effect</str<strong>on</strong>g>ive <strong>on</strong> micro filled<br />

composites and possibly <strong>on</strong> small-particle hybrid composites,<br />

which can explain <strong>the</strong> good results obtained when <strong>the</strong>y were<br />

applied <strong>on</strong> <strong>the</strong> Solitaire composite <strong>surface</strong>s. When <strong>the</strong> Alert<br />

composite was polished with <strong>the</strong> Politip rubber polishers, <strong>the</strong><br />

results were not as good as for <strong>the</strong> Solitaire composite, probably<br />

due to <strong>the</strong> large filler particle size. However, <strong>the</strong>se rubber<br />

polishers recorded <strong>the</strong> sec<strong>on</strong>d best <strong>surface</strong> <strong>roughness</strong> average<br />

for <strong>the</strong> Alert composite.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> results suggested that each composite requires specific<br />

finishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> devices, depending <strong>on</strong> <strong>the</strong> size,<br />

hardness and amount <str<strong>on</strong>g>of</str<strong>on</strong>g> filler <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> composite used. Carbide<br />

burs provided <strong>the</strong> best finish for <strong>the</strong> larger particle packable<br />

Alert, and, for Solitaire, all were comparable except diam<strong>on</strong>d<br />

burs and Enhance, which produced <strong>the</strong> roughest <strong>surface</strong>. For<br />

most <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> <str<strong>on</strong>g>polishing</str<strong>on</strong>g> techniques a significantly smoo<strong>the</strong>r<br />

fmish was obtained for Solitaire.<br />

Fur<strong>the</strong>r studies should evaluate <strong>the</strong> results <str<strong>on</strong>g>of</str<strong>on</strong>g> different<br />

composite <str<strong>on</strong>g>polishing</str<strong>on</strong>g> <str<strong>on</strong>g>systems</str<strong>on</strong>g> <strong>on</strong> different resin-based composites.<br />

a. Heraeus Kulzer, Wehrheim!TS, Germany.<br />

b. Jeneric/Pentr<strong>on</strong>, Wallingford, CT, USA.<br />

c. Kota, Sao Paulo, SP, Brazil.<br />

d. Moyco Uni<strong>on</strong> Broach, York, PA, USA.<br />

e. Dentsply/Caulk, Milford, DE, USA.<br />

f. Vivadent, Schaan, Liechtenstein.<br />

g. KG-Sorensen, Barneri, SP, Brazil.<br />

h. Beavers Dental, Morrisburg, Ontario, Canada.<br />

i. Degussa Hills, Frankfurt, Germany.<br />

j. Mitutoyo, Tokyo, Japan.<br />

k. Zeiss, Munich, Germany.<br />

I. Balzers Uni<strong>on</strong>, Balzers, Liechtenstein.<br />

Acknowiedgnwus: This study was supported by FAPESP (Grant 98115535-5). <str<strong>on</strong>g>The</str<strong>on</strong>g><br />

authors are indebted to Pr<str<strong>on</strong>g>of</str<strong>on</strong>g>. E. W. Kitajima (NAP-MEP AlESALQ-USP).<br />

Dr. Reis is a Research Assistant, Dr. Giannini is Assistant Pr<str<strong>on</strong>g>of</str<strong>on</strong>g>essor & Dr.<br />

Lovadino is Assistant Pr<str<strong>on</strong>g>of</str<strong>on</strong>g>essor, Department <str<strong>on</strong>g>of</str<strong>on</strong>g> Restorative Dentistry, Piracicaba<br />

School <str<strong>on</strong>g>of</str<strong>on</strong>g> Dentistry, Camp in as State University, SP, Brazil. Dr. Dias is<br />

Assistant Pr<str<strong>on</strong>g>of</str<strong>on</strong>g>essor, Department <str<strong>on</strong>g>of</str<strong>on</strong>g> Ma<strong>the</strong>matics and Statistics, ESALQ,<br />

University <str<strong>on</strong>g>of</str<strong>on</strong>g> Sao Paulo, SP, Brazil.<br />

Fig. 6. Alert composite and a thirty-fluted tungsten carbide bur-produced <strong>surface</strong>.<br />

<str<strong>on</strong>g>The</str<strong>on</strong>g> bar denotes 20 11m (SEM x500.)<br />

1. Bowen RL. Dental filling material comprising vinyl-silane-treated fused<br />

silica and a binder c<strong>on</strong>sisting <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> reacti<strong>on</strong> product <str<strong>on</strong>g>of</str<strong>on</strong>g> bysphenol and<br />

glycidil methacrylate. US Patent 3,006,112, 1962.<br />

2. Leinfelder KF. Posterior composites. State-<str<strong>on</strong>g>of</str<strong>on</strong>g>-<strong>the</strong>-art clinical applicati<strong>on</strong>s.<br />

