Download PDF file

Download PDF file

Download PDF file

- TAGS

- download

- 81.169.135.155

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Rubber gaskets for ductile iron pipe systems<br />

Which came first – the pipe or the seal?<br />

by Felice Pavan<br />

1 Introduction<br />

It may have been pipes which existed first but<br />

it was only with seals that they could be connected<br />

into pipelines. The story of the transporting<br />

of drinking water is therefore also the story<br />

of sealing. In 1724, in his textbook on hydraulic<br />

engineering, Leupold [1] described the problem<br />

of making a permanently watertight connection<br />

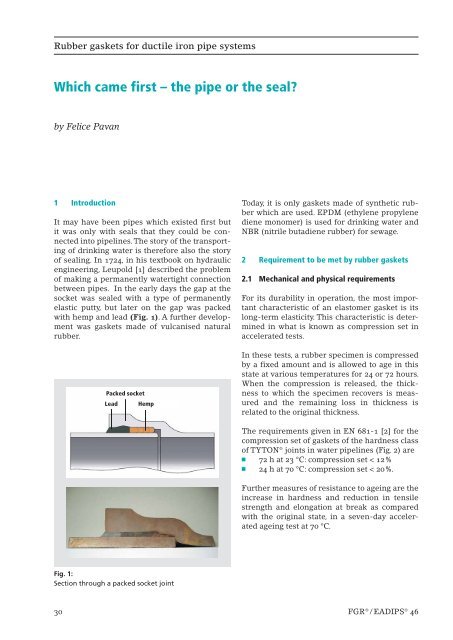

between pipes. In the early days the gap at the<br />

socket was sealed with a type of permanently<br />

elastic putty, but later on the gap was packed<br />

with hemp and lead (Fig. 1). A further development<br />

was gaskets made of vulcanised natural<br />

rubber.<br />

30<br />

Packed socket<br />

Lead Hemp<br />

Fig. 1:<br />

Section through a packed socket joint<br />

Today, it is only gaskets made of synthetic rubber<br />

which are used. EPDM (ethylene propylene<br />

diene monomer) is used for drinking water and<br />

NBR (nitrile butadiene rubber) for sewage.<br />

2 Requirement to be met by rubber gaskets<br />

2.1 Mechanical and physical requirements<br />

For its durability in operation, the most important<br />

characteristic of an elastomer gasket is its<br />

long-term elasticity. This characteristic is determined<br />

in what is known as compression set in<br />

accelerated tests.<br />

In these tests, a rubber specimen is compressed<br />

by a fixed amount and is allowed to age in this<br />

state at various temperatures for 24 or 72 hours.<br />

When the compression is released, the thickness<br />

to which the specimen recovers is measured<br />

and the remaining loss in thickness is<br />

related to the original thickness.<br />

The requirements given in EN 681-1 [2] for the<br />

compression set of gaskets of the hardness class<br />

of TYTON® joints in water pipelines (Fig. 2) are<br />

■ 72 h at 23 °C: compression set < 12 %<br />

■ 24 h at 70 °C: compression set < 20 %.<br />

Further measures of resistance to ageing are the<br />

increase in hardness and reduction in tensile<br />

strength and elongation at break as compared<br />

with the original state, in a seven-day accelerated<br />

ageing test at 70 °C.<br />

FGR® / EADIPS® 46