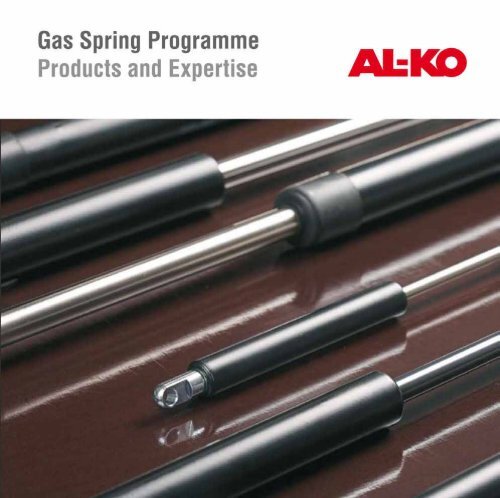

Gas spring GF 10/22 - AL-KO

Gas spring GF 10/22 - AL-KO

Gas spring GF 10/22 - AL-KO

- TAGS

- www4.al-ko.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>22</strong><br />

Connecting parts<br />

and accessories<br />

These pages give a summary<br />

of our extensive range<br />

of high-quality mounting<br />

fittings which provide<br />

optimum connections.<br />

28<br />

Expertise<br />

In this area you can find<br />

details about the possibilities<br />

for custom-made<br />

products, developments<br />

from aeronautical engineering,<br />

and details about<br />

wheel shock absorbers and<br />

overrun brake buffers.<br />

34<br />

Installation<br />

instructions<br />

We will give you important<br />

instructions to ensure that<br />

your gas <strong>spring</strong> operates<br />

in the best way possible.<br />

3

The company<br />

<strong>AL</strong>-<strong>KO</strong> damping technology – nothing is too much trouble<br />

