Italy Dominates in Crushning Buckets New Core Drills ... - PDWorld

Italy Dominates in Crushning Buckets New Core Drills ... - PDWorld

Italy Dominates in Crushning Buckets New Core Drills ... - PDWorld

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

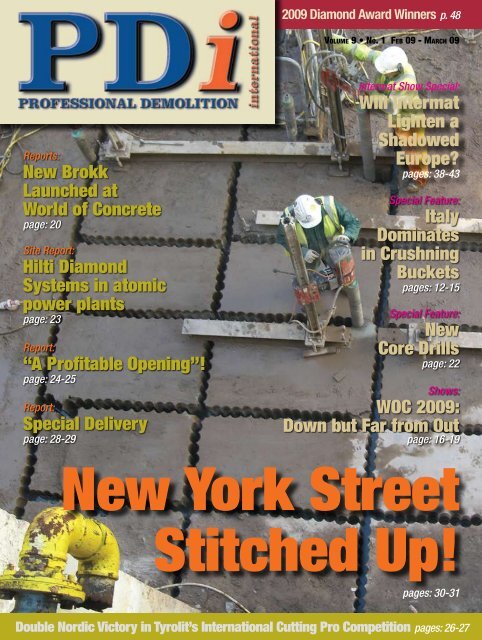

Reports:<br />

<strong>New</strong> Brokk<br />

Launched at<br />

World of Concrete<br />

page: 20<br />

Site Report:<br />

Hilti Diamond<br />

Systems <strong>in</strong> atomic<br />

power plants<br />

page: 23<br />

Report:<br />

“A Profitable Open<strong>in</strong>g”!<br />

page: 24-25<br />

Report:<br />

Special Delivery<br />

page: 28-29<br />

2009 Diamond Award W<strong>in</strong>ners p. 48<br />

Volume 9 • No. 1 Feb 09 - march 09<br />

Intermat Show Special:<br />

Will Intermat<br />

Lighten a<br />

Shadowed<br />

Europe?<br />

pages: 38-43<br />

Special Feature:<br />

<strong>Italy</strong><br />

<strong>Dom<strong>in</strong>ates</strong><br />

<strong>in</strong> Crushn<strong>in</strong>g<br />

<strong>Buckets</strong><br />

pages: 12-15<br />

Special Feature:<br />

<strong>New</strong><br />

<strong>Core</strong> <strong>Drills</strong><br />

page: 22<br />

Shows:<br />

WOC 2009:<br />

Down but Far from Out<br />

page: 16-19<br />

<strong>New</strong> York Street<br />

Stitched Up!<br />

pages: 30-31<br />

Double Nordic Victory <strong>in</strong> Tyrolit’s International Cutt<strong>in</strong>g Pro Competition pages: 26-27

1° Grand Prix<br />

International<br />

Exhibition of<br />

Inventions of<br />

Geneva<br />

www.mbcrusher.com<br />

TOUCH ME<br />

Experience the best with MB.<br />

MB crusher buckets,<br />

quality products backed by the worldwide leader.<br />

BF 120.4<br />

BF 90.3<br />

STAND 6K 070<br />

+ DEMO AREA<br />

AREAS OF APPLICATION<br />

DEMOLITION | ROAD WORK | EXCAVATION | QUARRIES & MINES | LAND RECLAMATION | BREAKING UP VINEYARDS<br />

BF 70.2 BF 60.1<br />

MB S.P.A. Tel. +39 0445 308148 - Fax +39 0445 308179 - <strong>in</strong>fo@mbcrusher.com

102

Professional Demolition International Magaz<strong>in</strong>e<br />

Address:<br />

P.O. Box 786, SE-191 27 Sollentuna, SWEDEN<br />

Visitors address:<br />

Skill<strong>in</strong>gevagen 14A., SE-192 71 Sollentuna, SWEDEN<br />

Phone: +46 8 631 90 70<br />

Telefax: +46 8 585 700 47<br />

E-mail: <strong>in</strong>fo@pdworld.com<br />

Website: www.pdworld.com<br />

ISSN Registration: ISSN 1650-979X<br />

Editor-<strong>in</strong>-Chief<br />

Jan Hermansson, Jan.Hermansson@pdworld.com<br />

Assist<strong>in</strong>g Editor<br />

Anita do Rocio Hermansson, Anita.Hermansson@pdworld.com<br />

Editorial staff<br />

Editor Global: Mikael Karlsson, mikael.karlsson@pdworld.com<br />

Editor Demolition: Mark Anthony,<br />

mark.anthony@pdworld.com<br />

Editor Recycl<strong>in</strong>g: Heikki Harri, heikki.harri@pp1.<strong>in</strong>et.fi<br />

Editor North & South America<br />

Jim Parsons, jim.parsons@pdworld.com<br />

Editor Asia Pacific<br />

Silvana Wirepa, silvana@pdworld.com<br />

Editor Russia<br />

Andrei Bushmar<strong>in</strong>, andrei.bushmar<strong>in</strong>@pdworld.com<br />

Editor Africa<br />

Kev<strong>in</strong> Mayhew, kev<strong>in</strong>m@addixion.co.za<br />

Publisher<br />

Jan Hermansson<br />

International Sales Offices<br />

Sweden, Norway & Denmark<br />

Contact the Editorial Office<br />

Phone: +46 (0)8 631 90 70, Fax: +46 (0)8 585 700 47<br />

E-mail: <strong>in</strong>fo@pdworld.com<br />

Germany/Austria/Switzerland/<br />

Liechtenste<strong>in</strong>/F<strong>in</strong>land<br />

Gunter Schneider GSM International<br />

Postfach 20 21 06 - D-41552 Kaarst<br />

Alma-Mahler-Werfel-Str. 15 - D- 41564 Kaarst<br />

Germany<br />

Phone: +49 2131 / 51 18 01<br />

E-mail: gsm-<strong>in</strong>ternational@web.de<br />

UK/Ireland/France/Belgium/<br />

the Netherlands/Spa<strong>in</strong>/Portugal<br />

M. Stéphane de Rémusat, REM - Europe Media Service<br />

Chem<strong>in</strong> de la Bourdette, F-31380 Gragnague, France<br />

Phone: +33 (0)5 34 27 01 30, Fax: +33 (0)5 34 27 01 31,<br />

+33 (0)5 34 27 01 34, Mobile: +33 (0)6 80 84 43 78<br />

E-mail : sremusat@aol.com<br />

<strong>Italy</strong><br />

Monica Colleoni & Romano Ferrario,<br />

Ediconsult Internazionale S.r.l.<br />

Via Savona 97, 20144 Milano, <strong>Italy</strong><br />

Phone: + 39 02 4771 0036, Fax: + 39 02 4771 1360<br />

E-mail: milano@ediconsult.com<br />

USA & Canada<br />

Contact PDi editorial office <strong>in</strong> Sweden.<br />

Australia/<strong>New</strong> Zealand/Asia Pacific/Korea/Japan<br />

Contact PDi editorial office <strong>in</strong> Sweden.<br />

Rest of the world<br />

Contact the PDi head office.<br />

The magaz<strong>in</strong>e PDI, Professional Demolition International is published four times per year<br />

with a worldwide circulation of 13000 copies. The annual airmail subscription rate is US$<br />

45. All subscription correspondance should be directed to: The subscription department,<br />

SCOP AB, P.O. Box 786, SE-191 27 Sollentuna, Sweden. PDI is mailed by second class<br />

postage paid at Stockholm, Sweden. © Copyright SCOP AB 2000-2009<br />

4 PDi • Is s u e 1 - 2009 • Fe b - Ma r c h<br />

CONTENTS<br />

PDi • issue no. 1 Feb 09 - March 09 • volume 9<br />

REGULARS<br />

Editorial<br />

6 The Optimist and the Pessimist<br />

Survey Cont<strong>in</strong>ues Profil<strong>in</strong>g<br />

Cutt<strong>in</strong>g Contractors<br />

Bus<strong>in</strong>ess<br />

8 BICES and AEM Jo<strong>in</strong> Forces<br />

Atlas Copco withdraws from Intermat<br />

Bobcat’s 50th anniversary competition w<strong>in</strong>ners<br />

Caterpillar launches Cat TV<br />

CONEXPO Russia May 2010<br />

Hillhead 2009 postponed<br />

Caterpillar launches Safety.cat.com<br />

Stone adds diamond saw blades<br />

Where music and demolition<br />

met, for one last time…<br />

<strong>New</strong> dumpers from AUSA<br />

<strong>New</strong> supplier <strong>in</strong> Australia<br />

10 Atlas Copco’s new bus<strong>in</strong>ess structure for the USA<br />

Five years of f<strong>in</strong>d<strong>in</strong>g concrete solutions<br />

JCB’s new £40 million factory<br />

Bobcat launches first wheeled excavator<br />

Shows<br />

16 Down but far from out<br />

38 Will Intermat Lighten Up a Shadowed Europe?<br />

Site Report<br />

23 Hilti diamond systems <strong>in</strong> atomic power plants<br />

30-31 <strong>New</strong> York Street Stitched Up!<br />

Reports<br />

24-25 “A profitable open<strong>in</strong>g”<br />

Concrete Cutt<strong>in</strong>g<br />

26 Double Nordic victory <strong>in</strong> Tyrolit’s<br />

International Cutt<strong>in</strong>g Pro Competition<br />

28-29 Special Delivery<br />

Associations<br />

48 2009 Diamond Award w<strong>in</strong>ners<br />

announced at World of Concrete<br />

CSDA Contractor Survey Results Offer Real Insight<br />

50 CSDA on the Cutt<strong>in</strong>g Edge with <strong>New</strong> Tra<strong>in</strong><strong>in</strong>g DVD<br />