Dent Clin N Am 1993; 37: 411-418.<br />

3. Leinfelder KF. A report <strong>on</strong> a new c<strong>on</strong>densable composite resin. Compend<br />

Cantin Educ Dent 1998; 19: 230-237.<br />

4. Leinfelder KF, Bayne SC, Swift EJ Jr. Packable composites: Overview<br />

and technical c<strong>on</strong>siderati<strong>on</strong>s. J Es<strong>the</strong>t Dent 1999; II: 234-249.<br />

5. Phillips RW, Avery DR,Mehra R, et af. Observati<strong>on</strong>s <strong>on</strong> a composite<br />

resin for Class 11 restorati<strong>on</strong>s: Two-year report. J Pros<strong>the</strong>t Dent 1972;<br />

28: 164-169.<br />

6. Eames WB, Strain JD, Weitman RT, et ai. Clinical comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

composite, amalgam and silicate restorati<strong>on</strong>s. J Am Dent Assoc 1974; 89:<br />

1111-1117.<br />

7. Leinfelder KF, Sluder TB, Santos JFF, et ai. Five-year clinical evaluati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> anterior and posterior restorati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> composite resin. Oper Dent<br />

1980; 5: 57-65.<br />

8. Leinfelder KF. Posterior composite resins: <str<strong>on</strong>g>The</str<strong>on</strong>g> materials and <strong>the</strong>ir<br />

clinical performance. JAm Dent Assoc 1995; 126: 663-676.<br />

9. Willems G, Lambrechts P, Lesaffre E, et af. Three-year follow-up <str<strong>on</strong>g>of</str<strong>on</strong>g> five<br />

posterior composites: In vivo wear results. J Dent 1993; 21: 79-86.<br />

10. Lambrechts P, Braem M, Vanherle G. Evaluati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> clinical performance for<br />

posterior composite resins and dentin adhesives. Oper Dent 1987; 12: 53-78.<br />

II. Wendt SL, Leinfelder KF. Clinical evaluati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a posterior composite<br />

resin: 3-year results. Am J Dent 1994; 7: 207-211.<br />

12. Bayne SC, Heyman HO, Swift Jr EJ. Update <strong>on</strong> dental composite<br />

restorati<strong>on</strong>s. JAm Dent Assoc 1994; 125: 687-701.<br />

13. lazetti G, Burgess 10, Gardiner 0, et ai. Color stability <str<strong>on</strong>g>of</str<strong>on</strong>g> fluoridec<strong>on</strong>taining<br />

restorative materials. Oper Dent 2000; 25:520-525.<br />

14. Perry R, Kugel G, Leinfelder Ie. One-year clinical evaluati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> SureFil<br />

packable composite. Compend Cantin Educ Dent 1999; 20: 544-550.<br />

15. Jacks<strong>on</strong> RD, Morgan M. <str<strong>on</strong>g>The</str<strong>on</strong>g> new posterior resins and a simplified<br />

placement technique. J Am Dent Assoc 2000; 131: 375-383.<br />

16. Jefferies SR. <str<strong>on</strong>g>The</str<strong>on</strong>g> art and science <str<strong>on</strong>g>of</str<strong>on</strong>g> abrasive finishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> in<br />

restorative dentistry. Dent Clin N Am 1998; 42: 613-627.<br />

17. Goldstein RE. Finishing <str<strong>on</strong>g>of</str<strong>on</strong>g> composites and laminates. Dent Clin N Am<br />

1989; 33: 305-318.<br />

18. Dietschi D, Campanile G, Holz J, et ai. Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong> color stability<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> ten new-generati<strong>on</strong> composites: An in vitro study. Dent Mater 1994;<br />

10: 352-262.<br />

19. Setcos JC, Tarim B, Suzuki S. Surface finish produced <strong>on</strong> resin composites<br />

by new <str<strong>on</strong>g>polishing</str<strong>on</strong>g> <str<strong>on</strong>g>systems</str<strong>on</strong>g>. Quintessence Int 1999; 30: 169-173.<br />

20. Weitman RT, Eames WB. Plaque accumulati<strong>on</strong> <strong>on</strong> composite resin<br />

<strong>surface</strong>s after various finishing procedures. J Am Dent Assoc 1975; 91:<br />

101-106.<br />

21. Chan KC, Fuller JL, Hormati AA. <str<strong>on</strong>g>The</str<strong>on</strong>g> ability <str<strong>on</strong>g>of</str<strong>on</strong>g> food to stain <strong>two</strong><br />

composites. J Pros<strong>the</strong>t Dent 1980; 43: 542-545.