We provide<br />

... creative minds, that develop<br />

innovative products to meet your needs<br />

in a skilled and professional manner<br />

... experienced hands, which have a good<br />

command of the technologies involved, and<br />

produce quality products<br />

... likeable employees, who are there for you<br />

and will be happy to help you in your product<br />

selection<br />

Send us your drawing and we will<br />

design and produce gas <strong>spring</strong>s for you that<br />

are tailored to meet your individual needs!<br />

4 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

Your contact<br />

<strong>AL</strong>-<strong>KO</strong> Dämpfungstechnik GmbH<br />

Bahnhofstr. 2-4<br />

04746 Hartha - Germany<br />

Fon: +49 (0)34328 67 0<br />

Fax: +49 (0)34328 67 <strong>22</strong>6<br />

info.hartha@al-ko.de<br />

www.al-ko.de

<strong>AL</strong>-<strong>KO</strong><br />

Our products<br />

■ are easy and safe solutions to be used for<br />

moving heavy components<br />

■ meet the highest quality requirements,<br />

therefore ensuring a long service life<br />

■ provide increased safety for the machine<br />

operating staff<br />

■ are technically functional and aesthetical<br />

■ reduce the maintenance and repair times to<br />

your plant and machinery<br />

Company<br />

55

Product summary<br />

<strong>Gas</strong> <strong>spring</strong>s<br />

Spring characteristic curve x = F 2 / F 1<br />

■ Insertion force: an<br />

external force is<br />

greater than the force<br />

of the gas <strong>spring</strong><br />

Basic type<br />

ø Diameter<br />

piston rod/<br />

cylinder in mm<br />

<strong>GF</strong> 6/15<br />

<strong>GF</strong> 8/19<br />

<strong>GF</strong> <strong>10</strong>/<strong>22</strong><br />

<strong>GF</strong> <strong>10</strong>/28<br />

<strong>GF</strong> 14/28<br />

F R max<br />

( N )<br />

40<br />

60<br />

60<br />

60<br />

<strong>10</strong>0<br />

x = F 2 / F 1<br />

( ≈ )<br />

6 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

■ Extension force:<br />

the external force is<br />

smaller than the force<br />

of the gas <strong>spring</strong><br />

1.4<br />

1.4<br />

1.4<br />

1.2<br />

1.4<br />

Stroke C<br />

5 5<br />

0<br />

F 1<br />

Extension force<br />

F R<br />

■ Frictional force: the difference<br />

between the insertion<br />

and extension forces is<br />

the result of the frictional<br />

force FR.<br />

F 2 F 4<br />

F 3<br />

Insertion force<br />

Force F (N)<br />

Connecting<br />

part<br />

Cylinder pipe<br />

Coating:<br />

epoxy resin<br />

lacquer<br />

Piston rod<br />

nitrided<br />

black/silver<br />

Connecting part

Basic type<br />

ø Diameter piston rod/<br />

cylinder in mm<br />

Non-lockable<br />

<strong>GF</strong> 6/15<br />

<strong>GF</strong> 8/19<br />

<strong>GF</strong> <strong>10</strong>/<strong>22</strong><br />

<strong>GF</strong> <strong>10</strong>/28<br />

<strong>GF</strong> 14/28<br />

OPTI LIFT<br />

(Non-lockable)<br />

<strong>GF</strong>Ba 14<br />

<strong>GF</strong>Bb 14<br />

Lockable<br />

G <strong>10</strong>/28<br />

Explanation<br />

Different extension speeds can be achieved<br />

■ The best solution for moving and/or balancing<br />

loads<br />

■ Absorb movements and therefore reduce<br />

the maintenance and repair times of your<br />

machinery<br />

■ One side of the gas <strong>spring</strong> is secured onto a<br />

roll so that its position changes according to<br />

the angle of the flap ➭ equal expenditure of<br />

energy for opening and closing<br />

■ Has all the advantages of a non-blockable<br />

gas <strong>spring</strong> with the additional possibility of<br />

being able to locate a load in any position<br />

Stroke C<br />

(in mm)<br />

50 ... 200<br />

60 ... 300<br />

60 ... 425<br />

60 ... 425<br />

50 ... 500<br />

45 ... 300<br />

Extension<br />

force F 1 (N)<br />

20 ... 350<br />

80 ... 700<br />

<strong>10</strong>0 ... 1250<br />

<strong>10</strong>0 ... 1250<br />

200 ... 2500<br />

400 ... 1<strong>10</strong>0<br />

400 ... 1500<br />

200 ... 900<br />

Page<br />

8<br />

<strong>10</strong><br />

12<br />

14<br />

16<br />

18<br />

18<br />

20<br />

7