NEWS<br />

CSDA/OSHA Alliance Focus on Defensive Driv<strong>in</strong>g<br />

20 <strong>New</strong> Brokk robot launched at World of Concrete<br />

32 Drill<strong>in</strong>g to the core at shard London Bridge<br />

Retipp<strong>in</strong>g saves costs<br />

Correct mark<strong>in</strong>g of abrasives<br />

– a must for oSa-members<br />

34 Trevi Benne dealers gathered <strong>in</strong> <strong>Italy</strong><br />

EDT Eurodima’s pursuit of top tool quality<br />

36 <strong>New</strong> Bobcat Products Shown for<br />

First Time at Intermat<br />

<strong>New</strong> robot from F<strong>in</strong>mac to be launched at Intermat<br />

42 MB at Intermat<br />

Two new breakers from Promove<br />

on display at Intermat<br />

44 Cat’s new S300B scrap shear series<br />

<strong>New</strong> special demolition recycl<strong>in</strong>g<br />

mach<strong>in</strong>e from Sennebogen<br />

45 <strong>New</strong> pulveriser from Mantovanibenne<br />

<strong>New</strong> multi-process<strong>in</strong>g crusher from Promove<br />

Special Feature<br />

12 <strong>Italy</strong> dom<strong>in</strong>ates <strong>in</strong> crush<strong>in</strong>g buckets<br />

22 <strong>Core</strong> <strong>Drills</strong>

The Optimist and<br />

the Pessimist<br />

Dear Readers<br />

I am so tired about hear<strong>in</strong>g and read<strong>in</strong>g a lot of negative op<strong>in</strong>ions about the current<br />

economic crisis. But I am the first to admit that the media often plays a key role <strong>in</strong><br />

mak<strong>in</strong>g the situation even worse than it is and is difficult to see the light at the end<br />

of the tunnel. If you are unfortunately one of those who lost your job and maybe also<br />

your house, it is perhaps difficult to be optimistic. In all situations there are normally<br />

two sides, but by try<strong>in</strong>g to have a positive attitude usually makes th<strong>in</strong>gs better.<br />

For some people it is natural to th<strong>in</strong>k and be optimistic. Some view situations<br />

<strong>in</strong> a darker ve<strong>in</strong> and foresee the worst and long before it is even possible to make a<br />

prediction. One th<strong>in</strong>g is for sure is that be<strong>in</strong>g negative does not help. But be<strong>in</strong>g realistic<br />

and see<strong>in</strong>g reality for what it is that is another th<strong>in</strong>g and far more helpful.<br />

I th<strong>in</strong>k that be<strong>in</strong>g negative is l<strong>in</strong>ked to hav<strong>in</strong>g bad self-esteem and lack of selfconfidence.<br />

A negative person perhaps does not want to be negative, but the poor<br />

self-esteem forces a negative attitude. Be<strong>in</strong>g negative may also create some sort of<br />

safety as it may give some comfort. A positive and optimistic attitude is often found<br />

<strong>in</strong> someone who is creative and wants to make th<strong>in</strong>gs happen and make changes.<br />

Someone with this type of character also needs to be prepared for be<strong>in</strong>g criticised<br />

and questioned and <strong>in</strong> these moments it is good to have self-confidence. But positive<br />

and optimistic people do not often have problems with be<strong>in</strong>g criticized; it is as if<br />

they get energy from it. They also have a tendency of not be<strong>in</strong>g afraid of admitt<strong>in</strong>g<br />

or mak<strong>in</strong>g mistakes. The magic with this type of character is that <strong>in</strong> these situations<br />

the optimism strengthens their self-esteem.<br />

The whole th<strong>in</strong>g is like a positive and negative spiral. Generally speak<strong>in</strong>g an optimist<br />

becomes more optimistic from negative <strong>in</strong>fluences, while it is often the opposite with a<br />

pessimist. I am generaliz<strong>in</strong>g, but be<strong>in</strong>g more optimistic <strong>in</strong> our daily lives and work will lead<br />

us faster out of this recession, rather than listen<strong>in</strong>g to all the negative <strong>in</strong>formation we are<br />

be<strong>in</strong>g fed every day. I believe that we solve problems better if we try to keep an optimistic<br />

attitude. But there are of course limits even with be<strong>in</strong>g an optimist. We cannot take stupid<br />

risks and we must make good judgements. Bad judgement and too much optimism have<br />

caused a lot of problems. But healthy optimism paired with good judgement will take<br />

us out of this recession faster. That is my op<strong>in</strong>ion even though I am no expert. I wish I<br />

always was that optimistic and the type of person I am describ<strong>in</strong>g. I am work<strong>in</strong>g on it<br />

and I believe it is possible to learn to become more optimistic and at the same time build<br />

up your self self-esteem and self-confidence. I th<strong>in</strong>k it is as simple as try<strong>in</strong>g to lower the<br />

amount of negative thoughts so the positive thoughts are dom<strong>in</strong>ant. With time you will<br />

experience a change <strong>in</strong> attitude. Try it and you will see that it actually works. The biggest<br />

task is to keep track and not fall <strong>in</strong>to<br />

negative habits.<br />

So to those of you who are worried<br />

about your company, your work<strong>in</strong>g situation,<br />

how to handle your private f<strong>in</strong>ances<br />

with mortgages and educat<strong>in</strong>g your children,<br />

give the positive flow a chance.<br />

6 PDi • Is s u e 1 - 2009 • Fe b - Ma r c h<br />

Jan Hermansson<br />

Editor-<strong>in</strong>-Chief<br />

jan.hermansson@pdworld.com<br />

Words from O’Brien<br />

Survey<br />

Cont<strong>in</strong>ues<br />

Profil<strong>in</strong>g<br />

Cutt<strong>in</strong>g<br />

Contractors<br />

In a previous column I discussed the hesitancy<br />

of the saw<strong>in</strong>g and drill<strong>in</strong>g <strong>in</strong>dustry to<br />

collect market data to def<strong>in</strong>e the state of the<br />

<strong>in</strong>dustry and how this tendency is gradually<br />

chang<strong>in</strong>g. The International Association of<br />

Concrete Drillers and Sawers cont<strong>in</strong>ues<br />

to press its effort to record worldwide<br />

contractor sales and the Concrete Saw<strong>in</strong>g<br />

and Drill<strong>in</strong>g Association (CSDA) had recently<br />

taken advantage of the Internet to develop<br />

a snapshot onl<strong>in</strong>e survey to gather basic<br />

operational and economic data.<br />

CSDA has also been <strong>in</strong>volved <strong>in</strong> conduct<strong>in</strong>g<br />

a comprehensive f<strong>in</strong>ancial and<br />

operat<strong>in</strong>g survey of contractors <strong>in</strong> 4-5<br />

year <strong>in</strong>tervals. The most recent survey was<br />

conducted <strong>in</strong> late 2008 and the results<br />

of this 40-question survey have just been<br />

published.<br />

The survey met with outstand<strong>in</strong>g acceptance<br />

with a 40% response rate,<br />

which was the highest ever, recorded. The<br />

53-page report is filled with operat<strong>in</strong>g and<br />

f<strong>in</strong>ancial data that cutt<strong>in</strong>g contractors will<br />

f<strong>in</strong>d <strong>in</strong>valuable.<br />

The responses represent a broad geographic<br />

cross section of the United States<br />

with 31% from the Midwest, 22% represent<strong>in</strong>g<br />

the Mid-Atlantic and 29% from the<br />

Western states. In terms of scope of work,<br />

more than half of their work is performed <strong>in</strong><br />

build<strong>in</strong>g renovation, 23% <strong>in</strong> new construction<br />

and 20% <strong>in</strong> <strong>in</strong>frastructure—highway,<br />

airport, bridge, dams and power plants. Flat<br />

saw<strong>in</strong>g accounts for 27.8% of total sales<br />

with core drill<strong>in</strong>g close beh<strong>in</strong>d at 25.8% and<br />

wall saw<strong>in</strong>g at 21.1%. Additional services<br />

be<strong>in</strong>g offered <strong>in</strong>clude selective demolition,<br />

decorative cutt<strong>in</strong>g, ground penetrat<strong>in</strong>g radar<br />

and surface preparation.<br />

With regards to personnel, there are an<br />

average of 25 full-time-equivalent employees<br />

at cutt<strong>in</strong>g contract<strong>in</strong>g companies with<br />

12.6 of these employees be<strong>in</strong>g saw<strong>in</strong>g<br />

and drill<strong>in</strong>g operators. The hourly wage for<br />

a typical operator who works 40.9 hours<br />

per week is $20.29. Dispatchers make a<br />

higher hourly average wage of $22.53 and<br />

estimators make $26.33. A typical manager<br />

works an average of 49.8 hours a week.<br />

An impressive n<strong>in</strong>e out of ten companies<br />

responded that they have a safety supervisor<br />

and written safety and environmental health<br />

programs <strong>in</strong> place.<br />

The average estimated sales volume<br />

for respondents’ companies <strong>in</strong> 2008<br />

is $2,663,690, up from an average of<br />

$2,394,578 reported by these companies<br />

for 2005, the first year reported <strong>in</strong> this<br />

survey. The average amount of a company’s<br />

sales per truck was $201,155. This figure<br />

is often used when compar<strong>in</strong>g sales performance<br />

among different firms.<br />

Operat<strong>in</strong>g statement <strong>in</strong>formation<br />

showed direct operat<strong>in</strong>g costs, which ranged<br />

from an average of $987,634 for operator/<br />

labour costs to $194,631 for diamond<br />

tools. Sell<strong>in</strong>g expenses <strong>in</strong>clud<strong>in</strong>g salaries,<br />

