ASSEMBLAGGIO_n119_MARZO_APRILE_2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

diversi vantaggi. Nei motori elettrici è previsto soprattutto<br />

per tre applicazioni: per la giunzione tra i magneti e il<br />

pacco di lamierini, tra l’albero e il rotore e tra lo statore<br />

e l’alloggiamento. Oltre a compensare le tolleranze di<br />

produzione più elevate ed evitare la corrosione da sfregamento<br />

e da contatto, le colle sono anche resistenti<br />

agli urti, caratteristica essenziale per contrastare gli effetti<br />

delle elevate forze dinamiche in gioco nei motori<br />

elettrici. Il loro effetto di smorzamento riduce i rumori<br />

delle vibrazioni, apportando miglioramenti dal punto di<br />

vista acustico. Grazie all’omogenea distribuzione delle<br />

tensioni, sono in grado di bilanciare lo stress termico<br />

che si può verificare, ad esempio, quando lo statore e<br />

l’alloggiamento presentano coefficienti di dilatazione<br />

termica diversi. Per quanto riguarda l’albero, esse sono<br />

in grado di impedire il gioco e lo slittamento grazie alle<br />

loro capacità di riempimento delle fessure.<br />

Inoltre, in molti casi, l’utilizzo di colle consente anche<br />

di diminuire i costi di produzione, in quanto, come già<br />

accennato, sono consentite tolleranze del pezzo più<br />

ampie. Infine, è possibile realizzare un’automazione<br />

semplice e per elevate produzioni, anche senza apporto<br />

di calore.<br />

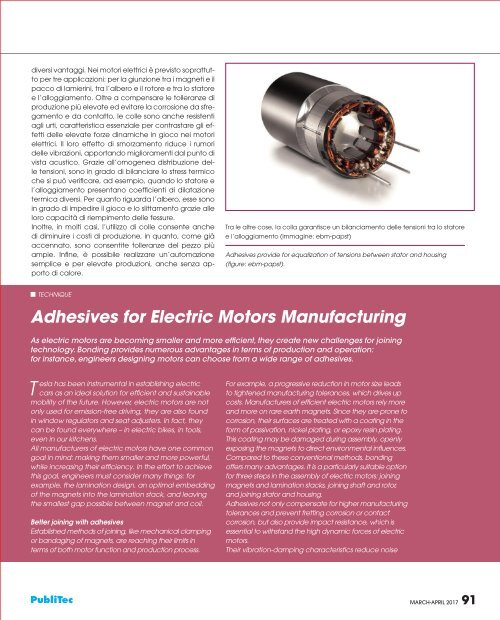

Tra le altre cose, la colla garantisce un bilanciamento delle tensioni tra lo statore<br />

e l’alloggiamento (immagine: ebm-papst)<br />

Adhesives provide for equalization of tensions between stator and housing<br />

(figure: ebm-papst).<br />

n TECHNIQUE<br />

Adhesives for Electric Motors Manufacturing<br />

As electric motors are becoming smaller and more efficient, they create new challenges for joining<br />

technology. Bonding provides numerous advantages in terms of production and operation:<br />

for instance, engineers designing motors can choose from a wide range of adhesives.<br />

T<br />

esla has been instrumental in establishing electric<br />

cars as an ideal solution for efficient and sustainable<br />

mobility of the future. However, electric motors are not<br />

only used for emission-free driving, they are also found<br />

in window regulators and seat adjusters. In fact, they<br />

can be found everywhere – in electric bikes, in tools,<br />

even in our kitchens.<br />

All manufacturers of electric motors have one common<br />

goal in mind: making them smaller and more powerful,<br />

while increasing their efficiency. In the effort to achieve<br />

this goal, engineers must consider many things: for<br />

example, the lamination design, an optimal embedding<br />

of the magnets into the lamination stack, and leaving<br />

the smallest gap possible between magnet and coil.<br />

Better joining with adhesives<br />

Established methods of joining, like mechanical clamping<br />

or bandaging of magnets, are reaching their limits in<br />

terms of both motor function and production process.<br />

For example, a progressive reduction in motor size leads<br />

to tightened manufacturing tolerances, which drives up<br />

costs. Manufacturers of efficient electric motors rely more<br />

and more on rare earth magnets. Since they are prone to<br />

corrosion, their surfaces are treated with a coating in the<br />

form of passivation, nickel plating, or epoxy resin plating.<br />

This coating may be damaged during assembly, openly<br />

exposing the magnets to direct environmental influences.<br />

Compared to these conventional methods, bonding<br />

offers many advantages. It is a particularly suitable option<br />

for three steps in the assembly of electric motors: joining<br />

magnets and lamination stacks, joining shaft and rotor,<br />

and joining stator and housing.<br />

Adhesives not only compensate for higher manufacturing<br />

tolerances and prevent fretting corrosion or contact<br />

corrosion, but also provide impact resistance, which is<br />

essential to withstand the high dynamic forces of electric<br />

motors.<br />

Their vibration-damping characteristics reduce noise<br />

PubliTec<br />

MARCH-APRIL <strong>2017</strong> 91