Extended length E ± 2<br />

<strong>Gas</strong> <strong>spring</strong> <strong>GF</strong> 6/15<br />

Stroke C<br />

∅ 15<br />

∅ 6<br />

M 5<br />

6<br />

8 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

6 thick<br />

Stroke<br />

(mm)<br />

∅ 6.1<br />

50<br />

75<br />

<strong>10</strong>0<br />

125<br />

150<br />

175<br />

200<br />

9<br />

16<br />

Extended<br />

length (mm)<br />

134<br />

184<br />

234<br />

284<br />

334<br />

384<br />

434<br />

20<br />

<strong>10</strong><br />

5<br />

∅ 5<br />

Order<br />

number<br />

280 452<br />

280 453<br />

280 454<br />

280 455<br />

280 456<br />

280 457<br />

280 458<br />

Special solutions available on request<br />

<strong>22</strong><br />

9 <strong>10</strong><br />

M 5<br />

SW 7<br />

18<br />

■ Extension force F 1<br />

20 - 350 N<br />

■ Extension speed<br />

0.2 - 0.4 ms -1<br />

11 12<br />

SW 8<br />

M 6<br />

■ Length of the shock absorbing<br />

action 20 ± <strong>10</strong> mm<br />

■ Admissible load in the<br />

direction of traction: ≤ 2000 N<br />

with plastic ball socket: ≤ 1500 N

Product solutions<br />

9 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range 9<br />

<strong>AL</strong>-<strong>KO</strong>

Extended length E ± 2<br />

<strong>Gas</strong> <strong>spring</strong> <strong>GF</strong> 8/19<br />

Stroke C<br />

∅ 19<br />

∅ 8<br />

M 6<br />

8<br />

<strong>10</strong> <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

<strong>10</strong> thick<br />

∅ 8.1<br />

Stroke<br />

(mm)<br />

75<br />

<strong>10</strong>0<br />

125<br />

150<br />

175<br />

200<br />

<strong>22</strong>5<br />

250<br />

300<br />

16<br />

Extended<br />

length (mm)<br />

203<br />

253<br />

303<br />

353<br />

403<br />

453<br />

503<br />

553<br />

653<br />

24<br />

12<br />

6<br />

∅ 6<br />

Order<br />

number<br />

280 000<br />

280 001<br />

280 002<br />

280 003<br />

283 683<br />

280 004<br />

282 823<br />

280 005<br />

280 006<br />

Special solutions available on request<br />

25<br />

13.5 13<br />

SW 8<br />

M 8<br />

18<br />

■ Extension force F 1<br />

80 - 700 N<br />

■ Extension speed<br />

0.1 - 0.3 ms -1<br />

13.5 13<br />

SW 13<br />

M 8<br />

■ Length of the shock absorbing<br />

action 20 ± <strong>10</strong> mm<br />

■ Admissible load in the<br />

direction of traction: ≤ 3000 N<br />

with plastic ball socket: ≤ 1500 N

Product solutions<br />

11 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range 11<br />

<strong>AL</strong>-<strong>KO</strong>

Extended length E ± 2<br />

<strong>Gas</strong> <strong>spring</strong> <strong>GF</strong> <strong>10</strong>/<strong>22</strong><br />

Stroke C<br />

∅ <strong>22</strong><br />

∅ <strong>10</strong><br />

M 8<br />

<strong>10</strong><br />

12 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

<strong>10</strong> thick<br />

∅ 8.1<br />

Stroke<br />

(mm)<br />

75<br />

<strong>10</strong>0<br />

125<br />

150<br />

175<br />

200<br />

250<br />

250<br />

300<br />

350<br />

400<br />

16<br />

Extended<br />

length (mm)<br />

2<strong>10</strong><br />

260<br />

3<strong>10</strong><br />

360<br />

4<strong>10</strong><br />

460<br />

560<br />

6<strong>10</strong><br />

660<br />

760<br />

860<br />

32<br />

16<br />

Order<br />

number<br />

280 007<br />

280 008<br />

280 009<br />

280 0<strong>10</strong><br />

283 595<br />

280 011<br />

280 012<br />

282 950<br />

280 013<br />

280 775<br />

280 778<br />

Special solutions available on request<br />

8<br />

∅ 8<br />

30<br />

13 16<br />

SW 11<br />

M 8<br />

18<br />

■ Extension force F 1<br />

<strong>10</strong>0 - 1250 N<br />

■ Extension speed<br />

0.1 - 0.3 ms -1<br />

13.5 13<br />

SW 13<br />

M 8<br />

■ Length of the shock absorbing<br />

action 20 ± <strong>10</strong> mm<br />

■ Admissible load in the<br />

direction of traction: ≤ 3000 N<br />

with plastic ball socket: ≤ 1500 N

Product solutions<br />

13 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range 13<br />

<strong>AL</strong>-<strong>KO</strong>

Extended length E ± 2<br />

<strong>Gas</strong> <strong>spring</strong> <strong>GF</strong> <strong>10</strong>/28<br />