advertis<strong>in</strong>g and travel expenses averaged<br />

$163,171 while general and adm<strong>in</strong>istrative<br />

expenses <strong>in</strong>clud<strong>in</strong>g managers, office and<br />

dispatch wages averaged $617,468. The<br />

average profit among the 80% of the firms<br />

report<strong>in</strong>g a profit was $302,690 while the<br />

average loss for the rema<strong>in</strong><strong>in</strong>g 20% of the<br />

firms was $163,817.<br />

Cutt<strong>in</strong>g contractors will use the data <strong>in</strong><br />

this survey to gauge how their company’s<br />

performance compares to the <strong>in</strong>dustry as<br />

a whole. Depend<strong>in</strong>g on where they stand<br />

relative to this <strong>in</strong>dustry benchmark they<br />

may decide to make changes to improve<br />

performance. These are great results and<br />

I am sure will spur much discussion about<br />

the bus<strong>in</strong>ess that exists today and changes<br />

that should be made to advance bus<strong>in</strong>esses<br />

to the next level <strong>in</strong> future years.<br />

Best regards<br />

Patrick O’Brien<br />

President IACDS

THE<br />

MISSING<br />

LINK<br />

NEW<br />

Fusion <br />

Coupler System<br />

©2009 Caterpillar Inc. All rights reserved. CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the POWER EDGE trade dress,<br />

as well as corporate and product identity used here<strong>in</strong>, are trademarks of Caterpillar and may not be used without permission<br />

HEAX3986<br />

The <strong>New</strong> Fusion coupler system is the perfect <strong>in</strong>terface between<br />

mach<strong>in</strong>e and work tool. It gives you real flexibility; one common<br />

<strong>in</strong>terface comb<strong>in</strong>ed with a wide range of work tools, offer<strong>in</strong>g near p<strong>in</strong>-on<br />

performance. At the same time, its <strong>in</strong>genious wedg<strong>in</strong>g mechanism ensures<br />

a tight, rattle-free fit.<br />

But that’s not all. When used <strong>in</strong> comb<strong>in</strong>ation with Cat wheel loaders,<br />

you have the perfect performance match. Un<strong>in</strong>terrupted productivity.<br />

Equipment to be proud of. A s<strong>in</strong>gle po<strong>in</strong>t of contact. And the backup of our<br />

unrivalled spare parts service and vast dealer network.<br />

Work with confidence. The Fusion coupler system.<br />

www.cat-worktools.com

BICES and AEM<br />

Jo<strong>in</strong> Forces<br />

The Beij<strong>in</strong>g International Construction Mach<strong>in</strong>ery<br />

Exhibition and Sem<strong>in</strong>ar and the Association<br />

of Equipment Manufacturers, which owns the<br />

CONEXPO Asia exhibition, have announced a<br />

cooperative effort to ensure the perpetuation of<br />

an <strong>in</strong>ternational construction mach<strong>in</strong>ery exhibition<br />

<strong>in</strong> Ch<strong>in</strong>a. The BICES-AEM partnership will br<strong>in</strong>g<br />

together manufacturers, customers and <strong>in</strong>dustry<br />

organizations to produce the most successful<br />

event possible for all <strong>in</strong>dustry stakeholders. BICES<br />

2009 will be held 3-6, November 2009 <strong>in</strong> Beij<strong>in</strong>g<br />

at the Jiuhua International Exhibition Centre.<br />

Atlas Copco withdraws<br />

from Intermat<br />

Atlas Copco together with Dynapac has withdrawn<br />

from participat<strong>in</strong>g at the construction trade show<br />

Intermat 2009, which will take place <strong>in</strong> Paris,<br />

France <strong>in</strong> April 2009. A trade show like Intermat<br />

requires extensive resources to attend, both <strong>in</strong><br />

terms of money and people. Because of the<br />

turmoil and uncerta<strong>in</strong>ty <strong>in</strong> the construction market,<br />

fewer visitors, particularly <strong>in</strong>ternational, are<br />

expected to come to Intermat. With this <strong>in</strong> m<strong>in</strong>d,<br />

Atlas Copco estimates it can br<strong>in</strong>g more benefits to<br />

customers by reallocat<strong>in</strong>g the effort spent on Intermat<br />

and focus<strong>in</strong>g on more targeted activities. Atlas<br />

Copco is committed to the construction market.<br />

The company says that it will also <strong>in</strong> this downturn<br />

develop the leadership by work<strong>in</strong>g closely to the<br />

customers. By focus<strong>in</strong>g on more direct customer<br />

activities, they will <strong>in</strong>teract more efficiently with the<br />

customers and will be better able to respond to<br />

the direct needs of the market.<br />

Bobcat’s 50th<br />

Anniversary<br />

Competition W<strong>in</strong>ners<br />

Bobcat has announced the three prize-w<strong>in</strong>ners<br />

<strong>in</strong> the ‘What Did Bobcat Do For Me?’ 50th anniversary<br />

celebratory competition. The w<strong>in</strong>ner of<br />

the Grand Prize, a trip to the USA, <strong>in</strong>clud<strong>in</strong>g a visit<br />

to the Bobcat factories at Bismarck and Gw<strong>in</strong>ner<br />

<strong>in</strong> North Dakota and a one-day visit to <strong>New</strong> York,<br />

was David Arthon of Fuveau <strong>in</strong> Aix-en-Provence <strong>in</strong><br />

Southern France, a customer of the Bobcat dealer<br />

Boïs. The second prize, a EUR 1000 voucher for<br />

Bobcat products, went to Richard Heskens of the<br />

Netherlands, a customer of Bobcat Zoeterwoude.<br />

Mathias Morlion of Belgium, a customer of Bobcat<br />

dealer, Vangaever, won the third prize of a EUR<br />

500 voucher for Bobcat products.<br />

www.bobcat.com<br />

8 PDi • Is s u e 1 - 2009 • Fe b - Ma r c h<br />

Caterpillar<br />

launches Cat TV<br />

Caterpillar has launched a new <strong>in</strong>teractive website,<br />

CAT TV at www.mycattv.com, <strong>in</strong>troduc<strong>in</strong>g a<br />

previously unseen level of engagement with the<br />

public <strong>in</strong> the Caterpillar world. Visitors to the site<br />

will experience web-based video communication<br />

that allows everyone from large m<strong>in</strong><strong>in</strong>g companies<br />

to schoolchildren to see the strengths<br />

of Caterpillar products and services <strong>in</strong> a visual,<br />

<strong>in</strong>teractive way.<br />

<strong>New</strong> videos are added to the six channels of<br />

CAT TV regularly, and Caterpillar selects a videoof-the-week.<br />

All videos can be embedded <strong>in</strong>to<br />

other websites and used, for example, for tra<strong>in</strong><strong>in</strong>g<br />

purposes. To ensure maximum <strong>in</strong>teractivity, visitors<br />

to the site can also share their own Caterpillar<br />

videos and, at a later stage, post and read comments<br />

on all videos.<br />

www.cat.com<br />

CONEXPO Russia<br />

May 2010<br />

The Association of Equipment Manufacturers<br />

and its member companies have announced<br />

that the next CONEXPO Russia will be<br />

delayed until 2010 to allow the economy<br />

to improve. It has been rescheduled for<br />

19-22 May 2010 and will be held at the<br />

Transport-Exhibition Complex next to the<br />

Zhukovsky Airport, Moscow. Some of the<br />

companies already support<strong>in</strong>g and participat<strong>in</strong>g<br />

<strong>in</strong> the next CONEXPO Russia <strong>in</strong>clude Chetra,<br />

Caterpillar, Terex, JCB, Komatsu, Volvo and the<br />

Gaz Group.<br />

Hillhead 2009<br />

Postponed<br />

In view of both the scale and speed with which the<br />

current adverse economic climate has developed,<br />

a decision has been made to postpone the UK<br />

show Hillhead scheduled for June 2009 for a<br />

period of 12 months. Despite the show be<strong>in</strong>g<br />

heavily booked as usual, discussions took place<br />

with lead<strong>in</strong>g exhibitors at the end of January<br />

follow<strong>in</strong>g which it was concluded that it would<br />

be <strong>in</strong> the best <strong>in</strong>terests of the event if it were put<br />

back a full year to allow UK market conditions<br />

time to stabilise. The organisers apologise for any<br />

<strong>in</strong>convenience this may cause and the new dates<br />

for Hillhead 2010 are 22-24 June.<br />

www.hillhead.com<br />

Caterpillar launches<br />

Safety.cat.com<br />

Caterpillar has launched SAFETY.CAT.COM, to<br />

promote the safety and health of everyone <strong>in</strong>,<br />

on or around Caterpillar products. It is available <strong>in</strong><br />

English, French, Spanish and Portuguese and re<strong>in</strong>forces<br />

safety messages found <strong>in</strong> the company’s<br />

official Operation and Ma<strong>in</strong>tenance Manuals. The<br />

site also covers the world of safety <strong>in</strong> motion.<br />

Caterpillar videos on walk around <strong>in</strong>spections<br />

and operat<strong>in</strong>g tips are available on demand from<br />

one onl<strong>in</strong>e source. Other offer<strong>in</strong>gs <strong>in</strong>clude OMM<br />

excerpts, multimedia pieces, and toolbox talks on<br />

a variety of safety topics.<br />

Stone adds<br />

diamond saw blades<br />

The US company Stone Construction Equipment,<br />

Inc has added a l<strong>in</strong>e of diamond saw blades to<br />

complement its range of masonry and concrete<br />

saws. The new saw blade l<strong>in</strong>e covers the most<br />

common sizes for the vast majority of cutt<strong>in</strong>g applications.<br />

