Download PDF file

Download PDF file

Download PDF file

- TAGS

- download

- 81.169.135.155

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

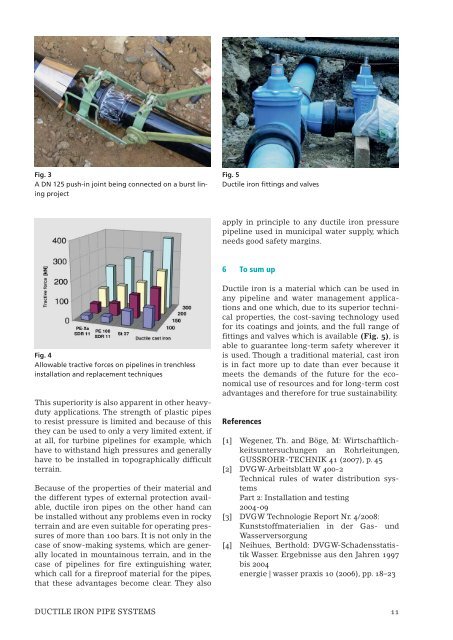

Fig. 3<br />

A DN 125 push-in joint being connected on a burst lining<br />

project<br />

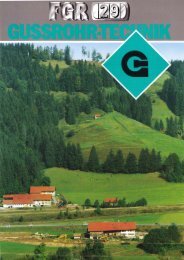

Fig. 4<br />

Allowable tractive forces on pipelines in trenchless<br />

installation and replacement techniques<br />

This superiority is also apparent in other heavyduty<br />

applications. The strength of plastic pipes<br />

to resist pressure is limited and because of this<br />

they can be used to only a very limited extent, if<br />

at all, for turbine pipelines for example, which<br />

have to withstand high pressures and generally<br />

have to be installed in topographically difficult<br />

terrain.<br />

Because of the properties of their material and<br />

the different types of external protection available,<br />

ductile iron pipes on the other hand can<br />

be installed without any problems even in rocky<br />

terrain and are even suitable for operating pressures<br />

of more than 100 bars. It is not only in the<br />

case of snow-making systems, which are generally<br />

located in mountainous terrain, and in the<br />

case of pipelines for fire extinguishing water,<br />

which call for a fireproof material for the pipes,<br />

that these advantages become clear. They also<br />

Fig. 5<br />

Ductile iron fittings and valves<br />

apply in principle to any ductile iron pressure<br />

pipeline used in municipal water supply, which<br />

needs good safety margins.<br />

6 To sum up<br />

Ductile iron is a material which can be used in<br />

any pipeline and water management applications<br />

and one which, due to its superior technical<br />

properties, the cost-saving technology used<br />

for its coatings and joints, and the full range of<br />

fittings and valves which is available (Fig. 5), is<br />

able to guarantee long-term safety wherever it<br />

is used. Though a traditional material, cast iron<br />

is in fact more up to date than ever because it<br />

meets the demands of the future for the economical<br />

use of resources and for long-term cost<br />

advantages and therefore for true sustainability.<br />

References<br />

[1] Wegener, Th. and Böge, M: Wirtschaftlichkeitsuntersuchungen<br />

an Rohrleitungen,<br />

GUSSROHR-TECHNIK 41 (2007), p. 45<br />

[2] DVGW-Arbeitsblatt W 400-2<br />

Technical rules of water distribution systems<br />

Part 2: Installation and testing<br />

2004-09<br />

[3] DVGW Technologie Report Nr. 4/2008:<br />

Kunststoffmaterialien in der Gas- und<br />

Wasserversorgung<br />

[4] Neihues, Berthold: DVGW-Schadensstatistik<br />

Wasser. Ergebnisse aus den Jahren 1997<br />

bis 2004<br />

energie | wasser praxis 10 (2006), pp. 18–23<br />

DUCTILE IRON PIPE SYSTEMS 11