22. lalkind MM, Keisar 0, Ever-Hadani P, et al. Accumulati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Streptococcus mu/ans <strong>on</strong> light-cured composites and amalgam: An in<br />

vitro study. J Es<strong>the</strong>/ Denl 1998; 10: 187-190.<br />

23. Berastegui E, e/ al. Surface <strong>roughness</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> finished composites resins. J<br />

Proslhel Den11992; 68: 742-749.<br />

24. Stoddard JW, Johns<strong>on</strong> GH. An evaluati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>polishing</str<strong>on</strong>g> agents for composite<br />

resins.J Pros/hetDenI1991; 65: 491-495.<br />

25. Tjan AHL, Chan CA. <str<strong>on</strong>g>The</str<strong>on</strong>g> polishability <str<strong>on</strong>g>of</str<strong>on</strong>g> posterior composites. J Proslhel<br />

Den11989; 61: 138-146.<br />

26. Van Noort R, Davis LG. <str<strong>on</strong>g>The</str<strong>on</strong>g> <strong>surface</strong> finish <str<strong>on</strong>g>of</str<strong>on</strong>g> composite resin restorative<br />

materials. Br Den/Jl984; 157: 360-364,1984.<br />

27. Wils<strong>on</strong> F, Heath JR, Watts DC. Finishing composite restorative materials. J<br />

Oral Rehabill990; 17: 79-87.<br />

28. Toledano M, De La Torre FJ, Osorio R. Evaluati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>two</strong> <str<strong>on</strong>g>polishing</str<strong>on</strong>g> methods<br />

for resin composites. Am J Den11994; 7: 328-330.<br />

29. GIants PO, Lars<strong>on</strong> LA. Surface <strong>roughness</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> composite resins before and<br />

after finishing. Acla Od<strong>on</strong>lol Scand 1972; 30: 335.<br />

30. McLundie AC, Murray FD. Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> methods used in finishing<br />

composite resin. A scanning electr<strong>on</strong> microscope study. J Proslhel Dent<br />

1974; 31: 164-171.<br />

31. Lee HL, Swartz ML. Scanning electr<strong>on</strong> microscope study <str<strong>on</strong>g>of</str<strong>on</strong>g> composite<br />

restorative materials. J Dent Res 1970; 49: 149-158.<br />

32. Maccchi RL, Craig RG. Physical and mechanical properties <str<strong>on</strong>g>of</str<strong>on</strong>g> composite<br />

restorative materials. JAm Dent Assoc 1969; 78: 328.<br />

33. McCabe JF, Chen C, Caddick RJK. <str<strong>on</strong>g>The</str<strong>on</strong>g> finishing <str<strong>on</strong>g>of</str<strong>on</strong>g> composite restorati<strong>on</strong>s.<br />

BrDentJl978; 145: 101-104.<br />

34. Chandler HH, Bowen RL, Paffenbarger GC. Method for finishing composite<br />

restorative materials. JAm Dent Assoc 1971; 83: 344-348.<br />

35. Heath JR, Wils<strong>on</strong> HJ. Surface <strong>roughness</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g>restorati<strong>on</strong>s. Br Dent J 1976;<br />

140: 131-140.<br />

36. Pratten D, Johns<strong>on</strong> G. An evaluati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> finishing instruments for an anterior<br />

and a posterior composite resin. J Proslhet Dent 1988; 60: 154-158.<br />

37. Strass1er H. Polishing composite resins to perfecti<strong>on</strong> depends <strong>on</strong> <strong>the</strong> filler.<br />

Denl Ojf1990; 10; 9-10.<br />

38. Christensen RP, Christensen GJ. Comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> instruments and<br />

commercial pastes used for finishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> composite resin. Gen<br />

Dent 1981 ;29:40-45.<br />

39. Chung K..Effects <str<strong>on</strong>g>of</str<strong>on</strong>g> finishing and <str<strong>on</strong>g>polishing</str<strong>on</strong>g> procedures <strong>on</strong> <strong>the</strong> <strong>surface</strong> texture<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> resin composites. Dent Maler 1994; 10: 325-330.<br />

40. Kaplan BA, Goldstein GR, Kijayaragliavan TV, et al. <str<strong>on</strong>g>The</str<strong>on</strong>g> <str<strong>on</strong>g>effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> three <str<strong>on</strong>g>polishing</str<strong>on</strong>g><br />

<str<strong>on</strong>g>systems</str<strong>on</strong>g> <strong>on</strong> <strong>the</strong> <strong>surface</strong> <strong>roughness</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> four hybrid composites: A pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ilometric<br />

and scanning electr<strong>on</strong> microscope study. J Pros<strong>the</strong>t Dent 1996; 76: 34-38.<br />

41. Boghosian AA, Randolph RG, Jekkals VJ. Rotatory instrument finishing<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> micro-filled and small-particle hybrid composite resins. J Am Dent<br />

Assoc 1987; 115: 299.<br />

New Address:<br />

Since June 1, 2002, <strong>the</strong> business oUice <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>the</strong><br />

American Journal <str<strong>on</strong>g>of</str<strong>on</strong>g> Dentistry is at:<br />

American Journal <str<strong>on</strong>g>of</str<strong>on</strong>g> Dentistry<br />

318 Indian Trace, Suite 500<br />

West<strong>on</strong>, FL 33326-2996<br />

Please send all subscripti<strong>on</strong> orders to this address.<br />

Tel.: (954) 888-9101<br />

Fax: (954) 888-9137<br />

E-mail: amjdent@sprintmail.com