The 26 primarily general purpose blades <strong>in</strong><br />

the l<strong>in</strong>e fall <strong>in</strong>to two categories, Saw-lect the value<br />

l<strong>in</strong>e, and Saw-preme the premium l<strong>in</strong>e.<br />

The laser welded blades are extremely well<br />

balanced and flatter deliver<strong>in</strong>g faster, straighter<br />

cuts, the first time, every time.<br />

The blades<br />

range <strong>in</strong> size from<br />

305mm to 508mm,<br />

with bond rat<strong>in</strong>gs<br />

from 3 to 8 to cut<br />

brick, block, stone, cured concrete, green concrete,<br />

asphalt and asphalt over concrete. The<br />

blades fit all 25mm arbours and can be used<br />

wet or dry. They fit both Stone saw l<strong>in</strong>es, and the<br />

majority of the blades can also be used on high<br />

speed saws.<br />

www.stone-equip.com<br />

Where music and<br />

demolition met, for<br />

one last time…<br />

The iconic Astoria music venue <strong>in</strong> the heart of London’s<br />

theatre land has played host to some of the<br />

biggest bands <strong>in</strong> the music bus<strong>in</strong>ess. In its 30-year<br />

history, the Astoria’s 2,000 capacity venue played<br />

host to everyone from the Beach Boys and David<br />

Bowie to current stars such as Amy W<strong>in</strong>ehouse,<br />

Oasis and the Arctic Monkeys.<br />

But as preparation for London’s Crossrail<br />

project gathers pace, the venue hosted its last-ever<br />

gig. Even as concert goers were queu<strong>in</strong>g, amid<br />

TV and radio journalists captur<strong>in</strong>g the moment<br />

for posterity, scaffold<strong>in</strong>g was be<strong>in</strong>g put <strong>in</strong> place<br />

to facilitate the demolition works. Bizarrely, <strong>in</strong><br />

the middle of all this, a music journalist for BBC<br />

Radio, who was there to see the demolition, was<br />

<strong>in</strong>terview<strong>in</strong>g PDi’s Mark Anthony, who was there<br />

purely to watch the bands.<br />

<strong>New</strong> dumpers<br />

from AUSA<br />

In response to customer demand, Spanish<br />

construction equipment manufacturer AUSA has<br />

recently launched two new 2.5t articulated rotat<strong>in</strong>g<br />

dumpers, the D 250 AHGA and the D 250 AHG,<br />

which complete its l<strong>in</strong>e of dumpers. The dumpers<br />

have been designed specially for the Central European<br />

and Scand<strong>in</strong>avian markets, where there is<br />

a strong demand for high performance mach<strong>in</strong>es,<br />

the company claims.<br />

www.ausa.com<br />

<strong>New</strong> supplier<br />

<strong>in</strong> Australia<br />

Asia Pacific with focus on Australia and <strong>New</strong> Zealand<br />

has got a new supplier of concrete cutt<strong>in</strong>g and construction<br />

mach<strong>in</strong>ery <strong>in</strong> the newly formed company<br />

Traxx Construction Products. Traxx is essentially a<br />

group of well-know <strong>in</strong>dividuals <strong>in</strong> this <strong>in</strong>dustry <strong>in</strong><br />

Australia headed by Lloyd Williams. Traxx is set<br />

out to supply quality, <strong>in</strong>novative and competitively<br />

priced diamond tools and associated mach<strong>in</strong>ery.<br />

In essence, mach<strong>in</strong>ery that typically consumes<br />

diamond tools.<br />

“We have however, also formed a division that<br />

supplies complementary tools to the respective<br />

<strong>in</strong>dustries we deal with as well as consultancy<br />

services to, <strong>in</strong> particular, the concrete saw<strong>in</strong>g and<br />

drill<strong>in</strong>g professionals,” says Lloyd Williams.<br />

Primarily customer of TRAXX will be a consumer<br />

of goods <strong>in</strong>volved <strong>in</strong> the concrete saw<strong>in</strong>g and drill<strong>in</strong>g,<br />

rental, demolition, concrete placement, construction,<br />

til<strong>in</strong>g, surface preparation and stone process<strong>in</strong>g <strong>in</strong>dustries.<br />

TRAXX manufactures many of its own products<br />

but reserves the right to source the very latest and<br />

<strong>in</strong>novative additions to the construction <strong>in</strong>dustry, from<br />

a vast network of bus<strong>in</strong>ess partners. The people<br />

beh<strong>in</strong>d Traxx are Lloyd Williams, Gail Williams, Dianne<br />

Eade, Lorra<strong>in</strong>e Kenny, Stuart Smith and Mark Snoad.<br />

More about Traxx <strong>in</strong> the next issue of PDi.<br />

www.traxxcp.com.au

LEADING<br />

CORE DRILL<br />

TECHNOLOGY<br />

TEL: 0044 (0) 161 406 0609 | FAX: 0044 (0) 161 406 0211<br />

E-MAIL: sales@diaquip.co.uk

Atlas Copco’s new<br />

bus<strong>in</strong>ess structure<br />

for the USA<br />

Atlas Copco Construction Equipment LLC is the<br />

name of the new Atlas Copco bus<strong>in</strong>ess dedicated<br />

to serv<strong>in</strong>g the US construction market. This new<br />

entity comb<strong>in</strong>es the Portable Air operations of<br />

Atlas Copco Compressor Technique’s US sales<br />

company with the Atlas Copco Construction Tools<br />

US sales company. Atlas Copco Construction<br />

Equipment is responsible for the sales and service<br />

of portable compressors, generators, pneumatic,<br />

hydraulic and gasol<strong>in</strong>e-powered construction and<br />

demolition tools, along with related aftermarket<br />

services, for both the Atlas Copco and Chicago<br />

Pneumatic brands.<br />

The new organization is based <strong>in</strong> Commerce<br />

City, Colorado, shar<strong>in</strong>g offices and back office<br />

functions with the Atlas Copco Construction M<strong>in</strong><strong>in</strong>g<br />

Technique USA customer centre. Although<br />

the two companies will operate <strong>in</strong>dependently,<br />

they have much the same culture and market<br />

knowledge and can benefit from these and other<br />

synergies. The Westfield, Massachusetts office of<br />

the Construction Tools bus<strong>in</strong>ess will be closed at<br />

the end of March 2009.<br />

Top priorities of Atlas Copco Construction<br />

Equipment LLC are to stabilize the sales and<br />

service structure, to support customers, and to<br />

cont<strong>in</strong>ue to be a leader <strong>in</strong> the construction equipment<br />

bus<strong>in</strong>ess. The new company will have three<br />

sales and service regions <strong>in</strong> the North, South and<br />

West United States.<br />

Erik Sparby heads up Atlas Copco Construction<br />

Equipment as its general manager. “We are<br />

look<strong>in</strong>g at this as an opportunity to become more<br />

focused and dedicated, specializ<strong>in</strong>g on the unique<br />

needs of the construction <strong>in</strong>dustry,” he said.<br />

www.atlascopco.com<br />

Five years of f<strong>in</strong>d<strong>in</strong>g<br />

concrete solutions<br />

Diamonds have come up trumps for the Australian<br />

company Kennards Concrete Care, which<br />

celebrated its fifth anniversary <strong>in</strong> January this<br />

year. S<strong>in</strong>ce 2004, the specialist equipment hire<br />

company has helped hundreds of contractors<br />

10 PDi • Is s u e 1 - 2009 • Fe b - Ma r c h<br />

Angus Kennard drives a m<strong>in</strong>i loader with a 3000 power planer, used for remov<strong>in</strong>g<br />

thick coat<strong>in</strong>gs, heavy l<strong>in</strong>e mark<strong>in</strong>g and uneven surfaces like trip hazards.<br />

tackle all sorts of concrete related jobs, from<br />

demolition, drill<strong>in</strong>g and cutt<strong>in</strong>g to gr<strong>in</strong>d<strong>in</strong>g, stripp<strong>in</strong>g<br />

and plan<strong>in</strong>g.<br />

Start<strong>in</strong>g with a hire centre <strong>in</strong> Sydney, Kennards<br />

Concrete Care quickly added outlets <strong>in</strong> Brisbane,<br />

Melbourne and Perth. Growth has come not just<br />

from the array of equipment on offer, but from the<br />

expertise of staff, who can advise customers on the<br />

right mach<strong>in</strong>e or the right diamond for their job.<br />

Kennards Concrete Care was the idea of<br />

Angus Kennard, whose grandfather, Walter,<br />

founded Kennards Hire <strong>in</strong> 1948. While work<strong>in</strong>g<br />

<strong>in</strong> the general hire bus<strong>in</strong>ess, Angus developed an<br />