Stroke C<br />

∅ 28<br />

∅ <strong>10</strong><br />

M 8<br />

<strong>10</strong><br />

14 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

<strong>10</strong> thick<br />

∅ 8.1<br />

Stroke<br />

(mm)<br />

75<br />

<strong>10</strong>0<br />

125<br />

150<br />

200<br />

250<br />

300<br />

350<br />

400<br />

16<br />

Extended<br />

length (mm)<br />

2<strong>10</strong><br />

260<br />

3<strong>10</strong><br />

360<br />

460<br />

560<br />

660<br />

760<br />

860<br />

32<br />

16<br />

8<br />

∅ 8<br />

Order<br />

number<br />

280 728<br />

280 729<br />

280 730<br />

280 731<br />

280 732<br />

280 727<br />

280 733<br />

281 739<br />

281 740<br />

Special solutions available on request<br />

30<br />

13 16<br />

SW 11<br />

M 8<br />

18<br />

■ Extension force F 1<br />

<strong>10</strong>0 - 1250 N<br />

■ Extension speed<br />

0.1 - 0.3 ms -1<br />

13.5 13<br />

SW 13<br />

M 8<br />

■ Length of the shock absorbing<br />

action 20 ± <strong>10</strong> mm<br />

■ Admissible load in the<br />

direction of traction: ≤ 3000 N<br />

with plastic ball socket: ≤ 1500 N

Product solutions<br />

15 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range 15<br />

<strong>AL</strong>-<strong>KO</strong>

Extended length E ± 2<br />

<strong>Gas</strong> <strong>spring</strong> <strong>GF</strong> 14/28<br />

Stroke C<br />

∅ 28<br />

∅ 14<br />

M <strong>10</strong><br />

9.5<br />

16 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

Stroke<br />

(mm)<br />

<strong>10</strong>0<br />

150<br />

200<br />

250<br />

275<br />

300<br />

300<br />

350<br />

400<br />

400<br />

450<br />

500<br />

12 thick<br />

∅ 8.1<br />

Extended<br />

length (mm)<br />

268<br />

368<br />

468<br />

568<br />

618<br />

668<br />

718<br />

768<br />

868<br />

918<br />

968<br />

<strong>10</strong>68<br />

16<br />

Order<br />

number<br />

280 694<br />

280 711<br />

280 493<br />

280 494<br />

280 749<br />

280 495<br />

282 967<br />

280 496<br />

280 497<br />

283 577<br />

280 498<br />

280 499<br />

Special solutions available on request<br />

40<br />

20<br />

<strong>10</strong><br />

∅ <strong>10</strong><br />

■ Extension force F 1<br />

200 - 2500 N<br />

■ Extension speed<br />

0.1 - 0.3 ms -1<br />

35<br />

16 20<br />

SW 13<br />

■ Length of the shock absorbing<br />

action 20 ± <strong>10</strong> mm<br />

■ Admissible load in the<br />

direction of traction: ≤ 5000 N<br />

M <strong>10</strong>

Product solutions<br />

17 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

<strong>AL</strong>-<strong>KO</strong><br />

17

<strong>Gas</strong> <strong>spring</strong> OPTI LIFT<br />

d<br />

Close<br />

18 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

One side of the gas <strong>spring</strong> is secured onto a<br />

roll so that its position changes according to<br />

the angle of the flap.<br />

u<br />

F1<br />

a<br />

90<br />

Blocking support<br />

Type<br />

<strong>GF</strong>Ba 14<br />

<strong>GF</strong>Bb 14<br />

<strong>Gas</strong> <strong>spring</strong><br />

F 1 (N)<br />

400 - 1<strong>10</strong>0<br />

400 - 1500<br />

G Open<br />

Web guide<br />

α<br />

d (mm)<br />

809<br />

1<strong>10</strong>0<br />

The energy expenditures required for<br />

opening and closing are equally as low as<br />

each other due to the constant optimum<br />

adjustment position.<br />

Advantages:<br />

■ Easy movement of large and heavy flaps<br />

■ Particularly even travel with constantly<br />

low expenditure of energy<br />

Extension force F 1 :<br />

F 1 = G · a · k<br />

G: Flap weight (kg)<br />

a: Balance point distance (mm)<br />

k: Calculation constants according to table<br />

when using two gas <strong>spring</strong>s per flap<br />

u (mm)<br />

193<br />

251<br />

k<br />

0.02025<br />

0.01660<br />

Our employees carry out calculation and design; special solutions available on request<br />

