Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technology <strong>Oerlikon</strong> <strong>Schlafhorst</strong> <strong>Express</strong> 11<br />

<strong>Oerlikon</strong> <strong>Schlafhorst</strong> and Birla Cellulose<br />

Spun-dyed viscose –<br />

the all-rounder among viscose fibres<br />

The international fibre manufacturer Birla Cellulose<br />

of India is the world’s biggest producer of viscose<br />

fibres for clothing textiles. Its production plants all<br />

over the world have a combined annual production<br />

capacity of more than 250 million tonnes. Among<br />

the particularly well-known products and brands of<br />

the company are Birla Viscose, Birla Ecocel, Birla Modal<br />

and Birla Excel. Birla also produces spun-dyed viscose fibres under<br />

the Birla Spunshades brand.<br />

Global market leaders like to pair up and partnerships in this<br />

regard are of great value to all those involved, especially for spinning<br />

and weaving mills. This is highlighted by the close and exclusive<br />

working relationship between Birla Cellulose and <strong>Oerlikon</strong><br />

<strong>Schlafhorst</strong> in the field of textile product development using<br />

spun-dyed viscose fibres. In Kharach, India, Birla Cellulose<br />

has set up a dedicated <strong>Textile</strong><br />

Research and Application<br />

Development Centre (TRADC)<br />

for this. In this technical centre,<br />

which contains a modern Autocoro<br />

rotor spinning machine and all the<br />

downstream textile processing machines,<br />

Birla Cellulose can simulate the practical textile<br />

process perfectly, thus offering superb opportunities<br />

for the development of marketable fibres, yarns<br />

and textiles.<br />

Spun-dyed viscose – good for the coffers<br />

and great for the environment<br />

Activities there in recent months have centred on<br />

the further development of spun-dyed viscose.<br />

These viscose fibres are proving to be ecological<br />

and economical all-rounders. They are the only<br />

viscose fibres that contain no heavy metals and<br />

are 100 percent biodegradable. Fibre production<br />

is thrifty in respect of all resources, both with<br />

regard to water and energy consumption and<br />

also time. The wastewater and steam balance<br />

is also extremely favourable. The thriftiness<br />

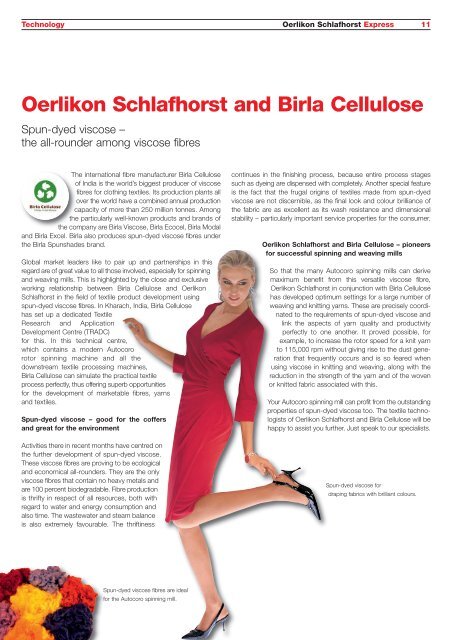

Spun-dyed viscose fibres are ideal<br />

for the Autocoro spinning mill.<br />

continues in the finishing process, because entire process stages<br />

such as dyeing are dispensed with completely. Another special feature<br />

is the fact that the frugal origins of textiles made from spun-dyed<br />

viscose are not discernible, as the final look and colour brilliance of<br />

the fabric are as excellent as its wash resistance and dimensional<br />

stability – particularly important service properties for the consumer.<br />

<strong>Oerlikon</strong> <strong>Schlafhorst</strong> and Birla Cellulose – pioneers<br />

for successful spinning and weaving mills<br />

So that the many Autocoro spinning mills can derive<br />

maximum benefit from this versatile viscose fibre,<br />

<strong>Oerlikon</strong> <strong>Schlafhorst</strong> in conjunction with Birla Cellulose<br />

has developed optimum settings for a large number of<br />

weaving and knitting yarns. These are precisely coordinated<br />

to the requirements of spun-dyed viscose and<br />

link the aspects of yarn quality and productivity<br />

perfectly to one another. It proved possible, for<br />

example, to increase the rotor speed for a knit yarn<br />

to 115,000 rpm without giving rise to the dust generation<br />

that frequently occurs and is so feared when<br />

using viscose in knitting and weaving, along with the<br />

reduction in the strength of the yarn and of the woven<br />

or knitted fabric associated with this.<br />

Your Autocoro spinning mill can profit from the outstanding<br />

properties of spun-dyed viscose too. The textile technologists<br />

of <strong>Oerlikon</strong> <strong>Schlafhorst</strong> and Birla Cellulose will be<br />

happy to assist you further. Just speak to our specialists.<br />

Spun-dyed viscose for<br />

draping fabrics with brilliant colours.