<strong>in</strong>terest <strong>in</strong> concrete equipment, and began add<strong>in</strong>g<br />

more products at the branches he managed. He<br />

believed there was a need that was not be<strong>in</strong>g<br />

fully met, and after travell<strong>in</strong>g overseas to learn<br />

more, launched Kennards Concrete Care as a<br />

stand-alone entity. “Our bus<strong>in</strong>ess is about provid<strong>in</strong>g<br />

solutions to problems,” said Angus. “Rather than a<br />

customer com<strong>in</strong>g <strong>in</strong> and say<strong>in</strong>g, ‘I want a gr<strong>in</strong>der,’<br />

he is more likely to say, ‘I have this situation, what<br />

have you got that will do the job?’<br />

“In a general hire company, staff know a<br />

small amount about a lot of equipment, whereas<br />

our team knows a lot about a small number of<br />

items. When you are work<strong>in</strong>g with concrete, there<br />

are many variables and job limitations that have<br />

to be considered. With surface preparation, there<br />

is the hardness of the concrete, the product to<br />

be removed, surface f<strong>in</strong>ish required, whether it is<br />

<strong>in</strong>side or outside, is it a wet or dry environment,<br />

is there a need for dust control and what power<br />

source, if any, is available. We have grown largely<br />

because satisfied customers come back, more<br />

people are f<strong>in</strong>d<strong>in</strong>g us through our website and our<br />

product range cont<strong>in</strong>ues to expand.”<br />

www.concretecare.com.au<br />

JCB’s new £40<br />

million factory<br />

In the UK the curta<strong>in</strong> has fallen on almost 140<br />

years of manufactur<strong>in</strong>g history <strong>in</strong> Uttoxeter as<br />

the f<strong>in</strong>al mach<strong>in</strong>e to be made at JCB’s Heavy<br />

Products factory rolled off the production l<strong>in</strong>e.<br />

The manufacture of tracked and wheeled<br />

excavators is be<strong>in</strong>g transferred to the new<br />

purpose-built £40 million JCB Heavy<br />

Products factory <strong>in</strong> Uttoxeter.<br />

“This is the end of an era because my<br />

family has been l<strong>in</strong>ked to this site s<strong>in</strong>ce<br />

the n<strong>in</strong>eteenth century when Bamfords<br />

Ltd started manufactur<strong>in</strong>g agricultural<br />

mach<strong>in</strong>ery,” said JCB Chairman Sir Anthony<br />

Bamford. “But this is also the start of a<br />

new and excit<strong>in</strong>g era, not only for JCB’s<br />

excavator bus<strong>in</strong>ess, but also for Uttoxeter<br />

because the relocation offers the opportunity<br />

to redevelop and enhance an important<br />

area of the town.”<br />

Sir Anthony’s great-grandfather Joseph<br />

Bamford was one of five brothers who were the<br />

orig<strong>in</strong>al partners of Bamfords Ltd. Sir Anthony’s<br />

own father, the late Joseph Cyril Bamford, was<br />

famously sacked from Bamfords Ltd by his uncle<br />

Henry. Joseph Cyril Bamford later went on to<br />

found JCB, which has grown <strong>in</strong>to one of the<br />

world’s most successful construction equipment<br />

manufacturers.<br />

The move to the new JCB Heavy Products<br />

factory represents an opportunity for JCB to grow<br />

its tracked and wheeled excavator bus<strong>in</strong>ess once<br />

the global construction markets recover from the<br />

current downturn. The company’s excavator range<br />

comprises mach<strong>in</strong>es from 7t to 46t.<br />

www.jcb.com<br />

Bobcat launches first<br />

wheeled excavator<br />

Bobcat has launched its first wheeled excavator<br />

the 5.5 t E55W powered by a 40.8 kW Yanmar<br />

liquid-cooled diesel eng<strong>in</strong>e. Equipped as standard<br />

with s<strong>in</strong>gle tyre configuration, dual tyres are<br />

available as an option. The E55W offers 2 travel<br />

speed ranges, with a maximum travel speed of<br />

30km/h. The maximum digg<strong>in</strong>g depth is 3.495m,<br />

the maximum dump height is 4.265m and the<br />

maximum reach at ground level is 5.89m.<br />

The undercarriage consists of a rigid, welded<br />

frame. The rout<strong>in</strong>g of hydraulic l<strong>in</strong>es, protection for<br />

the transmission and heavy-duty axles make the<br />

undercarriage ideal for wheeled excavator applications.<br />

Both the outriggers and dozer blade are p<strong>in</strong><br />

type for maximum flexibility.<br />

The operator cab offers the same space as<br />

that found <strong>in</strong> the cabs on much larger medium and<br />

heavy-duty mach<strong>in</strong>es. The steer<strong>in</strong>g wheel can be<br />

positioned to suit the operator and the position and<br />

angle of the seat cushion as well as the position<br />

of the consoles can be adjusted <strong>in</strong>dependently<br />

of each other. The operat<strong>in</strong>g controls have been<br />

arranged to ensure convenience and comfort. The<br />

hydraulic joystick levers have grips that allow the<br />

operator to perform precise operations easily.<br />

In addition to the normal trench<strong>in</strong>g and<br />

groundwork jobs, the E55W’s stability and lift<strong>in</strong>g<br />

capacity allow the excavator to be used for applications<br />

such as truck load<strong>in</strong>g and unload<strong>in</strong>g<br />

and mov<strong>in</strong>g pipes and materials. For maximum<br />

safety dur<strong>in</strong>g all operations <strong>in</strong>volv<strong>in</strong>g lift<strong>in</strong>g work,<br />

the E55W is equipped with an overload warn<strong>in</strong>g<br />

device as well as safety valves <strong>in</strong> the boom and<br />

dozer blade hydraulic systems.<br />

www.bobcat.com

PDI_183x122_:Layout 1 27-02-2009 15:54 Pag<strong>in</strong>a 3<br />

TheOrig<strong>in</strong><br />

of theSpecies<br />

TREVI BENNE spa<br />

36025 Noventa Vicent<strong>in</strong>a -VI-<strong>Italy</strong><br />

Via A.Volta, 5 -T0444 760773<br />

F 0444 861182 -<strong>in</strong>fo@trevibenne.it<br />

CONGRATULATIONS!<br />

EUROPEAN CHAMPIONS 2009<br />

– 600 people from 17 countries watched Kim Guldbæk from Denmark w<strong>in</strong>!<br />

– Next Cutt<strong>in</strong>g Pro Competition <strong>in</strong> 2010<br />

– Information on www.cutt<strong>in</strong>gprocompetition.com<br />

A Company with<strong>in</strong> the SWAROVSKI Group<br />

www.trevibenne.it

<strong>Italy</strong> dom<strong>in</strong>ates <strong>in</strong><br />

Crush<strong>in</strong>g <strong>Buckets</strong><br />

Crush<strong>in</strong>g, sort<strong>in</strong>g and<br />

screen<strong>in</strong>g buckets are<br />

considered the latest<br />

<strong>in</strong>novation <strong>in</strong> hydraulic<br />

attachments related<br />

to the demolition and<br />

recycl<strong>in</strong>g <strong>in</strong>dustries.<br />

The new Allu SCH screener crusher<br />

can handle various k<strong>in</strong>ds of demolition<br />

waste effectively like bricks <strong>in</strong><br />

this case.<br />

12 PDi • Is s u e 1 - 2009 • Fe b - Ma r c h<br />

The first crush<strong>in</strong>g buckets for full-scale use <strong>in</strong> demolition<br />

and recycl<strong>in</strong>g applications were launched at the end of<br />

the 1990s. Their forerunners, to simplify demolition and<br />

recycl<strong>in</strong>g, were the hydraulic crushers and pulverisers.<br />

Today these attachments complement each other and have<br />

made the demolition and recycl<strong>in</strong>g process so much easier.<br />

The F<strong>in</strong>nish manufacturer Allu launched its first screen<strong>in</strong>g<br />

crusher <strong>in</strong> 1991 for crush<strong>in</strong>g lighter demolition waste.<br />

Compact and flexible recycl<strong>in</strong>g on site<br />

The bucket crusher is a hydraulic tool, developed from<br />

traditional jaw crusher technology. Although unlike a<br />

conventional crusher, a bucket crusher is operated by<br />

hydraulic power provided by the excavator it is attached<br />

to. The bucket makes it possible to pick up the rock to be<br />

crushed and then to load <strong>in</strong>to trucks or use as back fill<strong>in</strong>g<br />

on site. The reduction <strong>in</strong> outlay costs is clear because this<br />

system makes it possible to reuse <strong>in</strong>ert materials without<br />

hav<strong>in</strong>g to take them to a landfill, while the ability to crush<br />

different types of materials makes it possible to use them<br />

directly on site.<br />

The areas of application of these tools are numerous<br />

and <strong>in</strong>clude demolition, build<strong>in</strong>g construction, earthmov<strong>in</strong>g,<br />

excavation, road works, quarry<strong>in</strong>g and m<strong>in</strong><strong>in</strong>g, land<br />

reclamation and trench<strong>in</strong>g and rock break<strong>in</strong>g or crush<strong>in</strong>g<br />

of quarry material.<br />

Upgraded model from Trevi Benne<br />

The Italian manufacturer Trevi Benne is now strengthen its<br />

position as supplier of crush<strong>in</strong>g buckets by <strong>in</strong>troduc<strong>in</strong>g an<br />