∙ max (°)<br />

86<br />

86

Force in N<br />

Force in N<br />

Product solutions<br />

19 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range 19<br />

<strong>AL</strong>-<strong>KO</strong><br />

150<br />

<strong>10</strong>0<br />

50<br />

0<br />

-50<br />

-<strong>10</strong>0<br />

-150<br />

150<br />

<strong>10</strong>0<br />

50<br />

0<br />

-50<br />

-<strong>10</strong>0<br />

-150<br />

Handling load path - standard gas <strong>spring</strong><br />

0 6 12 18 25 31 37 43 49 55 61 68 74 80 86<br />

Opening in °<br />

Handling load path OPTILIFT<br />

0 6 12 18 25 31 37 43 49 55 61 68 74 80 86<br />

Opening in °

Extended length E ± 2<br />

16.5<br />

<strong>Gas</strong> <strong>spring</strong> G <strong>10</strong>/28<br />

lockable, fixed<br />

Stroke C<br />

∅ 4<br />

∅ 28<br />

∅ <strong>10</strong><br />

M <strong>10</strong> x 1<br />

6 ± 1,5<br />

M <strong>10</strong><br />

20 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

9.5<br />

Stroke<br />

(mm)<br />

45<br />

60<br />

90<br />

120<br />

150<br />

180<br />

2<strong>10</strong><br />

240<br />

270<br />

300<br />

12 thick<br />

* without mounting fittings<br />

∅ 8.1<br />

Extended<br />

length* (mm)<br />

197.5<br />

242.5<br />

3<strong>22</strong>.5<br />

392.5<br />

462.5<br />

532.5<br />

602.5<br />

672.5<br />

742.5<br />

783.5<br />

16<br />

Order<br />

number<br />

1217982<br />

1217983<br />

1218151<br />

1218152<br />

1218153<br />

1218154<br />

1218155<br />

1218156<br />

1218157<br />

1218158<br />

Special solutions available on request<br />

40<br />

20<br />

<strong>10</strong><br />

∅ <strong>10</strong><br />

■ Extension force F 1<br />

200 N bis 900 N<br />

35<br />

■ Entire stroke hydraulically<br />

absorbed<br />

■ Permissible load in<br />

insertion direction: 5 x F 1<br />

extension direction: ≤ 3000 N<br />

■ Deblocking force<br />

≤ 200 N with a deblocking<br />

distance of 3,5 mm<br />

16 20<br />

SW 13<br />

M <strong>10</strong>

Product solutions 21 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

21<br />

<strong>AL</strong>-<strong>KO</strong>

Connecting parts and accessories<br />

Provide the best connection<br />

<strong>22</strong> <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

The gas <strong>spring</strong>s can only move loads safely if<br />

they have been attached securely and in the<br />

optimum positions. To ensure that this is the<br />

case we have an extensive range of high quality<br />

mounting fittings and accessories to suit<br />

a variety of applications. The following pages<br />

define the technical details for the dimensions<br />

of these parts.<br />

Please feel free to contact us if you have any<br />

questions. Our team shall be pleased to help<br />

you select the appropriate connectors.<br />

We look forward to hearing from you.

