Download PDF file

Download PDF file

Download PDF file

- TAGS

- download

- 81.169.135.155

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

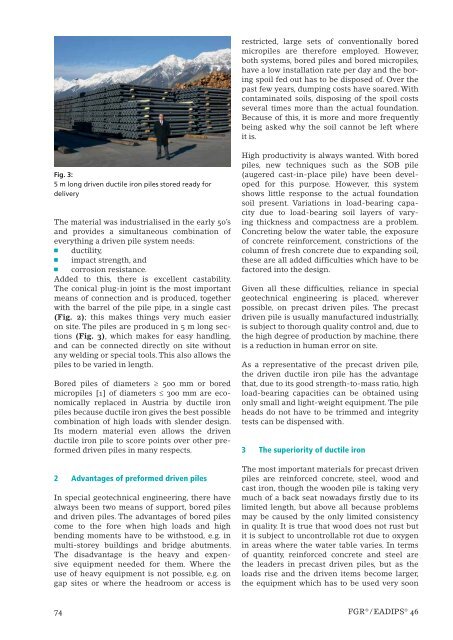

Fig. 3:<br />

5 m long driven ductile iron piles stored ready for<br />

delivery<br />

The material was industrialised in the early 50’s<br />

and provides a simultaneous combination of<br />

everything a driven pile system needs:<br />

■ ductility,<br />

■ impact strength, and<br />

■ corrosion resistance.<br />

Added to this, there is excellent castability.<br />

The conical plug-in joint is the most important<br />

means of connection and is produced, together<br />

with the barrel of the pile pipe, in a single cast<br />

(Fig. 2); this makes things very much easier<br />

on site. The piles are produced in 5 m long sections<br />

(Fig. 3), which makes for easy handling,<br />

and can be connected directly on site without<br />

any welding or special tools. This also allows the<br />

piles to be varied in length.<br />

Bored piles of diameters � 500 mm or bored<br />

micropiles [1] of diameters � 300 mm are economically<br />

replaced in Austria by ductile iron<br />

piles because ductile iron gives the best possible<br />

combination of high loads with slender design.<br />

Its modern material even allows the driven<br />

ductile iron pile to score points over other preformed<br />

driven piles in many respects.<br />

2 Advantages of preformed driven piles<br />

In special geotechnical engineering, there have<br />

always been two means of support, bored piles<br />

and driven piles. The advantages of bored piles<br />

come to the fore when high loads and high<br />

bending moments have to be withstood, e. g. in<br />

multi-storey buildings and bridge abutments.<br />

The disadvantage is the heavy and expensive<br />

equipment needed for them. Where the<br />

use of heavy equipment is not possible, e.g. on<br />

gap sites or where the headroom or access is<br />

74<br />

restricted, large sets of conventionally bored<br />

micropiles are therefore employed. However,<br />

both systems, bored piles and bored micropiles,<br />

have a low installation rate per day and the boring<br />

spoil fed out has to be disposed of. Over the<br />

past few years, dumping costs have soared. With<br />

contaminated soils, disposing of the spoil costs<br />

several times more than the actual foundation.<br />

Because of this, it is more and more frequently<br />

being asked why the soil cannot be left where<br />

it is.<br />

High productivity is always wanted. With bored<br />

piles, new techniques such as the SOB pile<br />

(augered cast-in-place pile) have been developed<br />

for this purpose. However, this system<br />

shows little response to the actual foundation<br />

soil present. Variations in load-bearing capacity<br />

due to load-bearing soil layers of varying<br />

thickness and compactness are a problem.<br />

Concreting below the water table, the exposure<br />

of concrete reinforcement, constrictions of the<br />

column of fresh concrete due to expanding soil,<br />

these are all added difficulties which have to be<br />

factored into the design.<br />

Given all these difficulties, reliance in special<br />

geotechnical engineering is placed, wherever<br />

possible, on precast driven piles. The precast<br />

driven pile is usually manufactured industrially,<br />

is subject to thorough quality control and, due to<br />

the high degree of production by machine, there<br />

is a reduction in human error on site.<br />

As a representative of the precast driven pile,<br />

the driven ductile iron pile has the advantage<br />

that, due to its good strength-to-mass ratio, high<br />

load-bearing capacities can be obtained using<br />

only small and light-weight equipment. The pile<br />

heads do not have to be trimmed and integrity<br />

tests can be dispensed with.<br />

3 The superiority of ductile iron<br />

The most important materials for precast driven<br />

piles are reinforced concrete, steel, wood and<br />

cast iron, though the wooden pile is taking very<br />

much of a back seat nowadays firstly due to its<br />

limited length, but above all because problems<br />

may be caused by the only limited consistency<br />

in quality. It is true that wood does not rust but<br />

it is subject to uncontrollable rot due to oxygen<br />

in areas where the water table varies. In terms<br />

of quantity, reinforced concrete and steel are<br />

the leaders in precast driven piles, but as the<br />

loads rise and the driven items become larger,<br />

the equipment which has to be used very soon<br />

FGR® / EADIPS® 46