upgrade version of their crush<strong>in</strong>g bucket series BM. The<br />

Crusher Bucket BM Series is available <strong>in</strong> two different<br />

models. The BM 25 weighs 2.5t and BM 35 3.5 t. They<br />

are designed for crush<strong>in</strong>g <strong>in</strong>ert materials from demolitions<br />

and build<strong>in</strong>g renovations such as concrete, asphalt, waste<br />

material from storage centres and debris <strong>in</strong> quarries, to<br />

provide a f<strong>in</strong>ished product for use as backfill.<br />

The Crusher Bucket allows on the spot recycl<strong>in</strong>g of<br />

waste material for immediate reuse on the site. The power<br />

is produced from the eccentricity of the pound<strong>in</strong>g unit<br />

for crush<strong>in</strong>g the material <strong>in</strong> the bucket. The <strong>in</strong>terchangeable<br />

plate system reduces ma<strong>in</strong>tenance costs and limits<br />

downtime.<br />

www.trevibenne.it<br />

Allu a truly global player<br />

There are just a few manufacturers of crush<strong>in</strong>g buckets<br />

with global sales. One of the companies is Allu F<strong>in</strong>land<br />

Ltd, which was founded <strong>in</strong> 1985 by Markku Jonn<strong>in</strong>en. The<br />

company was first called Ideachip Ltd, but it changed its<br />

name to Allu F<strong>in</strong>land Ltd <strong>in</strong> 2007. The new name stems<br />

from the company’s globally recognised trademark Allu.<br />

Allu F<strong>in</strong>land Ltd created the Screener Crusher method <strong>in</strong><br />

1991. To date, their sales constitute over 80% of the world<br />

market for Screener Crushers.<br />

Last year Allu released their Allu SCH Screener<br />

Crusher for heavy applications. Allu SCH Heavy series<br />

are suitable for 20–34t excavators and 12–24t wheel loaders.<br />

In this series, the frame is re<strong>in</strong>forced and the eng<strong>in</strong>e<br />

is a heavy-duty model. The maximum driv<strong>in</strong>g output of

WELCOME TO<br />

OUR KIND OF PLAYGROUND<br />

OUR KIND OF PLAYGROUND is often<br />

a very dangerous environment and<br />

there are no good arguments for expos<strong>in</strong>g<br />

you or your staff to fall<strong>in</strong>g debris<br />

or dangerous vibrations. Our demolition<br />

mach<strong>in</strong>es, from the small Brokk 50<br />

which is perfect for limited spaces, to<br />

the big and powerful Brokk 400 have<br />

certa<strong>in</strong> th<strong>in</strong>gs <strong>in</strong> common: they are radio<br />

controlled and electrically driven so<br />

that you are not exposed to dangerous<br />

fumes. Another th<strong>in</strong>g which makes the<br />

mach<strong>in</strong>es even better is that you can<br />

demolish up to 5 times quicker than<br />

traditional saw<strong>in</strong>g and cutt<strong>in</strong>g methods.<br />

Time is,as we all know money!<br />

Visit www.brokk.com or your local dealer<br />

for more <strong>in</strong>formation!<br />

Brokk AB | PO Box 730 | SE-931 27 Skellefteå | SWEDEN | Tel +46 910 711 800 | Fax +46 910 711 811 | www.brokk.com | <strong>in</strong>fo@brokk.com

14 PDi • Is s u e 1 - 2009 • Fe b - Ma r c h<br />

Heavy series Screener Crushers is 80 kW. The Allu Heavy<br />

Series functions well for crush<strong>in</strong>g light to medium heavy<br />

demolition debris.<br />

In addition Allu has the stronger Monster Series suitable<br />

for 22–40t excavators and 13–26t wheel loaders. The maximum<br />

driv<strong>in</strong>g output of Monster series Screener Crushers is<br />

140 kW. The features also <strong>in</strong>clude double power transmission<br />

and two heavy-duty eng<strong>in</strong>es. The range can take on heavier<br />

demolition debris then the Heavy Series.<br />

www.allu.fi<br />

MB first with the Bucket Crusher<br />

Another manufacturer that has proven to be a world-class<br />

supplier of crush<strong>in</strong>g buckets for heavy use <strong>in</strong> demolition<br />

and recycl<strong>in</strong>g applications is the Italian company Meccanica<br />

Breganzese. MB has specialised <strong>in</strong> construction and sales<br />

of jaw-action bucket crushers and manufactures four basic<br />

models. These are BF 60.1, the smallest <strong>in</strong> the range, suitable<br />

for excavators <strong>in</strong> the 8-14t class, BF 70.2 for excavators from<br />

14-20t, BF 90.3 for excavators from 20-28t, and the largest<br />

model, BF 120.4, for excavators weigh<strong>in</strong>g more than 28t.<br />

Accord<strong>in</strong>g to MB they produced the world’s very first bucket<br />

crusher. By us<strong>in</strong>g an MB crusher the crushed material can be<br />

recycled directly on site result<strong>in</strong>g <strong>in</strong> a significant reduction<br />

of costs. The equipment is versatile and all that is needed is<br />

a standard excavator <strong>in</strong> order to work efficiently.<br />

The benefits with the MB crushers are the facility to<br />

crush any type of material <strong>in</strong>situ and <strong>in</strong> any type of situation,<br />

with a significant reduction of operat<strong>in</strong>g costs. Thanks<br />

to their production capacity, MB bucket crushers can be<br />

utilised <strong>in</strong> small, medium-sized and large worksites, thus<br />

dispens<strong>in</strong>g with both plant hire and transport costs. The<br />

bucket crush<strong>in</strong>g solution elim<strong>in</strong>ates the problem of waste<br />

disposal. Product output can be received <strong>in</strong> the required size<br />

just like a standard crusher.<br />

MB’s models<br />

The smallest BF60.1 <strong>in</strong> the range weighs 1.5t and is recommended<br />

for excavators <strong>in</strong> the 8-12t class. Crusher jaw<br />

open<strong>in</strong>g is 600 x 450 mm and bucket capacity is 0.5m 3 . The<br />

material size is adjustable between 20 and 100mm, while<br />

average hourly production is between 9.1 and 19.8 m3,<br />

depend<strong>in</strong>g on the required product size.<br />

The second smallest model, BF 70.2, weighs 2.25t and<br />

is recommended for excavators weigh<strong>in</strong>g between 14 and<br />

20t. Crusher jaw open<strong>in</strong>g is 700 x 550 mm and bucket<br />

capacity is 0.6m 3 . The output size is adjustable between<br />

20 and 120mm, with average hourly output of between<br />

12 and 30m 3 , depend<strong>in</strong>g on the required product size.<br />

The first bucket crusher to be manufactured and<br />

marketed was the Bf 90.3 weigh<strong>in</strong>g 3.5t and recommended<br />

for excavators of 20-28t. Crusher jaw open<strong>in</strong>g<br />

is 900 x 450mm and bucket capacity is 0.75m 3 . The<br />

output size is adjustable from 20 to 120mm, with average<br />

hourly output of between 18 and 40m 3 , depend<strong>in</strong>g on<br />

the required product size.<br />

The largest bucket <strong>in</strong> the range is BF 120.4. It weighs<br />

4.9t and recommended for excavators from 28t. Crusher<br />

jaw open<strong>in</strong>g is 1200 x 450mm and bucket capacity is 1m 3 .<br />

The output size is adjustable between 20 and 120mm<br />

with average hourly output between 25 and 50m 3 , depend<strong>in</strong>g<br />

on the required product size.<br />

MB has also an iron separator system that was<br />

unveiled at the end of 2007 at the SAIE trade fair <strong>in</strong><br />

Bologna. Available for all MB bucket crusher models,<br />

this device is composed of a 250kg magnet, a magnet<br />

support, and an <strong>in</strong>stallation kit. The device is easy to<br />

<strong>in</strong>stall on the bucket and allows the separation of ferrous<br />

materials from <strong>in</strong>ert material to be crushed.<br />

www.mbcrusher.com<br />

VTN Europe - Three different series<br />

The Italian manufacturer VTN Europe is manufactur<strong>in</strong>g<br />

three series of crush<strong>in</strong>g and screen<strong>in</strong>g equipment, the SB, FB<br />

and SR series. The SB Series is commonly used for screen<strong>in</strong>g<br />

demolition material and quarry residues. The material<br />

is screened us<strong>in</strong>g the <strong>in</strong>novative vibrat<strong>in</strong>g and alternat<strong>in</strong>g<br />

movement of the screens fitted longitud<strong>in</strong>ally <strong>in</strong>side the<br />

bucket. Thanks to the vast range of screen sizes available<br />

and their <strong>in</strong>terchangeability, the same model of bucket can<br />

be used to screen materials of different sizes.<br />

The heavier FB series is a full size crush<strong>in</strong>g bucket,<br />

which has been designed and built to meet the <strong>in</strong>creas<strong>in</strong>g<br />

necessity for immediate on-site recycl<strong>in</strong>g and reuse of waste<br />

material deriv<strong>in</strong>g from construction and demolition work.<br />

The high performance levels of the FB crush<strong>in</strong>g bucket,<br />

available <strong>in</strong> two models, make it the ideal solution, not<br />

only for small and medium-sized construction sites with<br />

limited amounts of waste material, but also for extremely<br />

demand<strong>in</strong>g work conditions, such as quarries. It is made<br />

entirely of Hardox 400 and equipped with a fixed and a<br />

mov<strong>in</strong>g jaw. The adjustment of the mov<strong>in</strong>g jaw allows the<br />

size of the crushed material to be adapted to the different<br />

operat<strong>in</strong>g needs.<br />

VTN also produce a rotary screen<strong>in</strong>g bucket called SR.<br />

The SR series is made <strong>in</strong> five models for use on excavators<br />

with capacities rang<strong>in</strong>g from 7-35t and has widespread application<br />