Connecting parts<br />

23 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

<strong>AL</strong>-<strong>KO</strong><br />

23

Connecting parts<br />

Overview<br />

24 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

Milled eye a b c d e f<br />

Eye 6.1-6x16 M5 6.1 16 6 M5 <strong>10</strong> 9<br />

Eye 8.1-5x28 M6 8.1 28 5 M6 15 13<br />

Eye <strong>10</strong>.1-5x28 M6 <strong>10</strong>.1 28 5 M6 15 13<br />

Eye 8.1-5x28 M8 8.1 28 5 M8 15 13<br />

Eye 8.1-<strong>10</strong>x30 M<strong>10</strong> 8.1 30 <strong>10</strong> M<strong>10</strong> 18 16<br />

Eyes <strong>10</strong>.1-<strong>10</strong>x30 M<strong>10</strong> <strong>10</strong>.1 30 <strong>10</strong> M<strong>10</strong> 18 16<br />

Moulded eye a b c d e<br />

Eye 8.1-<strong>10</strong>x16 M6 8.1 16 <strong>10</strong> M6 19<br />

Eye 8.1-<strong>10</strong>x23.5 M6 8.1 23.5 <strong>10</strong> M6 15<br />

Eye 8.1-<strong>10</strong>x16 M8 8.1 16 <strong>10</strong> M8 19<br />

Eye <strong>10</strong>.1-<strong>10</strong>x16 M8 <strong>10</strong>.1 16 <strong>10</strong> M8 19<br />

Eye 8.1-12x16 M<strong>10</strong> 8.1 16 12 M<strong>10</strong> 19<br />

Eye <strong>10</strong>.1-12x16 M<strong>10</strong> <strong>10</strong>.1 16 12 M<strong>10</strong> 19<br />

Eye 12.1-12x16 M<strong>10</strong> 12.1 16 12 M<strong>10</strong> 19<br />

Clevis a b c d e<br />

G 5x<strong>10</strong>-M5 5 20 5 M5 <strong>10</strong><br />

G 6x12-M6 6 24 6 M6 12<br />

G 8x16-M8 8 32 8 M8 16<br />

G 6x16-M8 6 32 8 M8 16<br />

G <strong>10</strong>x20-M<strong>10</strong> <strong>10</strong> 40 <strong>10</strong> M<strong>10</strong> 20<br />

G 8x16-M<strong>10</strong> 8 32 8 M<strong>10</strong> 16<br />

Distance piece a b c d<br />

M8x34 M8 34 12 M8<br />

M8x58 M8 58 12 M8<br />

M<strong>10</strong>x<strong>22</strong> M<strong>10</strong> <strong>22</strong> 16 M<strong>10</strong><br />

M<strong>10</strong>x50 M<strong>10</strong> 50 16 M<strong>10</strong><br />

Thickness<br />

c<br />

Thickness<br />

c<br />

b<br />

a<br />

e<br />

∅ c<br />

e<br />

a<br />

d<br />

e<br />

a<br />

d<br />

c<br />

d<br />

b<br />

f<br />

a<br />

b<br />

b<br />

d

c<br />

c<br />

c<br />

c<br />

a<br />

d<br />

b<br />

d<br />

d<br />

f b<br />

sw<br />

f b<br />

f b<br />

l<br />

sw<br />

sw<br />

a<br />

a<br />

a<br />

Hinged joint CS a b c d e f sw<br />

WG CS 8x<strong>22</strong>-M5/M5 M5 <strong>10</strong> <strong>22</strong> M5 8 9 7<br />

WG CS <strong>10</strong>x25-M6/M6 M6 12 25 M6 <strong>10</strong> 11 8<br />

WG CS <strong>10</strong>x25-M6/M8 M8 13 25 M6 <strong>10</strong> 13.5 13<br />

WG CS <strong>10</strong>x19-M6/M8 M8 13 19 M6 <strong>10</strong> 13.5 13<br />

WG CS 13x30-M8/M8 M8 16 30 M8 13 13 11<br />

WG CS 13x30-M8/M<strong>10</strong> M<strong>10</strong> 20 30 M8 13 13 17<br />

WG CS 16x35-M<strong>10</strong>/M<strong>10</strong> M<strong>10</strong> 20 35 M<strong>10</strong> 16 16 13<br />

Hinged joint S a b c d e f sw<br />

WG S <strong>10</strong>x19-M5/M6 M6 12 19 M5 <strong>10</strong> 11 8<br />

WG S <strong>10</strong>x19-M5/M8 M8 13 19 M5 <strong>10</strong> 13.5 13<br />

WG S <strong>10</strong>x19-M6/M8 M8 13 19 M6 <strong>10</strong> 13.5 8<br />

WG S <strong>10</strong>x25-M6/M8 M8 23 25 M6 <strong>10</strong> 13.5 13<br />

WG S <strong>10</strong>x19-M8/M8 M8 13 19 M8 <strong>10</strong> 13.5 13<br />

WG S <strong>10</strong>x19-M8/M6 M6 13 19 M8 <strong>10</strong> 13.5 8<br />

Plastic hinged joint a b c d e f sw<br />

PWG S <strong>10</strong>x18-M5/M6 M5 12 18 M6 <strong>10</strong> 11 8<br />

PWG S <strong>10</strong>x18-M6/M6 M6 12 18 M6 <strong>10</strong> 11 8<br />

PWG S <strong>10</strong>x18-M8/M8 M8 13 18 M8 <strong>10</strong> 13.5 13<br />

Blocking supports<br />

a b c l<br />

Galvanised steel 8.5 15.5 18.5 <strong>10</strong>0 to 500 mm stroke<br />

25

∅ a<br />

g f<br />

sw<br />

l<br />

d<br />

a<br />

a<br />

c<br />

f<br />

b<br />

d<br />

e<br />

e<br />

b<br />

Steel protection pipe a l<br />

<strong>GF</strong>8 24 from 75 mm to 300 mm stroke<br />

<strong>GF</strong><strong>10</strong> 27.5 from 75 mm to 400 mm stroke<br />

<strong>GF</strong>14 34.6 from <strong>10</strong>0 mm to 500 mm stroke<br />

Bearing bracket a b c d e f g<br />

8x15 8 24 15 4.3 45 14 17<br />

6x6 6 24 6 4.3 45 14 17<br />

8x6 8 24 6 4.3 45 14 17<br />

Cap bearing bolt a b sw d e f<br />

Cap bearing bolt 8 19 14 M8 39 12<br />

27

Expertise<br />

Custom-made gas <strong>spring</strong>s<br />

Complete solutions<br />

■ Development of complete solutions<br />

for your special applications<br />

■ Delivery of ready-to-install gas<br />

<strong>spring</strong>s with fittings and assembly<br />

parts<br />

28 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

Individually designed<br />

Individually designed according to your<br />

requirements<br />

■ Printed with your company name<br />

■ In different colours<br />

■ In your desired size and extension<br />

force<br />

Highest corrosion specification<br />

■ Specially produced for use under<br />

extreme challenging conditions, for<br />

example in sand, salt, dust etc.<br />

■ Salt spray tested to guarantee the<br />

best possible corrosion resistance

Expertise<br />

29 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range 29<br />

<strong>AL</strong>-<strong>KO</strong>

Expertise<br />

Dampers from aeronautical engineering<br />

<strong>AL</strong>-<strong>KO</strong> LOK: Seat adjustment in aeroplanes<br />

MSA: Secure closing of bins to improve fire prevention<br />

30 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

RATE CONTROL: For easy opening of overhead lockers

The dampers have numerous possible<br />

applications. We use our experience<br />

in the area of aeronautical engineering<br />

to develop product solutions for your<br />

specific needs.<br />

Expertise<br />

31 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range 31<br />

<strong>AL</strong>-<strong>KO</strong>

Expertise<br />

Wheel shock absorbers and overrun brake buffers<br />

Hydraulic double-pipe telescopic shock absorbers<br />

■ Absorb wheel vibrations in<br />

vehicles with mechanical and<br />

pneumatic suspension<br />

■ Suitable for transporters and car<br />

trailers up to 3.5 tonnes<br />

Hydro-pneumatic single-pipe dampers<br />