<strong>in</strong> screen<strong>in</strong>g natural material, such as river beds,<br />

quarry residues, sand and dry soil, as well as all situations<br />

where f<strong>in</strong>e screen<strong>in</strong>g is required.<br />

www.vtneurope.com<br />

The CB-l<strong>in</strong>e from Simex<br />

Simex has expanded its operations <strong>in</strong>to produc<strong>in</strong>g crush<strong>in</strong>g<br />

buckets, which were shown for the first time at the exhibition<br />

SAIE <strong>in</strong> 2006. The new Simex CB l<strong>in</strong>e of crush<strong>in</strong>g<br />

buckets, conta<strong>in</strong> n<strong>in</strong>e different models <strong>in</strong> sizes from 1.4 to<br />

2.4m <strong>in</strong> width, bucket weights from 800 to 3500kg and<br />

crush<strong>in</strong>g sizes of the material from 10 to 80mm. They are<br />

suitable for use on wheel loaders and skid steers. What makes<br />

the Simex crush<strong>in</strong>g buckets different from other brands<br />

is the rotat<strong>in</strong>g function <strong>in</strong>stead of jaw crush<strong>in</strong>g. As <strong>in</strong> all<br />

other Simex products the ma<strong>in</strong> details and the functions are<br />

patented. The body of the teeth <strong>in</strong> the rotat<strong>in</strong>g crush<strong>in</strong>g<br />

unit is made of Hardox.<br />

www.simex.it

Two models from Italdem<br />

Italdem has been mak<strong>in</strong>g two models of jaw-crush<strong>in</strong>g buckets<br />

for several years. The GF 35 weighs 3.5t and has a feeder<br />

dimension of 800 x 700mm and a material output size of<br />

30 to 150mm. The GF 35 has a volume size of 0.7m 3 and<br />

is designed for carriers between 20 to 28t. The oil flow is<br />

150 - 160l/m<strong>in</strong> and the work<strong>in</strong>g pressure 180 - 200bar.<br />

The bigger model GF 45 has a weight of 4.5t and a<br />

feeder dimension of 900 x 700mm. The material output<br />

size is 30 to 150mm and volume of 1m 3 . It is designed for<br />

carriers between 28 to 40t. Oil flow and work<strong>in</strong>g pressure<br />

is the same as for GF 35.<br />

www.italdem.com<br />

�������������������������������������������������������������<br />

The Dust-Fighter, part of the Gladiator Range from Towerlight is<br />

synonymous with <strong>in</strong>novation, quality and environmentally friendly<br />

products for both construction and <strong>in</strong>dustrial applications.<br />

The Dust-Fighter is a Particle Dampen<strong>in</strong>g System that creates a<br />

forceful yet f<strong>in</strong>e mist that attracts dust which is harmful to both operator<br />

and mach<strong>in</strong>ery, and drives it <strong>in</strong>to the ground. Covers a distance of 20-60m.<br />

Gladiator by Towerlight Srl<br />

Via Stazione, 3 Bis 27030 Villanova d'Ardenghi (PV) - <strong>Italy</strong><br />

Tel. +39.0382.400.246 Fax +39.0382.400.247 email: <strong>in</strong>fo@towerlight.it<br />

www.towerlight.it www.gladiatorl<strong>in</strong>e.it<br />

Is s u e 1 - 2009 • Fe b - M a r c h • PDi 15

World of Concrete<br />

vendors and attendees<br />

keep a brave<br />

face despite uncerta<strong>in</strong><br />

times. Much the way<br />

celebrities and average<br />

citizens alike<br />

have used Las Vegas<br />

as a spr<strong>in</strong>gboard for<br />

re<strong>in</strong>vent<strong>in</strong>g themselves,<br />

WOC may want<br />

to consider adopt<strong>in</strong>g a<br />

new slogan: size isn’t<br />

everyth<strong>in</strong>g.<br />

The dual-head floor<br />

gr<strong>in</strong>der, 1500 ixT, from HTC Sweden.<br />

16 PDi • Is s u e 1 - 2009 • Fe b - Ma r c h<br />

The 2009 edition of the US construction <strong>in</strong>dustry’s premier<br />

annual trade show saw a 23% drop <strong>in</strong> attendance from last<br />

year, with most of the blame directed at the global economic<br />

upheaval that has slowed or halted build<strong>in</strong>g activity <strong>in</strong> nearly<br />

every market sector.<br />

The decision-makers came<br />

But although the 65,287 who attended WOC may not match<br />

previous shows, they were, for the most part, the people that the<br />

concrete cutt<strong>in</strong>g, demolition and floor prep <strong>in</strong>dustry vendors<br />

wanted to see. “These are the decision-makers, the people who<br />

have needs and are ready to buy,” observed Greg Smith of Allied<br />

Construction Products, which was show<strong>in</strong>g its TotalBreakerBits<br />

l<strong>in</strong>e of replacement tools for hydraulic hammers. Smith added<br />

that while many organizations may have been unable to afford<br />

dispatch<strong>in</strong>g large cont<strong>in</strong>gents to Las Vegas, <strong>in</strong>dustry vendors<br />

couldn’t afford to stay away. “It’s important to be here and be<br />

noticed regardless of the turnout,” he said. “If you’re <strong>in</strong>visible or<br />

pull back, no one will remember you when they are <strong>in</strong> position<br />

to buy new equipment.”<br />

Many exhibitors chose a more austere approach to tell<strong>in</strong>g<br />

their stories, even though exhibition space was only 2% off 2008’s<br />

total. “The one-upmanship among vendors isn’t here, someth<strong>in</strong>g<br />

that is probably long overdue,” said Stihl sales representative<br />

Hugh Munn.<br />

And while vendors may have come to WOC 2009<br />

with lowered expectations, a hopeful worker at Stanley Tools<br />

aptly observed that, “we just need that one visitor to make it<br />

all worthwhile.”<br />

A field day for concrete floors<br />

WOC’s attendance may have been down, but the proportion<br />

of concrete floor gr<strong>in</strong>d<strong>in</strong>g and preparation equipment was substantially<br />

higher. Among the many products vy<strong>in</strong>g for attendees’<br />

attention were DITEQ’s 762mm and 660mm planetary floor<br />

preparation and polish<strong>in</strong>g system, SASE Company’s EDGE<br />

Pro 180 variable-speed edger with pivot<strong>in</strong>g wheels,<br />

Terrco, Inc.’s direct-drive edger with adjustable<br />

depth-sett<strong>in</strong>g rollers, and HTC’s dual-head 1500<br />

ixT ride-on gr<strong>in</strong>der.<br />

Blastrac cont<strong>in</strong>ued to boost the profile of its<br />

US built Diamatic l<strong>in</strong>e with products such as the<br />

584mm BMGP 600-R gr<strong>in</strong>der, which uses the<br />

company’s po<strong>in</strong>t of development technology to collect<br />

dust and debris through the mach<strong>in</strong>e, result<strong>in</strong>g<br />

<strong>in</strong> a cleaner work path and cooler diamond and<br />

polish<strong>in</strong>g heads. “POD offers benefits on many<br />

different levels, such as cleaner, healthier work<br />

environments, longer tool life and reduced labour<br />

and equipment costs,” says<br />

Blastrac spokesman Jason<br />

Root.<br />

The proliferation of<br />

floor preparation and polish<strong>in</strong>g<br />

equipment comes<br />

as no surprise to ON-<br />

FLOOR Technologies,<br />

Tom Francis.<br />

“It’s all part of the<br />

<strong>in</strong>dustry’s current green<br />

consciousness,” said ON-<br />

FLOOR Technologies<br />

Floor gr<strong>in</strong>ders from US company SASE.<br />

representative Tom Francis. “On 90% of <strong>in</strong>dustrial floors, the<br />

surfaces are man made and will ultimately end up <strong>in</strong> landfills.<br />

Polished concrete floors elim<strong>in</strong>ate the need for chemicals to<br />

clean crevasses and improve reflectivity, which cuts energy costs,<br />

improves employee health, and makes for a brighter, more <strong>in</strong>vit<strong>in</strong>g<br />

environment.”<br />

Concrete polish<strong>in</strong>g also presents opportunities to apply<br />

alternative energy sources, such as propane, which powers Eagle<br />

Solutions’ EnviroPro WA27 burnisher, and Concrete Polish<strong>in</strong>g<br />

Technologies’ 27-hp alum<strong>in</strong>ium-bodied G320 PRO gr<strong>in</strong>der.<br />

CPT vice president Dave Padgett said that although a lot of<br />

companies are jump<strong>in</strong>g <strong>in</strong>to the surface preparation market, the<br />

ones who will make it are more <strong>in</strong> touch with needs of contractor<br />

and their customers’ market trends. They are also the ones<br />

who know how to provide smaller contractors with technical<br />

support.<br />

Greater awareness of risks with dust<br />

More gr<strong>in</strong>d<strong>in</strong>g of floors and other surface types also means more<br />

dust to control. Dust Collection Products president John Buser<br />

said that awareness across the <strong>in</strong>dustry of silicosis and associated<br />

health risks is grow<strong>in</strong>g, albeit slowly. “Many contractors just don’t<br />

realize that silicosis has cumulative effects, and that they need to<br />

be consistent about protective measures,” said Buser. “OSHA’s<br />

<strong>in</strong>volvement has put pressure on contractors to take action, and<br />

we’re gradually see<strong>in</strong>g more <strong>in</strong>terest <strong>in</strong> th<strong>in</strong>gs that will help.”<br />