■ Absorb overrun movements of<br />

braked single-axle and tandem<br />

trailers up to a total weight of 3.5<br />

tonnes<br />

■ Stabilise the driving and braking<br />

performance, and therefore increase<br />

safety<br />

32 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

■ Available with a large selection of<br />

fastening fittings<br />

■ Meet the requirements of guideline<br />

EC 71/320 EEC Appendix VIII<br />

■ Are maintenance-free up until the<br />

stated use limit period

Overview of the <strong>AL</strong>-<strong>KO</strong> overrun buffer range<br />

Type<br />

E 8<br />

E <strong>10</strong><br />

Expertise<br />

33 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

<strong>AL</strong>-<strong>KO</strong><br />

Stroke<br />

(mm)<br />

60 - 200<br />

60 - 200<br />

Extended<br />

length (mm)<br />

230 - 605<br />

230 - 605<br />

Ø Piston rod<br />

(mm)<br />

8<br />

<strong>10</strong><br />

Ø Cylinder<br />

(mm)<br />

Overview of the <strong>AL</strong>-<strong>KO</strong> wheel shock absorber range<br />

Type<br />

BG 2<br />

BG 3<br />

K1<br />

K2<br />

Damping power<br />

Tension (N) max<br />

3500<br />

4500<br />

150<br />

80<br />

Damping power<br />

pressure (N) max<br />

800<br />

<strong>10</strong>00<br />

750<br />

1600<br />

24<br />

27<br />

Ø External<br />

Cylinder (mm)<br />

39<br />

45<br />

24<br />

29<br />

Mounting fittings<br />

piston rod<br />

Thread M8 /<br />

M8 x 1<br />

Sleeves<br />

Pipe sections<br />

Thread M8 /<br />

M8 x 1<br />

Sleeves<br />

Pipe sections<br />

Ø External<br />

protective pipe (mm)<br />

47<br />

58<br />

30<br />

38<br />

Mounting fittings<br />

Cylinder<br />

Sleeves<br />

Plates<br />

Pipe sections<br />

Sleeves<br />

Plates<br />

Pipe sections<br />

Stroke<br />

(mm)<br />

70 - 300<br />

70 - 300<br />

70 - 150<br />

70 - 150<br />

33

Installation instructions<br />

Tips and recommendations<br />

The gas <strong>spring</strong>s are designed specifically for your intended application and are supplied<br />

ready-for-installation. Please follow the operating instructions to ensure optimum performance<br />

of your gas <strong>spring</strong>s:<br />

■ Installation takes place with the piston<br />

rod directed downwards<br />

■ Impurities or colouring of the piston<br />

rod destroy the seal of the gas <strong>spring</strong><br />

■ The gas <strong>spring</strong> must not be twisted<br />

■ Avoid the occurrence of bending and<br />

lateral forces; therefore please only use<br />

suitable connecting parts<br />

■ Do not undertake any mechanical<br />

processing of the gas <strong>spring</strong><br />

■ Observe the stated maximum permitted<br />

tensile forces<br />

34 <strong>AL</strong>-<strong>KO</strong> <strong>Gas</strong> <strong>spring</strong> range<br />

■ Do not heat above 120°C!<br />

■ The gas <strong>spring</strong> is subject to high pressure<br />

(up to 200 bar)! Please do not open it!<br />

■ The alignment of the connecting parts in<br />

comparison with each other must be made in<br />

a clockwise direction; please do not dismantle<br />

the fastening fittings<br />

■ The standard gas <strong>spring</strong>s are designed for<br />

use in temperatures ranging from -30°C to<br />

+80°C; obviously we can also produce gas<br />

<strong>spring</strong>s for extreme application conditions if<br />

you require.