Dust control solutions on display at WOC ranged from KHK<br />

Diamond Products’ polycrystall<strong>in</strong>e diamond blades for reduc<strong>in</strong>g<br />

material to larger chunks, to Dustless Technology’s ToolSynch<br />

mechanism for remotely operat<strong>in</strong>g its vacuums, provid<strong>in</strong>g convenience<br />

and energy sav<strong>in</strong>gs as well as improved productivity.<br />

Dust Control Technology also featured its new DustBoss DB-45<br />

mid-range sprayer, which can control dust and odour particulates<br />

across an area of 1,115m 2 .<br />

Metabo Corporation executive vice<br />

president Dave Smith said that contractors<br />

should also be th<strong>in</strong>k<strong>in</strong>g about protect<strong>in</strong>g<br />

their workers from excess vibration from<br />

gr<strong>in</strong>ders, hammers, and other equipment.<br />

“Though not yet a major concern <strong>in</strong> the<br />

US, it is very big <strong>in</strong> Europe where EU<br />

regulations are already <strong>in</strong> place,” says<br />

Smith. “But contractors will soon have<br />

US manufacturer Blastrac made a<br />

strong promotion of their floor gr<strong>in</strong>d<strong>in</strong>g<br />

mach<strong>in</strong>e brand Diamatic.

Pentruder wallsaws from Tractive <strong>in</strong> action.<br />

to study vibration data on equipment to determ<strong>in</strong>e how long<br />

workers can safely use equipment.”<br />

Several products at WOC emphasized their vibration control<br />

qualities. Metabo’s new WEO-125 125mm angle gr<strong>in</strong>der<br />

has electronic speed stabilization and auto balance features that<br />

m<strong>in</strong>imize user fatigue, while Hilti’s new TE60 Combihammer<br />

features a built-<strong>in</strong> mass damper system that produces only a<br />

third of the vibration of the company’s TE70, but delivers 15%<br />

more performance.<br />

Saws <strong>in</strong> the spotlight<br />

The cutt<strong>in</strong>g side of concrete work also figured prom<strong>in</strong>ently at<br />

the show. ICS Blount, Inc., announced the beg<strong>in</strong>n<strong>in</strong>g of full<br />

production of its FORCE4 diamond cha<strong>in</strong>, which has 50%<br />

more tensile strength to deliver more power with less risk of<br />

breakage. ICS market<strong>in</strong>g director Ed Hanson expla<strong>in</strong>ed that its<br />

expanded manufactur<strong>in</strong>g facilities for the FORCE4 l<strong>in</strong>e will not<br />

only provide a price po<strong>in</strong>t below its PRO series cha<strong>in</strong>s, but also<br />

A Husqvarna floor gr<strong>in</strong>der show<strong>in</strong>g the dual drive system<br />

clearly which is a Husqvarna patent.<br />

allows the company to offer an expanded product l<strong>in</strong>e with five<br />

bar lengths from 250mm to 635mm, and new cha<strong>in</strong> options to<br />

handle a wider range of materials.<br />

FORCE4 is also the foundation for a new track-mounted<br />

hydraulic wall saw that ICS plans to <strong>in</strong>troduce to the rental market<br />

later this year. “This concept has been around for 10 years,<br />

but FORCE4 made it possible,” says Hanson. “It’s particularly<br />

helpful for production open<strong>in</strong>gs <strong>in</strong> limited access areas, and<br />

elim<strong>in</strong>ates a lot of hassles and conflicts for contractors.”<br />

Also tout<strong>in</strong>g wall saw expertise was Husqvarna, which<br />

demonstrated its WS440 HF with a water-cooled 400-hz electric<br />

motor that generates up to 17 hp. Husqvarna also launched a<br />

new dust suppression system that uses a m<strong>in</strong>imum of water<br />

mist and is developed to be used among other together with<br />

their series of hand held electric power cutters. More about this<br />

novelty <strong>in</strong> the next issue of PDi.<br />

In Diamond B’s booth it was crowded as usual with concrete<br />

cutters wait<strong>in</strong>g for a test drive of the latest from the Pentruder<br />

l<strong>in</strong>e of high frequency wallsaws, wiresaws and core drills.<br />

Tractive, the manufacturer of the Pentruder series announced<br />

<strong>in</strong>troduction of a new wall saw, a completely new core drill<strong>in</strong>g<br />

system and a new contact system that will simplify the work.<br />

Onfloor’s new mach<strong>in</strong>e CreteBoss.<br />

Blastrac-Diamatics new BMGP-600R.<br />

The efficient outdoor dust control<br />

device DustBoss from Dustcontrol<br />

Technology.<br />

Is s u e 1 - 2009 • Fe b - M a r c h • PDi 17

The new <strong>Core</strong> Bore drill rig from Diamond<br />

Products.<br />

HTC’s gr<strong>in</strong>der 1500 ixT.<br />

Efficient dust vacs from Dustcontrol.<br />

The new attachment from Genesis.<br />

A lot of demonstrations took place among others <strong>in</strong> the<br />

Husqvarna booth.<br />

Another high-cycle cutt<strong>in</strong>g option on display was Sanders<br />

Saws’ new lightweight BRAXX 1,000-hz wall saw system that<br />

supports both wire and blade saw<strong>in</strong>g operations. “At 43hp, the<br />

BRAXX can handle up to 1.5m diameter blades,” said spokesman<br />

Mike Horan. “The wire saw version features a number of<br />

add-on components for extra versatility that take advantage of<br />

high-cycle’s improved dependability.”<br />

Also anticipat<strong>in</strong>g a spike <strong>in</strong> demand for alternative power<br />

cutt<strong>in</strong>g was MK Diamond Products with the <strong>in</strong>troduction of its<br />

MK-4000 and MK-3000 series self-propelled saws that utilize<br />

three-phase totally enclosed fan-cooled motors. The 30 hp MK-<br />

4000B series provides 89Nm of torque at the blade shaft while<br />

the 20 hp MK-3000B series provides 69Nm. MK Diamond<br />

vice president and general manager Brian Delahut said that the<br />

new products meet the US Environmental Protection Agency’s<br />

Tier 3 emissions standards, which may be a requirement for<br />

contractors seek<strong>in</strong>g <strong>in</strong>frastructure work funded by the recently<br />

enacted stimulus programme. “If they have a lot of old saws,<br />

they’ll need to replace them with compliant equipment,” says<br />

Delahut. “We expect there’ll be high demand <strong>in</strong> the rental market<br />

for these k<strong>in</strong>ds of products.”<br />

The pursuit of productivity<br />

One quality never <strong>in</strong> short supply at WOC is <strong>in</strong>novation. For<br />

example, Genesis Attachments displayed its new GDR 200<br />

demolition recycler. Designed to work with 20t class mach<strong>in</strong>es,<br />

the fully rotatable recycler delivers 115t of crush<strong>in</strong>g power and<br />

features three jaw set configurations. “We drew on a lot of<br />

contractor <strong>in</strong>put and ideas to make an attachment that is light,<br />

powerful, and <strong>in</strong>expensive,” said Genesis southwest regional<br />

manager Bla<strong>in</strong>e Archibald.<br />

For all-<strong>in</strong>-one core drill<strong>in</strong>g, Diamond Products presented<br />

its Ultimate Drill<strong>in</strong>g Mach<strong>in</strong>e; a self-conta<strong>in</strong>ed mobile unit for<br />

electric and hydraulic powered drill<strong>in</strong>g of 100mm to 610mm<br />

diameter cores through asphalt and concrete up to 300mm thick.<br />

Attendees explor<strong>in</strong>g remotely controlled demolition options<br />

evaluated Husqvarna’s 29.5-hp DXR 310 robot, scheduled to<br />

Big jaws from Allied-Gator.<br />

18 PDi • Is s u e 1 - 2009 • Fe b - ap r I l<br />

A smart gyro stand that makes core drill<strong>in</strong>g so much easier<br />

were demonstrated <strong>in</strong> the Dibo Mach<strong>in</strong>e booth.<br />

Hydrodemolition equipment manufacturer Conjet showed their<br />

remote controlled diesel power robot Conjet Robot 432.<br />

Hilti brought and impressive whole build<strong>in</strong>g to the show<br />

which, among others, <strong>in</strong>cluded their professional l<strong>in</strong>e of<br />

concrete cutt<strong>in</strong>g equipment.<br />

Dust extraction equipment is grow<strong>in</strong>g <strong>in</strong> importance and<br />

a good example of that is Pullman Ermator and its new<br />

partnership with US company Pullman-Holt.<br />

make its US debut later this year. The DXR 310 was <strong>in</strong>troduced<br />

on the European market dur<strong>in</strong>g the fall of 2008. Brokk’s brand<br />

new 260 robot with its 1,900Nm hammer and 7m reach (see<br />

article on page 20) were shown for the first time ever at the Las<br />

Vegas show. In door the manufacturer also showed another<br />

novelty, their largest mach<strong>in</strong>e Brokk 400.<br />

Despite offer<strong>in</strong>g aisle upon aisle of <strong>in</strong>terest<strong>in</strong>g products,<br />

however, WOC could not totally <strong>in</strong>sulate attendees and ven-